OPTIMIZATION OF IMPORT BUSINESS PROCESS

AND SYSTEM DESIGN IN BULK PORT BASED ON INTERNET

OF THINGS

Xin Song and Lei Huang

School of Economics and Management, Beijing Jiaotong University, Beijing, China

Keywords: Internet of Things(IOT), Port Informatization, Import Business Process, System Design.

Abstract: In this paper, the current status of bulk port import business process has been analyzed, and the concept,

basic properties and characteristics of the Internet of Things have been introduced. On this basis the paper

uses the IOT technology to promote the bulk port import business process optimization and raising

production efficiency of the enterprises. And then from the angle of information system design the paper

proposes a system framework for the new import business process based on IOT.

1 INTRODUCTION

Waterway logistics is to use the ship as a mode of

transport which plays a main role in transportation

route form for the delivery of freight, and is mainly

responsible for a large number of long-distance

transportation. Having a self-evident role in supply

chain of logistics industry, the port is an important

hub of modern logistics industry. At present,

although a considerable part of the port logistics

enterprises have adopted information systems to

manage, the functionality is very simple, particularly

in bulk transport.

Import business means the freight be unloaded

from the ship to the port and be out of the port by

truck, barge and other means of transport, which is

the principal business of bulk port. With the growing

volume of port operations, the existing business

processes and management of imports have exposed

many problems on the following aspects:

1) In the aspect of scheduling, unloading freight

and the out of storage planning and scheduling

mechanism which are not perfect usually depend on

artificial experience and easily become the

bottleneck to improve production efficiency.

2) In the aspect of data acquisition, using of

artificial means to conduct cargo handing record can

not guarantee the accuracy of the information

collected and normative as a key role of the

constraint of port handling operation and library

management automation.

3) In the aspect of data transmission, it will have

a serious impact on real-time of data transmission of

site operations and lead to errors and omissions by

using paper documents to transport freight

information.

4) In the aspect of intelligent management, it

lacks of effective technical means and can not

achieve automatic control and intelligent

management, such as the need of human

intervention and records in the weighing area and so

on.

Above all, this paper will introduce the

technology of Internet of Things (IOT) into the

import business of bulk port and achieve a

comprehensive, accurate and real-time management

through the terminal information and data collection

and transport of freight. Besides, it has a

comprehensive considerate on actual needs of bulk

import business and optimizes the port business

processes from unloading, out of storage and

switching stacks. At last, from the system point of

view, it puts forward a design framework of import

business management system on bulk port based on

IOT technology.

2 THE OVERVIEW OF IOT

2.1 The Definition of IOT

The Internet of Things (IOT) is a novel paradigm

that is rapidly gaining ground in the scenario of

509

Song X. and Huang L..

OPTIMIZATION OF IMPORT BUSINESS PROCESS AND SYSTEM DESIGN IN BULK PORT BASED ON INTERNET OF THINGS.

DOI: 10.5220/0003588805090512

In Proceedings of the 13th International Conference on Enterprise Information Systems (ITLS-2011), pages 509-512

ISBN: 978-989-8425-56-0

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

modern wireless telecommunications. The basic idea

of this concept is the pervasive presence around us

of a variety of things or objects – such as Radio-

Frequency identification (RFID) tags, sensors,

actuators, mobile phones, etc. – which, through

unique addressing schemes, are able to interact with

each other and cooperate with their neighbours to

reach common goals (

The Internet of Things, Springer,

2010).

The IOT is a new vision of the future

technological ubiquity in ubiquitous computing and

communication era radically transforming the

society, corporate, communities, and personal

spheres.

The IOT networks everything together. It has

two meanings. First, the core and foundation of

Internet of Things is still the Internet; Second,

Internet’s client is computer or other things,

however, the clients of IOT extend to any freight.

The IOT has the following three characteristics.

The first characteristic is the comprehensive

perception which is implemented by RFID, sensors

and two dimensional barcode. The second

characteristic is the credible and real-time transfer.

The information of things is accurately transmitted

out rightly through various telecoms networks and

the Internet.

The last characteristic is the intelligent

processing. The IOT uses various kinds of intelligent

computing technology, such as cloud computing,

fuzzy recognition, etc., to manage and analyze large

pools of data and information.

2.2 The Application of IOT in Bulk

Port

2.2.1 RFID Technology

The basic principle of RFID is to use radio

frequency signal and spatial coupling characteristics

to realize the Automatic identification of objects.

RFID is mainly composed by RFID tags as data

carriers and the reader for reading the date from the

RFID tags. The RFID reader through the antenna

and RFID tags for wireless communication,which

is able to realize the read or written operations of tag

identifiers and memory date.

RFID technology essentially is a kind of coded

identification, but it has over traditional bar code

technology and card technology superior technology

features. It is mainly reflected in non-contact

identification, no wear, long service life, response

speed ,strong penetration, effectively reused , no

light condition identification and so on. These

technical Features have played a significant role in

promoting the expanding the application of RFID

technology.

This paper use RFID technology to realize the

automatic acquisition of information of freight and

delivery tools.

2.2.2 License Plate Recognition Technology

License plate identification technique is refers to the

use of camera guns and special recognition software

to realize car license plate recognition. This

technology has been more mature, and identification

accuracy is getting higher and higher .The system

mainly includes three parts: license plate location,

license plate Segmentation and character

recognition. The task of license plate location is to

give the position of license plate in the image. The

main task of license plate segmentation is to

segment out the characters in the area of license

plate which has been located. The last part is the

character recognition, it is mainly use to recognize

the characters has been segment out.

This paper use license plate identification

technology for delivery vehicle license plate

automatic acquisition.

3 OPTIMIZATION OF IMPORT

BUSINESS PROCESS

Business process optimization is the prerequisite and

foundation of the realization of information

technology application in production business,

aiming to achieve rapid development and progress in

production efficiency, cost control , management

mode and ability , and produce a leap on key

indicators ( customer satisfaction for example),

finally to realize the fundamental reform of

enterprise management mode by redesign the

original business process, including the

corresponding resource structure adjustment and

human resources adjustment.

This section first introduces the foundation work

of bulk cargo import business process optimization;

then optimize the process of bulk cargo import

business in aspects of unloading and warehousing

process, outbound business process and switching

stack process.

3.1 Basic Work

The preparations include assembling sino-scale and

RFID tags for stacks.

1) Divide stack into different regions according

to the port of bulk cargo container stack

ICEIS 2011 - 13th International Conference on Enterprise Information Systems

510

environment and characteristic, place heaps brand

with unique RFID tags in each region, and then bind

stack cards numbers and RFID tag in the

management system.

2) Assemble RFID reader, license plate

identification equipment, land coils and infrared

sensing equipment in the original land sino-scale

system of bulk cargo ports, forming intelligent

weighing system. Land coils and infrared sensing

equipment perceive whether the trucks are on the

load meter equipment, which is in charge of starting

automatically RFID reader, camera gun and sino-

scale to gather and store the RFID card information,

license plate information and the weight of delivery

vehicles.

3.2 Unloading and Warehousing

Process Optimization

This process is unloading freight from ship to shore

and then transported to the yard. After the

optimization process can be divided into three

specific areas.

1) Before unloading and storing the freight, the

port planners in accordance with the actual needs to

development of "freight storage plan", entry the

freight information in the management system, plan

the number of heap-bit and bind the freight with a

RFID tag.

2) When the freight into the storage, the

warehouse staff read the "freight storage plan" with

PDA, and guide workers unload the freight to the

specified heap-bit and the RFID tags into the stack

bit.

3) After the storage, the warehouse staff should

confirm the unloading ship plan and automatically

generates records storage. .If the actual switch stack

is different from the plan stack, they should notify

the planners to modify the information.

3.3 Out of Storage Process Optimization

The out of storage process refers to loading freight

from the yard to the trucks, and then transports them

through the port access control systems to outside

port. Optimized based on RFID technology, the

specific process includes four parts.

1) Before the cargo owner delivery the freight,

port planners, in accordance with actual needs of this

business and the conditions of stockpiling, develop

bill of lading and more than one RFID cards to bind

RFID cards already in the system, referred to as the

delivery of the certificate cargo owners.

2) Before out storage operations, the port

planners in accordance with actual needs of this

business develop out “out storage plan” and input

information of delivery of freight in the management

system and the RFID number.

3) Stack delivery: The warehouse staff reads

RFID number of loading freight trucks by the PDA

machine, compares with the freight RFID and out of

storage plan, and transmits it through the wireless

network to the back-end system to guide loading

operations.

4) When the truck weighing, the smart weighing

system reads the information from RFID tag which

is bound on the truck. And then the management

system would record the car weighing and produce

the out storage weighing after through the heavy

pound.

3.4 Switch Stack Process Optimization

Switch stack process means that in view of the needs

of business, location of commercial vehicles changes

within storage yard of the port. Optimized based on

RFID technology, the specific process includes two

parts.

1) Before switch stack process, port planners in

accordance with actual needs of this business

develop "switch stack plan", which means they entry

the freight in the information system. The

information of freight includes RFID tag number,

former stack position and planned switch position.

2) When switch stack process starts, according

with the requirements of "switch stack plan",

warehouse staff guide the workers in the freight

transferred to the planned stack position .After that,

warehouse staff confirm the “switch stack plan” with

PDA and then automatically switch to stack records.

If the actual switch stack is different from the plan

stack, they should notify the planners to modify the

information.

Through the above analysis of three processes, it

is certainly that, after the application of RFID, the

import business process has been more

programmatic and management more standardized.

It also lays the foundation to the realization of the

port of handling automation and the use of

transparent in terminal.

4 SYSTEM DESIGN

4.1 The System Framework Design

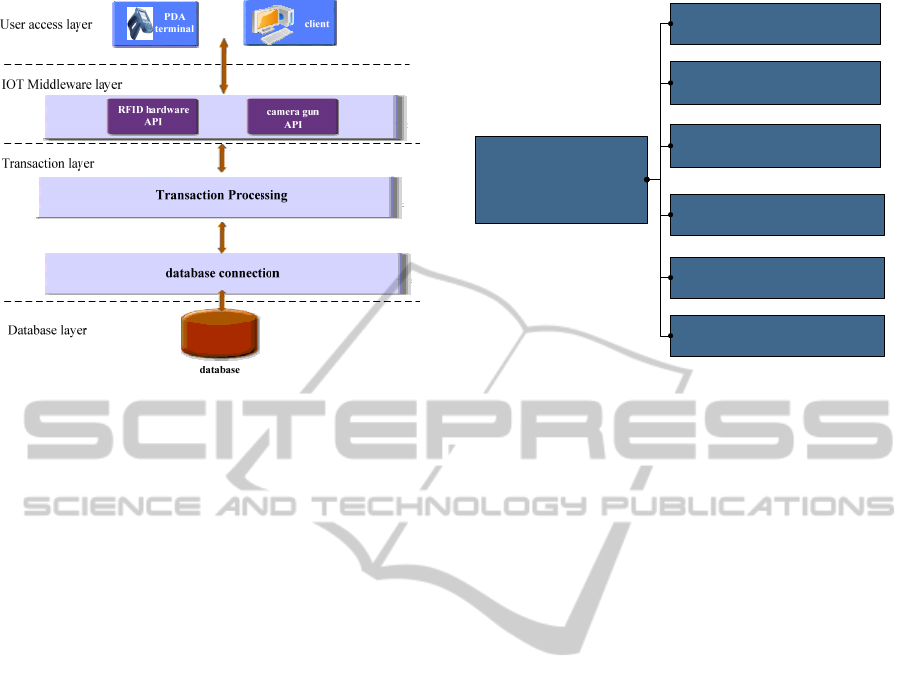

The framework of bulk port import business process

Management Information System can divide into

four parts, as illustrated in Fig 1.

OPTIMIZATION OF IMPORT BUSINESS PROCESS AND SYSTEM DESIGN IN BULK PORT BASED ON

INTERNET OF THINGS

511

Figure 1: The framework of the management system.

User access layer provide interfaces to users and

gather the demands from users. IOT Middleware

layer provide the interface to RFID reader and plate

identification equipment. Transaction layer mainly

deal with business demand of users and access the

database. Database layer is responsible for the work

of business data persistence. The system achieves

collection, transmission, processing and storage of

the Car delivery business data in bulk port, by

mutual cooperation of those four layers.

4.2 The System Function Design

The system function is divided into six parts,

according to the actual demand of the import

business, as illustrated in Fig 2.

1) Management of unloading and warehousing

process: This function includes making unload plan

of freight, recording freight information, like time

and concrete stack, during unloading process. At the

same time, it will create an integral unloading record.

2) Management of out of storage process

optimization: This function is responsible for make

plan of out of storage process, pick up information

of freight and truck, and check with the out of

storage plan. While this function will create a

integral out of storage record.

3) Management of witch stack process: It mainly

involves creating witch plan, collecting information

about witch time, original stack and new stack. And

this function will control the witch process by

matching the witch plan.

4) Visual management: Graphical stack

management is to facilitate the use of management

personnel view the stack, and the stockpiling of real-

time

management of freight. The platform can

Management system

of import businss

Management of witch stack process

Management of essential data

Comprehensive inquiry management

Management of library process

Management of unloading and

warehousing process

Visual management

Figure 2: Structure of system function.

automatically update view of the heap position

according to the business of out of storage.

5) Comprehensive inquiry management: This

function provides a various of inquiry services about

the out of storage information to users, such as

service about how much freight leave the port during

period of time, service about surplus of one stack,

and so on.

6) Management of essential data: It will be

charge of the data of the stack in terminal, and

binding the RFID tag to each stack.

ACKNOWLEDGEMENTS

The authors wish to acknowledge the support of the

project of Guangdong Province Education Ministry:

product business system of Guangzhou Port Group

and general software industry (Project

No.2008B090500244) and the project of RFID-

based vehicle management system application

demonstration project (Project

No.2009B090300467)

REFERENCES

D. Giusto, A. Iera, G. Morabito, L. Atzori (Eds.), The

Internet of Things, Springer, 2010. ISBN: 978-1-4419-

1673-0.

Huang Pengfei, RFID Technology in the Port Logistics

Application[J], Logistics Engineering and

Management. 2009(11).

Li Da, RFID Technology in the Port Informatization

Construction Application [J], China New Technologies

and Products. 2009(20).

ICEIS 2011 - 13th International Conference on Enterprise Information Systems

512