NEURAL NETWORK-BASED PROCUREMENT MODE

SELECTION OF MRO MATERIALS

Zhen Huang, Yiran Zhang

School of Business, Beijing Technology and Business University, Fucheng Road, Haidian District, Beijing, China

Haoxiong Yang, Yongsheng Zhou, Li Cui

School of Business, Beijing Technology and Business University, Beijing, China

Keywords: MRO, Procurement mode, Industrial logistics, Neural network, Clustering.

Abstract: Maintenance, Repair and operations (MRO) have following features: large sum of types, relatively low

requirement, and high transition cost. It costs companies a lot of money and human resource on MRO

procurement. In order to make MRO procurement more efficient and scientific, this paper compared the cost

of two MRO supply chain modes to get a scope for each mode. And then SOM neural networks method can

be used to cluster the materials. Different types of materials take advantage of different procurement mode.

1 INTRODUCTION

MRO is abbreviation of Maintenance Repair and

Operation, namely maintaining, repairing and

operating materials and it’s also called indirect

materials. This kind of materials includes spare

parts, machines, tools and consumables. Every

company needs certain kinds of MRO materials to

maintain their operation and business normally.

Because of the lots of kinds and specifications of

MRO materials and relatively small demand, MRO

materials procurement will inevitably lead to higher

transaction costs. According to the survey

(Wencheng Liu, 2008) , every industrial enterprise

has large sum of MRO suppliers, resulting in

inefficient MRO materials procurement, purchasing

value of total purchases accounted for only 8% of

enterprises, but it consumes more than 60% of

purchasing resources. Steve Stall (2003) mentioned

that MRO managers have come to realize that

success is no longer measured through meeting

production goals alone. They must now consider that

every purchase and maintenance decision has a

direct impact on their company's profit margin - as

well as their own department's measurement of

success. So you can see it is different from the direct

procurement of MRO materials, which involves not

only the normal production of enterprises, but also

take up a large number of enterprises of human and

financial resources. Therefore to strengthen the

management of MRO materials, procurement is very

important.

MRO study abroad is earlier, and the study

focused on e-procurement. Cade Metz (2000), Jerry

Goldstein (2001), Emily Kay (2001), Abbas

ForoughiMehmet C. Kocakülah (2003) mentioned

that MRO e-procurement can save time, improves

efficiency and reduces paper work. The domestic

study started from 2006. On the mode of

procurement of MRO materials, MRO materials

procurement study focused on the integration of

mode-based, Minjie Wu (2007) proposed integration

of the domestic industrial enterprises in international

MRO procurement. Kongji Li, Yue Li (2009)

proposed centralized procurement by the integration

of procurement service providers. Si Chen (2010)

mentioned that third party logistics providers

undertake procurement, sales and logistics role of

MRO supply chain to achieve integrated supply and

demand. But Xiaoyu Xu, Daoli Zhu (2001) thought

small and medium company can only take MRO

procurement market mode.

The earliest scholars believed that MRO material

should be obtained through the market, but in recent

years, scholars have generally agreed that MRO

materials procurement should be integrated.

However, the literatures in these two modes are not

theoretical or mathematical in-depth analysis to

523

Huang Z., Zhang Y., Yang H., Zhou Y. and Cui L..

NEURAL NETWORK-BASED PROCUREMENT MODE SELECTION OF MRO MATERIALS.

DOI: 10.5220/0003589205230526

In Proceedings of the 13th International Conference on Enterprise Information Systems (DMLSC-2011), pages 523-526

ISBN: 978-989-8425-55-3

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

clarify the scope of these two modes. According to

large sum of types and specifications of MRO

materials, taking all the materials the same mode is

not economic, so this paper is on the basis of

previous research, in-depth comparative analysis of

the two modes to propose the scope of the different

mode and provide the basis of procurement channel

for choosing.

2 ANALYSIS OF PROCUREMENT

MODES

There are two supply chain modes of procurement,

which are “manufacturers - companies” and

“manufacturer - distributor - companies “. For the

bulk procurement of raw materials, companies

usually select the "manufacturers - companies"

procurement mode. But according to MRO

materials’ special feature of variety of types and

specifications, if only selecting one of these two

modes, will inevitably result in uneconomical MRO

procurement management, So companies should

analyze and compare of the scopes of these two

modes, and then take a different mode to meet

different types of MRO materials’ requirements.

2.1 “Manufacturers - Companies”

Mode

"Manufacturers - companies” mode refers that

enterprises (the ultimate consumers) procure

materials from the manufacturer directly in

commerce flow. In logistics, MRO materials are sent

directly from the manufacturer to the enterprises (the

ultimate consumer).

The cost of this mode as following:

Assumption:

1

y ——Total cost of procurement in this

mode,

n ——Number of manufacturers,

i

c ——

Manufacturing cost ,

i

r ——Manufacturer’s

profits,

i

t ——Transaction costs.

Total cost of procurement in this mode as

following:

()

∑

=

++=

n

i

iii

trcy

1

1

2.2 “Manufacturers - Distributors –

Companies” Mode

"Manufacturers - Distributors - Companies” mode

refers that companies (the ultimate consumer)

procure a variety of MRO materials from a

distributor in commerce flow. In logistics, MRO

materials are sent from the distributor (namely

integrated MRO materials distributor, such as

Grainger, Yao Shun and other companies) directly to

the company (the ultimate consumer).

The cost of this mode as following:

Assumption:

2

y ——Total cost of procurement in this

mode ,

m ——Number of manufacturers ,

nm

<

,

i

c ——Manufacturing cost ,

i

r ——

Manufacturer’s profits,

i

t ——Transaction costs,

i

s ——Distributor’s profits.

Total cost of procurement in this mode as

following:

()()

∑∑

==

+++=

m

i

ii

n

i

ii

strcy

11

2

2.3 Modes Comparison

The difference between the two modes’ cost can be

used to illustrate which mode is more economic.

Namely,

∑∑

==

+−=−

m

i

ii

n

i

i

sttyy

11

21

)(

Assumption:

∑

=

=

n

i

i

tQ

1

1

,

∑

=

+=

m

i

ii

stQ

1

2

)(

,

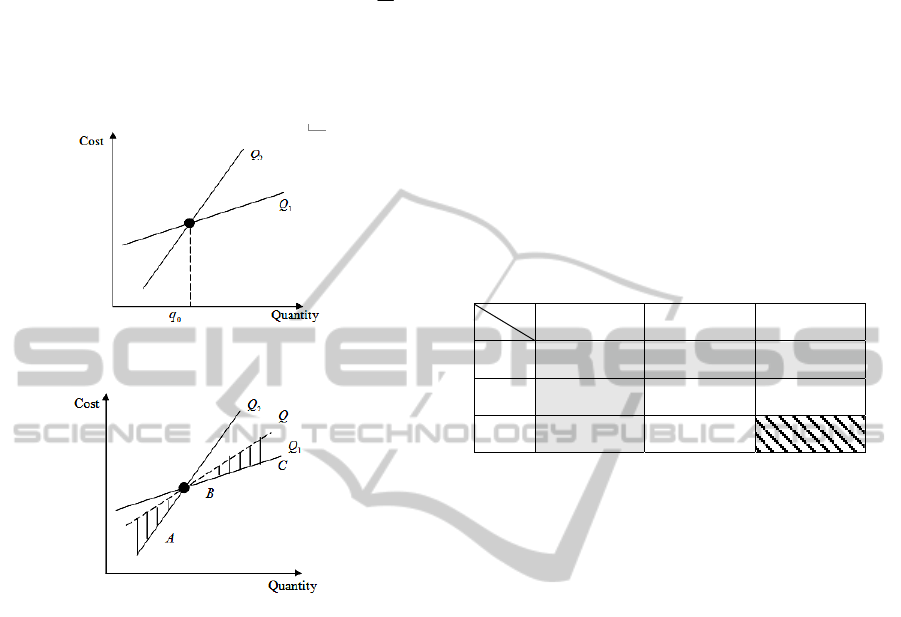

The functions of

1

Q and

2

Q are shown in figure

1. In figure 1,

0

q is the intersection of

1

Q and

2

Q ,

when

0

qq < , companies should select the

"Manufacturers - Distributors - Companies” mode.

When

0

qq > , companies should select the

"Manufacturers - Companies” mode.

ICEIS 2011 - 13th International Conference on Enterprise Information Systems

524

So the function of cost when companies combine

the two modes is ABC in Figure 2. If the enterprise

fails to combine the two modes, while using only

one mode, the average cost function is

Q .

Obviously, combining the two modes can cut cost

and the cost saving is in the area of the shaded in

figure 2.

Figure 1: Cost Functions of Two Modes.

Figure 2: Cost Savings.

3 SELECTION OF

PROCUREMENT MODES

3.1 Theoretical Methods

In reality, transaction costs, the profits of the

manufacturers and distributors are hard to be

separated. So direct calculating of the cost of the two

modes is hardly realized. For this reason, here are

trying to analyze the causes of cost to find the

obvious characteristics of different modes, so that

companies can use the scientific method to classify

MRO materials according to these characteristics. It

can easily and accurately identify different types of

MRO procurement mode to be applied.

In figure 3, the intersection of the functions

depends on purchasing quantity, which is to say the

choice of procurement mode is depends on

purchasing quantity. As MRO material has the

characteristics of demand uncertainty, so enterprises

generally sign a certain time frame contract of the

total procurement quantity of one year to the

supplier, which is the annual procurement volume.

Annual procurement volume is equal to material’s

value multiple quantity. Therefore, the product of

number and value of the purchasing material decides

the enterprise’s MRO procurement mode.

The number of materials’ value and quantity can

be classified by large, medium and small categories,

so that there are nine situations of the product, see

Table 1:

P represents the value of materials; Q represents

the number of procurement; A represents large

number; B represents medium number and C

represents small number.

Table 1: Nine situations.

A

P

B

P

C

P

A

Q

AA

QP ×

AB

QP ×

AC

QP ×

B

Q

BA

QP ×

BB

QP ×

BC

QP ×

C

Q

CA

QP ×

CC

QP ×

CC

QP ×

In order to achieve optimal benefit, companies

should choose a suitable procurement strategy for

each case in Table 1. Nine cases in Table 1 can be

divided into three categories, namely the different

three patents in Table 1:

① Gray Area

Gray area is on behalf of the large quantity of

procurement or high value materials. It is very easy

to be hand-selected in practice. The product is large

obviously. So in this case, companies should select

the "manufacturers - companies” mode.

② Slash Area

Slash area is on behalf of the small quantity and

value of material purchasing. It’s also very easy to

be hand-selected in practice. The product is small

obviously. So in this case, companies should select

"Manufacturers - Distributors - Companies” mode.

③ White Area

White area is on behalf of the medium or small

quantity or value. Because there are many kinds of

MRO materials and the demand relatively less, so in

manual work, a lot of material will be fall into this

category. And this kind of materials do not have a

typical product (relative maximum or relative

minimum), it is difficult to determine the

procurement mode by people.

In summary, the theoretical method is using

quantity and value of procurement as a characteristic

mark to select the MRO materials procurement

NEURAL NETWORK-BASED PROCUREMENT MODE SELECTION OF MRO MATERIALS

525

mode. However, in many cases, the feature can not

be man-made classified (cases in white area),

requiring a scientific and effective method to replace

the manual classification.

3.2 Actual Operation Method

In order to solve the above-mentioned problem that

artificially cannot be classified, this paper chooses

neural network of self-organizing feature mapping

network (SOM) algorithm for classification. The

SOM algorithm provides an effective way and

general framework for this type of problem, and it is

a kind of advanced artificially intelligent algorithm.

Self-organizing feature map (SOM, Self -

Organizing Feature Map) is also called the Kohonen

network, which is put forward by the Dutch scholar

Teuvo Kohonen in 1981. Kohonen think that a

neural network will be divided into different regions

when accept outside input mode, and each region

has a different input mode response characteristics

and this process is done automatically. Therefore,

SOM network is widely used for clustering research.

Based on the analysis of procurement, MRO

materials procurement model selection should be

based on the annual purchasing quantity

n

Q and

value of the procurement for clustering. In this

paper, we choose the plotsom neural network

function in the Matlab to implement clustering, and

the learning rate and other variables will use the

default values in Matlab.

4 CONCLUSIONS

This paper focus on the characteristics of MRO, that

the material type specification is so much while

purchase quantity relatively small, by comparing the

cost structure of the two modes of MRO materials’

supply chain, the scope of application of these two

types are obtained, and use the purchase quantity

and value as characteristic value, we know that

different kinds of materials should choose different

purchase mode. In order to put the theory into

practice, this paper use SOM neural network

classification of MRO materials, to solve the

problem that can’t solve manually, and select

different purchase model for different types of MRO

materials, which make the procurement of MRO

more efficiently. In this paper, the annual purchase

quantity and the value are used as the characteristic

value to establish the model. The method is simple,

convenient and feasible and provides an effective

way for enterprises to select the MRO materials

procurement model.

ACKNOWLEDGEMENTS

This work is supported by “Dynamic Allocation of

City Logistics Resource Based on the City

Sustainable Development Perspective”, a research

project of the humanities and social sciences of the

Ministry of Education of the People’s Republic of

China (No. 10YJC630324), and supported by

“Allocation of City Logistics Resource”, a project of

the Beijing Municipal Commission of Education

(No. PHR20110877).

REFERENCES

Abbas ForoughiMehmet C. Kocakülah, 2003. E-

procurement: Extending E-supply Chain Benefits to

MRO. Annual meeting of the decision sciences

institute, 20031122-25

Cade Metz, 2000. Purchasing Power. PC Magazine, 2000,

19 (20).

Emily Kay, 2001. Cut the Paperwork With Online

Procurement or MRO. Managing Automation, 2 001,

16 (3).

Jerry Goldstein, 2001. Heed These 10 Points When

Buying MRO Items Online. AFE Facilities

Engineering Journal, 2001, 28 (2).

Jili Kong, Yue Li, 2009. Research on Inventory

Management System of integrated Procurement

Service Providers of MRO Materials of Industrial

Enterprises. Logistics Engineering and Management,

2009, 12.

Minjie Wu, 2006. Transnational Integration of MRO

procurement. Modern Management Science, 2006, 10.

Si Chen, 2010. Research on the applications of integration

of supply and demand in the third-party MRO logistics

business. Market Modernization, 2010, 6.

Steve Stall, 2003. Making the Business Case for MRO

Initiatives. Technical Conference and 3rd Annual

Emerging Technologies Conference.

Wencheng Liu, 2008. MRO Procurement and Supply

Management - Discussing the Management of MRO

Applications in energy industry. China's bidding, (32):

25 -29.

Xiaoyu Xu, Daoli Zhu, 2001. Internet-based e-

Procurement Model. Logistics Technology, 2001, 5.

ICEIS 2011 - 13th International Conference on Enterprise Information Systems

526