SLUDGE MINIMIZATION BY THERMAL LYSIS DURING

BIOLOGICAL WASTEWATER TREATMENT

Experimental Study, Model Set Up and Calibration

Julien Laurent

Institut de Mécanique des Fluides et des Solides, CNRS FRE 3240, 2 rue Boussingault, 67000, Strasbourg, France

Romain Guignard, Magali Casellas, Christophe Dagot

GRESE, Université de Limoges, EA 4330, Site de l’ENSIL, 16 rue Atlantis, 87068 Limoges Cedex, France

Keywords: Sludge minimization, Thermal treatment, Pilot study, Modeling, ASM1.

Abstract: Sludge minimization by thermal treatment within activated sludge process was investigated at pilot scale. A

90°C treatment was set up in the return activated sludge loop. When keeping apparent sludge age at 15 days,

90°C treatment decreased sludge production by 30.4%. However, effluent quality was altered. A sludge

minimization ASM1 based model was set up and calibrated against experimental data, fractionation

experiments allowed us to determine state variables for treated sludge. Biomass lysis explained sludge

minimization whereas the decrease of heterotrophs growth rate yielded the higher effluent COD

concentration. The calibrated model will then be used to optimize the process.

1 INTRODUCTION

Wastewater treatment with activated sludge

processes generates large quantities of excess sludge

which must be disposed. Sludge production reached

nearly 9 million tons at the end of 2005 in Europe.

The disposal of excess sludge constitutes a major

issue for wastewater treatment plants operators and

communities due to increasing costs, strict

regulations, potential environmental hazards and

social acceptance problems. Thus, the interest for the

development of techniques allowing sludge volume

and mass reduction is presently increasing. Thermal

treatment is among of the most promising recent

technologies for reducing sludge production in

wastewater treatment plants (Ødegaard 2004). This

process can either be situated on the sludge line in

order to reduce sludge mass/volume or in the water

line in order to decrease sludge production during

biological treatment (Pérez-Elvira et al. 2006). On

the sludge line, the main goal is to improve sludge

biodegradability prior to anaerobic digestion

(Bougrier et al. 2006). On the water line, sludge

from aeration tank or secondary settled sludge is

treated before recycling in aeration tank (Camacho

et al. 2005). In such a process, the main phenomena

that could explain sludge production reduction are

(Salhi et al. 2003):

Solubilization of particulate Chemical Oxygen

Demand (COD),

Solubilization plus biodegradation leading to

mineralization of organic matter (namely cryptic

growth if considering cell lysis),

Increase of the biodegradability of the inert solid

organic fraction,

Increase of the cell decay rate and/or increase of

the maintenance energy requirements leading to a

decreased microbial growth for the same substrate

consumption.

Low temperature activated sludge thermal treatment

yields to several modifications of mixed liquor

physico-chemical characteristics: organic

compounds solubilization (Paul et al. 2006), cell

lysis (Prorot et al. 2008, 2009), modifications of

surface properties (Laurent et al. 2009) and

anaerobic/aerobic biodegradability improvement

(Salsabil et al. 2010).

Dynamic simulation analysis using numerical

models is a valuable tool for conception and

optimization of control strategies for wastewater

treatment plants (WWTPs). However, to date, only

360

Laurent J., Guignard R., Casellas M. and Dagot C..

SLUDGE MINIMIZATION BY THERMAL LYSIS DURING BIOLOGICAL WASTEWATER TREATMENT - Experimental Study, Model Set Up and

Calibration.

DOI: 10.5220/0003601903600365

In Proceedings of 1st International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH-2011), pages

360-365

ISBN: 978-989-8425-78-2

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

few attempts to model sludge minimization at source

within activated sludge process have been made

(Musser & Parker 2009; Camacho et al. 2005). In

this study, an Activated Sludge Model n°1 (ASM1)

(Henze et al. 2000) based model of sludge

minimization by thermal treatment is proposed and

validated against experimental data obtained during

a pilot study. The model is subsequently used to

investigate several scenarios and process

configurations for performance optimization.

2 METHODS

2.1 Pilots

Two identical lab-scale activated sludge processes

were built and conducted in parallel. One was used

as a control and the other included a thermal

disintegration step on the sludge recirculation line.

The volumes of rectangular aeration tanks and

settlers were 13.75 L and 8.3 L respectively. Bubble

diffusers located at the bottom of the reactors

provided aeration. In the combined system, thermal

treatment reactor was continuously included in the

recirculation line. Thermal treatment reactor

consisted of a stirred 900 mL glass recipient where a

heater (1 000 W) was dipped. Temperature was

measured by a Pt 100 probe and controlled by means

of a on/off temperature regulator.

2.2 Experimental Conditions

The pilots were continuously fed with primary

treated wastewater collected each week at the

Limoges (France) municipal wastewater treatment

plant. This plant has a 285 000 inhabitant-equivalent

capacity. Wastewater was kept in a refrigerated

(6°C) and agitated tank where it was directly

pumped to feed the pilots. Average characteristics of

feed wastewater during the experiments were: total

COD: 790 ± 140 mg O

2

.L

-1

, total suspended solids

(TSS): 370 ± 100 mg.L

-1

. Influent flow rate was set

up at 21.6 L.d

-1

corresponding to an influent

hydraulic residence time of 15.3 h in the aeration

tank. Sludge recirculation from the clarifier was

maintained at 100% of feed flow rate, allowing a 60

min return activated sludge retention time in the

thermal treatment reactor.

Aeration was operated by repeated

aerobic/anoxic cycles (2h/2h) in order to ensure

nitrification and denitrification. Air flow rate was

adjusted daily in order to have a dissolved oxygen

concentration around 2-4 mg.L

-1

in the reactors

during aerated phases (no limitation by oxygen

concentration). Solids residence time (i.e. sludge

age) was maintained at 15 days throughout the

experiments: settled sludge was wasted daily

accordingly considering sludge losses through the

effluent. The settlers were not considered in sludge

age calculations. A preliminary study indicated an

equal sludge production in the two processes when

thermal treatment was not carried out. The thermal

treatment experiment lasted 71 days.

Thermal treatment temperature was fixed at

90°C. The thermal sludge fraction (F) is defined here

as the fraction of sludge contained in aeration tank

treated each day. It was fixed at 0.2 d

-1

. The daily

duration of heater operation was calculated

accordingly. In order to avoid the injection of warm

sludge in the aeration tank, return activated sludge

was cooled at the outlet of the thermal reactor: the

pipe was circulated within fresh water cooled down

using a cryostat.

2.3 Calculation Procedure

The daily sludge production was calculated as grams

of Volatile Suspended Solids (VSS) produced. It is

based on a mass balance taking into account the

quantity of wasted sludge, the accumulation within

the reactor, and the sludge losses in the treated

effluent. As sludge production is directly related to

the amount of removed pollution, the sludge

production yield was calculated as the ratio of the

cumulative sludge production to the cumulative

COD removal in the reactors. This last calculation

considered a mass balance over COD entering and

leaving the system, neglecting the solubilized

COD during the treatment: the resulting sludge

production was therefore linked to global pollution

removal.

2.4 Model Development and

Calibration

Experimental data including influent, effluent,

activated and return activated sludge were grabbed

during whole experiment duration. They were

validated through the systematic procedure set up by

IWA Task Group on Good Modelling Practice

(2011).

2.4.1 Influent Wastewater Characterization

Fractionation of influent wastewater was deduced

from experimental measurements (influent and

effluent total and dissolved COD as well as TSS,

SLUDGE MINIMIZATION BY THERMAL LYSIS DURING BIOLOGICAL WASTEWATER TREATMENT -

Experimental Study, Model Set Up and Calibration

361

VSS) according to the following calculations:

S

i

= effluent COD

d

S

s

= influent COD

d

– S

i

X

i

= (1-VSS

inf

/TSS)*COD

t

X

s

= COD

t

-X

i

X

p

= 0

X

bh

= 0

X

ba

= 0

S

nh

= 0.755*NTK

S

nd

= 0.396*Norg

X

nd

= 0.604*Norg

S

no

= 0

S

alk

= 30 mg/L

With NTK = 0.123*COD

t

and N

org

= NTK – S

nh

.

(Typical ratios from Hauduc (2011) and Copp

(2001)).

2.4.2 Thermal Treatment Model Rationale

Based on the experimental data an ASM1-based

model (Henze et al. 2000) of sludge reduction has

been developed. It consists of a black box type

approach where return activated sludge fractionation

as well as some kinetic parameters is modified

following 90°C treatment.

The model assumes that a fraction

red

of the

recycled sludge is thermally treated. A fraction of

heterotrophs (X

h

) and nitrifiers (X

a

) is destroyed and

was determined from results obtained flow

cytometry measurements carried out in previous

studies (Prorot et al. 2008, 2009). The remaining

fraction has an activity level

bio

, used to describe

the damage that can be caused to cells.

The values of X

p

, S

s

, S

i

, X

nd

, S

nd

and S

nh

of

thermal treated activated sludge were assessed by

fractionation experiments performed on thermal

treated and untreated sludge. All other parameters

related to biomass growth and decay were taken as

in the original ASM1 model.

2.4.3 Treated Sludge Fractionation

Determination

Fractionation experiments were carried out as

follows: Activated sludge was sampled in the

recirculation line from Limoges WWTP (Total

Solids: 6.44 g/L) and treated thermally at 90°C.

The state variables of ASM1 were measured by a

method inspired by (Stricker, 2000) and used by

(Casellas et al. 2008). Four reactors were filled with

sludge according to the data presented in Table 1.

According to (Stricker, 2000) recommendations,

the reactors containing filtrated samples were

inoculated with activated sludge (1/1000 v/v). The

biodegradation tests lasted 30 days. The reactors

were continuously aerated and mixed. Soluble and

insoluble COD and nitrogen species were monitored

every day.

Table 1: Batch reactors configuration for fractionation

experiments.

Reactor 1 Reactor 2 Reactor 3 Reactor 4

Type of

sludge

Thermal

treated

Thermal

treated

Untreated Untreated

Volume 2L 2L 5L 5L

Filtration 1.2 µm None 1.2 µm None

Inoculum 2 mL None 5 mL None

2.4.4 Model Implementation

The model was finally incorporated a model

comprising a biological tank and a settler. The

simulation code was a modification of the script

FreeASM1 (original version downloadable at http://

www-imfs.u-strasbg.fr/content/FreeASM1) running

under SCILAB software. Settling was modeled by a

point settler model which considered a non-

settleable sludge fraction. The corresponding

parameter f

ns

was adapted to take into account the

presence of small floc fragments observed

experimentally.

3 RESULTS

3.1 Pilot Study Results

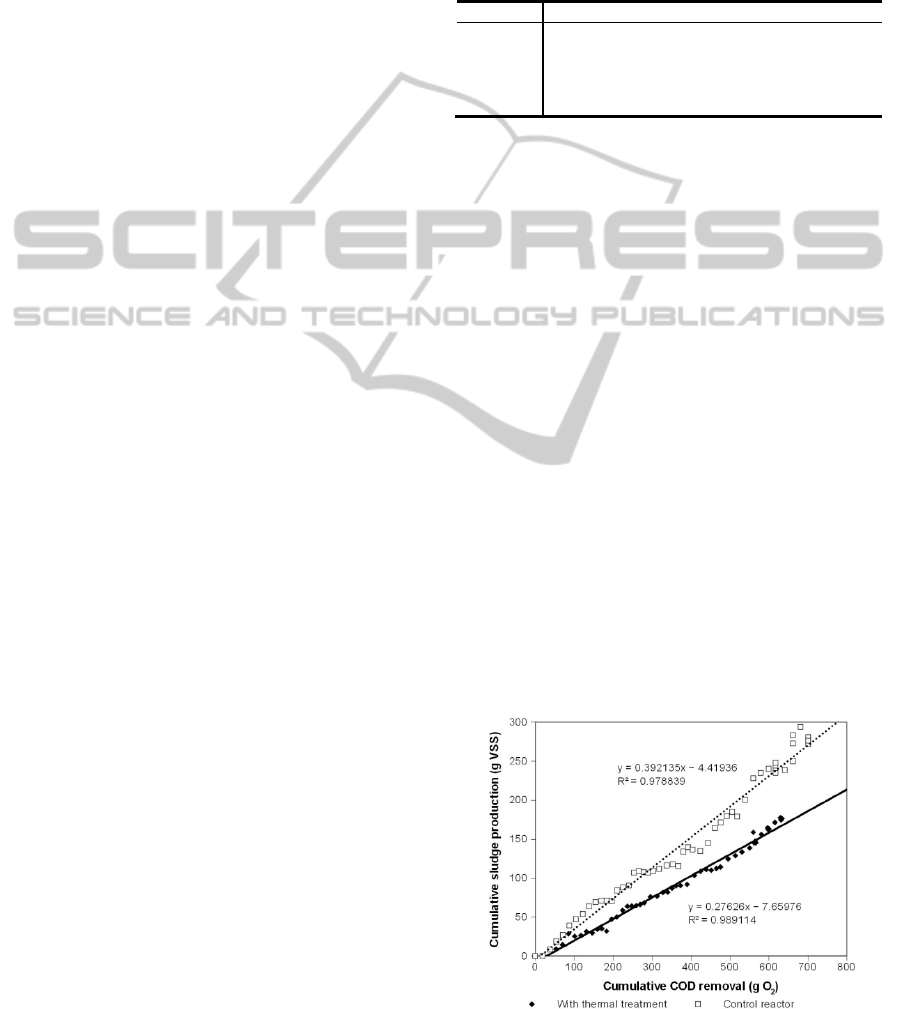

During pilot study, sludge production was reduced

by 30.4% on g VSS produced/g COD removed basis

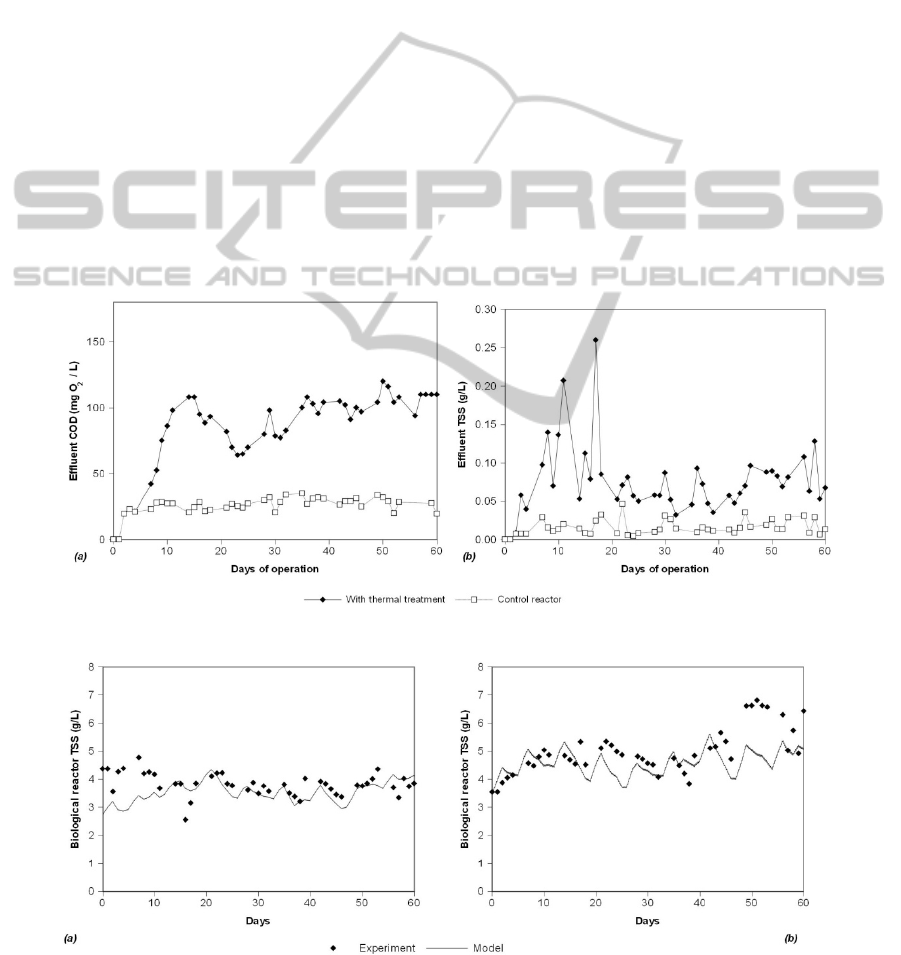

(Figure 1). At the same time, effluent COD

(determined after 1.2 µm filtration) drastically

increased (Figure 2a).

Figure 1: Sludge production yields with and without 90°C

treatment of return activated sludge.

SIMULTECH 2011 - 1st International Conference on Simulation and Modeling Methodologies, Technologies and

Applications

362

Thermal treatment also induced the increase of

the non settleable fraction of sludge particulates,

leading to higher effluent TSS concentration (Figure

2b).

3.2 Return Activated Sludge

Fractionation Following 90°C

Treatment

After thermal treatment, return activated sludge is

pumped back in the aeration tank and was

considered in this study as a substrate for the

remaining microorganisms. Therefore, the substrate

formed by thermal treated sludge was subjected to

fractionation experiments. Thermal treatment is

supposed to induce the solubilization of particulate

compounds as well as increase the biodegradability

of the return activated sludge. The obtained results

showed clearly these tendencies.

The solubilization was clearly evidenced by

fractionation results. Indeed, 77% of particulate

biodegradable substrate (Xp) was converted onto

soluble biodegradable substrate (Ss). At the same

time, biodegradability of organic compounds was

improved as inert fractions dropped after the

treatment (-54% for Si, -13% for Xi). Also flow

cytometry revealed that about 95% of bacterial cells

were lysed following the treatment (Prorot et al.

2008, 2009). These transformations were

incorporated in the model.

3.3 Model Calibration

Experimental data validation and model calibration

were performed for the two reactors (IWA Task

Group on Good Modeling Practice, 2011). Sludge

production was initially calibrated by modifying

WAS flow rate in order to fit WAS mass load

experimental data. The fraction of non settleable

solids was calibrated according to the average

experimental values of effluent TSS / activated

sludge ratio. Nitrogen treatment was not calibrated

as it was not systematically monitored during the

experiments.

Figure 2: Effluent quality with and without 90°C treatment of return activated sludge: (a) COD (b) TSS.

Figure 3: Experimental and modeled activated sludge in the reactors (a) activated sludge + 90°C treatment (b) control pilot.

SLUDGE MINIMIZATION BY THERMAL LYSIS DURING BIOLOGICAL WASTEWATER TREATMENT -

Experimental Study, Model Set Up and Calibration

363

The model accurately described both sludge

production and minimization mechanisms as the

relation between modeled and experimental VSS

production was about 0.9 in both reactors: Figure 3

shows the accuracy of the modeled TSS

concentrations.

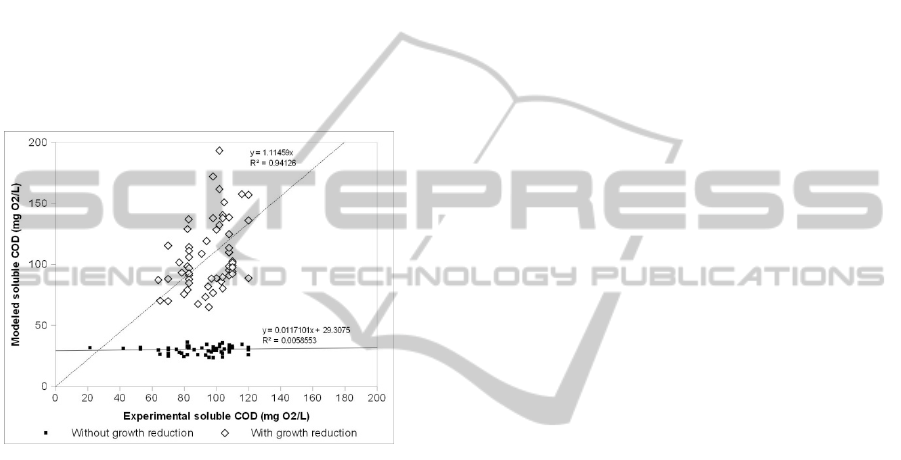

A discrepancy between experimental and

modeled effluent soluble COD was observed (Figure

4). A reduction factor for both aerobic and anoxic

heterotrophs growth kinetics was therefore

introduced and yielded a better fitting of

experimental data without significant impact on

sludge production (5% deviation) (Figure 4). This

underlines that the activity of microorganisms was

lower in the combined reactor.

Figure 4: Experimental versus modeled effluent soluble

COD for the combined reactor with and without reduction

of heterotrophs growth kinetics in the model.

Several hypotheses could explain this

phenomenon: bacterial “stress”, shift of microbial

populations, etc. It is also noteworthy that the

thermal treatment model induced a complete loss of

nitrification: cell lysis described in the model was

sufficient to describe a washout of autotrophic

biomass from the reactors, even when the reduction

factor of growth kinetic is not introduced. This trend

was confirmed by nitrogen species measurements

carried out at the end of pilot operation: effluent

ammonium concentrations were 35.30 ± 1.77 and

0.40 ± 0.02 mg/L for combined and control reactor

respectively.

4 CONCLUSIONS

Sludge thermal treatment (90°C) applied on the

water line of an activated sludge process was studied

at pilot-scale. Sludge production was effectively

lowered by about 30% following thermal treatment

in the studied conditions. However, effluent quality

was drastically decreased: effluent COD increased

as well as TSS concentration due to the generation

of non settleable particles. An ASM1 based model of

sludge minimization treatment was successfully set

up, following a simple systematic procedure, and

calibrated over experimental data. This model

assumes that sludge reduction is mainly due to the

biomass conversion in readily biodegradable

substrate followed by its recycling in the biological

reactor (solubilisation + cryptic growth). The

decrease of COD removal was modeled as a

reduction factor for the rates associated to biomass

growth. This model will be used in a near future to

optimize the process of sludge reduction i.e. obtain a

significant sludge minimization while keeping

satisfactory effluent quality.

5 NOMENCLATURE

COD

d

= dissolved COD (mg O

2

/L)

COD

t

= total COD (mg O

2

/L)

N

org

= organic nitrogen (mg N/L)

NTK = Kjeldahl nitrogen (mg N/L)

S

i

= soluble inert COD (mg O

2

/L)

S

no

= nitrates (mg N/L)

S

alk

= alkalinity (mg/L)

S

s

= soluble biodegradable COD (mg O

2

/L)

TSS = volatile suspended solids (mg/L)

VSS = volatile suspended solids (mg/L)

X

i

= particulate inert COD (mg O

2

/L)

(1-VSS

inf

/TSS

inf

)*COD

t,inf

X

s

= particulate biodegrabable COD (mg O

2

/L)

X

p

= bacterial products (mg O

2

/L)

X

bh

= heterotrophs (mg O

2

/L)

X

ba

= autotrophs (mg O

2

/L)

S

nh

= ammonia (mg N/L)

S

nd

= soluble organic nitrogen (mg N/L)

X

nd

= particulate organic nitrogen (mg N/L)

REFERENCES

Bougrier, C. et al., 2006. Combination of Thermal

Treatments and Anaerobic Digestion to Reduce

Sewage Sludge Quantity and Improve Biogas Yield.

Process Safety and Environmental Protection, 84(4),

p.280-284.

Camacho, P. et al., 2005. Understanding the mechanisms

of thermal disintegrating treatment in the reduction of

sludge production. Water Science and Technology,

52(10-11), p.235-245.

SIMULTECH 2011 - 1st International Conference on Simulation and Modeling Methodologies, Technologies and

Applications

364

Casellas, M. et al., 2008. Influent fractionation for the use

of ASM1 to optimize urban wastewater treatment:

Application to the removal of C and N in a SBR.

Revue des Sciences de l’Eau, 21(4), p.451-462.

Copp, J. B., 2001. The COST Simulation Benchmark:

Description and Simulator Manual, Luxembourg:

Office for Official Publications of the European

Community.

Hauduc, H., 2011. Modèles biocinétiques de boues

activées de type ASM : Analyse théorique et

fonctionnelle, vers un jeu de paramètres par défaut.

Antony, France & Québec, Canada: CEMAGREF /

Université Laval.

Henze, M. et al., 2000. Activated sludge models ASM1,

ASM2, ASM2d and ASM3, IWA Publishing.

IWA Task Group on Good Modelling Practice, 2011.

Guidelines for Using Activated Sludge Models,

London: IWA Publishing.

Laurent, J. et al., 2009. Fate of cadmium in activated

sludge after changing its physico-chemical properties

by thermal treatment. Chemosphere, 77(6), p.771-777.

Musser, J. & Parker, W., 2009. Modeling WAS

Reduction: Incorporating Ultrasonic Pretreatment Into

a Whole-Plant Simulator. WEFTEC 2009 83th Annual

Water Environment Federation Conference and

Exposition. Atlanta, Georgia, USA.

Ødegaard, H., 2004. Sludge minimization technologies -

An overview. Water Science and Technology, 49(10),

p.31-40.

Paul, E et al., 2006. Organic matter release in low

temperature thermal treatment of biological sludge for

reduction of excess sludge production. Water Science

and Technology, 54(5), p.59-68.

Pérez-Elvira, S. I. et al., 2006. Sludge minimisation

technologies. Re-views in Environmental Science and

Biotechnology, 5(4), p.375-398.

Prorot, A. et al., 2008. Assessment of physiological state

of microorganisms in activated sludge with flow

cytometry: Application for monitoring sludge

production minimization. Journal of Industrial

Microbiology and Biotechnology, 35(11), p.1261-

1268.

Prorot, A. et al., 2009. Biological and chemical

characterizations of the effects of activated sludge

sonication. New Biotechnology, 25(Supplement 1),

p.S239.

Salhi, M. et al., 2003. More insights into the reduction of

excess sludge production by ozone. Dans Biosolids

2003. Wastewater sludge as a resource. Trondheim,

Norway.

Salsabil, M. R. et al., 2010. Techno-economic evaluation

of thermal treatment, ozonation and sonication for the

reduction of wastewater biomass volume before

aerobic or anaerobic digestion. Journal of Hazardous

Materials, 174(1-3), p.323-333.

Stricker, A. E., 2000. Application de la modélisation à

l’étude du traitement de l’azote par boues activées en

aération prolongée : comparaison des performances en

temps sec et en temps de pluie. PhD Thesis,

Strasbourg: ENGEES.

SLUDGE MINIMIZATION BY THERMAL LYSIS DURING BIOLOGICAL WASTEWATER TREATMENT -

Experimental Study, Model Set Up and Calibration

365