THE RESEARCH OF PAPER REVERSE LOGISTIC NETWORK

OPTIMIZATION ON THE LOW-CARBON ECONOMY

Wu Rongxu, Ru Yihong, Wu Shengna

Beijing Jiatong University, Beijing, China

Su Chang

Beijing Jiatong University, Beijing, China

Keywords: Low-carbon economy, Reverse logistics, Network optimization, Paper reverse, Carbon emission.

Abstract: As the contradiction between natural resources and economic development become more and more serious,

people in the 21

st

century is facing a new revolution of the method of the economic development, with low

fuel consumption, low recourse consumption, low gas emission, and low environmental pollution, low-

carbon economy is a new choice for the future economic development. This paper firstly introduces the

current study status of low-carbon economy and reverse logistics network, then by taking the paper reverse

industry as an example, defines the mathematic relationship between reverse logistic network optimization

with the help of the relationship between paper and tree, and finally demonstrate the feasibility in the

combination of the low-carbon economy and reverse logistics network, making a model that maximizes the

benefits and minimizes the carbon emission. This paper provides a valuable reference for the subsequent

research.

1 CURRENT STATUS OF THE

STUDY

As low-carbon economy is on the rise globally,

many scholars made attribution to the study within

related fields. Currently low-carbon economic

researches have mainly focused on the macroscopic

policy and transition of renewable energy resources.

The research of reverse logistic network is also

wide, most of which analyze from the theoretical

view, including the mode, decisional problem and

network construction of the reverse logistics to

resolve the problem about location and transport

routes.

2 APER REVERSE LOGISTICS

NETWORK

Under the new social situation reverse logistics

network planning should meet the higher demands,

especially the paper recycling network which cost a

large amount of waste the resource .This research

has been carried out in the area of reverse logistics

of the paper recycling industry. Paper reverse

logistics network belongs to recycling reverse

logistics. Our national waste paper recycling

network is now inefficient. There are some cross

exist among main body of every level in the

network, and the waste paper recovery is fragmented

and complex.

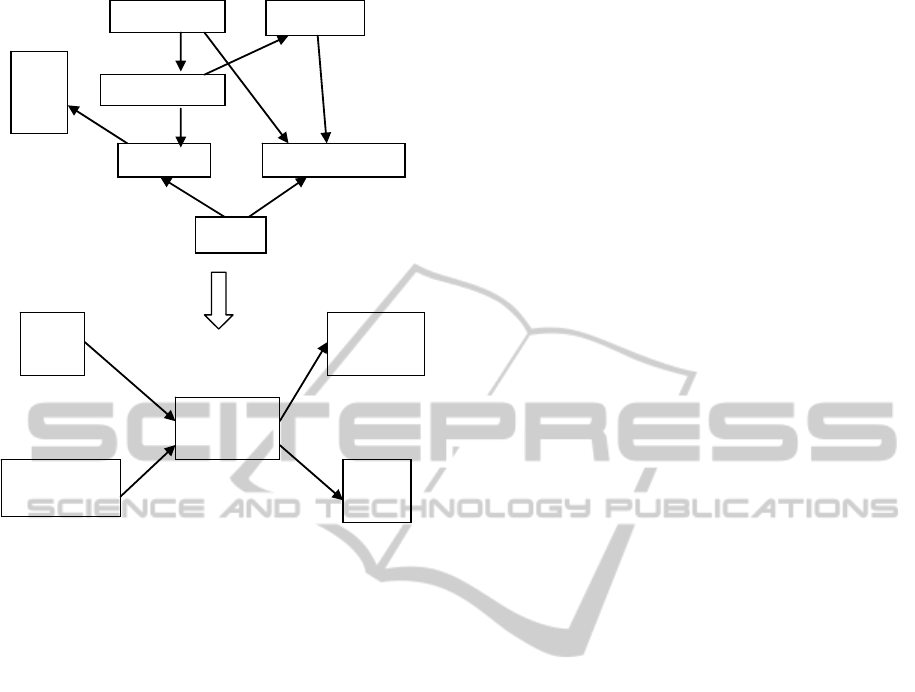

This article is based on the existing problems in

the waste paper recycling system and the reverse

network. Simplification of the network is on the

table. The primary level is consists of scattered

customers and trash treatment plants. The second

level contains waste pretreatment plants waste

recycling companies. The third includes the Second-

handed market and Paper Mill. The network of three

levels is as below:

336

Rongxu W., Yihong R., Shengna W. and Chang S..

THE RESEARCH OF PAPER REVERSE LOGISTIC NETWORK OPTIMIZATION ON THE LOW-CARBON ECONOMY.

DOI: 10.5220/0003604403360340

In Proceedings of the 13th International Conference on Enterprise Information Systems (BIS-2011), pages 336-340

ISBN: 978-989-8425-54-6

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

Garbage

Wastetransfer

Paperdisposal

Waste

disposa

l

plant

custome

Wasterecycling

Recycling

k

Customer

Wastedisposal

plants

Reprocessed

center

Secondary

market

Paper

mill

Figure 1: Paper reverse network.

The network set rules about specifications and

responsibilities of each main body while more

attention is distribute to the optimization of garbage

recycling network. In this way, it achieves higher

recycling rate and standard rules in waste recycling

field.

3 FEASIBILITY ANALYSIS IN

THE COMBINATION OF THE

LOW-CARBON ECONOMY

AND REVERSE LOGISTICS

NETWORK

At present, researches in low-carbon economy and

the reverse logistics network is plenty ,but little in

the coordination with both low-carbon economy and

the reverse logistics network.

This article takes the paper recycling reverse

logistics network as an example. With the analyses

of the relevance between them while taking the

carbon as the carrier, we realize the coordination

between the optimization of reverse logistics

network and the low-carbon economy. It mainly

displays in the following two aspects specifically.

First, the recycling of waste paper can reduce

carbon emissions. From the ecological footprint

analysis, the footprint of woodlands is based on the

original wood. With the consumption of wood-pulp

paper the paper trail, the waste paper recovery and

carbon emissions reduction of the relationship is a

sign of the waste paper recycling of paper

consumption .To begin with, proportion of pulp and

paper is about 0.9:1.

With the pulp of recovery which would be based

on carbon emissions and the recovery paper analyses

per ton saved carbon emissions. One ton per

recycling of waste paper can be made in 0.85 million

tons of paper and timber while three tons of a little

off the tree grown tall tree.

Secondly, the reverse logistics network can also

reduce carbon emissions. This process through the

path that rearrangement of transportation planning

and waste paper recovery is in a network, including

the customer and processing center, the secondary

market and paper. This four nodes can help

determine the location of the vehicle the transport

lines and reduce the amount of fuel as well as the

carbon emissions.

Low-carbon economic rely mainly on carbon

emissions reduction and waste paper recovery by the

reverse logistics network analysis. So that the

reverse network for the carbon emissions reduction

has a positive role and low carbon economic and

reverse the integrated logistics network show

feasibility.

4 MODEL BUILDING

4.1 Model Specification

With general consideration of the costs 、benefits

and carbon emissions. This article sets two goals: the

maximization of benefits and the minimization of

carbon emission.

With the control and action of pretreatment

centers number and current capacity of each node,

this study count out the location of customers,

garbage recycling centers, second-handed markets

and paper mills under the goals while it is also

capable to trace out the plan of recycling center

construction and capacity during the transportation.

4.2 Model Assumption

(1) Customers as well as trash treatment plant

quantity is acknowledged and each customer as

well as recycling production output of trash

treatment plant and price is known;

THE RESEARCH OF PAPER REVERSE LOGISTIC NETWORK OPTIMIZATION ON THE LOW-CARBON

ECONOMY

337

(2) All recycling product’s quality is the same while

part of them is secondary markets, carries on the

restoration a part to the paper mill;

(3) The location of each pretreatment center is

acknowledged, so as its fixed investment and

capability.

(4) The location and capability of each second-

handed market is acknowledged, so as each

Paper Mill.

(5) The costs of each processing step and carbon

emission from the three spots is known.

(6) Freight for each unit and carbon emission from

each node of the network is acknowledged.

(7) The number of pretreatment centers is restricted.

(8) Only a single-round static model

4.3 Model Establishment

(1) Symbols

I

: Collection of costumer

J

: Collection of garbage recycling centers

P

: Collection of splitting treatment centers

S

: Collection of second – handed markets

H

: Collection of paper mill

s

S

W

: Unit income from paper sold from the second –

handed market

h

H

W

: Unit income from paper sold from the paper

mill

s

S

X

: Output of paper from the second – handed

market

h

H

X

: Output of paper from the paper mill

0

C

: Reverse costs from reprocessed center to

customers

1

C

: Reverse costs from reprocessed center to paper

recycling center

ip

A

1

: Unit transport costs from customer I to

reprocessed center p

jp

A

2

: Unit transport costs from paper recycling j to

reprocessed to reprocessed center p

sp

A

3

:Unit transport costs from reprocessed center p

to paper recycling s

ph

A

4

: Unit transport costs reprocessed center p to

paper mill h

ip

D

1

: Distance from customer i to reprocessed center

p

sp

D

2

: Distance from paper recycling center to

reprocessed center p

sp

D

3

: Distance from reprocessed center p to

secondary markets s

ph

D

4

: Distance from reprocessed center p to paper

mill h

p

f

: Fixed cost of the reprocessed center p per year

*

D

C

: Carbon emission from each unit of transport

λ

: Coefficient of carbon emission of one ton

waste paper

P

p

α

: Recovery rate of treatment center

H

h

α

: Production rate of paper mill

P

p

Q

: Operational capacity restrictions of treatment

center

S

s

Q

: Operational capacity restrictions of second –

handed market

H

h

Q

: Restoration ability limitation of paper mill

γ

: Restiction of the number of Treatment center

M

: Carbon emissions from transportation before

optimization

(2) Decision variable

p

P

: 0-1 variable, 1 represents to buid reprocessed

center, 0 represents not

p

i

I

X

: the amount of paper reversed from reprocessed

p to costumer i

p

j

J

X

: the amount of paper reversed from costumer p to

recycling center j

ip

X

1

: the amount of paper reversed from customer I to

reprocessed center p

jp

X

2

: the amount of paper reversed from recycling

center j to reprocessed center p

sp

X

3

: the amount of paper reversed from reprocessed

center p to secondary market s

ph

X

4

: the amount of paper reversed from reprocessed

center p to paper mill h

(3) Objective function

∑

−

∑

−

∑∑∑

−

∑∑ ∑∑ ∑∑

−−−−

∑∑

−−

∑

+

∑

+

∑

+

∑

+−

∑∑

+

∑∑

+

∑∑

+

∑∑

H

p

P

p

f

H

h

H

X

h

C

P

p

P

X

p

C

PH

ph

X

ph

D

ph

A

IP JP PS

ps

X

ps

D

ps

A

jp

X

jp

D

jp

A

ip

X

ip

D

ip

A

IJ

j

J

XC

i

I

XC

h

H

X

H

h

H

W

s

S

X

S

s

S

W

h

h

H

X

s

S

S

XM

PH

PH

D

PS

PS

D

JP

JP

D

IP

IP

DMax

*

4

*

34

*

4

*

4

3

*

3

*

32

*

2

*

21

*

1

*

1

*

1

*

0

**

6.48*)](

4321

[

λ

(4) Constraints

∑

=

P

ip

X

I

X

i

1

(1)

∑

=

P

jp

X

J

X

j

2

(2)

∑

∑

∑

∑

+=+

SH

ph

X

ps

X

IJ

jp

X

ip

X

P

p 43

)

21

(

α

(3)

s

S

X

P

ps

X ≤

∑

3

(4)

ICEIS 2011 - 13th International Conference on Enterprise Information Systems

338

h

H

X

P

ph

X

H

h

=

∑

4

α

(5)

p

P

P

p

Q

J

jp

X

I

ip

X *

21

≤+

∑∑

(6)

∑

≤

P

S

s

Q

ps

X

3

(7)

∑

≤

P

H

h

Q

ph

X

4

(8)

γ

≤

∑

p

p

P

(9)

Pp

p

P ∈∀= 1,0

(10)

0≥∀X

(11)

Constraints (1) ~ (5) is for the customers,

garbage collection center, processing center, the

second-handed market and paper mill .Five points in

the flow of conservation are based on the type

constraint; (6)~ (9) are based on the limitation

of processing center, the second-handed market and

paper mill. (10) ~ (11) concerns on variable value.

5 ANALYSIS

A waste paper recycling centre of the network has

three large waste treatment centre: a seconded

market, one paper mill, waste paper from one

customer and a garbage collection centre.

The treatment center’s recycling rate is 70%

while the production rate of the paper mill is

35%.The recovery for customer and garbage

collection centre from the pretreatment is 39000 tons

and 91000 tons. The second-handed market and

paper mill can get 44,000 tons and 59000 tons from

the pretreatment center.

The second-handed market’s selling price of

paper is 1500 Yuan per ton while the paper mill’s is

1300 Yuan. The transportation costs from the

pretreatment center to the second-handed market are

1.3 Yuan while one from pretreatment center to the

paper mill is 1.2 Yuan. The transportation costs from

the customer to the pretreatment center is 1.2 Yuan

while one from recycling center to pretreatment

center is 1.1 Yuan. Cost of customer and recycling

centers to be dealt with the transportation is 1.1 and

1.2 billion Yuan. In the past, emissions of carbon

from transportation was 620 tons a year while

transportation of carbon emissions from 0.00042

tons for a ton and paper for discharge coefficient is

0.0026 one unit of data.

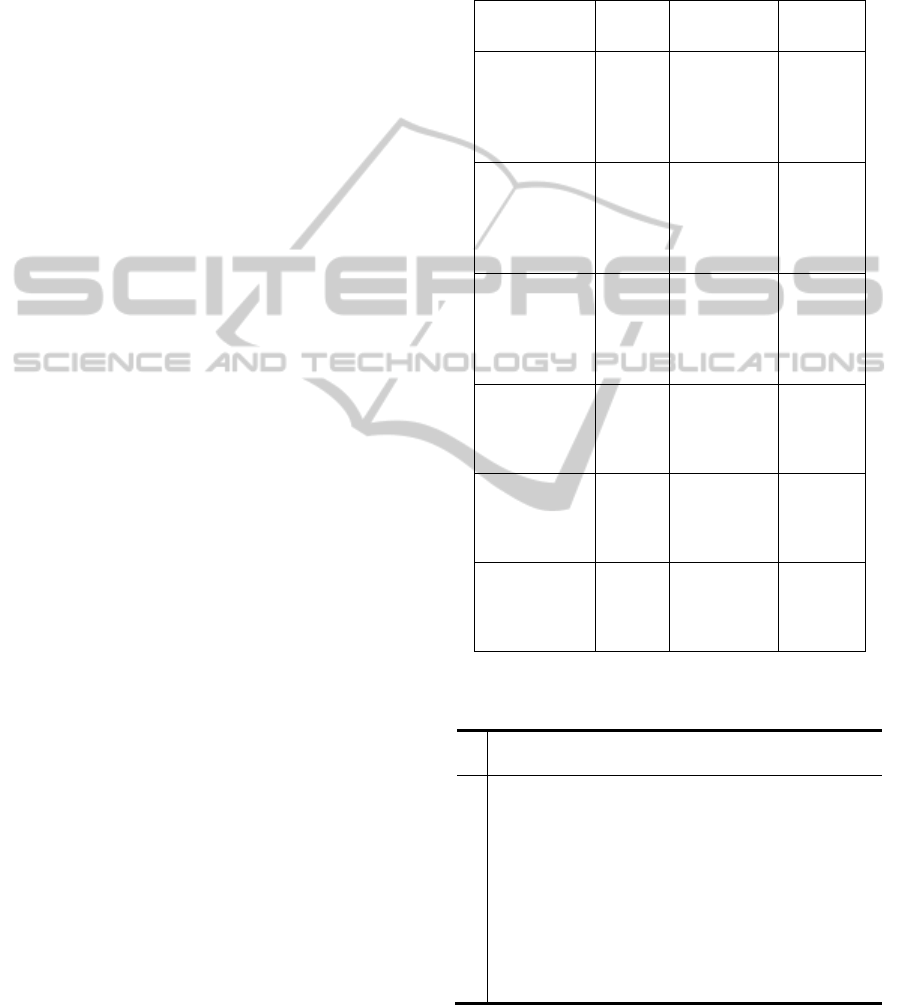

Table 1: Distance among customers, recycling center,

reprocessed center and paper mill.

Distance

(Km)

Distance

(Km)

Distance from

customer to

reprocessed

center 1

3 Distance from

reprocessed

center 1 to

recycling

center

15

Distance from

customer to

reprocessed

center 2

2 Distance from

reprocessed

center 2 to

recycling

center

20

Distance from

customer to

reprocessed

center 3

5 Distance from

reprocessed

center 3 to

recycling

center

10

Distance from

recycling center

to reprocessed

center 1

15 Distance from

reprocessed

center 1 to

paper mill

20

Distance from

recycling center

to reprocessed

center 2

10 Distance from

reprocessed

center 2 to

paper mill

23

Distance from

recycling center

to reprocessed

center 3

20 Distance from

reprocessed

center 3 to

paper mill

15

Table 2: The maximum processing ability ofreprocessed

center, secondary market and paper mill.

PPP

1

i

I

X

2

i

I

X

3

i

I

X

1

i

I

X

2

i

I

X

3

i

I

X

0 0 1 0 0 39000 0 0 91000

1 0 0 39000 0 0 91000 0 0

1 1 0 14500 24500 0 91000 0 0

0 1 0 0 39000 0 0 91000 0

0 1 1 0 12500 26500 0 78500 12500

With the data for the objective function and

constraints, we use lingo11. 0 to achieve the result :

Recycling centre will only transport waste paper to the

further processing center while customers sent the waste to

THE RESEARCH OF PAPER REVERSE LOGISTIC NETWORK OPTIMIZATION ON THE LOW-CARBON

ECONOMY

339

the waste treatment centre 1 and 2. Finally, the maximum

income is 2670000 Yuan. Results shown in Table 3:

Table 3: Results of the modelling.

results(ton)

Maximum ability of

reprocessed center

150000

Maximum ability of

secondary market

100000

Maximum ability of

paper mill

120000

Figure of table 3 shows that the number of

Figure of table 3 shows that the number of

pretreatment center is two at most. Customers can

deliver waste to pretreatment centre 1 and 2 while

waste paper recycling centre will always be handled

by the central treatment centre. 1 and 2 will be sent

to the second-handed market. The waste paper from

the pretreatment center 2 of the waste treatment

centre will be sent to paper mill.

6 CONCLUSIONS

On the basis of the low-carbon economy and reverse

logistic network, this article works on the waste

paper recovery and recycling network .It takes waste

paper recycling reverse logistic network as example

as well. It argues for the feasibility of the model in

which low-carbon economic and the optimization of

the reverse logistics network can perfectly combine.

With the construction of the model, it can achieve

the two goals while it is also effective.

However, this article is base on the assumption

of the maximize benefit from each node in the

supply chain and the minimization of carbon

emission, which leads to the contradiction that either

the whole or the each node can achieve the

maximize profit. Therefore, the next step may be

based on this and focus on the benefit distribution in

the method the Nash Equilibrium, a principles of

economics.

REFERENCES

Stock J. R. Development and implementation of reverse

logisties Programs. Oakbrook , IL: Council of

logisties management,1998.

Fleisehmanna M,Krikke H. R.,Dekker R.,et al. A

characterization of logisties networks for Product

recovery. Omega, 2000,Vol.28(6):653-666.

达庆利等.逆向物流系统结构研究的现状及展望.中国管

理科学,2004,vol.12(l):131-138.

Fleiselllnarin M. Reverse logistics network structures and

design. Erim report series research in management,

2001.

Jayaraman V.,Guide J. V.,Srivastava R. A closed-loop

logisties model for remanufacturing . Journal of the

operational research society,1999,Vol.50:497-508.

秦小辉.废旧电子产品逆向物流网络优化设计研究.西南

交通大学,2008,vol.29(128):14-16.

Listes O. A decomposition approach to a stochastic model

for supply-and-return network design. Econometric

Institute Reports EI2002-43.

马祖军,张殿业,代颖.再制造逆向物流网络优化设计

模型研究. 交通运输工程与信息学报,2004 ,

Vol.2(2):53-58.

赵宜,尹传忠,蒲云.回收物流设施多层选址模型及其

算法.西南交通大学学报,2005,Vol.40(4):530-534

邢继润.发展低碳经济的公共政策研究:[D].华中科技大

学,2009

Neto J. Q. F., Bloelnhof-Ruwaard J. M.,van Nunen J. A.

E. E. et al. Designing and evaluating sustainable

logistics networks. Erasmus research institute of

management report series research in management,

ERS-2006-003-LIS,2006.1.

Bloelnhof-Ruwaard J. M. , Wassenhove L. N. Van ,

Gabel H. L. , et al. An environmental life cycle

optimization model for the European pulp and paper

industry,Omega

,

Intemational joumal of manage-

ment science, 1996,Vol.24(6):615-629

ICEIS 2011 - 13th International Conference on Enterprise Information Systems

340