TYPE-1 AND TYPE-2 FUZZY CONTROL OF AN ANTI-LOCK

BREAKING SYSTEM (ABS) AND EVALUATION

OF ITS PERFORMANCES

Ayse Cisel Aras

1

, Yesim Oniz

1

, Okyay Kaynak

1

and Rahib Abiyev

2

1

Department of Electrical and Electronics Engineering, Bogazici University, Istanbul, Turkey

2

Department of Computer Engineering, Near East University, Lefkosa, North Cyprus

Keywords:

Antilock braking system, Type-1 fuzzy neuro system, Type-2 fuzzy neuro system, Gradient descent algorithm.

Abstract:

The control of nonlinear systems is a challenging task in control engineering and the use of type-1 Fuzzy

Logic Controllers (FLCs) has been proposed as a possible approach. However, traditional type-1 FLCs can

prove to be inadequate in dynamically unstructured environments that include large amount of uncertainties.

Under such circumstances, type-2 fuzzy logic controllers can be a viable alternative. In this paper, an Anti-

Lock Breaking System (ABS) is controlled both by a type-1 and an interval type-2 fuzzy logic controller

with and without noisy input measurement. The performances of both controllers are approximately the same

without noise in the input measurement. However, with noisy input measurements, interval type-2 fuzzy logic

controller results in better performance, indicating its superiority when there exist considerable amount of

uncertainties in the system to be controlled.

1 INTRODUCTION

Type-1 Fuzzy Logic Systems (T1-FLSs) were first in-

troduced by Zadeh in 1965, and since then the area

has drawn the interest of many scientists and been

extensively used for modeling and control purposes.

In literature, there are noteworthy studies that have

used type-1 Fuzzy Logic Controllers (FLCs) as ref-

erenced in a recent survey paper (Precup and Hellen-

doorn, 2011).

In most real world applications, the control engi-

neers are confronted with uncertainties and imprecise

information due to the internal and the external dy-

namics of the system to be controlled. Type-1 fuzzy

logic controllers may prove to be inefficient in han-

dling these kinds of uncertainties. To overcome the

problem, the use of type-2 FLCs is suggested in the

literature and many successful applications are re-

ported (Hagras, 2007), (Liang and Mendel, 2000).

Most of these are based on interval type-2 (IT2) struc-

tures (Abiyev and Kaynak, 2010),(Castillo and Melin,

2008).

In this study, uncertainty and noise handling capa-

bility of the considered IT2 FLCs is investigated. The

rule-base of IT2 Fuzzy Neuro System (FNS) structure

is of TSK type. The antecedent part of the fuzzy IF-

THEN rules is composed of interval type-2 member-

ship functions and the consequent part is a first order

polynomial. The design parameters in the antecedent

part are the centers and the standard deviations of the

Gaussian membership functions. Their means are as-

sumed to be uncertain. The design parameters in the

consequent part are the coefficients of the first order

polynomial. These parameters of the structure are

tuned by using gradient descent algorithm.

In Section 2, the mathematical description of the

ABS system used as the test bed is presented. In Sec-

tion 3, the structure of the type-2 fuzzy neural system

is described and parameter update rules are derived.

The simulation studies carried out on the ABS system

are presented in Section 4. In Section 5, an analysis

of the results is given and the further work in the area

is discussed.

2 THE MATHEMATICAL

DESCRIPTION OF ABS

SYSTEM

To derivethe mathematical model of the ABS, the free

body diagram of the quarter vehicle model shown in

503

Cisel Aras A., Oniz Y., Kaynak O. and Abiyev R..

TYPE-1 AND TYPE-2 FUZZY CONTROL OF AN ANTI-LOCK BREAKING SYSTEM (ABS) AND EVALUATION OF ITS PERFORMANCES.

DOI: 10.5220/0003645505030508

In Proceedings of the 8th International Conference on Informatics in Control, Automation and Robotics (ICM-2011), pages 503-508

ISBN: 978-989-8425-74-4

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

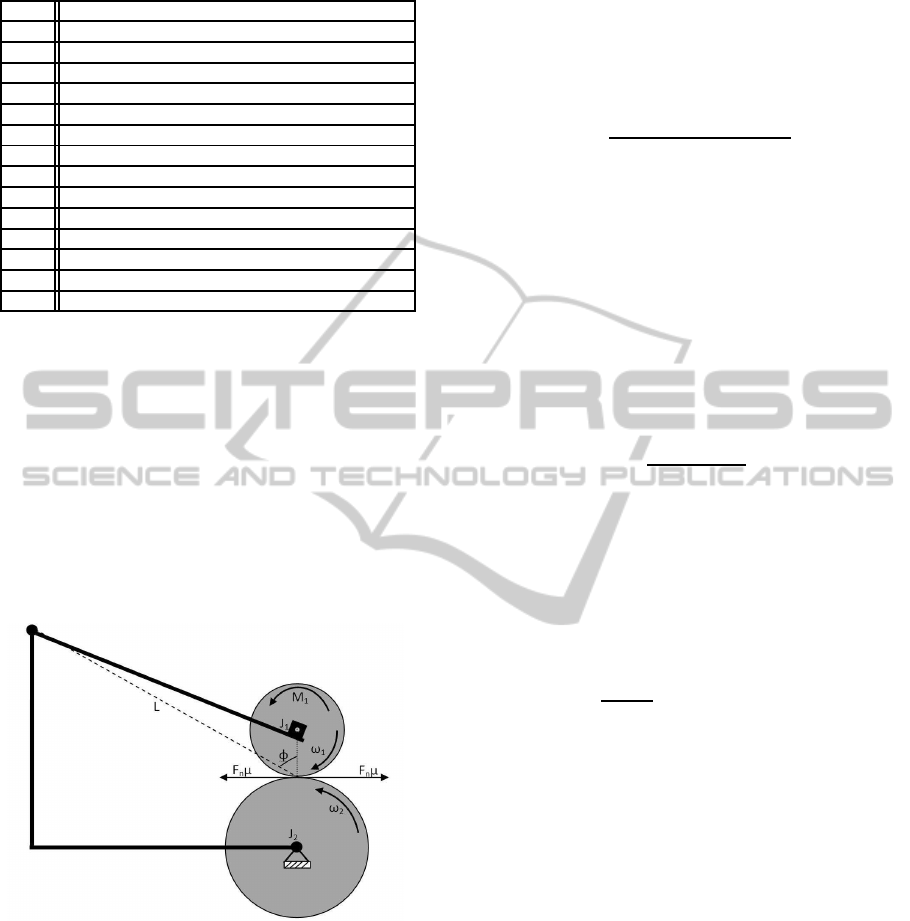

Table 1: System Parameters.

ω

1

Angular velocity of the upper wheel

ω

2

Angular velocity of the lower wheel

T

B

Braking torque

r

1

Radius of the upper wheel

r

2

Radius of the lower wheel

J

1

Moment of inertia of the upper wheel

J

2

Moment of inertia of the lower wheel

d

1

Viscous friction coefficient of the upper wheel

d

2

Viscous friction coefficient of the lower wheel

F

n

Total normal load

µ Road adhesion coefficient

λ Wheel slip

F

t

Road friction force

M

10

Static friction of the upper wheel

M

20

Static friction of the lower wheel

Fig. 1 is considered. The model is quite simple, but

it maintains the fundamental characteristics of a real

system. The lower wheel imitates the relative road

motion, whereas the upper wheel, mounted to the bal-

ance lever, animates the wheel of the vehicle. Several

assumptions are made in deriving the dynamic equa-

tions of the system: The lateral and vertical motions

of the vehicle have been neglected and only the longi-

tudinal dynamics have been considered. Additionally,

it is assumed that there is no interaction between the

four wheels of the vehicle.

Figure 1: Schematic view of experimental setup.

Regarding Fig.1, three torques act on the upper

wheel. These are the braking torque, the friction

torque in the upper bearing, and the friction torque

among the wheels. Similarly, two torques act on the

lower wheel, which are the friction torque in the lower

bearing and the friction torque between these wheels.

For braking, a torque is applied to the upper wheel,

which causes the wheel to slow down. According to

the Newton’s second law, the equation of the motion

of the system can be written as:

J

1

˙

ω

1

= F

t

r

1

− (d

1

ω

1

+ M

10

+ T

B

) (1)

J

2

˙

ω

2

= −(F

t

r

2

+ d

2

ω

2

+ M

20

) (2)

In these equations F

t

can be stated as

F

t

= µ(λ)F

n

(3)

The normal force, F

n

, is computed with the following

formula:

F

n

=

d

1

ω

1

+ M

10

+ T

B

+ M

g

L(sinφ− µ(λ) cosφ)

(4)

In Eq. (4), L is the distance between the contact point

of the wheels and the rotational axis of the balance

lever and Φ corresponds to the angle between the nor-

mal in the contact point and the line L. During driv-

ing, the speed of the vehicle and the rotational ve-

locity of the wheel have matching values. However,

during braking, the braking torque is generated at the

interface between the wheel and road surface, which

causes the wheel speed to decrease. Consequently, the

wheel speed will tend to be lower than vehicle speed.

The parameter used to specify this difference in these

velocities is called wheel slip and denoted by λ.

λ =

r

2

ω

2

− r

1

ω

1

r

2

ω

2

(5)

A zero wheel slip means that the wheel velocity is

equal to the speed of the car, whereas a ratio of one in-

dicates that the wheel is not rotating, but the car is still

moving, i.e. the wheels are skidding on the road and

the vehicle is no more steerable. The road adhesion

coefficient is a nonlinear function of some physical

variables including wheel slip and it can be approxi-

mated by the following formula (Inteco, 2007):

µ(λ) =

c

4

λ

p

a+ λ

p

+ c

3

λ

3

+ c

2

λ

2

+ c

1

λ (6)

The resulting road adhesion coefficient vs. wheel slip

curve is presented in Fig. 2. As can be seen from this

figure, a wheel slip value of 0.2 corresponds to the

maximum value of the road adhesion coefficient.

The numerical values used in this study for the

simulations are:

r

1

= 0.0995(m)

r

2

= 0.0990(m)

φ = 65.61(

◦

)

L = 0.37(m)

J

1

= 0.00753(kgm

2

)

J

2

= 0.0256(kgm

2

)

d

1

= 0.00011874(kgm

2

/s)

d

2

= 0.00021468(kgm

2

/s)

M

10

= 0.0032(Nm)

M

20

= 0.0925(Nm)

c

1

= −0.04240011450454,

c

2

= 0.00000000029375,

c

3

= 0.03508217905067,

c

4

= 0.40662691102315,

a = 0.00025724985785, and

p = 2.09945271667129.

ICINCO 2011 - 8th International Conference on Informatics in Control, Automation and Robotics

504

Figure 2: Road adhesion coefficient vs. wheel slip.

3 THE THEORETICAL AND

MATHEMATICAL

BACKGROUND OF T2-FNS

In real world applications, systems experience many

uncertainties due to the dynamically unstructured en-

vironments. Traditional fuzzy logic systems may not

be able to handle these kind of uncertainties. In this

study a type-2 fuzzy-neuro structure is used as the

controller of a system which has two inputs, the error

(e) and the derivative of the error (△e). The structure

of the MISO (multi-input, single-output) neuro fuzzy

controller is given in Fig. 3.

Figure 3: The structure of neuro-fuzzy inference system.

This structure is constructed as a IT2 TSK fuzzy

logic system. Such systems are divided in the lit-

erature into three models depending on the types of

membership functions on the antecedent and the con-

sequent parts of the fuzzy IF-THEN rules (Liang and

Mendel, 1999). This work focusses on the second

model.

In Fig. 3, the first layer of the network is fed by the

external input signal, X = x

1

,x

2

,...,x

n

. In the second

layer, the input space is defined by using Gaussian

membership functions with uncertain mean which are

initially distributed onto the input domain equally as

shown in Fig. 4.

Figure 4: Initial interval type-2 Gaussian membership func-

tions with uncertain mean.

The fuzzy IF-THEN rule structure has the follow-

ing form:

IF x

1

is

˜

˜

A

1j

and...and x

m

is

˜

˜

A

mj

THEN y

j

is

m

∑

i=1

w

ij

x

i

+ b

j

(7)

where x

i

(i = 1,...,m) are the input variables, y

j

( j =

1,...,n) are the output variables which are the linear

functions. The antecedent part of the rule is composed

of interval type-2 fuzzy sets,

˜

˜

A

ij

for the j-th rule of the

i-th input, and the consequent part of the rule is a first

order polynomial with the coefficients, w

ij

and b

j

.

The second layer in Fig. 3, the upper and lower

membership functions degrees are determined by us-

ing Eq. (8).

µ

˜

A

i

k

= [µ

˜

A

i

k

(x

k

),µ

˜

A

i

k

(x

k

)] = [µ

i

,µ

i

] (8)

Lower and upper membership functions between

i

th

input and j

th

hidden neurons of layer 3 can be

given as follows:

µ

ij

(x) =

(

G(c2

ij

,σ

ij

,x

i

) x

i

≤

c1

ij

+c2

ij

2

G(c1

ij

,σ

ij

,x

i

) x

i

>

c1

ij

+c2

ij

2

µ

ij

(x) =

G(c1

ij

,σ

ij

,x

i

) x

i

< c1

ij

1 c1

ij

≤ x

i

≤ c2

ij

G(c2

ij

,σ

ij

,x

i

) x

i

> c2

ij

(9)

TYPE-1 AND TYPE-2 FUZZY CONTROL OF AN ANTI-LOCK BREAKING SYSTEM (ABS) AND EVALUATION

OF ITS PERFORMANCES

505

where G(c

ij

,σ

ij

,x

i

) is determined as:

G(c

ij

,σ

ij

,x

i

) = exp

−

1

2

(x

i

− c

ij

)

2

σ

2

ij

(10)

The firing strengths of the rules are calculated by

using the prod t-norm operator at the third layer.

f = µ

˜

A

1

(x

1

) ∗ ··· ∗ µ

˜

A

n

(x

n

) (11)

f = µ

˜

A

1

(x

1

) ∗ ··· ∗ µ

˜

A

n

(x

n

) (12)

The output of the consequent part of the each rule

is calculated at the fourth layer as follows:

y

j

=

m

∑

i=1

w

ij

x

i

+ b

j

(13)

The type reduction and the defuzzification proce-

dures are realized at the fifth, the sixth and the seventh

layers of the neuro-fuzzy structure. The defuzzified

output of the type-2 TSK fuzzy system is determined

by using the inference engine proposed in (Biglarbe-

gian et al., 2010), and has the following form:

u =

p

∑

N

j=1

f

j

y

j

∑

N

j=1

f

j

+

q

∑

N

j=1

f

j

y

j

∑

N

j=1

f

j

(14)

where f

j

and f

j

are the lower and upper firing

strength of each rule, respectively. p and q are the de-

sign parameters that weight the sharing of lower and

upper firing levels of each fired rule, N is the number

of rules.

4 TRAINING OF THE T2-FNS

After the output of the system is calculated, the gra-

dient descent algorithm is applied to tune the design

parameters of the system which are the center and the

standard deviation of the membership functions at the

antecedent part, the coefficients of the first order poly-

nomial at the consequent part, p and q values in Eq.

(14).

Initially, the output error is determined as follows:

E =

1

2

O

∑

i=1

(u

d

i

− u

i

)

2

(15)

where O is the number of output, u

d

i

and u

i

are the

desired and the actual output of the network, respec-

tively.

The parameters at the antecedent part of the rules,

c1

ij

, c2ij, σ

ij

and the parameters at the consequent

part of the rules, w

ij

, b

j

are tuned by using gradient

descent algorithm as follows:

w

ij

(t + 1) = w

ij

(t) − γ

∂E

∂w

ij

;b

j

(t + 1) = b

j

(t) − γ

∂E

∂b

j

(16)

c1

ij

(t+1) = c1

ij

(t)−γ

∂E

∂c1

ij

;c2

ij

(t+1) = c2

ij

(t)−γ

∂E

∂c2

ij

(17)

σ

ij

(t + 1) = σ

ij

(t) − γ

∂E

∂σ

ij

(18)

where γ is the learning rate. The derivatives in Eqs.

16-18 are determined as follows:

∂E

∂w

ij

=

∂E

∂u

∂u

∂y

j

∂y

j

∂w

ij

(19)

∂E

∂b

j

=

∂E

∂u

∂u

∂y

j

∂y

j

∂b

j

(20)

∂E

∂σ

ij

=

∑

j

∂E

∂u

∂u

∂f

j

∂f

j

∂µ

ij

∂µ

ij

∂σ

ij

+

∂u

∂f

j

∂f

j

∂µ

ij

∂µ

ij

∂σ

ij

∂E

∂c1

ij

=

∑

j

∂E

∂u

∂u

∂f

j

∂f

j

∂µ

ij

∂µ

ij

∂c1

ij

+

∂u

∂f

j

∂f

j

∂µ

ij

∂µ

ij

∂c1

ij

∂E

∂c2

ij

=

∑

j

∂E

∂u

∂u

∂f

j

∂f

j

∂µ

ij

∂µ

ij

∂c2

ij

+

∂u

∂f

j

∂f

j

∂µ

ij

∂µ

ij

∂c2

ij

where

∂E

∂u

= u(t)−u

d

(t);

∂u

∂f

j

= p

y

j

− u

∑

n

j=1

f

j

;

∂u

∂f

j

= q

y

j

− u

∑

n

j=1

f

j

u =

∑

n

j=1

f

j

y

j

∑

n

j=1

f

j

;u =

∑

n

j=1

f

j

y

j

∑

n

j=1

f

j

(21)

t-norm prod operator has the following form.

∂f

j

∂µ

ij

=

N1

∏

k = 1

k 6= i

µ

kj

(22)

∂f

j

∂µ

ij

=

N1

∏

k = 1

k 6= i

µ

kj

(23)

where i =,...,N1, k = 1,...,N1, and j = 1, ...,N2.

Then,

∂µ

j

(x

i

)

∂c1

ij

=

G(c1

ij

,σ

ij

,x

i

)

(x

i

−c1

ij

)

σ

2

ij

, x

i

< c1

ij

0, c1

ij

≤ x

i

≤ c2

ij

0, x

i

> c2

ij

ICINCO 2011 - 8th International Conference on Informatics in Control, Automation and Robotics

506

∂µ

j

(x

i

)

∂c1

ij

=

(

0, x

i

≤

c1

ij

+c2

ij

2

G(c1

ij

,σ

ij

,x

i

)

(x

i

−c1

ij

)

σ

2

ij

), x

i

>

c1

ij

+c2

ij

2

(24)

∂µ

j

(x

i

)

∂c2

ij

=

0, x

i

< c1

ij

0, c1

ij

≤ x

i

≤ c2

ij

G(c2

ij

,σ

ij

,x

i

)

(x

i

−c2

ij

)

σ

2

ij

, x

i

> c2

ij

∂µ

j

(x

i

)

∂c2

ij

=

(

G(c2

ij

,σ

ij

,x

i

)

(x

i

−c2

ij

)

σ

2

ij

), x

i

≤

c1

ij

+c2

ij

2

0, x

i

>

c1

ij

+c2

ij

2

(25)

∂µ

j

(x

i

)

∂σ

ij

=

G(c1

ij

,σ

ij

,x

i

)

(x

i

−c1

ij

)

2

σ

3

ij

, x

i

< c1

ij

0, c1

ij

≤ x

i

≤ c2

ij

G(c2

ij

,σ

ij

,x

i

)

(x

i

−c2

ij

)

2

σ

3

ij

, x

i

> c2

ij

∂µ

j

(x

i

)

∂σ

ij

=

G(c2

ij

,σ

ij

,x

i

)

(x

i

−c2

ij

)

2

σ

3

ij

), x

i

≤

c1

ij

+c2

ij

2

G(c1

ij

,σ

ij

,x

i

)

(x

i

−c1

ij

)

2

σ

3

ij

), x

i

>

c1

ij

+c2

ij

2

(26)

The parameters p and q enable us to adjust the lower

and upper portions of the final output in Eq. (14). The

optimization algorithm for these parameters is given

by the following equations. The initial value for both

parameters is taken as 0.5.

p(t + 1) = p(t) − γ

∂E

∂p

(27)

q(t + 1) = q(t) − γ

∂E

∂q

(28)

where

∂E

∂p

= (u− u

d

)

f

j

∑

n

j=1

f

j

(29)

∂E

∂q

= (u− u

d

)

f

j

∑

n

j=1

f

j

(30)

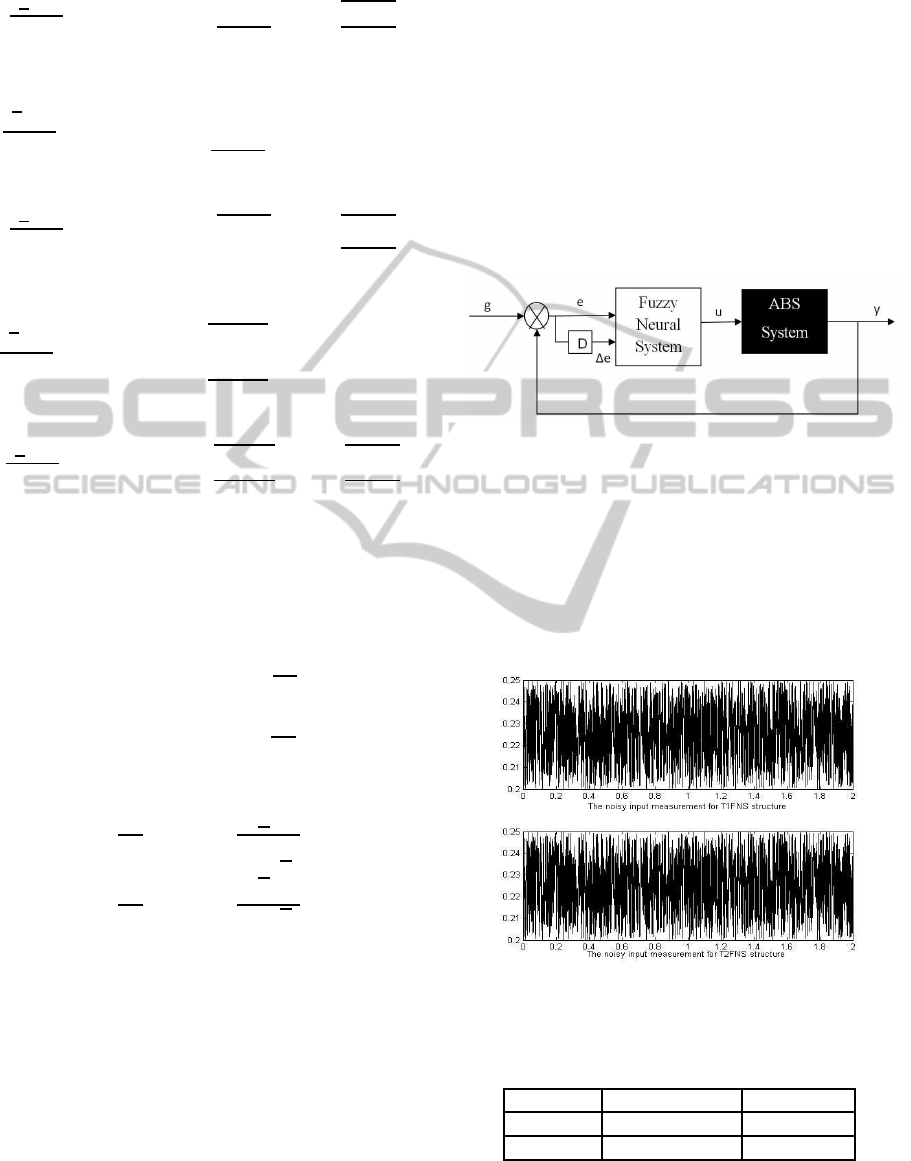

5 SIMULATION RESULTS

A number of simulation studies are carried out with

type-1 and type-2 FNS controllers acting on the ABS

system described and the results obtained are com-

pared. The block diagram of the type-2 FNS system

is shown in Fig. 5. As has been discussed earlier, the

FNS block has two inputs, e is the error and △e is

the derivative of the error. g is the reference signal,

u is the control input signal and y is the output of the

system.

In the simulations, the sampling time is set to 1ms.

The rotational velocity of the upper and lower wheels

before the braking operation is selected 250 rad/s.

The reference wheel slip is set to 0.2 which corre-

sponds to the peak value of µ − λ. In order to de-

termine the efficiency and the accuracy of the pro-

posed controller two sets of simulation studies have

been conducted. In the first study, the performances

of both controllers are tested without noise in the in-

put measurement. Then, in the second set of simula-

tions, the noise effect is included as shown in Fig. 6.

The signal-to-noise ratio (SNR) is about 17dB.

Figure 5: The structure of type-2 Neuro Fuzzy System.

The initial membership functions for error and the

derivative of the error are distributed equally onto the

input domain. The initial weights of the neural net-

work are selected randomly.

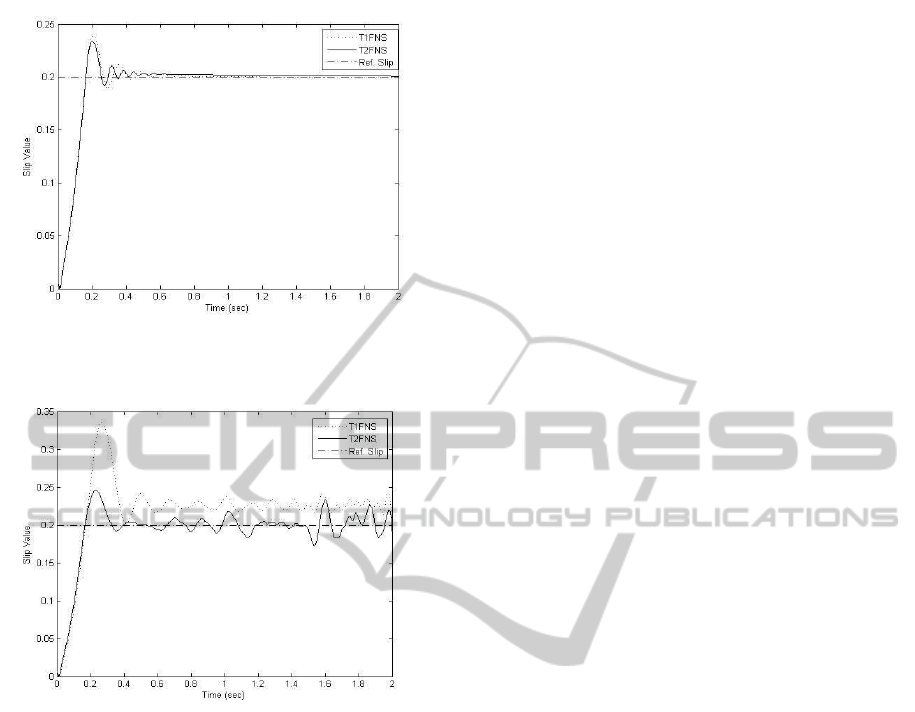

Table 2 shows Root Mean Squared Error (RMSE)

values to compare the performances of the both algo-

rithms.

Figure 6: The noisy input measurement for the two cases.

Table 2: Root Mean Squared Error values of the type-1 and

type-2 FNS algorithms.

without Noise with Noise

T1 FNS 1.731 2.419

IT2 FNS 1.714 2.197

TYPE-1 AND TYPE-2 FUZZY CONTROL OF AN ANTI-LOCK BREAKING SYSTEM (ABS) AND EVALUATION

OF ITS PERFORMANCES

507

Figure 7: Wheel slip of type-1 and type-2 FNS without

noise in the input measurement.

Figure 8: Wheel slip of type-1 and type-2 FNS with noise

in the input measurement.

6 CONCLUSIONS

In this paper, two different structures, a type-1 and a

type-2 structure are used to control ABS system. The

functions of the layers in each structure are explained

in detail and the parameter update rules of the struc-

tures are given which are based on gradient descent

algorithms.

A number of simulation studies are carried out.

Firstly, it is assumed that the input measurements are

not corrupted with noise. The results indicate that

both controllers have similar responses. However,

in real life, the measurements usually include some

level of noise. To simulate this, a band limited white

noise is added to the slip measurement. In this case,

it can be seen from Fig. 8 that type-2 FNS outper-

forms type-1 FNS. It can therefore be concluded that

type-2 FNS structure results in a better performance

when there exists uncertainties. Encouraged by the

simulation results, an experimental study is about to

be launched.

ACKNOWLEDGEMENTS

The authors would like to acknowledge TUBITAK

Grant No: 107E284 and Bogazici University Project

Grant No: 08A204.

REFERENCES

Abiyev, R. and Kaynak, O. (2010). Type-2 fuzzy neu-

ral system structure for identification and control of

time-varying plants. In IEEE Trans. Indust. Electron.

vol.57, no.12, pp.4147-4159.

Biglarbegian, M., Melek, W., and Mendel, J. (2010). On

the stability of interval type-2 TSK fuzzy logic control

systems. In IEEE Transactions on Systems, Man, and

Cybernetics, Part B: Cybernetics. vol.40, issue 3, pp.

798-818.

Castillo, O. and Melin, P. (2008). Type-2 Fuzzy Logic: The-

ory and Applications, Studies in Fuzziness and Soft

Computing. Springer, Vol. 223.

Hagras, H. (2007). Type-2 FLCs: A new generation of

fuzzy controllers. In IEEE Computational Intelligence

Magazine. vol.2, pp.30-43.

Inteco (2007). The Laboratory Antilock Braking System

Controlled from PC. Inteco Ltd., Poland, user’s man-

ual edition.

Liang, Q. and Mendel, J. (1999). An introduction to type-

2 TSK fuzzy logic systems. In IEEE International

Fuzzy Systems Conference. vol.3, pp. 1534-1539.

Liang, Q. and Mendel, J. (2000). Interval type-2 fuzzy logic

systems: Theory and design. In IEEE Transactions on

Fuzzy Systems. vol.8, pp.535-550.

Precup, R. and Hellendoorn, H. (2011). A survey on indus-

trial applications of fuzzy control. In Computers in

Industry. vol.62, pp.213-226.

ICINCO 2011 - 8th International Conference on Informatics in Control, Automation and Robotics

508