MODULAR DESIGN FOR SPACE ENGINEERING RESEARCH

PLATFORMS

Mark Post, Regina Lee and Brendan Quine

Earth and Space Science and Engineering, York University, 4700 Keele St., Toronto, Canada

Keywords:

Field robotics, Mobile robots, Embedded systems, Electronics.

Abstract:

In this paper, we describe a modular design approach that is used in developing several research platforms for

space engineering research at York University. We briefly describe three distinct research projects for space

science and engineering research: a 6kg micro-rover under development for the Northern Light mars lander

mission, a 50kg rover built by the York University Rover Team to compete in the annual University Rover

Challenge, and a 1U CubeSat design for nanosatellite technology development research. All three research

projects share a design philosophy to achieve modularity, efficiency, robustness and simplicity by adopting a

common embedded hardware configuration using COTS hardware and a simple control topology. An on-board

computer board stack based on a PC/104 or similar form-factor provides centralized control using an ARM

microcontroller. Payloads and application-specific components are added using robustSPI, synchronous serial,

and RS-485 interfaces, with provision made for ethernet and USB connectivity when needed. The software for

this system is is based on open-source compilers and operating systems and is also modular in nature, using

a portable base station GUI, wireless mesh networking between different systems, and JAUS messaging for

flexible component-level communications. The proposed design approach allows sharing of resources while

optimizing design features with cost-effective, readily-available commercial components for complex research

projects.

1 INTRODUCTION

The challenges of creating system designs for space

engineering research and education are often differ-

ent from those encountered in industry. To mini-

mize costs and development time, commercial-off-

the-shelf (COTS) components and free open-source

software (FOSS) tools are preferred for building sys-

tems for use in research and student projects. Addi-

tionally, the engineers tasked with building and pro-

gramming the robotic hardware are often students

with limited knowledge of embedded systems and

minimal hands-on experience, so using simple inter-

faces and design methodologies is generally benefi-

cial. In many cases, it is necessary to integrate net-

works of simple componentsin a manner that not only

keeps communications simple and efficient for pro-

totype robots such as in (Candini et al., 2009), but

also to allow sufficient flexibility for enlarging and

upgrading the systems later.

This approach must be balanced by the necessity

to design and build reliable systems that can tolerate

potentially hostile environments while operating.

Noise tolerance, thermal limitations, and ESD pro-

tection need to be considered for the system to be ro-

bust in practical use. As many universities, includ-

ing York University in Toronto, are now participating

in the development of microsatellites and nanosatel-

lites, such systems may also need to be operable in

the extremes of vacuum, temperature and radiation in

outer space. Successful nanosatellite missions using

off-the-shelf hardware such as CanX-2 (Sarda and C.,

2010) have proven that given good engineering prac-

tice, it is not always necessary to use very special-

ized hardware to operate in hostile or distant environ-

ments, and depending on the mission, simple radia-

tion shielding and temperature control may be suffi-

cient.

2 DESIGN CRITERIA

The following four criteria are proposed for the de-

velopment of an adaptable, mobile robotic research

platform.

427

Post M., Lee R. and Quine B..

MODULAR DESIGN FOR SPACE ENGINEERING RESEARCH PLATFORMS.

DOI: 10.5220/0003649804270436

In Proceedings of the 8th International Conference on Informatics in Control, Automation and Robotics (MORAS-2011), pages 427-436

ISBN: 978-989-8425-75-1

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

1. Modularity. Parts of the system can be added and

removed as needed for the purpose at hand, but

the system uses common modules and interfaces

for multiple purposes.

2. Efficiency. Most space hardware is solar-

powered, and most mobile robotic hardware is

battery-powered, so minimizing power use and

weight is essential.

3. Robustness. Components and bus systems have

to tolerate environmental variations and extremes

that arise from the variety of conditions that may

be encountered.

4. Simplicity. For a research institution, hardware

must be simple to understand and flexible in op-

eration so that it can be applied to many different

levels of projects.

Recently, the rapid development of low-cost micro-

controllers and highly-integrated logic devices for the

mobile device market has made it possible to build

modular, general purpose robotic hardware for a frac-

tion of the cost and complexity needed even two

decades ago. Designing and constructing these sys-

tems in-house has the benefits of easy modification,

low cost, and a better overall understanding of the

system’s dynamics, and students can work in depth

with the system as part of their education. To lever-

age this capability, we propose a modular electronic

design philosophy for electronic systems that can be

used in a variety of research projects. The hardware

should be easily adaptable to different uses. System

modules should be easily field-replaceable and ser-

viceable. Electronic parts used in this system need to

be readily available for ease of development, tolerant

of noise and voltage in field conditions, and inexpen-

sive. Components in ball-grid array and other no-lead

packages should be avoided to facilitate soldering, re-

pair, and improve vibration resistance. Programming

should make use of open and freely-available tools to

ensure continuing availability.

2.1 Current Implementations

The motivation for designing a standardized set of in-

terfaces and implementation guidelines is that differ-

ent research groups with varying hardware require-

ments can share designs, hardware, and program code

so more time and effort can be spend on the re-

search itself as opposed to the hardware necessary

to accomplish it. This paper describes a framework

for field robotics that lends itself well to modular

robotic systems such as rovers with payloads, un-

manned aerial vehicles, sensor networks, and even

nanosatellites. The focus is on efficiency and mini-

mization so that physically small and solar-powered

systems can be built, but the embedded hardware is

centered on a modern ARM microcontroller that is

powerful enough to support a variety of autonomous

operating modes. This modular design is being put

to use in several student and research projects at York

University.

Foremostly, a micro-rover (or “µrover”) prototype

known as the Beaver is currently under development

for use in the Northern Light Mars Lander mission

(Quine et al., 2008), a Canadian Mars lander and rover

system instrumented to provide new information on

the Martian atmosphere, surface, and subsurface. The

6kg micro-rover is capable of autonomous operation

and is built on a four-wheel drive swing-arm suspen-

sion chassis with two science payload spaces at the

front and back. The first version of the Beaver was

tested at the Algonquin Radio Observatory in Novem-

ber 2010, and the results of testing have confirmed the

usability of the modular system. The uRover design is

based on a 10 x 10 x 20 cm form factor to accommo-

date PC/104 form factor boards, batteries, and associ-

ated hardware, and the on-board computer is based on

a low-power ARM microcontroller that uses routed

messaging for inter-component communications. A

research prototype is shown in Figure 1 (a).

Also, The York University Rover Team (YURT)

is a student group that has achieved podium finishes

for all three years competing in the University Rover

Challenge held by the Mars Society. Each year, the

team builds a new 50kg rover based on the experi-

ence gained in previous years and uses it to perform

four distinct remotely-guided tasks in desert condi-

tions with rocky terrain and > 30

◦

C heat at the Mars

Desert Research Station in Utah, USA (Post and Lee,

2011). The modular system design described here has

both influenced and been influenced by the experi-

ences of YURT, and each generation of rover refines

the standards and implementation of the previous one.

Figure 1 (b) shows the rover developed for the 2011

competition, known as E.V.E. (Enhanced Vehicle Ex-

plorer)

Finally, the nanosatellite development program at

York University is in the process of designing a 1U

CubeSat (of size 10 x 10 x 10 cm) that follows the

modular embedded design philosophy. For a typi-

cal CubeSat application, external payload interfaces

and command routing is not necessary, as every com-

ponent is contained on the on-board computer stack.

The components are different but the engineering can

remain consistent and retain most of the compatibil-

ity with other robotic systems. A conceptual view

of the CubeSat when completed is shown in Figure

ICINCO 2011 - 8th International Conference on Informatics in Control, Automation and Robotics

428

1 (c). Planned future work includes development of

unmanned aerial vehicles similar to those described

in (Cho et al., 2007) using the same modular system.

(a) Beaver micro-rover prototype.

(b) YURT2011 competition rover E.V.E.

(c) York CubeSat nanosatellite concept.

Figure 1: Existing implementations of modular system.

3 HARDWARE ARCHITECTURE

To achieve the described flexibility in configuration

of the the embedded on-board computer (OBC) hard-

ware, a stack of printed circuit boards (PCB) is pro-

posed as the basis for the modular system. This OBC

stack includes a common motherboard for central-

ized control, and additional daughterboards that can

be added to suit the application. If more complexity

is needed, additional stacks can be added and linked

together.

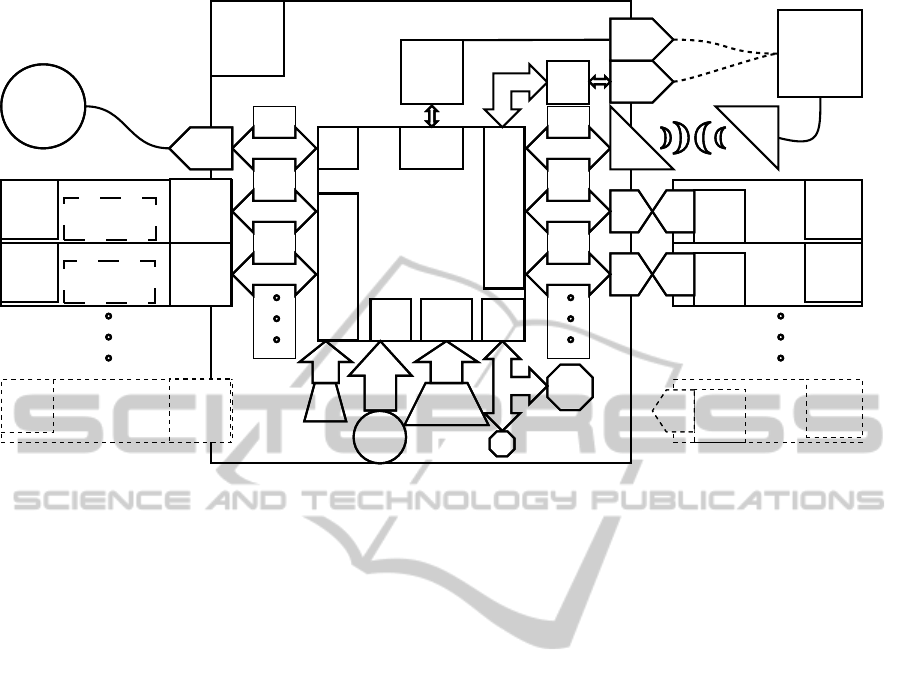

A diagram of proposed component and interface

organization in the modular system is shown in Fig-

ure 2. To date, most implementations have been

built by hand using through-hole components, which

makes the motherboards, daughterboards and pay-

loads larger and heavier. A surface-mount electronic

implementation in PC/104 form factor is currently un-

dergoing critical design review, and will be used for

the micro-rover prototype, while a slightly different

but compatible implementation is under development

for the nanosatellite prototype. The PC/104 form fac-

tor describes a stack of PCBs with pass-through 0.1“

64-pin and 40-pin headers, and was chosen because

it is a common standard for embedded systems in in-

dustry and robotics, and strikes a good balance be-

tween compactness and flexibility. The pinout is al-

tered to contain the communications interfaces de-

scribed here. The resulting board stack will look as

shown in Figure 3.

3.1 Control Topology

The proposed modular system is built around a pow-

erful central microcontroller on a single motherboard

in the OBC stack that is responsible for autonomy

and system coordination. Additional daughterboards

can contain a set of small component microcontrollers

that perform low-level tasks and can be customized to

suit different requirements. To make most effective

use of off-the-shelf components, the interfaces used

by rover systems have to be common enough to be

present on most modern embedded hardware, but still

well-suited for real-time robotic applications.

The standardized ARM architecture is preferred

for central microcontrollersas it is possible to use em-

bedded operating systems and program source code

that are easily ported between specific microcon-

trollers, with only the low-level hardware interfaces

requiring modification in some cases. In the case of

embedded Linux, these low-level interfaces are gen-

erally handled in the kernel and accessible by means

of user-space device interfaces. Currently, the Atmel

AT91RM9200 and AT91SAM9260 ARM9 microcon-

MODULAR DESIGN FOR SPACE ENGINEERING RESEARCH PLATFORMS

429

ARM

Microcontroller

NAND Flash

or MMC Card

Parallel

I/O

Motherboard

Inertial

Sensors

RS485

Driver

RS485

Driver

NOR

Flash

SPI 0

I2C Bus

RTC

Daughterboard 1

Daughterboard 2

SPI Chan. 1

SPI Chan. 2

Serial Port 1

Serial Port 2

Pin

Header

Pin

Header

Micro-

controller

Switching

DC-DC

Converters

Switching

DC-DC

Converter

Switching

DC-DC

Converter

Micro-

controller

Payload 1

Payload 2

Micro-

controller

Switching

DC-DC

Converter

Switching

DC-DC

Converter

Micro-

controller

Serial Port 0

Driver

Driver

SPI

Ctrl

USART

Ctrl

I2C

Ctrl

Memory

Ctrl

MII

Ctrl

Packet

Radio

Console

USB-

Serial

Micro-USB

Host PC

Packet

Radio

Ethernet

PHY

RJ-45

Jack

USB

Ctrl

USB Host

ISI

/GPIO

Parallel

I/O

USB

Other Payloads

Other Boards

in Stack

Motor Controllers

and Drivers

External Sensor

Interfaces

CMOS

Camera

Interface

USB

Peripherals

Figure 2: Diagram of modular system topology.

trollers are used, though a variety of automation-

oriented ARM microcontrollers are available, most

notably the Cortex-M3 and M4 series that use the

Cortex Microcontroller Software Interface Standard

(CMSIS), and will be used in future implementations.

Due to the master-slave paradigm used in the mod-

ular system, only one central ARM motherboard is

usable in each OBC stack, but this limitation has not

caused problems as ARM microcontrollers compara-

ble in power to desktop computers are now available,

and multiple OBC stacks can be used on a vehicle

if needed. As per CubeSat standards, the 1U Cube-

Sat under development at York University is based

on the PC/104 form factor with an ARM-based cus-

tom OBC stack. The YURT rovers use an ALIX em-

bedded router motherboard with external serial inter-

faces rather than an ARM microcontroller and hard-

ware stack, but future implementations may use ARM

systems for better power efficiency and higher inte-

gration with other systems.

The component microcontrollers can be inexpen-

sive 8-bit microcontrollers for motor control, sen-

sor monitoring, and payload management, or more

complex controllers if required. The microcontroller

most often chosen for this role is the Atmel AVR

8-bit RISC architecture, which is easily in-system

programmable using the GNU C/C++ compilers and

open-hardware SPI programmers. Modularity is

achieved by attaching these to the central ARM mi-

crocontroller using simple serial and parallel bus stan-

dards and pin headers, or D-sub connectors for exter-

nal connections. The use of small microcontrollers in

this manner allows hardware customization without

having to change the central controller in the system

or its motherboard, which is often the most complex

and costly component in a small robotic system.

To maximize reliability, “multiple-hop“ commu-

nications are avoided. SPI channels are connected

directly to the central microcontroller and serial in-

terfaces are connected via a MAX489 or similar se-

rial buffer IC with high voltage and ESD protection.

Damage to robotic components, which is often caused

by ESD and electrical shorts, is isolated by means

of the communication buffers and is less likely to

spread to adjacent components. Programmable logic

devices such as FPGAs and CPLDs is avoided, since

these devices often require proprietary software and

hardware to program, and can consume significantly

more power than microcontrollers of similar capabil-

ity. However, low-power CPLD devices can be used

where microcontrollers are less well-suited, such as

high-speed encoding and decoding tasks.

3.2 Board-to-Board Communications

All signals are carried between OBC boards as shown

in Figure 3 via standard 0.1“ pin headers. This fa-

cilitates connection between boards and wires, and

makes debugging easy. Proprietary connectors are

often hard to test and usually are not compatible be-

tween manufacturers and sizes. Due to the resiliency

of using separate transmit, receive, clock, and frame

ICINCO 2011 - 8th International Conference on Informatics in Control, Automation and Robotics

430

synchronization wires, SPI is preferred for board-to-

board communication at high bit rates, though a syn-

chronous serial interface with clock like also provides

a reliable connection. Communication with payloads

is generally achieved using 8-bit serial communica-

tions, which is the most common low-level way to

interface with embedded systems, but TTL serial in-

terfaces are also broken out through the pin headers

for use in used in board-to-board communications.

For debugging and system recovery purposes, one se-

rial port should be designated as a system console

or debug port, and this is usually available via USB-

to-Serial converter IC for convenience in connecting

portable PCs. GPS Devices and embedded radios

are often serial devices that can be included in the

OBC stack. Though very common, high speed per-

sonal computer buses such as PCI and PCI-Express

do not present significant benefit to low-speed embed-

ded systems with limited I/O resources and integrated

controllers.

The number of Serial and SPI devices is only lim-

ited by the number of SPI and Serial interfaces on

the ARM microcontroller. Provision is made on the

board headers for at least four serial interfaces and

four SPI interfaces with chip selects. Board headers

do not make use of line drivers to save power. There

have been no problems using direct pin connections

between boards so long as the housing for the OBC

stack is sealed from sources of ESD and contami-

nants. The York CubeSat manages all onboard sys-

tems through a mixture of SPI and synchronous TTL

serial interfaces.

For register-level access to onboard sensors and

peripherals, I

2

C is a synchronous bus widely used for

register-level communications to multiple embedded

ICs, but because it must embed addressing, bus ar-

bitration, and multi-master capability using only two

wires and a simple protocol, it is very sensitive to in-

terference and noise from the environment. To maxi-

mize reliability, trace lengths to the I

2

C host must be

minimized and daughterboardsand payloads must use

a microcontroller to transfer data to SPI or serial bus

lines from the I

2

C device.

For interfacing high-bandwidth devices, CMOS

and CCD cameras are interfaced directly to the cen-

tral ARM microcontroller via either a parallel bus of

general-purpose input-output (GPIO) pins or if avail-

able, a dedicated image sensor interface (ISI). Both

volatile (RAM) and non-volatile (Flash) memory is

interfaced by means of dedicated memory hardware,

i.e. RAM interface, NAND Flash interface, and SDIO

bus. Nearly all modern ARM microcontrollers have

dedicated memory interfaces.

Figure 3: Rendering of PC/104 stack as used on micro-

rover.

3.3 Payload Communications

For external payload communications, RS-485 has

been selected as the standard of choice. The RS-485

interface is an industry standard for differential-pair

serial communications to multiple transceivers, and is

already used on many robotic systems. It may be used

in either half-duplex mode (separate transmit and re-

ceive pairs) or full-duplex mode (pairs connected),

but full-duplex with a single master is preferred to

avoid byte collisions and the need for bus arbitration.

RS-422 devices are also compatible with this inter-

face.

Additionally, the RS-485 interface is designed for

bidirectional communication with up to 32 devices

on a single bus, the number of potential payloads

is high enough to accommodate large robotic sys-

tems. The 2011 YURT rover uses an RS-485 bus

to control six arm motor control boards from a sin-

gle serial interface. While RS-485 can operate at 10

megabits per second at 40 feet and 100 kilobits per

second at 4000 feet, to allow low-speed microcon-

trollers to communicate reliably, the standard baud

rate of 115200 baud is used as the default speed unless

higher bandwidth for the specific payload is required.

For long-distance disconnectable operation, an RJ-45

jack and twisted-pair cabling also provides good per-

formance. For extreme environments, an additional

pair is used to transmit a clock signal for synchronous

operation to ensure reliable transmission. With the

exception of high-bandwidth devices such as optical

sensors, memory, and media interfaces, these serial

links are more than capable of real-time command

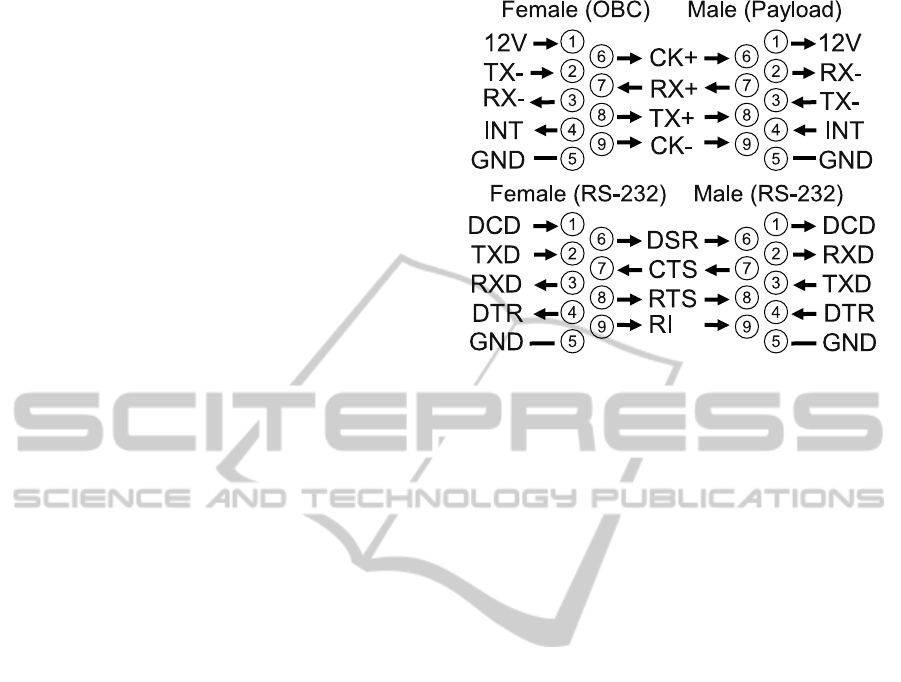

transmission. As no standardized D-sub pinout has

been accepted for RS-485 communications, one was

created to suit the modular system with differential

clock (CK) power supply, and interrupt pins. The ex-

ternal interfaces are situated on a board in the OBC

stack with line drivers and external DE9 connectors.

To pass GPIO signals and parallel buses, DB25 con-

nectors are useful with each pin buffered against ESD

and high voltage also.

The very common RS-232 serial port, while still

MODULAR DESIGN FOR SPACE ENGINEERING RESEARCH PLATFORMS

431

present in a huge number of devices, is not tradition-

ally compatible with RS-485 interfaces and is less ef-

ficient as it is based on negative logic and ±5− 15V

signal levels. A dedicated converteris the best method

for interconnection. However, given that most mod-

ern hardware uses only ±5−7V and has thresholds at

1V, it is possible for RS-232 and RS-485 devices to

communicate directly if required, for example, in new

hardware testing or field debugging using RS-232.

The payload pinout, shown in Figure 4, was chosen to

be electrically compatible with RS-232 for this reason

and to increase safety in case of accidental RS-232

connection. The RS-485 TX-(Z) and RX-(B) pins are

connected to RS-232 RX and TX respectively to in-

vert logic levels, TX+(Y) and RX+(A) are connected

to RS-232 CTS and RTS respectively to serve as a

ground reference. The CTS and RTS pins must be al-

lowed to float to ground, and if the hardware does not

allow this, TX+(Y) and RX+(A) must be connected

to the RS-232 ground instead. This method works

well using a MAX489 transceiver IC and is consid-

ered an option for debugging and testing with RS-232

hardware and purpose-built serial interfaces. But it is

less efficient than only RS-485 communications and

breaks the RS-232 specification by referencing sig-

nal levels to ground rather than ±5 − 15V. Newer

RS-232 hardware and USB to RS-232 converters that

have low signal voltages are useable, but older high-

voltage RS-232 hardware may be unsafe to use as the

RS-485 transceiver used must be able to tolerate the

signal voltages.

For devices other than system payloads, USB can

be used for COTS hardware, since the interface is

present on many embedded devices, but is gener-

ally restricted to hot-pluggable external hardware and

mass storage devices rather than hard-wired onboard

peripherals. Ethernet can also be used, but has sig-

nificant programming and routing overhead, so it is

preferred as an external network interface for de-

velopment purposes. Other industrial standards for

communications such as CAN, LIN, Firewire and

Spacewire, though often used in other systems for

reliability-critical applications (Torre et al., 2010), are

not present on the majority of embedded devices and

are not generally used in the interest of easy interop-

erability. The Spacewire bus in particular, designed

and used for space hardware, is very fast and robust,

but is only implemented in hardware on a very small

set of radiation-hardened devices which are very rare

and expensive.

Figure 4: Payload DE9 connector and RS-232 pinouts.

3.4 Radio Communications

Wireless communications between mobile robots and

control stations is a critical component in applications

requiring remote control or monitoring. To simplify

terrestrial work, it is desirable to use license-free ISM

bands or amateur radio bands when communicating.

The frequency must also be high enough to support

high bit rate communications, preferably at least the

basic system rate of 115200 baud. The 2.4GHz band

is by far the most popular, but higher frequency sys-

tems have lower range and worse non-line-of-sight

(NLOS) characteristics, and this band has also be-

come very crowded with interference from consumer

electronic devices. Another option is the 433MHz

band and below, which can be used by amateur radio

operators, but limits data rates on most radio hard-

ware to 38400 baud and lower. The 900MHz ISM

band is a good medium between these options, as it

provides reasonable range and NLOS characteristics,

can support bit rates above 115200 baud, and is not

used excessively by consumer devices.

Another consideration is the need for multi-point

communications and routing. There are many situa-

tions when several mobile robots need to stay in com-

munications with each other and with base station

units, but relative movement, terrain variations and

ambient conditions make static network structures un-

reliable. One popular solution to this is the mesh net-

work, which allows multiple transceiversto route data

to each other using dynamically maintained and self

healing network structures. The best known indus-

trial mesh network specification is ZigBee, which is

used frequently in sensor mesh networks but requires

a dedicated coordinator and router nodes which lim-

its the flexibility of the network. The B.A.T.M.A.N.

ICINCO 2011 - 8th International Conference on Informatics in Control, Automation and Robotics

432

(better approach to mobile ad-hoc networking) rout-

ing protocol was recently added to the Linux kernel to

allow mesh networking over wireless LAN networks,

but is not designed for low-level serial hardware.

To provide a long-range serial mesh networking

system, the Digi XBee PRO Digimesh 900 serial ra-

dio module is used frequently on modular research

hardware, one exception being the YURT rover which

requires high camera data rates and uses Ubiquiti

XR9 900MHz mini-PCI network cards, with XBee

modules as a fallback if needed. The Digimesh proto-

col is proprietary, but allows mesh networking with-

out a central coordinator. As these radio modules

use a well-known form factor, replacing them with

2.4GHz modules or custom modules that change fre-

quency, range, and protocol is simple.

Future work in this area includes the development

of an open-hardware transceiver module and purpose-

designed mesh network protocol. For higher-power

radio systems, an OBC daughterboard can be used.

The advantage of using simple serial communications

rather than Ethernet, Wireless LAN, or other IP com-

munications standards, is that a wider variety of ra-

dio systems and communications frequencies can be

used, up to and including S-band and UHF radio sys-

tems for space hardware. It is also easy to encapsu-

late serial communications over IP-based systems if

desired.

3.5 Power

Onboard batteries are expected to be used for power

storage, and can be charged from solar panels or other

sources. For small rovers and aerial vehicles, a sin-

gle cell or stack of lithium-ion (Li-Ion) cells in series

must be used to achieve high power densities. Since

the batteries must be balance-charged for longevity,

the electronics can run off the bottom cell in the stack,

which is done on the micro-rover prototype. For large

rovers, nickel metal hydride (NiMH) battery packs

can be used for higher stability and environmental

tolerance, and 24V is used for powering larger drive

motors with the rest of the electronics either being

powered by a separate 12V battery as previous YURT

rovers have been, or by using heavily-filtered switch-

ing converters tolerant of high voltages. Battery volt-

age and current monitoring is done via analog-to-

digital converters, which are present on most modern

microcontrollers and ideally are present on the central

ARM microcontroller. In-depth testing of Li-Ion cells

(Navarathinam et al., 2011), NiMH battery packs and

high-current DC-DC power converters has been done

to verify performance in extreme environmental and

operational conditions.

With the availability of low-cost highly-integrated

switch-mode converters, it is feasible for each mod-

ule in the system to convert DC power from the sys-

tem battery to whatever level is needed. Daughter-

boards in the OBC generally use the system battery

for power as well as regulated 3.3V and 5V sup-

ply rails provided by the motherboard. The choice

of power supply is important. Simple linear volt-

age regulators that are commonly used on microcon-

troller boards become less efficient relative to the in-

put/output voltage difference, and are unsuitable for

use in vacuum or high-temperature environments as

the only mechanism for cooling is direct radiation of

heat. To achieve the highest power conversion ef-

ficiency possible, switching step-down (buck) con-

verters are used, if at all possible, rather than step-

up (boost) converters. Using only low-dropout buck

converters with high input voltage tolerance makes it

possible to achieve system efficiencies close to 90%.

Also, each module is responsible for filtering its own

load noise via capacitor-inductor networks to avoid

injecting power supply transients back into the OBC.

Zener diodes should also be used to protect from ESD

and over-voltages.

3.6 Motor Control

An essential element of most robots is electronic mo-

tor and actuator control. Traditionally, brush DC mo-

tors with mechanical commutation have been used

for robotic movement due to their cost-effectiveness

and simplicity of implementation, and brush DC mo-

tors are still dominant in the marketplace. However,

the recent availability of high-speed microcontrollers

and integrated drive bridges have made brushless DC

motors, which require external electronic commuta-

tion, increasingly popular. Brushless DC motors have

generally higher efficiency and longevity due to the

lack of mechanical brushes and are preferred for haz-

ardous environments and space applications, but re-

quire a different control method usually considered

incompatible with brush DC (Lee et al., 2003).

Ideally, both BLDC and DC motors could be

driven with only software changes, so any changes to

the system could be made by a microcontroller. Many

small microcontrollers are suitable for implementing

feedback and control of motors, and some PIC and

AVR models include dedicated hardware for this pur-

pose, while still being programmable in C and using

minimal power. Flexible designs for multiple motors

have been achieved using FPGA hardware and DSP

ICs, such as in (Zerigui et al., 2007). While this ap-

proach provides high control speeds, it requires more

power to run the FPGA and introduces significant

MODULAR DESIGN FOR SPACE ENGINEERING RESEARCH PLATFORMS

433

complexity in design and programming. To enable

a common system to drive both brush DC and brush-

less DC motors, a hybrid approach is required. DC

motors are usually controlled by using a fixed input

and pulse-width modulation (PWM) to manage the

amount of total power provided to the motor. Brush-

less DC motors are controlled by shunting power to

different motor coils (or ”phases“) one at a time in

synchronization with rotor speed, usually measured

by Hall sensors, and speed control is achieved by

changing the time that power is shunted. Both sys-

tems usually use field-effect transistors (FETs) in a

half-bridge configuration to control current flow, two

for a brush motor in the ”H-bridge“ configuration, and

one for each phase of a brushless motor. Brushless

motors usually have up to three phases, so a hybrid

controller can be built with three such half-bridges.

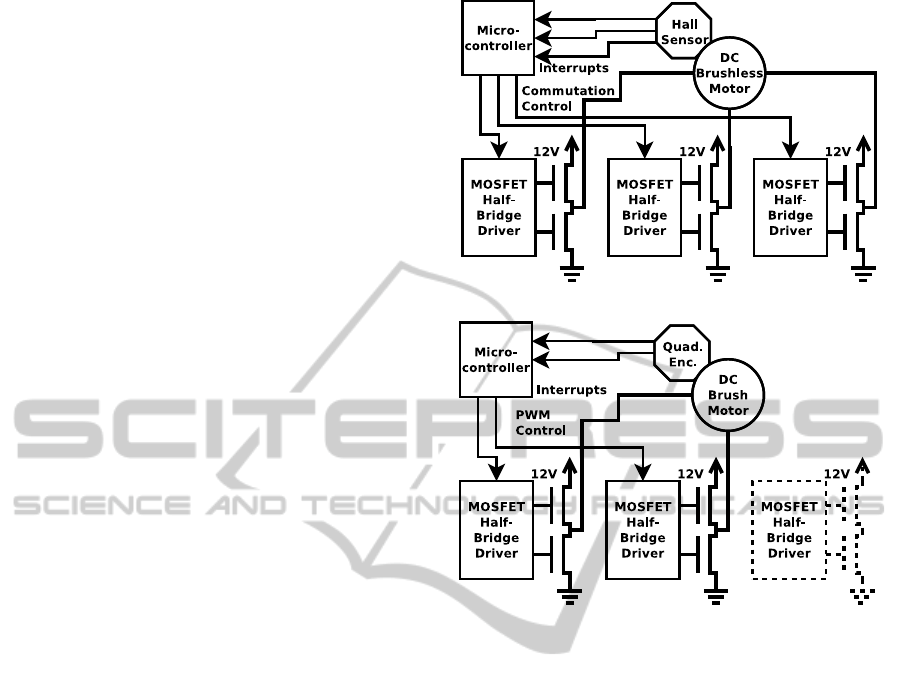

Figure 5 shows the hybrid system in both brush-

less DC (a) and brush DC (b) configurations. For

three-phase brushless use, a single set of three half-

bridges are cycled in sequence to supply power to

the three motor phases, while for brush use, two of

these form an H-bridge to supply pulse-width mod-

ulated DC power to the motor. Control feedback is

via a 3-phase Hall sensor in the brushless case and

bridges are commutated by setting GPIO lines, while

a quadrature (Gray code) encoder is used in the brush

case and pulse-width modulation control is used in

hardware. The drive controller 12V is assumed to be

the drive voltage in this diagram, but any appropriate

motor voltage can be used. Each motor requires the

use of one set of drive bridges, though a fast micro-

controller can usually drive more than one bridge at a

time. For small mobile robots and rovers, all needed

drive motor controllers can usually be implemented

on an OBC daughterboard, but for larger robots, the

drivecontroller is implemented as an external payload

to gain more space and better isolation. A prototype

of this hybrid system has been built for the micro-

rover, and shows promise for larger systems as well.

4 SOFTWARE ARCHITECTURE

In order to benefit from and support the open-source

community, and to ensure that the basis for the system

remains freely available and up-to-date, open-source

OS software and the GNU compiler collection (GCC)

is preferred to form the software base for the modu-

lar system. It is assumed that most mobile platform

software will have to control actuators, read sensors,

and communicate with a base station, a set of cen-

tral control programs for autonomous operation, or

both with system coordination occurring on the cen-

(a) Brushless Motor Configuration.

(b) Brush DC Motor Configuration.

Figure 5: DC motor controller basic configurations.

tral ARM microcontroller. The YURT rover (Post and

Lee, 2011) and micro-roverprototype are good exam-

ples of this kind of a system, as is the example is given

in (Marosy et al., 2009). As such, a robust multitask-

ing framework and a routing and command handling

system are essential to reliable operation.

The software for the system is stored in NAND

flash memory on the microcontrollers and on redun-

dant NAND and NOR flash devices on the mother-

board. NAND flash is the most common and provides

large storage capacity, while NOR flash devices can

store only a few megabytes but may be more resis-

tant to radiation and corruption (Farokh Irom, 2008).

To mitigate the risks of software corruption, in the

event of a boot failure the bootloader for the cen-

tral ARM microcontroller will switch between two

kernel/filesystem images. It is possible for the cen-

tral ARM microcontroller to boot from the smaller

failover device and retain sufficient capacity to re-

program internal component microcontrollers as re-

quired using SPI. Implementation of error-correction

codes is also proposed for improving storage reliabil-

ity, though it would have to be done either in software

or on an external logic device such as a programmable

ICINCO 2011 - 8th International Conference on Informatics in Control, Automation and Robotics

434

logic device (PLD). For NAND flash devices, the re-

cent addition of UBIFS to the Linux kernel provides

error detection and wear-leveling for NAND devices,

and currently appears to be the best option for NAND

devices in Linux.

4.1 Operating Systems

Direct-to-hardware programmingon the central ARM

microcontroller is possible, but an embedded operat-

ing system (OS) is usually used in research applica-

tions to to expedite software development and sim-

plify hardware interfacing. The Emdebian Linux OS

has been used for most of the existing development

work, and other FOSS systems are being investigated

for real-time flight hardware implementations such as

Linux with Xenomai for real-time support and FreeR-

TOS as a standalone real-time framework.

Customized Linux kernel patches and drivers that

implement user-space support for the embedded OBC

peripherals such as the RS-485 interfaces, SPI con-

trollers, and I2C sensors have been developed to pro-

vide hardware integration, and a set of dedicated li-

braries for 8-bit AVR microcontrollers has been cre-

ated to assist in programming component applications

for this system. The software for onboard systems has

been developed entirely in C and C++ for efficiency

and minimal code size. Other languages can be run

on resource-constrained hardware such as real-time

Java, and using a Linux environment enables the use

of Python as well. These will be retained as options

for future research.

For overall control and monitoring of remote sys-

tems at the base station, a graphic user interface (GUI)

has been developed using Java, with the philosophy

that it must be portable to whatever OS is used at the

base station, but need not run on resource-constrained

embedded hardware. The GUI development is based

on the work of the York University Rover Team, who

have been steadily improving their base-station GUI

concept for each generation of remotely-controlled

rover. The GUI integrates system health monitor-

ing, GPS localization, joystick movement control, and

camera displays for convenient use of the system op-

erator.

4.2 JAUS Messaging

For designs where only a few microcontrollers are

fixed in connection such as most nanosatellites, sim-

ple byte-by-byte protocols work fine, but for large

systems with multiple, changeable interfaces, a flexi-

ble message routing and communications protocol is

necessary. The routing system and protocol used cur-

rently for robotics is based on the Joint Architecture

for Unmanned Systems (JAUS), a messaging system

that groups similar or associated capabilities of a sys-

tem together and provides a consistent method of or-

ganizing subsystems (The joint architecture for un-

manned systems working group, 2007). The JAUS

structure can be considered close to the minimum of

functionality for universal point-to-point communica-

tions in a multi-device system. Although JAUS does

not specify implementation details, the JAUS refer-

ence implementation has been used as the basis for

the OpenJAUS project, an open-source framework for

remote operation of robotic systems that is portable to

a wide range of platforms.

The JAUS architecture is a tree structure, where an

entire system is composed of subsystems, each con-

taining nodes, each containing components, which

can have several redundant component instances. For

the architecture we are describing, an individual robot

represents a subsystem, a central ARM microcon-

troller represents a node and a microcontroller at-

tached to that controller represents a component,

which services a finite set of commands and may have

redundant systems on the same bus. More than one

central controller node can be present on a robot, and

each node must run a node manager for routing com-

munications to components, which is currently imple-

mented as the OpenJAUS node manager. As JAUS

commands can be large in scope and parsing require-

ments, microcontroller components can use custom

small-footprint commands for simple tasks. By us-

ing only a small set of commands for each microcon-

troller, most components are capable of sending and

receiving basic commands using JAUS natively, and

additional functionality is easy to implement.

The advantages of JAUS messaging between com-

ponents is that each node or component can initiate

messages to any other part of the system. While con-

trol is usually centralized in autonomous robots, the

capability of ”bypassing“ the central controller and

communicating directly between components using

only the node manager is sometimes useful and pro-

vides failover capabilities. However, the node man-

ager on each node must be very stable and should

be restarted if abnormal program behavior is noticed.

For ease of debugging, a ”console“ mode is used on

microcontrollers with sufficient flash memory, so that

by entering an escape sequence (commonly the AT

escape sequence ”+++“) a simple serial text console

can be used to send commands and check the status of

the microcontroller using ASCII keystrokes. This al-

lows easy field testing of components without requir-

ing a full JAUS implementation to be present. De-

velopment of JAUS-compatible code for the micro-

MODULAR DESIGN FOR SPACE ENGINEERING RESEARCH PLATFORMS

435

rover prototype is proceeding, and may be used in the

YURT rover in future as well.

5 CONCLUSIONS

In this paper, we briefly introduced three distinct

space engineering research projects at York, namely

micro-rover development, the York University Rover

Team’s larger scale Mars rover prototype design and

a 1U CubeSat-based nanosatellite design. In all three

distinct research projects, we aim to design mobile

platforms with a level of autonomy and simplicity

with distinct mission objects for each project. The

micro-rover is designed for Mars environment with

full autonomy and redundancy. The YURT rover

is designed each year to complete at the University

Rover Challenge with minimal autonomy, but with

flexibility for four separate tasks. The 1U CubeSat

is designed to demonstrate nanosatellite technologies

currently under development at York University.

The common design approach we have taken in

developing the above research platforms is the mod-

ularity and expandability in hardware and software

design. We described a centralized control topology,

in particular OBC design and communication proto-

cols, and introduced a subsystem design methodology

making use of highly-integrated commercial-off-the-

shelf (COTS) parts and low-cost components. In mo-

bile robots, the motor controllers provide selectable

brush or brushless DC motor management, while in a

satellite platform, the same design approach can drive

reaction wheels. A software architecture based on

open componentswas also developedwith modularity

in mind. In mobile platforms, mesh networking and

the JAUS structure was adopted to accommodate ef-

ficient point-to-point messaging communications. In

future, we plan to implement the proposed modular

design concept in other projects such as unmanned

aerial vehicles and distributed sensors for navigation,

mapping and remote sensing applications.

REFERENCES

Candini, G. P., Paolini, E., and Piergentili, F. (2009). Design

and manufacture of a low cost educational hexapod

rover. Acta Astronautica, 65(3-4):525 – 536.

Cho, A., Kim, J., Lee, S., Choi, S., Lee, B., Kim, B., Park,

N., Kim, D., and Kee, C. (2007). Fully automatic

taxiing, takeoff and landing of a uav using a single-

antenna gps receiver only. In Control, Automation and

Systems, 2007. ICCAS ’07. International Conference,

pages 821 –825.

Farokh Irom, D. N. N. (2008). Radiation tests of highly

scaled high density commercial nonvolatile flash

memories. Technical report, Jet Propulsion Labo-

ratory, California Institute of Technology, Pasadena,

CA.

Lee, J., Choi, J., Chung, J., and Lim, J. (2003). Design

and implementation of integrated drive circuit for a

small bldc motor. In Electrical Machines and Systems,

2003. ICEMS 2003. Sixth International Conference,

volume 2, pages 491 – 494 vol.2.

Marosy, G., Kovacs, Z., and Horvath, G. (2009). Effective

mars rover platform design with hardware / software

co-design. In Design and Diagnostics of Electronic

Circuits Systems, 2009. DDECS ’09, pages 148 –151.

Navarathinam, N., Lee, R., and Chesser, H. (2011). Charac-

terization of lithium-polymer batteries for cubesat ap-

plications. Acta Astronautica, 68(11-12):1752 – 1760.

Post, M. and Lee, R. (2011). Lessons learned from the

york university rover team (yurt) at the university

rover challenge 2008-2009. Acta Astronautica, 68(7-

8):1343 – 1352.

Quine, B., Lee, R., and Roberts, C. (2008). Northern light

- a canadian mars lander development plan. In Con-

ference Proceedings of CASI ASTRO 2008, Montreal,

Canada.

Sarda, K. and C., G. (2010). Canadian advanced nanospace

experiment 2 on-orbit operations; two years of push-

ing the nanosatellite performance envelope. In Con-

ference Proceedings of CASI ASTRO 2010, Toronto,

Canada.

The joint architecture for unmanned systems working group

(2007). Jaus reference architecture specification, vol-

ume ii, part i. http://www.openjaus.com/support/jaus-

documents.

Torre, A. D., Finzi, A. E., Genta, G., Curti, F., Schirone, L.,

Capuano, G., Sacchetti, A., Vukman, I., Mailland, F.,

Monchieri, E., Guidi, A., Trucco, R., Musso, I., and

Lombardi, C. (2010). Amalia mission lunar rover–the

conceptual design of the team italia rover, candidate

for the google lunar x prize challenge. Acta Astronau-

tica, 67(7-8):961 – 978.

Zerigui, A., Wu, X., quan Deng, Z., and Yu, K. (2007).

Common hardware design for (2n+2, 0*n*3) wheels

mobile rover. In Robotics and Biomimetics, 2007. RO-

BIO 2007, pages 712 –716.

ICINCO 2011 - 8th International Conference on Informatics in Control, Automation and Robotics

436