RELIABLE MODELLING AND OPTIMISATION CONTROL

OF REACTIVE POLYMER COMPOSITE MOULDING

PROCESSES USING BOOTSTRAP AGGREGATED

NEURAL NETWORK MODELS

Jie Zhang

1

and Nikos G. Pantelelis

2

1

School of Chemical Engineering and Advanced Materials, Newcastle University, NE1 7RU, Newcastle Upon Tyne, U.K.

2

Department of Mechanical Engineering, National Technical University of Athens, Athens, Greece

Keywords: Neural networks, Polymer composite moulding, Bootstrap re-sampling, Modelling, Optimisation.

Abstract: This paper presents using bootstrap aggregated neural networks for the modelling and optimisation control

of reactive polymer composite moulding processes. Bootstrap aggregated neural networks combine multiple

neural networks developed from bootstrap re-sampling replications of the original training data in order to

enhance model prediction and generalisation capability. Neural network models for modelling the degree of

cure (through modelling the measured resistance) are developed from real industrial process operational

data. Both static and dynamic models are developed and the developed neural network models are validated

on unseen process operation data. The bootstrap aggregated neural network models give accurate and

reliable predictions than single neural networks. Optimal heating profile is obtained by solving an

optimisation problem using the dynamic neural network model. The model prediction confidence bound is

incorporated in the optimisation objective function in order to enhance the reliability of the calculated

optimal control profile. In addition to maximise the final degree of cure, model prediction confidence bound

is minimised. Application results on a simulated polymer composite moulding process demonstrate that the

proposed reliable optimisation control strategy is effective.

1 INTRODUCTION

Polymer composite materials have been increasingly

used in many areas, for example, aerospace,

automobile, and construction industries, due to their

various advantages. For example, polymer

composite is of much light weight and comparable

strength compared with steel. Automobiles using

polymer composite parts instead of steel parts will

significantly save fuel consumption due to the much

reduced weight. Polymer composite is corrosion

resistant compared to steel making them ideal

materials for many manufacturing industries. The

curing of thermoset based polymer composite

material is dominated by complex process dynamics

and trial and error procedure is the only practical

tool for process optimisation (Pantelelis, 2005).

Reactive polymer composite moulding processes

are typical batch processes. The degree of cure is an

important parameter in reactive polymer composite

moulding processes. Only when the product is

almost fully cured the mould can be opened. Thus,

modelling the degree of cure is very important in the

control and optimisation of reactive polymer

composite moulding processes. Development of

detailed mechanistic models for the degree of cure is

generally time consuming and effort demanding.

Data based empirical modelling can be a very useful

alternative in this case. Neural networks have been

shown to be capable of approximating any

continuous nonlinear functions (Cybenko, 1989) and

have been applied to nonlinear process modelling

(Bhat and McAvoy, 1990); (Bulsari, 1995); (Su et

al., 1992).

A problem of conventional neural network is the

lack of robustness and generalization capability due

to limitation in training data and/or training

methods. An effective approach to improve neural

network model generalization is by combining

multiple neural networks (Breiman, 1996); (Sridhar

et al., 1996); (Zhang et al., 1997).

The paper

presents a study on using bootstrap aggregated

236

Zhang J. and G. Pantelelis N..

RELIABLE MODELLING AND OPTIMISATION CONTROL OF REACTIVE POLYMER COMPOSITE MOULDING PROCESSES USING BOOTSTRAP

AGGREGATED NEURAL NETWORK MODELS.

DOI: 10.5220/0003682602360241

In Proceedings of the International Conference on Neural Computation Theory and Applications (NCTA-2011), pages 236-241

ISBN: 978-989-8425-84-3

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

neural networks for modelling the degree of cure

and optimisation of polymer composite moulding

processes.

The paper is organised as follows. Section 2

presents modelling of reactive polymer composite

moulding process using bootstrap aggregated neural

networks. Section 3 presents optimisation control of

reactive polymer composite moulding process based

the neural network model. Section 4 concludes the

paper.

2 MODELLING OF REACTIVE

POLYMER COMPOSITE

MOULDING PROCESS USING

NEURAL NETWORKS

2.1 Bootstrap aggregated Neural

Networks

Neural networks have been shown to be capable of

approximating any continuous nonlinear functions

(Cybenko, 1989) and have been applied to nonlinear

process modelling (Bhat and McAvoy, 1990);

(Bulsari, 1995); (Su et al., 1992). In most of the

reported applications, a single neural network is

used to model the concerned nonlinear process. A

limitation of single neural network models is that

they can lack generalisation when applied to unseen

data, i.e. the trained neural network gives good

performance on the training data but gives

unsatisfactory performance on unseen data which is

not used in the training process. Several techniques

have been reported in the literature for improving

neural network generalisation capability, such as

regularisation (Bishop, 1991), early stopping

(Bishop, 1995), Bayesian learning (MacKay, 1992),

training with both dynamic and static process data

(Zhang, 2001), and combining multiple networks

(Sridhar et al., 1996); (Wolpert, 1992); (Zhang et al.,

1997). In training with regularisation, the magnitude

of network weight is introduced as a penalty term in

the training objective function in order to avoid

unnecessarily large network weights which generally

lead to poor generalization performance. In training

with early stopping, neural network performance on

the testing data is checked during the training

process and the training process stops when the

neural network prediction errors on the testing data

start to increase. Among these techniques,

combining multiple networks is a very promising

approach to improving model predictions on unseen

data. The emphasis of this approach is on

generalisation accuracy on future predictions (i.e.

predictions on unseen data). When building neural

network models, it is quite possible that different

networks perform well in different regions of the

input space. By combining multiple neural networks,

prediction accuracy on the entire input space could

be improved. Bootstrap aggregated neural networks

have been successfully used for the inferential

estimation of polymer quality (Zhang et al., 1997),

prediction of final product quality (Zhang et al.,

1998), and estimation of reactive impurities and

reactor fouling (Zhang et al., 1999) in a batch

polymerisation process.

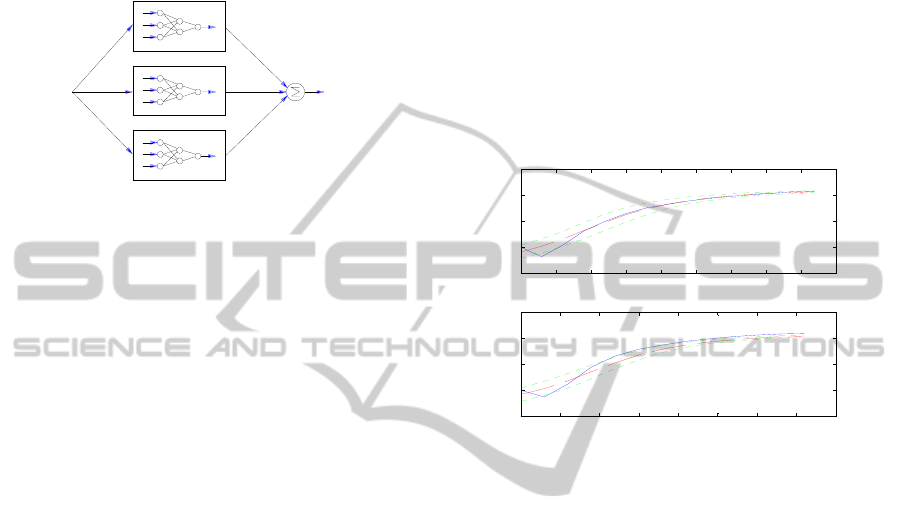

A diagram of bootstrap aggregated neural

networks is shown in Fig. 1, where several neural

network models are developed to model the same

relationship. Instead of selecting a “best” single

neural network model, these individual neural

networks are combined together to improve model

accuracy and robustness. The overall output of the

aggregated neural network is a weighted

combination of the individual neural network

outputs. This can be represented by the following

equation.

fX wf X

i i

i

n

() ()

1

(1)

where f(X) is the aggregated neural network

predictor, f

i

(X) is the ith neural network, w

i

is the

aggregating weight for combining the ith neural

network, n is the number of neural networks, and X

is a vector of neural network inputs. Proper

determination of the stacking weights is essential for

good modelling performance. A popular choice of

stacking weights is simple averaging, i.e. the stacked

neural network output is an average of the individual

network outputs. Since the individual neural

networks are highly correlated, appropriate stacking

weights could be obtained through principal

component regression (PCR) (Zhang et al., 1997).

Instead of using constant stacking weights, the

stacking weights can also dynamically change with

the model inputs (Ahmad and Zhang, 2005; 2006).

Another advantage of bootstrap aggregated

neural network is that model prediction confidence

bounds can be calculated from individual network

predictions (Zhang, 1999). The standard error of the

ith predicted value is estimated as

2/12

1

})];();([

1

1

{

i

n

b

b

ie

xyWxy

n

(2)

where y(x

i

; .) =

n

b

b

i

nWxy

1

/);(

and n is the

number of neural networks in an aggregated neural

RELIABLE MODELLING AND OPTIMISATION CONTROL OF REACTIVE POLYMER COMPOSITE MOULDING

PROCESSES USING BOOTSTRAP AGGREGATED NEURAL NETWORK MODELS

237

network. Assuming that the individual network

prediction errors are normally distributed, the 95%

prediction confidence bounds can be calculated as

y(x

i

; .) 1.96

e

. A narrower confidence bound, i.e.

smaller

e

, indicates that the associated model

prediction is more reliable.

X

Y

Figure 1: A bootstrap aggregated neural network.

2.2 Modelling the Degree of Cure in an

Industrial Polymer Composite

Moulding Process

Neural network models were developed using

industrial data from an EU research project –

iREMO (intelligent reactive polymer composite

moulding). The process is for the manufacturing of

car parts

.

In the real reactive polymer composite moulding

processes studied in this project, the curing process

is monitored using OptiMould which measures

resistance. The data set contains 6 runs at different

moulding temperatures. Data from 4 runs were used

to build neural network models and data from the

other 2 runs were used as unseen validation data.

The original data were sampled and stored at

unequal sampling times due to the limitation in the

sensor. For the purpose of neural network modelling,

especially dynamic modelling, the data were re-

sampled at equal sampling time. A sampling time of

30s were used.

Two types of neural network models were

developed: a static model and a dynamic model. The

static model is of the following form:

),()( TtftR

(3)

where R(t) is the resistance at time t (min), T is the

moulding temperature (

o

C), and f() is a nonlinear

function represented by a neural network.

A bootstrap aggregated neural network

containing 30 single hidden layer neural networks

each with 12 hidden neurons was developed. The

networks were trained with Levenberg-Marquardt

algorithm (Marquardt, 1963) with regularisation and

early stopping. Figure 2 shows the predicted

resistance on the 2 unseen validation runs. In Figure

2, the actual measure resistances are shown as the

solid lines whereas the neural network predictions

are shown as dashed lines. The dotted lines are the

95% prediction confidence bounds. It can be seen

that the neural network predictions are very

accurate. Furthermore, the prediction confidence

bounds are quite narrow, especially towards the end

of the curing cycle where the model predictions are

of more importance. This indicates that the bootstrap

aggregated neural network gives accurate and

reliable predictions. Thus it can be applied to the

real industrial process with confidence.

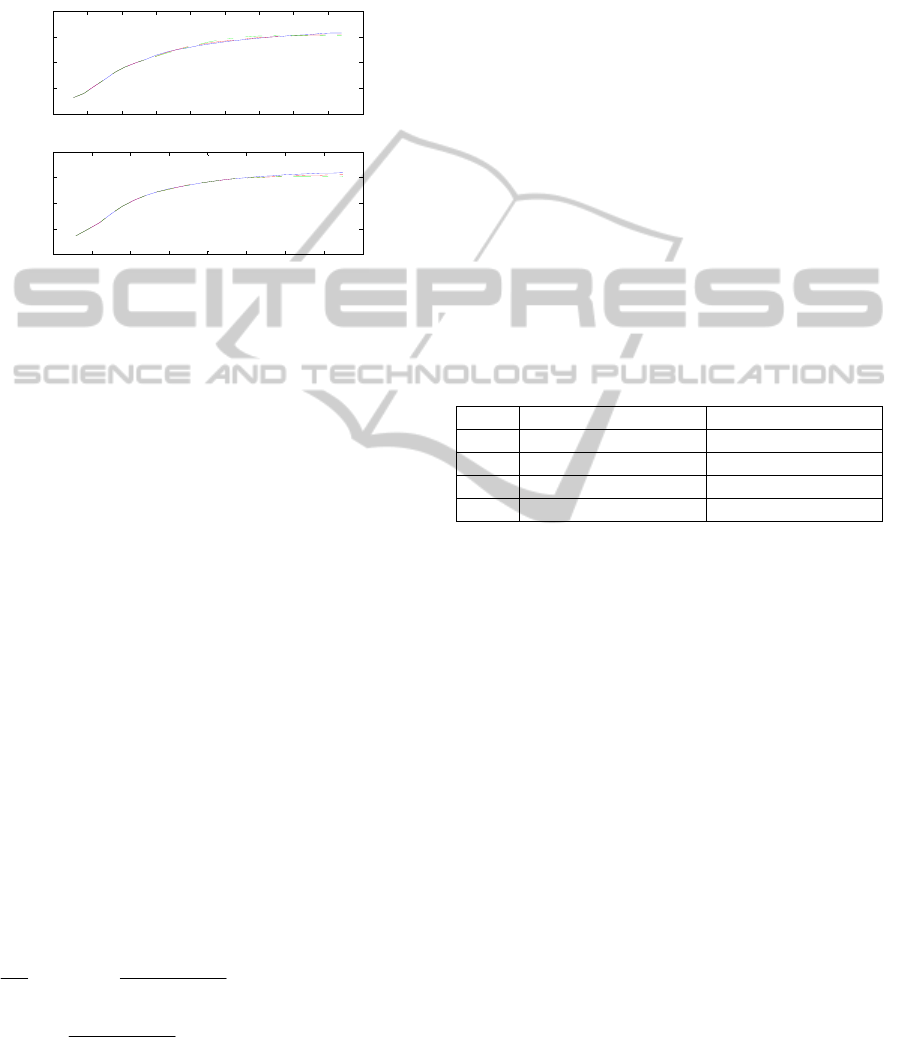

0 100 200 300 400 500 600 700 800 900

10

0

10

2

10

4

10

6

10

8

Tim e (s )

Resist ance (MOhm)

-:actual; --:NN model prediction; ..:95% confidence

0 100 200 300 400 500 600 700 800

10

0

10

2

10

4

10

6

10

8

Tim e (s )

Resistance (MOhm)

-:actual; --:NN model prediction; ..:95% confidence

Figure 2: Static neural network model predicted resistance

and the 95% prediction confidence bounds on the 2 unseen

runs.

The dynamic model is of the following form:

y(t) = f[y(t-1), y(t-2), u(t-1)] (4)

where y is the resistance, u is the applied

temperature, t is discrete time, f() is a nonlinear

function represented by the neural network.

A bootstrap aggregated neural network

containing 30 single hidden layer neural networks

with 8 hidden neurons was developed. The networks

were trained with Levenberg-Marquardt algorithm

with regularisation and early stopping. Figure 3

shows the predicted resistance on the 2 unseen

validation runs. In Figure 3, the actual measure

resistances are shown as the solid lines, one-step-

ahead predictions are shown as dashed lines, and

multi-step-ahead predictions are shown as the dash-

dotted lines. It can be seen that the neural network

one-step-ahead predictions are very accurate. The

multi-step-ahead predictions are also very accurate,

though not as accurate as the one-step-ahead

predictions. In contrast to the static model,

predictions in the dynamic model can be updated

using the online measured resistance. The static

model, on the other hand, does not require measured

NCTA 2011 - International Conference on Neural Computation Theory and Applications

238

resistance as model input. When the measured

resistance is affected by air bubble or carbon fibre,

the dynamic model would not give good predictions

and the static model can be used. Thus the two types

of models can used in a complimentary way.

0 100 200 300 400 500 600 700 800 900

10

0

10

2

10

4

10

6

10

8

Time (s )

Resist ance (MOhm)

-:actural; --:NN model 1-step-ahead predic tion; -.:mult i-s tep ahead predict ion

0 100 200 300 400 500 600 700 800

10

0

10

2

10

4

10

6

10

8

Time (s )

Resist ance (MOhm)

-:actural; --:NN model 1-step-ahead predic tion; -.:mult i-s tep ahead predict ion

Figure 3: Dynamic neural network model predicted

resistance on the 2 unseen runs.

3 RELIABLE OPTIMISING

CONTROL

Using a neural network dynamic model, the optimal

control profile (e.g. heating profile) is calculated off-

line by solving the following optimisation problem.

)()]([min

321

,,

1

feffd

tuu

twtwtwJ

fN

s.t. product quality and operation constraints

where

d

is the desired degree of cure, t

f

is the batch

time, σ

e

is the standard error of neural network

predictions, w

1

, w

2

and w

3

are weighting factors, and

u

1

,…, u

N

form the control profile. Earlier studies by

Zhang (2004) and Mukherjee and Zhang (2008)

show that penalising wide model prediction

confidence bounds (i.e. large σ

e

) leads to reliable

optimal control policies.

The optimisation control strategy is tested on

simulation using the mechanistic model given in

(Pantelelis, 2005). The basic kinetic model is a

combination of autocatalytic and nth order reaction

terms with Arrhenius dependence of the rate

constants:

76

5

)1(

)273(

exp

)1(

)273(

exp

2

4

1

3

PP

P

aa

TR

P

P

a

TR

P

P

dt

da

(5)

where P

1

and P

2

are the activation energies, P

3

and

P

4

are the rates constants, and P

5

to P

7

are the

reaction orders. Two improved models incorporating

glass transition temperature and a diffusion term are

given in (Pantelelis, 2005). The improved model is

used in this study and the model parameters can be

found in (Pantelelis, 2005). From simulation, 7

batches were simulated and the sampling time is 4

minutes.

A dynamic neural network model was developed

using 3 batches (batches 3, 5, 7) and the developed

models are validated on 4 unseen validation batches

(batches 1, 2, 4, 6). The developed model is a

bootstrap aggregated neural network containing 30

neural networks. Each network is a single hidden

layer feed forward neural network with 5 hidden

neurons. The network was trained with Levenberg-

Marquardt algorithm with regularisation and early

stopping. Table 1 shows the mean squared errors

(MSE) from one-step-ahead predictions and multi-

step ahead predictions on the 4 unseen validation

batches. It can be seen from Table 1 that the model

predictions are very accurate.

Table 1: MSE of model predictions on validation data.

batch 1-step-ahead predictions Long range predictions

1 0.0316×10

-3

0.2853×10

-3

2 0.0422×10

-3

0.2235×10

-3

4 0.1126×10

-3

0.1968×10

-3

6 0.0253×10

-3

0.2047×10

-3

In this study, the desired degree of cure is set to 1

and the constraints on the applied temperature are

20

o

C T 160

o

C and 0

o

C ΔT 70

o

C. The batch

time is divided into several intervals each of 4

minutes and several possible batch times (in multiple

of 4) were considered. Several batch ending times

were considered and it is found that a batch time of

20 minutes is the shortest possible batch time. Two

types of control profiles were considered: piecewise

linear profile where the applied temperature linearly

increases within each interval and piecewise

constant profile where the applied temperature is

kept constant within each interval. The optimisation

problem is solved using sequential quadratic

programming (SQP) implemented in the MATLAB

Optimisation Toolbox. The SQP optimisation

method mimics Newton’s method for constrained

optimisation in that at each major iteration an

approximation is made of the Hessian matrix of the

Lagrangian function using a quasi-Newton updating

method. This is then used to generate a quadratic

programming sub-problem which is solved and the

solution is used to form a search direction for a line

search procedure. The weighting parameter w

3

is

selected as 0.1 in both cases.

RELIABLE MODELLING AND OPTIMISATION CONTROL OF REACTIVE POLYMER COMPOSITE MOULDING

PROCESSES USING BOOTSTRAP AGGREGATED NEURAL NETWORK MODELS

239

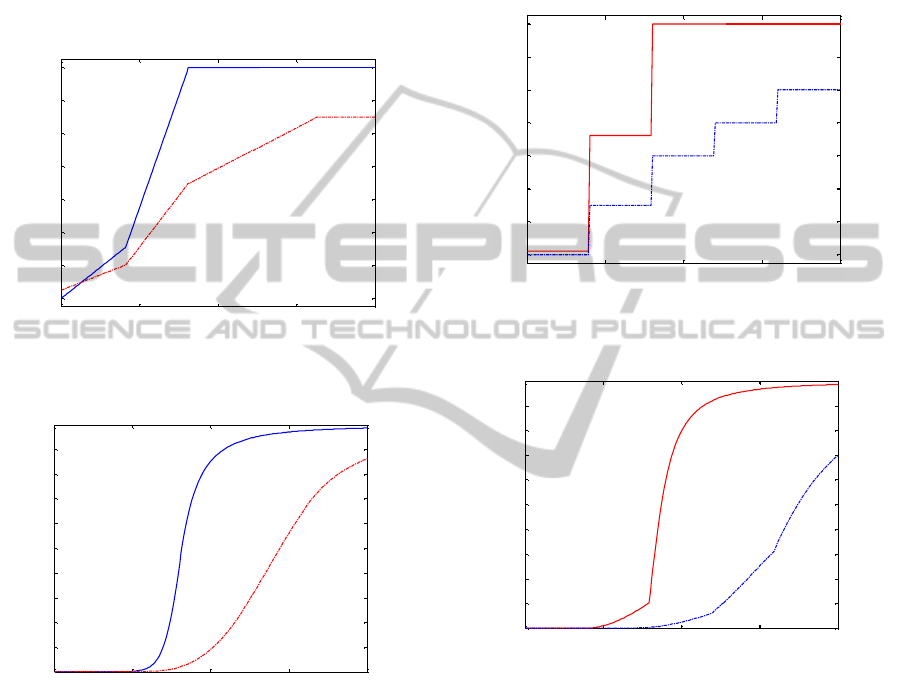

Figure 4 shows the initial and optimised

temperature profiles for the piecewise linear control

profile and Figure 5 shows the corresponding degree

of cure profiles. It can be seen from Figure 5 that the

final degree of cure under the initial temperature

profile is less than 0.9. Through optimisation based

on the neural network model, the final degree of

cure under the optimised temperature profile is

0.9866, which is very close to one.

0 5 10 15 20

20

40

60

80

100

120

140

160

Time (min)

Temperature (

o

C)

-:after optimisation; -.:before optimisation

Figure 4: Temperature before (-.) and after (-) optimisation

for the piecewise linear control profiles.

0 5 10 15 20

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

Time (min)

Degree of cure

-:after optimisation; -.:before optimisation

Figure 5: Degree of cure before (-.) and after (-)

optimisation for the piecewise linear control profiles.

Figure 6 shows the initial and optimised

temperature profiles for the piecewise constant

control profile and Figure 7 shows the corresponding

degree of cure profiles. It can be seen from Figure 7

that the final degree of cure under the initial

temperature profile is less than 0.7. Through

optimisation based on the neural network model, the

final degree of cure under the optimised temperature

profile is 0.9876, which is very close to one. The

neural network predicted final degree of cure under

this optimal curing temperature profile is 0.9722,

which is very close to the actual value.

The results obtained demonstrate that the neural

network models developed from polymer composite

moulding process operation data can accurately

represent the process and can be effectively used in

finding the optimal temperature profile. The final

degree of cure can be significantly improved through

optimisation using the neural network models.

0 5 10 15 20

20

40

60

80

100

120

140

160

Time (min)

Temperature (

o

C)

-:after optimisation; -.:before optimisation

Figure 6: Temperature before (-.) and after (-) optimisation

for the piecewise constant control profiles.

0 5 10 15 20

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

Time (min)

Degree of cure

-:after optimisation; -.:before optimisation

Figure 7: Degree of cure before (-.) and after (-)

optimisation for the piecewise constant control profiles.

4 CONCLUSIONS

A reliable modelling and optimisation control

strategy for reactive polymer composite moulding

process based on bootstrap aggregated neural

networks is presented in this paper. Application

results on both simulated and real industrial data

demonstrate that the developed neural network

models can accurately predict the degree of cure

(through predicting the measured resistance). In

addition, model prediction confidence bounds are

obtained from bootstrap aggregated neural networks.

By incorporating the model prediction confidence

NCTA 2011 - International Conference on Neural Computation Theory and Applications

240

bounds into the optimisation objective function and

penalising wide model prediction confidence

bounds, reliable optimisation control policy is

obtained. Application to a simulated reactive

polymer composite moulding process demonstrates

that the proposed reliable optimisation control

technique is very effective.

ACKNOWLEDGEMENTS

The research is supported by the EU through the

project iREMO – intelligent reactive polymer

composite moulding (grant No. NMP2-SL-2009-

228662).

REFERENCES

Ahmad, Z. and J. Zhang, (2005). “Bayesian selective

combination of multiple neural networks for

improving long range predictions in nonlinear process

modelling”, Neural Computing & Applications, 14,

78-87.

Ahmad, Z. and J. Zhang, (2006). “Combination of

multiple neural networks using data fusion techniques

for enhanced nonlinear process modeling”, Computers

& Chemical Engineering, 30, 295-308.

Bhat, N. V. and T. J. McAvoy, (1990). “Use of neural nets

for dynamical modelling and control of chemical

process systems”, Computers & Chemical

Engineering, 14, 573-583.

Bishop, C., (1991). “Improving the generalisation

properties of radial basis function neural networks”,

Neural Computation, 13, 579-588.

Bishop, C., (1995). Neural Networks for Pattern

Recognition. Oxford University Press: Oxford.

Breiman, L., (1996). “Bagging predictor”, Machine

Learning, 24, 123-140.

Bulsari, A. B., (Ed), (1995). Computer-Aided Chemical

Engineering, Vol.6, Neural Networks for Chemical

Engineers, Elsevier: Amsterdam.

Cybenko, G., (1989). “Approximation by superposition of

a sigmoidal function”, Math. Control Signal Systems,

2, 303-314.

MacKay, D. J. C., (1992). “Bayesian interpolation”,

Neural Computation, 4, 415-447.

Marquardt, D., (1963). “An algorithm for least squares

estimation of nonlinear parameters”, SIAM J. Appl.

Math., 11, 431-441.

Mukherjee, A. and J. Zhang, (2008). “A reliable multi-

objective control strategy for batch processes based on

bootstrap aggregated neural network models”, Journal

of Process Control, 18, 720-734.

Pantelelis, N. G., (2005). “Towards the dynamic

optimisation for the cure control of thermoset-matrix

composite materials”, Composites Science and

Technology, 65, 1254–1263.

Sridhar, D. V., R. C. Seagrave, and E. B. Bartlett, (1996).

“Process modelling using stacked neural networks”,

AIChE Journal, 42, 2529-2539.

Su, H. T., T. J. McAvoy, and P. Werbos (1992). “Long-

term prediction of chemical process using recurrent

neural networks: a parallel training approach”, Ind.

Eng. Chem. Res., 31, 1338-1352.

Tian, Y., J. Zhang, and A. J. Morris, (2001). “Modeling

and optimal control of a batch polymerization reactor

using a hybrid stacked recurrent neural network

model”, Ind. Eng. Chem. Res., 40, 4525-4535.

Wolpert, D. H., (1992). “Stacked generalization”, Neural

Networks, 5, 241-259.

Zhang, J., A. J. Morris, E. B. Martin, and C. Kiparissides,

(1997). “Inferential estimation of polymer quality

using stacked neural networks”, Computers &

Chemical Engineering, 21, s1025-s1030.

Zhang, J., A. J. Morris, E. B. Martin, and C. Kiparissides,

(1998). “Prediction of polymer quality in batch

polymerisation reactors using robust neural networks”,

Chemical Engineering Journal, 69, 135-143.

Zhang, J., A. J. Morris, E. B. Martin, and C. Kiparissides,

(1999). “Estimation of impurity and fouling in batch

polymerisation reactors through the application of

neural networks”, Computers & Chemical

Engineering, 23(3), 301-314.

Zhang, J., (1999). “Developing robust non-linear models

through bootstrap aggregated neural networks”,

Neurocomputing, 25, 93-113.

Zhang, J., (2001). “Developing robust neural network

models by using both dynamic and static process

operating data”, Ind. Eng. Chem. Res., 40, 234-241.

RELIABLE MODELLING AND OPTIMISATION CONTROL OF REACTIVE POLYMER COMPOSITE MOULDING

PROCESSES USING BOOTSTRAP AGGREGATED NEURAL NETWORK MODELS

241