NANOSTRUCTURED VS. CARBONACEOUS BIOSENSORS

Comparative Studies for Detection of Phenolic Compounds

Constantin Apetrei

1

, Jose Antonio de Saja

2

and Maria Luz Rodriguez-Mendez

3

1

Department of Chemistry, Physics and Environment, Faculty of Sciences and Environment,

“Dunărea de Jos” University of Galaţi, Galaţi, Romania

2

Dptm. Física de la Materia Condensada, Facultad de Ciencias, University of Valladolid, Valladolid, Spain

3

Dptm. Química Física y Química Inorgánica, E. T. S. Ingenieros Industriales, University of Valladolid, Valladolid, Spain

Keywords: Biosensor, Langmuir-Blodgett, Carbon paste electrode, Bisphthalocyanine, Tyrosinase.

Abstract: The biosensing properties of tyrosinase biosensors were investigated for two different immobilization

matrixes: carbon paste and Langmuir-Blodgett thin film. In both cases the electron mediator was the

lutetium (III) bisphthalocyaninate. The electrochemical responses of biosensors towards phenol and

catechol were analyzed and compared. The tyrosinase maintains its bioactivity well within the

immobilization matrices. A clearly defined reduction current proportional to the phenolic compounds

concentration was observed in cyclic voltammetry, which attributed to the reduction of enzymatically

produced quinone at the electrode surface. It was demonstrated that the biosensor based on Langmuir-

Blodgett thin film shows the best performances in terms of kinetics and detection limit for the phenolic

compounds analyzed.

1 INTRODUCTION

A considerable number of phenolic compounds,

extensively distributed throughout the environment,

are important pollutants in medical, food and

environmental matrixes. They are used in numerous

industrial processes such as fabrication of paper,

polymers, drugs, dyes, and pesticides (Hill, 2004).

They are ones of the most important contaminants in

soil and surface water (Manahan, 1991). Almost all

of them are easily absorbed and have been shown to

have negative effects on animal health (Bukowska

and Kowalska, 2004). Taking into consideration

their high toxicity and persistence in the

environment, the determination of phenolic

compounds becomes an important theme. For

quantification of phenolics, several methods were

developed such as colorimetry, gas chromatography,

liquid chromatography, and capillary

electrophoresis, fluorescence, and electrochemical

methods (Moldoveanu and Kiser, 2007; Ma et al,

2005; Kovács et al, 2011). However, these analysis

methods are relatively time-consuming, difficult to

perform requiring complex samples pre-treatment,

and may not be suitable for in situ monitoring. These

inconveniences diminish its practical applications.

Electrochemical sensors and biosensors can be a

possible alternative to these techniques.

Electrochemical analytic technique based on

biosensors is an attractive method due to simplicity,

low expense, high sensitivity and possibility of

miniaturization. Enzymes are complex proteins that

produce a specific chemical reaction in other

substances without themselves being modified

carrying out as biocatalysts by lowering the

activation energy (Palmer, 1991). For the detection

of phenolic compounds, biosensors based on

tyrosinase have been developed (Carralero et al,

2006; Cosnier et al, 2001; Tsai and Chiu, 2007).

Tyrosinase catalyzes the transformation of

monophenols to diphenols and also the reaction of o-

diphenols to o-quinones (Kazandjian and Klibanov,

1985). Several methods have been used for the

immobilization of tyrosinase onto various substrates

including carbon paste immobilization (Kumar

Vashist et al, 2011; Granero et al, 2010), sol–gel

immobilization (Zejli et al, 2008), physical

adsorption (Shiddiky and Torriero, 2011),

Langmuir–Blodgett thin films (Cabaj, 2010; Apetrei,

2011; Pavinatto, 2011), electrochemical entrapment

of enzyme within conducting polymer or composite

matrix (Ameer and Adeloju, 2009). Langmuir–

104

Apetrei C., de Saja J. and Rodriguez-Mendez M..

NANOSTRUCTURED VS. CARBONACEOUS BIOSENSORS - Comparative Studies for Detection of Phenolic Compounds.

DOI: 10.5220/0003716701040109

In Proceedings of the International Conference on Biomedical Electronics and Devices (BIODEVICES-2012), pages 104-109

ISBN: 978-989-8425-91-1

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

Blodgett (LB) technique offers a possibility of

developing an ultra-thin film with well-organized

structure on molecular scale (Roberts, 1990). On the

other hand, this technique is considered as a suitable

immobilization method for biosensor because this

can produce well-ordered thin films and can control

the quantity of biocomponents by the number of

deposited layers.

The immobilization of the enzyme tyrosinase

into carbon paste electrodes has resulted in a number

of biosensor configurations that have been shown to

be relatively sensitive, specific, and durable in the

detection and measurement of phenols (Granero et

al, 2010). Various aspects concerning their

construction and operation have been studied and

optimized including the use of different binders

(Rogers et al, 2001) and the use of redox mediators

(Yin, 2010).

In this paper, carbon paste biosensors and LB

biosensors based on tyrosinase and lutetium (III)

bisphthalocyaninate (as electron mediator) have

been prepared and their capability to detect phenolic

compounds has been compared. For this purpose,

phenol and catechol have been analyzed in aqueous

solutions. The response dependences and

amperometric characteristics including sensitivity,

kinetics, linear range and limits of detection of the

prepared enzyme electrode in the detection of

phenolic compounds have been investigated.

2 EXPERIMENTAL

2.1 Chemicals and Solutions

Carbon paste was made with graphite powder (High

purity Ultracarbon®, Ultra F purity) mixed with

high purity mineral oil (Nujol, Fluka). The sources

of materials and reagents used were as follows:

arachidic acid, phenol, catechol from Sigma;

tyrosinase (EC 1.14.18.1, from mushroom) was

purchased from Sigma. A 67μg·μL

−1

solution of

tyrosinase in buffer phosphate 0.01 M (pH=7) was

used for the enzyme immobilization.

The buffer was prepared from potassium

monobasic and dibasic phosphate salts (pH 7) from

Aldrich. All the aqueous solutions were prepared

using 18 MΩ·cm MilliQ water (Millipore).

The lutetium (III) bisphthalocyaninate (LuPc

2

was synthesized and purified in their neutral radical

state following previously published procedures.

2.2 Biosensor Construction

2.2.1 Carbon Paste based Biosensor

Carbon paste electrodes were prepared as previously

reported by mixing graphite powder and the

bisphthalocyanine (15%, w/w). Nujol was used as

the binder of the composite mixture. Carbon pastes

were packed into the body of a 1mL plastic syringe

and compressed. A metallic copper wire was used as

a contact.

The enzyme, tyrosinase (Tyr), was immobilized

on the above carbon paste electrodes by a casting

technique followed by cross-linking. 5μL of 0.01 M

phosphate buffer (pH 7.0) containing 67μg·μL

−1

of

enzyme, was added onto carbon paste electrode

surface. After drying, the biosensor was exposed to a

2.5% (v/v) glutaraldehyde solution (in phosphate

buffer 0.01M of pH 7) for 20 minutes at room

temperature. The enzyme-immobilized electrode

was dried at 10ºC and rinsed with phosphate buffer

solution thrice to remove any unbound enzyme from

the biosensor surface and was further dried at 10ºC

and stored at 4ºC.

2.2.2 Langmuir-Blodgett based Biosensor

LB films were prepared in a KSV 5000 System 3

Langmuir–Blodgett trough equipped with a

Wilhelmy plate to measure the surface pressure.

Films containing tyrosinase, LuPc

2

and arachidic

acid (Tyr/LuPc

2

-AA) were prepared by spreading a

chloroform solution (10

−5

M) of arachidic acid and

LuPc

2

onto a water subphase (NaCl 0.1M, phosphate

buffer 0.01M of pH 7 in ultrapure water – Millipore

MilliQ; 20ºC). After the evaporation of the solvent,

10μL of a 67μg·μL

−1

solution of tyrosinase in

0.01M phosphate buffer (pH 7) was injected drop by

drop underneath the air/water interface.

Molecules were compressed using a symmetrical

two barrier compression system. At a surface

pressure of 30mN·m

−1

, 20 monolayers were

deposited onto the ITO (indium tin oxide) surface.

The substrate speed used was 2mm·min

−1

. LB films

were prepared by Y-type deposition with a transfer

ratio close to 1. The biosensor was washed using

phosphate buffer, dried at 10ºC and stored at 4ºC.

2.3 Apparatus

Electrochemical experiments and analytical testing

were carried out in a 100 mL electrochemical cell

using a platinum electrode as the counter electrode

and a biosensor as the working electrode. The

NANOSTRUCTURED VS. CARBONACEOUS BIOSENSORS - Comparative Studies for Detection of Phenolic

Compounds

105

potentials were measured and referred to a

Ag/AgCl/KCl 3M electrode. Electrochemical

measurements were carried out with an EG&G

PARC Model 263 potentiostat/galvanostat

(Princeton Applied Research Corp.).

The electrochemical experiments were carried

out in 0.01 M phosphate buffer solution (PBS) of

pH=7 as supporting electrolyte.

3 RESULTS AND DISCUSSIONS

The suitable immobilization of the enzyme in solid

substrates is crucial for the development of the

biosensors. The structure of the matrix used for

immobilize Tyr should contribute to the preservation

of enzyme functionality.

3.1 Cyclic Voltammetry Studies

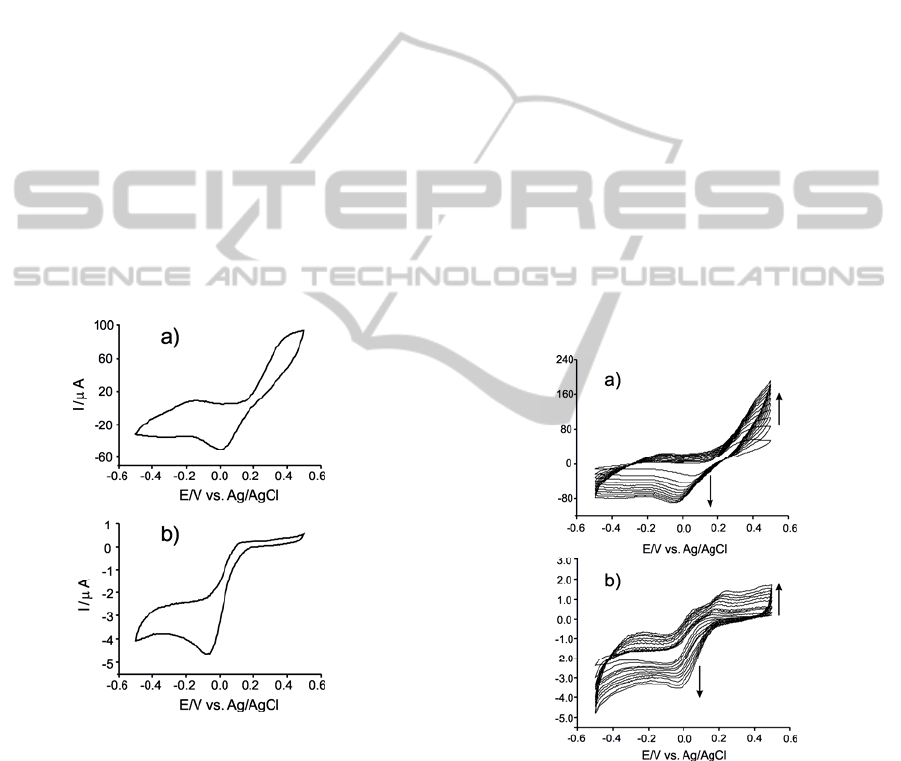

The response towards phenolic compounds of the

biosensors was registered in the range from -0.5 V to

+0.5V at a scan rate of 0.050 V·s

-1

(Figure 1).

Figure 1: Cyclic voltammograms of biosensors immersed

in 4·10

-4

M catechol (in PBS, pH=7); a) Tyr/LuPc

2

-AA, b)

Tyr/LuPc

2

-CP.

The cyclic voltammogram of the Tyr/LuPc

2

-AA

biosensor in 4·10

-4

M catechol (pH 7.0 phosphate

buffer solution) showed a redox pair at E

1/2

=-0.24V

associated with the one electron reduction of the

phthalocyanine ring (de Saja and Rodriguez-

Mendez, 2005). The peaks related with catechol

appear at +0.01V (cathodic peak associated with the

reduction of the enzymatically formed o-quinone to

catechol) and at +0.40V (anodic peak associated to

the electrochemical oxidation of the catechol),

respectively.

The cyclic voltammogram of the Tyr/LuPc

2

-CP

biosensor in the same solution do not show the peaks

related with phthalocyanine. As is show in the

Figure 1b, only the peak corresponding to enzymatic

reduction of the o-quinone to catechol appearing at

-0.07V is observed.

The results are similar in the case of phenol

analysis. The peak pair corresponding to LuPc

2

is

clear only in the case of Tyr/LuPc

2

-AA biosensor.

Additionally, only the reduction peak of the

enzymatically formed o-quinone at biosensor surface

is observed. In the case of LB biosensor the peak

appear at +0.01V and in the case of CP biosensor at

-0.07V.

The presence of reduction peak indicates that the

immobilization process retains the biological activity

of tyrosinase in both solid substrates.

3.2 Kinetic of the Biosensors

Kinetic studies were performed by registering the

cyclic voltammograms of the biosensors at different

scan rates, from 0.02 to 0.20V·s

-1

(Figure 2).

Figure 2: Cyclic voltammograms of biosensors a)

Tyr/LuPc

2

-AA, b) Tyr/LuPc

2

-CP registered at different

scan rates. Electrolyte solution was 4·10

-4

M catechol (in

PBS 0.01M, pH=7).

In both cases, the cathodic peak currents were

proportional to sweep rates pointing to a charge

transfer limited process due to the catalytic activity

of the enzyme deposited in the surface of the

electrode. The principal parameters of linear

regression equation of the plots I vs. V were

BIODEVICES 2012 - International Conference on Biomedical Electronics and Devices

106

presented in the Table 1.

Table 1: Quantitative data obtained from kinetic studies

for cathodic peak.

Tyr/LuPc

2

-AA

m R

2

Γ

/ mol·cm

−2

Phenol

-0.1124 0.988 2.20·10

-9

Catechol

-0.2812 0.986 1.77·10

-8

Tyr/LuPc

2

-CP

m R

2

Γ

/ mol·cm

−2

Phenol

-0.0036 0.981 7.04·10

-10

Catechol

-0.0068 0.976 4.28·10

-9

m- is the slope of the plots I

c

vs. v

The trends observed when immersing the biosensors

in phenolic compounds solutions were similar. In

both cases, the same o-quinone is enzymatically

formed, which is electrochemically reduced at

biosensor surface.

Tyr/LuPc

2

-AA biosensor showed a

fast electron transfer between the phenolic

compounds and LB thin film. When the carbon

matrix was used as support material, the electron

transfer was difficult and the signals showed a

smaller intensity. The differences are in the range of

two orders of magnitude.

From the slope of this line and using the Laviron

equation:

I

c

= n

2

F

2

v A Γ / 4 R T

(1)

where Γ is the surface coverage of the redox species

(o-quinone) (mol·cm

−2

), A is the electrode area

(cm

2

), ν is the potential sweep rate and n, I

c

, F, R

and T have their usual meanings (Bard and Faulkner,

2001), the total surface coverage could be

calculated.

The values obtained were presented in Table 1.

The highest surface coverage values were obtained

in the case of Tyr/LuPc2-AA biosensor. This result

suggests that in the LB thin film exist a greater

number of active sites comparing with carbonaceous

matrix. Therefore, the enzyme preserve better the

biocatalytic activity when is immobilized in a

biomimetic environment.

The intensity of peaks related to the

electrochemical oxidation of phenolic compounds

increases linearly with the square root of the sweep

rate (Table 2) indicating a diffusion controlled

processes according to the Randles-Sevcik equation.

I

a

=2.687·105 n

3/2

v

1/2

D

1/2

A C (2)

where I

a

is the peak current, A is the electrode

surface area, D is the diffusion coefficient, and C is

the concentration. From the I

a

, in function of v

1/2

plot, the diffusion coefficient D could be calculated.

Table 2: Quantitative data obtained from kinetic studies

for anodic peak.

Tyr/LuPc

2

-AA

m R

2

D / cm

2

·s

-1

Phenol

0.2235 0.967 6.32·10

-6

Catechol

0.6276 0.978 7.87·10

-5

Tyr/LuPc

2

-CP

m R

2

D / cm

2

·s

-1

Phenol

0.0024 0.959 5.40·10

−7

Catechol

0.0063 0.961 5.34·10

-6

m- is the slope of the plots I

a

vs. v

1/2

From the above results, could be concluded that the

Tyr/LuPc

2

-AA presents the fastest diffusion

coefficients pointing that the electrochemical

processes a more rapid in the case of nanostructured

thin film.

3.3 Amperometric Response of the

Biosensors

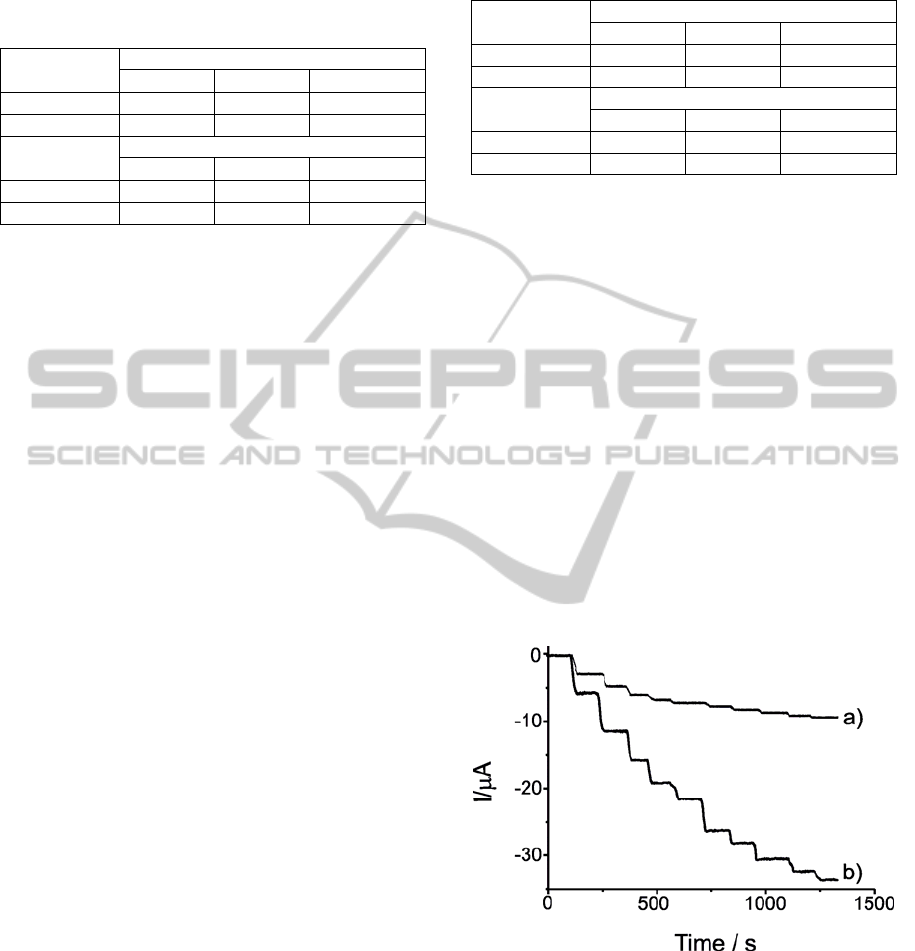

Figure 3 illustrates the amperometric response for

the Tyr/LuPc

2

-CP biosensor at -0.07V V (a) and for

the Tyr/LuPc

2

-AA biosensor at +0.01V V (b) after the

addition of successive aliquots of phenol to the 0.01

M PBS (pH 7.0) under constant stirring. Definite

reduction currents proportional to the concentration

of phenol were observed, which results from the

electrochemical reduction of o-quinone species

enzymatically formed.

Figure 3: Amperometric response of a) Tyr/LuPc

2

-CP and

b) Tyr/LuPc

2

-AA biosensors to phenol in 0.01 M PBS

solution (pH=7).

The Tyr/LuPc

2

-AA biosensor achieves 95% of steady-

state current in less than 4 s. The response rate is

much faster than that of 7 s obtained in the case of

Tyr/LuPc

2

-CP biosensor. The faster response could

be attributed to a more rapid electron transfer

between the enzymatically-produced quinone and

NANOSTRUCTURED VS. CARBONACEOUS BIOSENSORS - Comparative Studies for Detection of Phenolic

Compounds

107

the biomimetic LB thin film comparing with carbon

paste biosensor.

3.4 Effect of Phenolic Compounds

Concentration

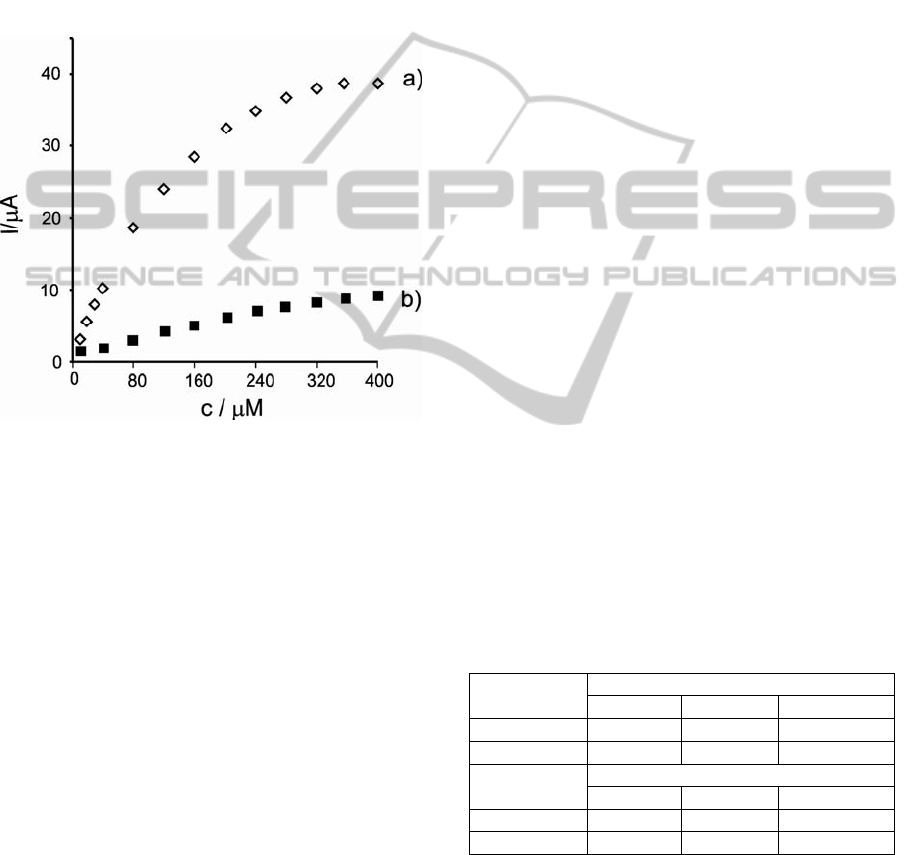

Figure 4 showed the relationship between the

response current of the biosensors and the phenol

concentration in PBS (pH 7.0) at +0.01V for

Tyr/LuPc

2

-AA biosensor and -0.07V for Tyr/LuPc

2

-

CP biosensor (calibration curves).

Figure 4: The calibration curve between the reduction

current and the concentration of catechol in PBS (pH 7.0)

of a) Tyr/LuPc

2

-AA and b) Tyr/LuPc

2

-CP biosensors to

phenol in 0.01 M PBS solution (pH=7).

The response current of Tyr/LuPc

2

-AA biosensor is

linear with phenol concentration in the range from

10 to 120μM, indicating that the enzyme catalytic

reaction of Tyr is the first-order reaction. Then, with

further increasing catechol concentration, the current

increases slowly, and the enzyme reaction shows a

transition from first to zero-order. The sensitivity of

the biosensors is 0.053μA·μM

-1

. The corresponding

detection limits were calculated according to the

3s

b

/m criterion, where m is the slope of the

calibration graph, and s

b

was estimated as the

standard deviation (n = 7) of the amperometric

signals from different solutions of the substrate at

the concentration level corresponding to the lowest

concentration of the calibration plot. The detection

limits calculated were 5.4 μM. The values obtained

are lower than that obtained in the case of

Tyr/LuPc

2

-CP biosensor (the sensitivity is

0.0075μA·μM

-1

and the detection limit is 8.57 μM).

Therefore the Tyr/LuPc

2

-AA biosensor has better

quality performances comparing with Tyr/LuPc

2

-CP

biosensor.

From the calibration data, the Hill coefficient (h)

can be calculated by representing the log[I/(I

max

-I)]

vs. log [S] (the logarithm of substrate concentration).

A Hill coefficient of 1.09 was calculated for the

reduction process of o-quinone formed from the

enzymatic reaction on the electrode surface

(R

2

=0.952) for Tyr/LuPc

2

-AA biosensor. In the case

of Tyr/LuPc

2

-CP biosensor a Hill coefficient of 0.94

was obtained. The value obtained for the h

parameter, calculated from the corresponding Hill’s

plot, was close to unity demonstrated that the

kinetics of the enzymatic reaction fitted into a

Michaelis–Menten type kinetics. The value slightly

higher than 1 obtained for Tyr/LuPc

2

-AA biosensor

(h=1.09) demonstrates a positive cooperative effect

between the occupied active sites. A negative

cooperative effect between the occupied active sites

takes place in the case of Tyr/LuPc

2

-CP biosensor

(h=0.94).

The apparent Michaelis–Menten constant (K

M

) is

calculated for the immobilized Tyr by using the

linearization of Lineweaver-Burk expressed by eq.

(3) (Shu and Wilson, 1976).

1/I = 1/I

max

+ K

M

/ (I

max

·[S] ) (3)

where I is the cathodic current, I

max

is the steady-

state current, K

M

is the apparent Michaelis-Menten

constant and [S] is the concentration of substrate.

The maximum current response and apparent

Michaelis–Menten constant were calculated from the

intercept and slope. The values obtained for both

biosensors immersed in phenolic compounds

solutions were presented in Table 3.

Table 3: Response characteristics of the biosensors to

phenolic compounds.

Tyr/LuPc

2

-AA

LD /

μ

MI

max

/

μ

A K

M

/

μ

M

Phenol

5.40 39.11 81.52

Catechol

1.80 45.65

24.56

Tyr/LuPc

2

-CP

LD /

μ

MI

max

/

μ

A K

M

/

μ

M

Phenol

8.57 9.31 241.93

Catechol

8.19 11.61 92.42

In agreement with the inherent characteristic of

Michaelis–Menten constant, the small the value of

K

M

, the stronger will be the affinity between Tyr and

substrate. A highest I

max

indicate a higher sensitivity

of the biosensor (Kiralp and Toppare, 2006).

BIODEVICES 2012 - International Conference on Biomedical Electronics and Devices

108

The values obtained indicate that the Tyr/LuPc

2

-AA

biosensor have highest quality performances.

4 CONCLUSIONS

It is demonstrated that the biomimetic LB thin film

biosensor have the advantages of maintaining

enzyme bioactivity, making the enzyme catalytic

sites close and easily accessible to the substrate

molecules comparing with tyrosinase-based carbon

paste biosensor.

The kinetic studies demonstrate that Tyr/LuPc

2

-

AA biosensor have a fast electron transfer between

the phenolic compounds and LB thin film. In the

case of Tyr/LuPc

2

-CP biosensor, the electron

transfer was difficult and the signals showed a

smaller intensity.

These advantages lead to significant

improvement of the affinity, response sensitivity and

detection limit of Tyr/LuPc

2

-AA to phenol and

catechol in pH 7.0 phosphate buffer.

ACKNOWLEDGEMENTS

The authors are grateful to the Spanish Ministry of

Science-CICYT (Grant AGL2009-12660/ALI) for

the financial support.

REFERENCES

Ameer, Q., Adeloju, S. B., 2009. Sens. Actuators B 140,

5–11.

Apetrei, C., Alessio, P., Constantino, C. J. L., de Saja, J.

A., Rodriguez-Mendez, M. L., Pavinatto, F. J.,

Fernandes, E. G., Zucolotto, V., Oliveira, O. N., 2011.

Biosens. Bioelectronics 26, 2513-2519.

Bard, A. J., Faulkner, L. R., 2001. Electrochemical

Methods, John Wiley and Sons, New York.

Bukowska, B., Kowalska, S., 2004. Toxicol. Lett., 152,

73–84.

Cabaj, J., Sołoducho, J., Nowakowska-Oleksy, A., 2010.

Sens. Actuat. B, 143, 508-515.

Carralero, V., Mena, M. L., Gonzalez-Cortes, A., Yanez-

Sedeno, P., Pingarron, J. M., 2006. Biosens.

Bioelectron., 22, 730–736.

Cosnier, S., Szunerits, S., Marks, R. S., Lellouche, J.,

Perie, K., 2001. J. Biochem. Biophys. Methods, 50,

65–77.

de Saja, J. A., Rodríguez-Méndez, M. L., 2005. Adv.

Colloid Interf. Sci. 116, 1 –11.

Granero, A.M., Fernández, H., Agostini, E., Zón, M. A.,

2010. Talanta 83, 249-255.

Hill, M. K., 2004. Understanding environmental pollution,

Cambridge University Press, UK.

Kazandjian, R., Klibanov, A., 1985. J. Am. Chem. Soc.

107, 5448-5450.

Kiralp, S., Toppare, L., 2006. Process Biochem. 41 236–

239.

Kovács, A., Mörtl, M., Kende, A., 2011. Microchem. J.,

99, 125-131.

Kumar Vashist, S., Zheng, D. Al-Rubeaan, K., Luong,

J.H.T., Sheu, F.S., 2011. Biotechnol. Adv. 29, 169-

188.

Ma, Y., Yang, C., Li, N., Yang, X., 2005. Talanta, 67,

979–983.

Manahan S. E., 1991. Environmental Chemistry, Lewis

Publishers, New York.

Moldoveanu, S.C., Kiser, M., 2007. J. Chromatography A,

1141, 90–97.

Palmer, T., 1991.Understanding Enzymes, Prentice-

Hall/Ellis Horwood, London.

Pavinatto, F. J., Fernandes, E. G. R., Alessio, P.,

Constantino, C. J. L., de Saja, J. A., Zucolotto, V.,

Apetrei, C., Oliveira Jr., O. N., Rodriguez-Mendez M.

L., 2011. J. Mater. Chem. 21, 4995-5003.

Roberts, G. G., 1990. Langmuir Blodgett Films, Plenum,

New York.

Rogers, K. R., Becker, J. Y., Cembrano, J., Chough, S.H.,

2001. Talanta 54, 1059–1065.

Shiddiky, M. J. A., Torriero, A. A. J., 2011. Biosens.

Bioelectronics 26, 1775-1787.

Shu, F. R., Wilson G. S., 1976. Anal. Chem. 48, 1679-

1686.

Tsai, Y., Chiu, C., 2007. Sens. Actuators B, 125, 10–16.

Yin, H., Zhou, Y., Xu, J., Ai, S., Cui, L., Zhu, L., 2010.

Anal. Chim. Acta 659, 144–150.

Zejli, H., Hidalgo-Hidalgo de Cisneros, J. L., Naranjo-

Rodriguez, I., Liu, B., Temsamani, K. R., Marty, J. L.,

2008. Anal. Chim. Acta 612, 198-203.

NANOSTRUCTURED VS. CARBONACEOUS BIOSENSORS - Comparative Studies for Detection of Phenolic

Compounds

109