MICROLENSES FOR STEREOSCOPIC IMAGE FORMATION

R. P. Rocha, J. P. Carmo and J. H. Correia

Dept. Industrial Electronics, University of Minho, Campus Azurem, 4800-058 Guimaraes, Portugal

Keywords: Microlenses, Optical filters, RGB, Image sensor, Stereoscopic vision, Low-cost fabrication.

Abstract: This paper presents microlenses for integration on a stereoscopic image sensor in CMOS technology for use

in biomedical devices. It is intended to provide an image sensor with a stereoscopic vision. An array of

microlenses potentiates stereoscopic vision and maximizes the color fidelity. An array of optical filters

tuned at the primary colors will enable a multicolor usage. The material selected for fabricating the

microlens was the AZ4562 positive photoresist. The reflow method applied to the photoresist allowing the

fabrication of microlenses with high reproducibility.

1 INTRODUCTION

Currently, the available image sensing technology is

not yet ready for stereoscopic acquisition. The final

quality of the image will be improved because of the

stereoscopic vision but also due to the system’s high

resolution. Typically, two cameras are used to

achieve a two points of view (POV) perspective

effect. But this solution presents some problems

mainly because the two POVs, being sufficiently

different, cause the induction of psycho-visual

confusion by the user (Andorko et al., 2010). The

parallax effect (see Figure 1) is used to achieve

stereoscopic vision.

Figure 1: Illustration of the parallax effect for inducing

sensation of depth in the human brain (Andorko et al.,

2010).

The result is obtained by “tricking” the brain

causing it to gain depth perception (also known as

stereopsis). This means that bad quality stereoscopy

induces perceptual ambiguity in the viewer (Zeki,

2004). The reason for this phenomenon is that the

human brain is simultaneously more sensitive but

less tolerant to corrupt stereo images as well as

vertical shifts of both images, being more tolerant to

monoscopic images. Therefore, the brain does not

consent the differences between the images coming

from the left and right channels that are originated

from the two independent and optically unadjusted

cameras. A very interesting application for this type

of imaging technology is in the biomedical field.

Wireless capsule endoscopy, that take pictures along

the digestive system, present themselves as excellent

devices where to apply these image sensors

(Qureshi, 2004; Iddan et al., 2000), broadening the

possibilities of non-invasive examination methods.

Furthermore, the outspread of low-power small

dimensioned high-resolution cameras motivates

even more the fabrication of the next generation of

endoscopic swallowable pills. These capsules can be

electronically controlled for several purposes, from

guidance inside the digestive system to drug delivery

mechanisms. Presently, the capsules determine

where they are according to the pH levels in their

surroundings based on the different acidity profiles

across the digestive system. Another advantage of

the proposed imaging sensor is the compatibility

with the CMOS technology. Most notably, CMOS

allows the decrease of the power consumption and,

unlike the CCD technology, CMOS sensors can be

fabricated using the same manufacturing facilities as

the high-volume products of the semiconductor

114

P. Rocha R., P. Carmo J. and H. Correia J..

MICROLENSES FOR STEREOSCOPIC IMAGE FORMATION.

DOI: 10.5220/0003728901140118

In Proceedings of the International Conference on Biomedical Electronics and Devices (BIODEVICES-2012), pages 114-118

ISBN: 978-989-8425-91-1

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

industry. Thus, CMOS microdevices are more

standardized and cost-effective to produce then the

CCDs microdevices. Considering the low-power

consumption of the CMOS microdevices, another

possibility that presents itself for the imaging

sensors is the integration of thin-films batteries with

silicon compatibility (Chan et al., 2008) and low

toxicity (Armand and Tarascon, 2008). The inherent

characteristics of the proposed imaging sensor

presented in this paper make it an interesting

solution for the capsule endoscopy integration

including the thin-films battery as the power source.

The fabrication of such a microdevice can be done

using the 0.7 µm CMOS process in the AMIS

foundry because it allows the production of both the

photodetectors and the read-out electronics within a

reasonable cost. Finally, since the aforementioned

process is very well characterized and known, the

time to manufacture the first working prototype is

expected to be short. This paper addresses on the

design and fabrication technology of the microlenses

for providing stereoscopic vision.

2 IMAGE SENSOR

ARCHITECTURE

The image sensor is composed by two pupils (two

entrance apertures just like the human eyes) from

where the left and right channels (the two POVs that

will originate the tridimensional effect) pass through

before being focused by an objective lens. This lens

focuses the two incident beams in the direction of

the microlens, where the light is concentrated in a

small sensitive area where the photodiodes are

placed. After passing through the optical filters, the

wavelengths coming from both the entrance

apertures are directed towards the respective CMOS

photodiodes. The two viewpoints are separated by

focusing each side onto the appropriate sensor

column under the microlens and optical filters.

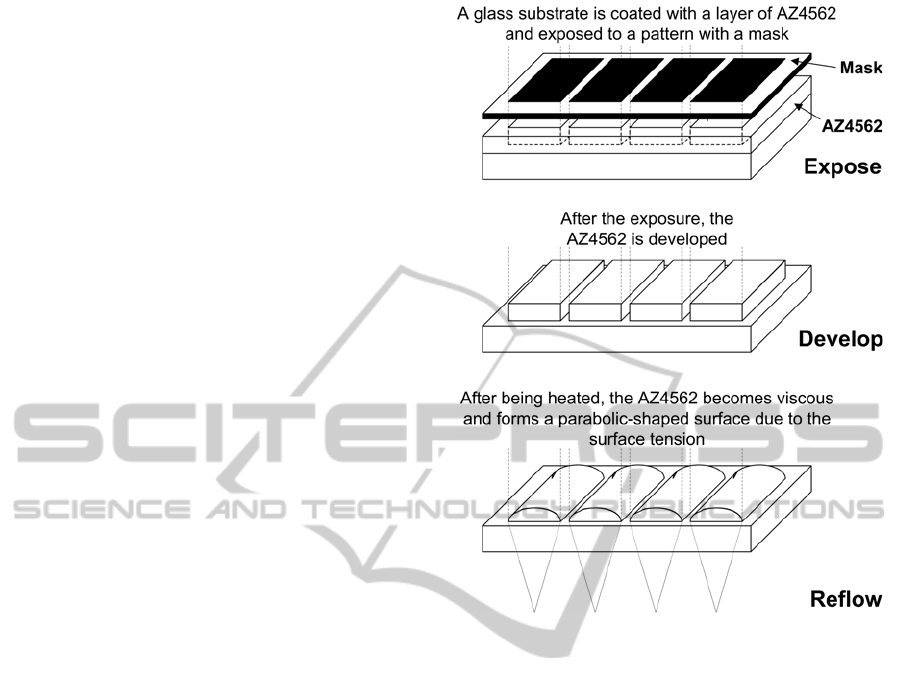

3 MICROLENSES FABRICATION

A. Microlens fabrication

There is a huge number of materials available for

fabricating microlenses arrays such as the SU-8/2,

AZ9260 and AZ4562, for example. These polymers

allow the microlens fabrication by thermally

reflowing the raw material, whose processing steps

Figure 2: The reflow process applied to the AZ4562

photoresist for fabricating microlenses arrays.

of the reflow process are presented in the Figure 2.

This permits the production of arrays containing a

million or more microlens of good optical quality in

just a few minutes and with high degree of

reproducibility of their characteristics. There are a

few geometrical parameters to take in account before

fabricating the microlenses. As depicted in Figure 3,

the paraxial focal length, f, of a microlens consisting

of a single spherical surface of radius R in a medium

of refractive index, n, is given by f=R/(n-1) and the

height, h, of the surface undulation of a microlens

with an aperture radius, r, is h=R-(R

2

-r

2

)

1/2

. The

volume of a cylinder of resist is Tπr

2

, where T is the

thickness before melting and the volume of the

microlens is 1/3πh

2

(3R-h). It therefore follows that

the necessary thickness is given by T=h/6×[3+(h/r)

2

].

The reflow process works well for microlenses of a

relatively high-numerical aperture (and low-focal

length, f), where the lens constitutes a significant

fraction of a hemisphere. This process is very tolerant

of the state of resist before melting, thus, acceptable

lenses can be made with aperture ratios between f/1

and f/3.

MICROLENSES FOR STEREOSCOPIC IMAGE FORMATION

115

f

h

R

Refraction index

n

Air

Microlens surface

Figure 3: Factors determining the focal length of

microlens.

Good-quality lenses are fabricated with relatively

crude lithography although greater consistency and

reliability is achieved only if the process is carried

out efficiently. The precise form of the microlenses,

and hence their focal properties, are determined by

the effects of the surface tension (Roulet et al.,

2001). In particular the contact angle of the softened

resist with the surface of the substrate will strongly

influence the shape of the microlens.

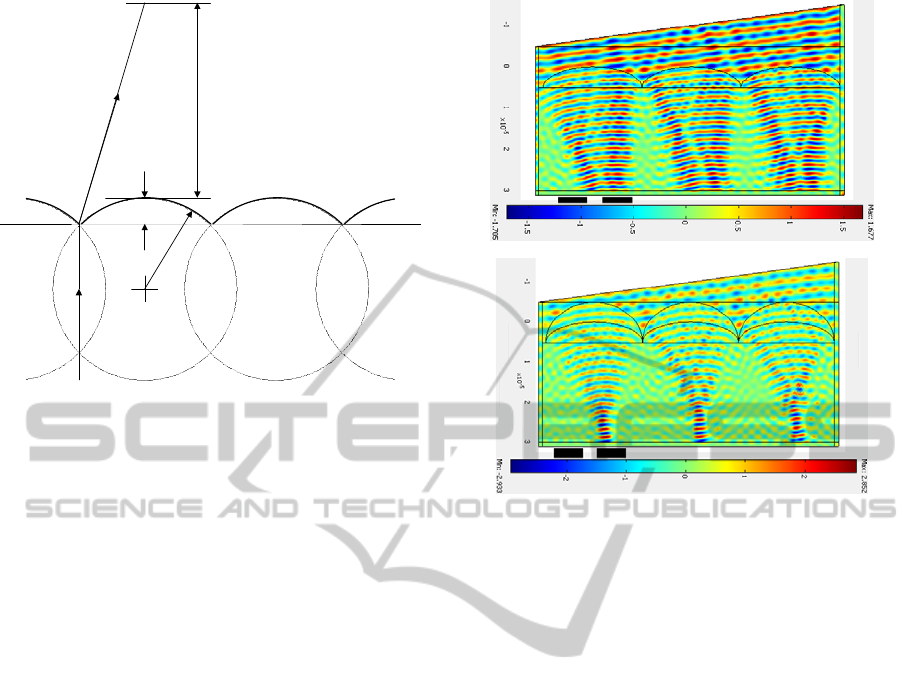

B. Microlens simulation

In Figure 4 it is possible to see the results of some

finite element method (FEM) simulations. These

simulations were performed considering the

impinging light with an angle of 7.6º degrees from

the left channel, but this methodology is also

applicable to the right channel and both channels

overlapping for the global effect. The dimensions of

the presented microlenses simulations have a W/L

ratio of 4.8 and 2.4 in (a) and (b), respectively. It is

clearly seen that the light concentrates in the

direction of the photodiodes represented as pairs of

black rectangles on the bottom of the figure. The

simulations also show that the best results, i.e. more

concentration of light, are achieved with microlenses

having a higher curvature. Moreover, another

important conclusion is shown, that it is possible to

separate the left and right channels for focusing the

specific wavelengths into the respective

photodiodes. This also allows estimating the cross-

talk between adjacent photodiodes, being smaller in

the micro lenses with higher curvature. It is assumed

in the simulations that the light had already passed

through the optical filters.

(a)

(b)

Figure 4: FEM simulations showing the light

concentration into the right photodiode. The simulations

where obtained respectively for lenses measuring with (a)

W/L=4.8 and (b) W/L=2.4. The simulations also allows to

roughly estimate the degree of cross talk between two

adjacent photodiodes (e.g., between the left and right

channels).

4 EXPERIMENTAL

C. Fabrication

The fabrication process of the microlenses array

requires several steps. First, it is necessary to deposit

the photoresist by means of a spin coater in a

previously cleaned substrate. To achieve the desired

thickness, the spin velocity is 6000 rpm and the time

will depend on the desired thickness. After the

coating, a prebake phase, using a computer

controlled hot plate at 100º C for 100 seconds, is

necessary to evaporate the solvents present in the

photoresist. This step is critical otherwise the resist

surface dries very fast and doesn’t allow the solvent

to exit the photoresist creating bubbles and possibly

the photoresist to lift. Next, to obtain the required

array-like structure, the mask with the correspondent

geometrical design is placed on top of the substrate

with the photoresist. This step serves for exposing

the PR to UV light, during 2 minutes, to make the

unexposed material insoluble. Afterwards, the

development phase, using the AZ 351B developer in

BIODEVICES 2012 - International Conference on Biomedical Electronics and Devices

116

a 1:4 concentration with distilled water, is required

to leave just the unexposed photoresist in the

substrate. To do this, the substrate is immersed in

the developer bath in a magnetic stirrer for 1 minute.

Finally, the structure is also placed in the hot plate

for a postbake phase at 115 º C for 100 seconds for

obtaining the final chemical stabilization and

substrate adhesion improvement. In order to obtain

the lens profile, a reflow technique is used. The

substrate with the PR array is placed at 180º C

during 10 hours.

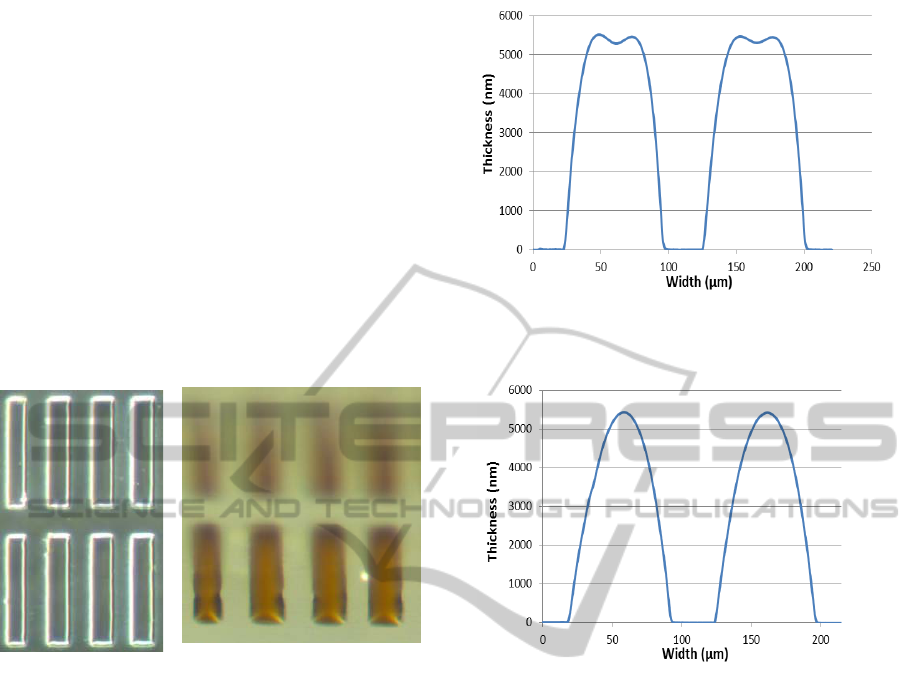

D. Characterization

In Figure 5, two photographs show the PR array

before and after the reflow step, respectively, on the

left, top view and on the right, tilted view.

Figure 5: (a) Figure 5: (b)

In Figures 6 (a) and (b) it is possible to see the

profiles of the PR before and after the reflow process

measured with a Veeco Dektak 150 profilometer.

This figure presents the typical initial profile

seen during the fabrication of microlenses using PR

(Emadi et al., 2009; O’Neill et al., 2002). After

applying a temperature higher than the glass

transition temperature of the PR, the viscosity

decreases and the consequent flow due to surface

tension occurs. These structures are the first

prototypes built using photolithography but the final

size of the microlenses can be further reduced using

a chromium-on-glass mask. Nevertheless, it is clear

from the previous figures that the thermal reflow

process permitted obtaining the desired microlens

profile to concentrate the light into specific

directions.

Figure 6 (a): Profile of the PR array before the thermal

reflow

.

Figure 6 (b): Profile of the microlenses obtained after the

thermal reflow step.

5 CONCLUSIONS

This paper presented a microlenses fabrication

process for integration on a stereoscopic image

sensor in CMOS technology for use in biomedical

devices. The microlenses design started with the

FEM simulations to set some parameters needed to

fulfill the desired objectives. These objectives

included the microlenses’ W/L dimensional ratio of

4.8 and 2.4 because of the size and pitch of the

photodetectors. Each photodetector measures a

specific wavelength with is difracted by the

microlenses. The complete fabrication process was

explained and the initial and final structures obtained

were physically characterized. It was shown that the

reflow step is what determines the actual

microlenses profile. The several steps that comprise

the photolithographic fabrication process were done

for a first prototype but smaller ones are already

being developed and tested using a chromium-on-

glass mask and a mask aligner as the UV light

MICROLENSES FOR STEREOSCOPIC IMAGE FORMATION

117

source. The integration of such stereoscopic imaging

sensor in a biodevice such as an endoscopic capsule

for non-invasive examination of the digestive system

is a very appealing solution for the presented

fabrication technology.

ACKNOWLEDGEMENTS

This work was fully supported by the Portuguese

Foundation for Science and Technology under the

project FCT/PTDC/EEA-ELC/109936/2009.

REFERENCES

I. Andorko, et al., "Hardware implementation of a real-

time 3D video acquisition system", in proc. of 12th

International Conference on Optimization of Electrical

and Electronic Equipment (OPTIM 2010), Brasov,

Ronaia, 20-22 May, pp. 920-925.

S. Zeki, "The neurology of ambiguity", Consciousness and

Cognition, Vol. 13, pp. 173-196, 2004.

W. Qureshi, "Current and future applications of the

capsule camera", Nature Reviews Drug Discovery,

Vol. 3, pp. 447-480, May 2004.

G. Iddan, et al, "Wireless capsule endoscopy", Nature,

Vol. 405, pg. 417, May 2000.

C. K. Chan, et al, "High-performance lithium battery

anodes using silicon nanowires", Nature, Vol. 3, pp.

31-35, January 2008.

M. Armand, M. Tarascon, "Building better batteries",

Nature, Vol. 451, pp. 652-657, February 2008.

J-C. Roulet, et al, “Fabrication of Multilayer Systems

Combining Microfluidic and Microoptical Elements

for Fluorescence Detection”, Journal of

Microelectromechanical systems, Vol. 10, No. 4,

December 2001.

A Emadi, et al, “Vertically tapered layers for optical

applications fabricated using resist reflow”, J.

Micromech. Microeng., 19, 2009.

F. O’Neill, et al, “Photoresist reflow method of microlens

production Part I: Background and experiments”,

Optik 113, No. 9, pp. 391-404, 2002

BIODEVICES 2012 - International Conference on Biomedical Electronics and Devices

118