BIOFUNCTIONAL INTERFACES FOR BIOSENSING

APPLICATIONS

Saroja Mantha

1

, Virginia Davis

2

, Bryan Chin

1

and Aleksandr Simonian

1

1

Departments of Materials Research and Education Center, Auburn University, Auburn, AL 36849, U.S.A.

2

Department of Chemical Engineering, Auburn University, Auburn, AL 36849, U.S.A.

Keywords: Layer-by-layer assembly, CNTs, Multifunctional nanointerfaces, Biosensing, Detection, Glucose, Paraoxon.

Abstract: Layer-by-layer assembled CNTs customized with biopolymers has recently attracted a great attention as a

simple, robust and inexpensive method for creating nanocomposite thin films with a high degree of control

that may provide potentially powerful interfaces for multiple applications, including but not limited to

biomedicine and biosensing. Intercalation of oppositely charged polymers and catalytically active proteins

on the CNT surface allow assembling of unique nanointerfaces with the ability to detect single or multiple

analytes (Hitzky et al., 2005; Kumar and Swetha, 2010; Dujardin and Mann, 2002; Palin et al., 2005; Geetha

et al., 2006; Yan et al., 2010; Riccardi et al., 2006; Darder et al., 2005; Liu et al., 2004; Raravikar et al.,

2005; Du et al., 2004; Katz and Willner, 2004; Wang, 2005; Allen et al., 2007; Ghindilis et al., 1997; Joshi

et al., 2005; Chikkaveeraiah et al., 2009; Wang et al., 2006). The aim of this study is to design of

multifunctional systems for the detection of numerous compounds, such as glucose and OP neurotoxins, in

one platform using nanocomposite interface. A redox enzyme glucose oxidase (GOX) and organophosphate

hydrolase (OPH), a phosphotriesterase catalyzing degradation of phosphorus-containing toxins and

pesticides, were covalently immobilized on the multiwalled carbon nanotube (MWNT) surface using

EDC/NHS chemistry. Layer-by-layer assembly (LBL) of oppositely charged CNTs customized with

different biopolymers were examined on several substrates including glass or silicon slides and glassy

carbon electrode. The interface assembly were characterized using Thermogravimetric analysis, Raman

spectroscopy, Fourier Transform Infrared Spectroscopy, and scanning electron microscopy (SEM). The

catalytic activity of the biopolymer layers were characterized using absorption spectroscopy and

electrochemical analysis. Experimental results show that this approach yields an easily fabricated catalytic

multilayer with well-defined structures and properties for biosensing applications whose interface can be

reactivated via a simple procedure.

1 EXPERIMENTAL

1.1 Enzyme Immobilization

Enzyme immobilization on carboxylated MWNTs

was performed using carbodiimide chemistry. A

dispersed solution that was optically homogeneous

to the naked eye was obtained by mixing 2 mg of

MWNT in 5 ml of de-ionized water and sonicating

the mixture for 1 hr. Under fast stirring condition

EDC (20 mM) was then added to initiate the

coupling of NHS to the carboxylic groups on the

oxidized nanotubes and the mixture was stirred at

400 rpm for 30 min. The activated nanotube solution

was then filtered through a 200 nm polycarbonate

membrane and rinsed thoroughly with MES buffer

to remove excess EDC and NHS and re-dispersed in

protein solution (Pedrosa et al., 2010). After

incubating the mixture on a platform shaker at 4°C

for 9.5 h, the nanotube suspension was centrifuged

at 13200 rpm and rinsed with MES buffer solution

three times to remove unbound protein. The protein–

nanotube conjugate was finally suspended in CHES

buffer solution. Oxidized MWNT were separately

dispersed in PEI (1 mg/ml) by sonicating for 1 hr in

ultra sonication; excess polymer was then removed

by centrifugation at 13200 rpm for about 30 min.

Similarly 0.1 wt% of MWNT was dispersed in 0.1

wt% of DNA by sonication for 1 hr in ultra sonicator

bath followed by centrifugation at 13200 rpm for

about 30 min to remove unbound DNA.

1.2 Instruments

The samples of raw MWNT and oxidized MWNT

were analyzed by thermogravimetric analysis (TGA)

127

Mantha S., Davis V., Chin B. and Simonian A..

BIOFUNCTIONAL INTERFACES FOR BIOSENSING APPLICATIONS.

DOI: 10.5220/0003734901270131

In Proceedings of the International Conference on Biomedical Electronics and Devices (BIODEVICES-2012), pages 127-131

ISBN: 978-989-8425-91-1

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

using TGA Q500 (TA Instrument, USA) instrument

in air atmosphere over a temperature range from 30

to 800 °C at a heating rate of 10 °C/min. Raman

spectroscopy was performed using 785 nm laser

excitation (model SDL-8530, SDL Inc.) on

Reinshaw inVia Raman microcope system. FT-IR

measurements were taken for raw, oxidized MWNT

and MWNT-OPH. The samples were ground with

potassium bromide (KBr) to form a very fine

powder using a mortar and pestle. This powder was

then compressed into a thin and transparent pellet

and was placed into the sample holder for analysis.

Analysis was performed using a Shimadzu (Thermo-

Electron Corp., Waltham, MA) bench machine with

32 scans. A drop of MWNT-OPH solution was

placed on the glass slide, allowed to spread

uniformly, and dried over night. The slide was

examined by field emission scanning electron

microscopy equipped with an energy dispersive X-

ray analyzer (JEOL USA, Inc., Peabody, MA).

Cyclic voltammetric and amperometric

measurements were performed using a CV-50

potentiostat (BAS USA) connected to a personal

computer. A three-electrode configuration was

employed, consisting of modified/glassy carbon

(GC) electrode (3-mm diameter) serving as a

working electrode, whereas Ag/AgCl (3 M KCl) and

platinum wire served as the reference and counter

electrodes respectively. Batch electrochemical

experiments were carried out in a 2 ml voltammetric

cell at room temperature (25 °C).

2 LAYER-BY-LAYER ASSEMBLY

OF MWNT THIN FILMS

2.1 Slides

Glass or silicon slides were cleaned in concentrated

H

2

SO

4

/30% H

2

O

2

(3:1). The negatively charged

slides were alternately immersed in aqueous

dispersion of MWNT-PEI and MWNT-DNA. The

adsorption time of 15 min was considered sufficient

for the formation of MWNT monolayer. After each

layer deposition, the substrate was rapidly dried

using 50 psi air from a nozzle for 30 seconds. On top

of these cushioning layers, alternate layers of

MWNT-OPH and MWNT-DNA were deposited by

immersing the slide in aqueous solutions of MWNT-

OPH and MWNT-DNA for 15 min. The surface was

renewed by immersing the slides in MWNT-OPH

solution for 15 minutes. These solutions appear

stable even after a year.

2.2 Glassy Carbon Electrode

The glassy carbon electrode (GCE) was polished

with 0.10 and 0.05 μm alumina slurries and then

ultrasonically cleaned in water for 15 min. The GC

electrode was put into 1 M NaOH solution for 5 min

and potential of 1.2 V was applied to introduce

negative charges on the surface; this was followed

by two washings steps with distilled water. The

positively charged MWNT-PEI was adsorbed by

dipping the negatively charged GC electrode in an

aqueous solution of MWNT-PEI for 15 minutes, and

the MWNT-PEI/GC electrode was dried in nitrogen.

Using the same procedure, a layer of negatively

charged MWNT-DNA was adsorbed. Following

that, MWNT-OPH layer was adsorbed on the

(MWNT-DNA/MWNT-PEI)

4

/GC electrode by

dipping in MWNT-OPH solution, and further

bilayers were formed in the same way. The

modified electrode was stored at refrigerated

conditions until use. All the electrochemical

measurements were performed at room temperature.

A three electrode system containing platinum as

auxiliary electrode, an LbL modified glassy carbon

working electrode and a saturated Ag/AgCl

reference electrode was used. The buffer solution

was 50 mM PBS (pH 7.54). The regeneration of the

biosensor interface was realized by immersing the

sensor in a fresh solution of MWNT-OPH for 15

min.

3 RESULTS AND DISCUSSION

The objective of this work was to design the hybrid

catalytic interfaces based on the interaction of

anionic/cationic biomolecular layers structured with

MWNTs (Figure 1). The initial step requires

assembling of supporting bilayer of oppositely

charged MWNT- polyethyleneimine (PEI) and

MWNT-DNA. This allows for further adsorption of

positively charged complex of MWNT-protein

which adsorbs better on this cushioning support

rather than adsorbing directly on a solid support.

MWNT-PEI (+)

MWNT-DNA (-)

MWNT-DNA (-)

MWNT-PEI (+)

MWNT-DNA (-)

MWNT-OPH (+)

MWNT-OPH (+)

MWNT-PEI (+)

MWNT-DNA (-)

MWNT-DNA (-)

MWNT-PEI (+)

MWNT-DNA (-)

MWNT-OPH (+)

MWNT-OPH (+)

Figure 1: LbL interface design (not in scale): the initial

layers of MWNT-PEI and MWNT-DNA provide support

for subsequent layers of MWNT-OPH and MWNT-DNA.

BIODEVICES 2012 - International Conference on Biomedical Electronics and Devices

128

Confirmation of nanotube functionalization was

provided by Raman spectroscopy and FTIR analysis.

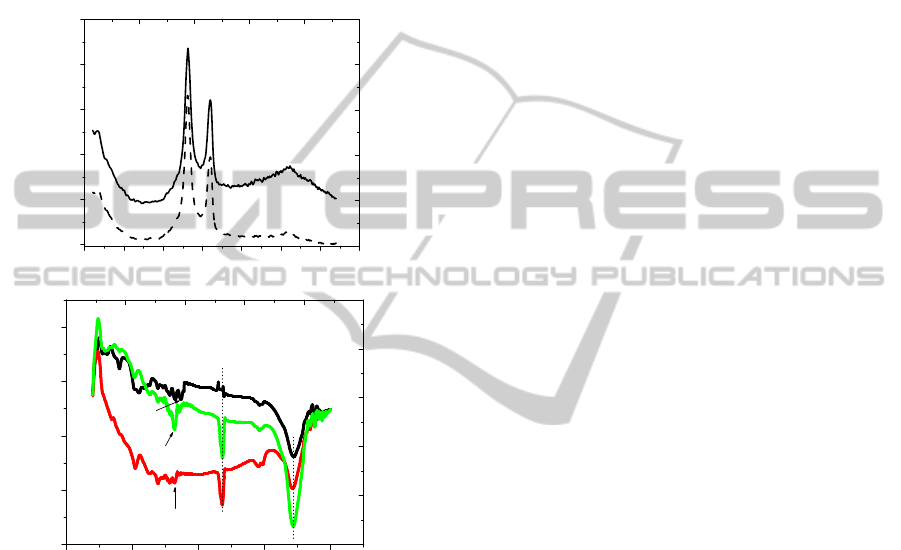

It is obvious from Figure 2a that the intensity of

characteristic peaks of MWNTs, namely, the D band

at 1305 cm

-1

and the G band at 1580 cm

-1

have

changed after functionalization. The D/G ratios of as

received MWNTs and oxidizes MWNTs were found

around 1.36 and 1.7 respectively, and the increased

D/G ratio corresponds to the increased degree of

functionalization.

0 500 1000 1500 2000 2500 3000 3500

0

500

1000

1500

2000

2500

Intensity (a.u.)

Raman shift (cm

-1

)

0 1000 2000 3000 4000

80

84

88

92

96

3450, OH

% Transmittance (a.u.)

Wave Number (cm

-1

)

1647, C=C

1737, C=O

2370, CH

2

1634, N-H

C

B

A

a

b

Figure 2: (a) Raman spectra of intact MWNT (––) and

oxidized MWMT (---) at 785 nm; (b) FT-IR spectra of (A)

intact MWNT, (B) MWNT-OPH and (C) oxidized

MWNT.

In order to get direct affirmation for the added

functional groups on the nanotube surfaces and

immobilization of OPH on oxidized MWNT, FT-IR

analysis was performed on as received MWNTs,

oxidized MWNT and MWNT-OPH samples. Figure

2b shows spectra of as received MWNT (A),

oxidized MWNT (B) and MWNT-OPH (C)

respectively. The oxidation of CNT by the

combination of H

2

SO

4

and HNO

3

results in the

formation of hydrophilic groups at defect sides and

ends,

−COOH, −C=O and −OH. All spectra for the

oxidized CNT displayed a peak at 1734 cm

-1

corresponding to –COOH and 1650 cm

-1

which

corresponds to –COO

-

. These results are consistent

with previous work on CNT oxidation; the exact

peak positions are the result of the extent of

oxidation. In addition, the increased in intensity of

3434 cm

-1

peak clearly confirms introduction of

more –OH groups after acid treatment. The

introduction of OPH results in the peaks at

3434 cm

-1

and 2857 cm

-1

are respectively attributed

to symmetric and asymmetric –CH

2

stretching.

However, after the enzyme immobilization on

oxidized MWNT, the 1734 cm

− 1

peak disappeared

and a new peak at ~1634 cm

− 1

was observed. This

can be attributed to the in-plane N–H molecular

vibrations of the amine group. It is believed that a

substitution reaction occurs and a –NH group

replaces the –OH group of the carboxylated

MWNTs after amide functionalization to form the –

CO–NH functional group.

The aim of this study is to design of

multifunctional systems for the detection of umerous

compounds in one platform. To demonstrate

catalytic properties of nanocomposite interface for

single analyte, organophosphate hydrolase (OPH)

enzyme was used in multilayer assembly. It is well

known that OPH hydrolyzes the phosphotriester

bond of the model OP paraoxon (λ

max

= 274 nm),

releasing the hydrolysis products p-nitrophenol

(PNP) (λ

max

= 405 nm) (Wang, 2005). Absorption

spectra show two peaks, one corresponding to

paraoxon at 274 nm and the peak at 405 nm

corresponds to PNP, the hydrolysis product formed

after exposure of the paraoxon solution to the slide

with MWNT-OPH interface. Presumably, the

activity of layers with catalytically active

biopolymer should be different from that for non-

catalytic layer. Slides with different number of

layers ending with MWNT-OPH or MWNT-DNA

were exposed to 0.1 μM paraoxon for 10 min and

the absorption spectrum was recorded. As shown in

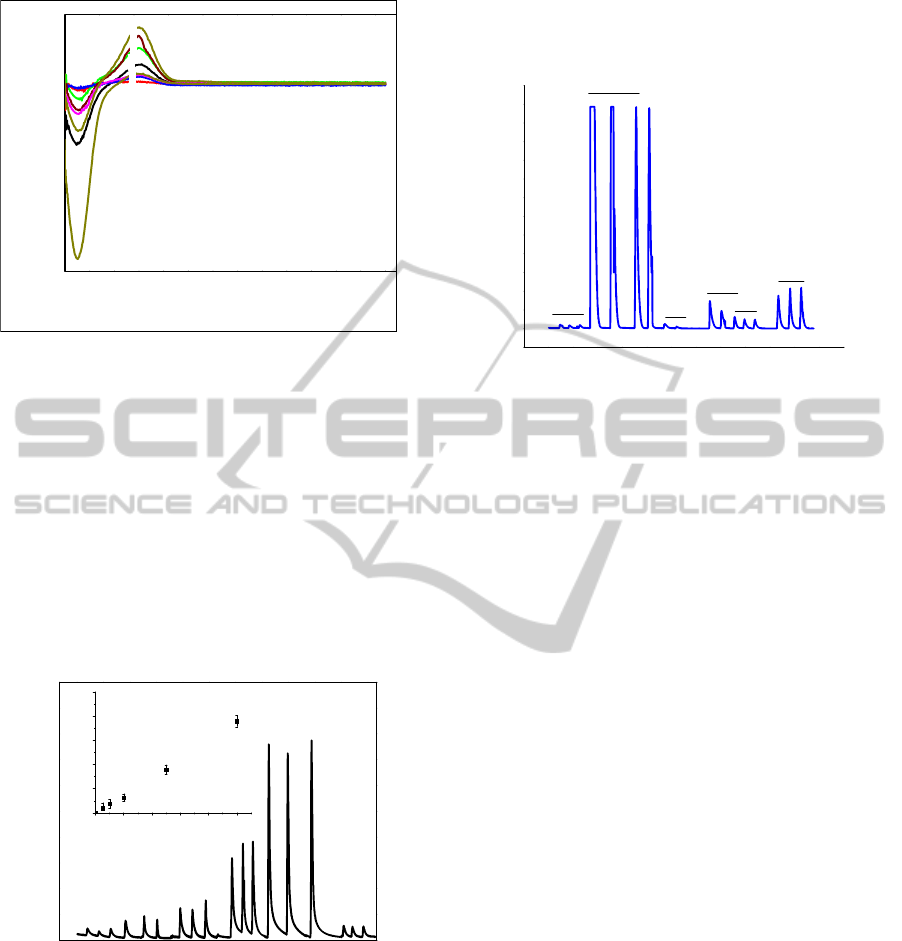

Figure 3 the absorption at 405 nm increased with the

number of layers with an MWNT-OPH ending,

indicating a raise in the enzymatic activity

proportional to the number of enzyme layers.

Contrary to that, absorbance was much lower for

layers ending with MWNT-DNA. These results

indicate that assembled multilayers are relatively

permeable for paraoxon, which penetrate into the

deeper layers and react with OPH. More detailed

investigation of layers density and deepness of

substrate penetration and permeability in such

interfaces are following.

Electrochemical studies of LBL on glassy carbon

electrode showed increase in response with the

subsequent addition of paraoxon and glucose.

BIOFUNCTIONAL INTERFACES FOR BIOSENSING APPLICATIONS

129

Figure 3: UV-Vis absorption spectra of LbL assembly for

different number of layers by exposing the surface to 0.1

mM Paraoxon for 10 minutes.

Figure 4, a shows flow-injection calibration data for

paraoxon over the concentration ranges of 0.5-10

μM, and the inset shows that current linearly

increased with the concentration in the range from 0

to 10 μM. The system showed excellent sensitivities

(y = -8x10

-10

+ 0.074 A/µM cm

-2

calculated from the

slopes of the linear part of the calibration curve). In

addition, based on an estimated signal-to-noise (S/N)

ratio of 3, the sensor has a detection limit of 77 nM

paraoxon.

0 300 600 900 1200 1500

0.0

0.2

0.4

0.6

0.8

1.0

0246810

0.0

0.2

0.4

0.6

0.8

1.0

I / μA

[Paraoxon] x μM

F

E

D

C

B

A

I / μA

Time (s)

Figure 4: Amperometry for LBL on GCE injecting

paraoxon only in sequence at 850 mV using 10 mM PBS

buffer.

To demonstrate catalytic properties of

nanocomposite interface for multiple analytes, two

enzymes, glucose oxidase (GOX) and

organophosphate hydrolase (OPH) were used in

multilayer assembly. Since OPH and GOX are

oppositely charged, it was possible to use them in

alternating layers for LbL assembly. As shown in

Figure 5, the biosensor generating an adequate

responses on the sequential injection of glucose and

paraoxon.

0 200 400 600 800 1000 1200

0

2

4

6

8

10

12

0.5 μM(P)

1

μM(P)

1 mM(G)

0.1

μM(P)

10 mM(G)

Current, μA

Time, Sec

0.1 μM(P)

Figure 5: Amperometry for LBL on GCE injecting

paraoxon and glucose in sequence at 850 mV using 10

mM PBS buffer. For glucose detection a redox mediator

Ferrocene methanol was added.

Since the catalytic activity of the interface is

decreasing in time, it is desirable to regenerate it

after significant reduction of the activity (Dumas et

al., 1989). In experiments with OPH the electrode

surface was renewed after 6 months of usage, when

the electrode response dropped to 45% of its original

value. We found a very easy way to restore up to

95% of the original response level by immersing the

electrode in the MWNT-OPH solution for 15

minutes. The most probable reason for gradually

reducing activity of the electrode might be that the

upper MWNT-OPH layer is depleting. Taking into

account that the activity of the surface ending with

MWNT-DNA is about 50% less than for MWNT-

OPH ending layer, we may conclude that after 6

months of use the electrode surface is losing

completely its MWNT-OPH upper layer, and the

negatively charged MWNT-DNA layer is exposing

to the solution. Then, immersing the electrode in the

MWNT-OPH solution allows restoration of active

MWNT-OPH layer and restoration of initial activity.

Thus, this simple procedure of interface re-activation

brings a significant advantage of the LbL assembly

over other technologies and allows using the

biosensor for very long time.

In conclusion, this approach to the generation of

multifunctional LbL biopolymer nanocomposite

interfaces is relatively simple, does not require

complex synthesis, and yields excellent catalytically

active interfaces appropriate for biosensing and

other applications.

300 400 500 600 700 800 90

0

-0.5

-0.4

-0.3

-0.2

-0.1

0.0

0.1

0.2

2

4

1

3

5

7

Absorbance (a.u.)

Wave length (nm)

6

BIODEVICES 2012 - International Conference on Biomedical Electronics and Devices

130

REFERENCES

Hitzky, E. R.; Darder, M.; Aranda, P. J. Mater.Chem.

2005, 15, 3650-3662.

Kumar, A. S.; Swetha, P. Langmuir 2010, 26, 6874-6877.

Dujardin, E.; Mann, S. Adv. Mater. 2002, 14, 775-788.

Palin, E.; Liu, H.; Webster, T. J. Nanotechnology 2005,

16, 1828-1836.

Geetha, S.; Rao, C. R. K.; Vijayan, M.; Trivedi, D. C.

Anal. Chim. Acta 2006, 568, 119-125.

Yan, J.; Pedrosa, V.A.; Simonian, A. L.; Revzin, A. ACS

Appl. Mater. Interfaces, 2010, 2, 748-755.

C. D. Riccardi, H. Yamanaka, M. Josowicz, J. Kowalik, B.

Mizaikoff, C. Kranz, Anal. Chem. 2006, 78, 1139-

1145.

Darder, M.; Blanco, M. L.; Aranda, P.; Leroux, F.; Hitzky,

E. R. Chem. Mater. 2005, 17, 1969-1977.

Liu, T. X.; Phang, I. Y.; Shen, L.; Chow, S. Y.; Zhang, W.

D. Macromolecules 2004, 37, 7214-7222.

Raravikar, N. R.; Schadler, L. S.; Zhao, Y. P.; Wei, B. Q.;

Ajayan, P. M. Chem. Mater. 2005, 17, 974-983.

Du, F. M.; Scogna, R. C.; Zhou, W.; Brand, S.; Fischer, J.

E.; Winey, K. I. Macromolecules 2004, 37, 9048-

9055.

Katz, E.; Willner, I. ChemPhysChem 2004, 5, 1084-1104.

Wang, J. Electroanalysis 2005, 17, 7-14.

Allen, B.; Kichambare, P.; Star, A. Adv. Mater. 2007, 19,

1439-1451.

Ghindilis, A. L.; Atanasov, P.; Wilkins, E. Electroanalysis

1997, 9, 661-674.

Joshi, P. P.; Merchant, S. A.; Wang, Y.; Schmidtke, D. W.

Anal. Chem. 2005, 77, 3183-3188.

Chikkaveeraiah, B. V.; Bhirde, A.; Malhotra, R.; Vyomesh

P.; Silvio Gutkind, J.; Rusling, J. F. Anal. Chem. 2009,

81, 9129-9134.

Wang, Y. D.; Joshi, P. P.; Hobbs, K. L.; Johnson, M. B.;

Schmidtke, D. W. Langmuir 2006, 22, 9776–9783.

Pedrosa, V. A.; Paliwal, S.; Balasubramanian, S.; Nepal,

D.; Davis, V. A.; Wild, J.; Ramanculov, E.; Simonian,

A. L. Colloids and Surf., B 2010, 77, 69-74.

Dumas, D. P.; Wild, J. R.; Raushel, F. M. J. Biol. Chem.

1989, 264, 19659-19665.

BIOFUNCTIONAL INTERFACES FOR BIOSENSING APPLICATIONS

131