INCUBATION TYPE PLANAR PATCH CLAMP BIOSENSOR

Basic Performances

Tsuneo Urisu

1,2

, Hidetaka Uno

1,2

, Zhi-Hong Wang

1,2

, Senthil Kumar Obuliraj

1,2

, Noriko Takada

2,3

,

Masaki Aoyama

2,3

, Mitsukazu Suzui

2,3

, Toshifumi Asano

2,4

, Toru Ishizuka

2,4

and Hiromu Yawo

2,4

1

FIRST Research Center for Innovative Nanobiodevice, Nagoya University,

Furo-cho, Chikusa-ku, 464-8603, Nagoya, Japan

2

JST, CREST, 5, Sanbancho, Chiyoda-ku, 102-0075, Tokyo, Japan

3

Institute for Molecular Science, Myodaiji, 444-8585, Okazaki, Japan

4

Graduate School of Life Sciences, Tohoku University, 2-1-1Katahira, Aoba-ku, 980-8577, Sendai, Japan

Keywords: Planar patch clamp, Ionchannel, Biosensor, HEK293, TRPV1, PMMA.

Abstract: The biosensors based on the incubation type planar patch clamp method was developed and the basic

properties were investigated. Usefulness of light-gated ionchannel method on the performance of the device

was confirmed. The excess current noise and the thermal noise due to the micropore resistance and the seal

resistance were the main sources of the noise, and the noise level of the developed biosensor was 7 pA at the

1 kHz low pass filter. This value is slightly larger than the single ionchannel current level (~4pA) of TRPV1.

We consider that the developed device has a sufficient performance for the whole cell measurements, and

extremely suitable for the high throughput screening application with neural network, in which incubation

function is essentially necessary.

1 INTRODUCTION

Although the patch-clamp method using the pipette

is now in practical use, it is not suitable for

miniaturization and high throughput screening

applications, since the measurement system is large

and requires high level of skills for operations. It is

expected that the breakthrough for these technical

problems can be realized by the planarization of the

device. For the planar typed ion channel biosensor,

glass (Fertig, 2002), Si (Sordel, 2006, Matthews,

2006, Pantoja, 2004), quartz (Sett, 2003) and a

silicon elastomer PDMS (Li, 2006), etc. have been

reported as the substrate materials. And for Si, it has

been considered that the background noise current is

large due to the free charge carrier density in the

substrate. However, we have recently demonstrated

that the noise current can be significantly reduced by

using silicon-on-insulator (SOI) or polymethyl

methacrylate (PMMA) substrate.

Commercialized planer patch clamp devices,

however, can not be used in a system that requires

long incubation periods. New functional analysis

and/or screening devices could be realized by adding

an incubation function to the planar patch clamp

method, and these would be especially useful in

applications such as in vitro systems of neurons and

neural networks using dissociated cultured neurons

(Tao, 2000, Taylor, 2010, Reska, 2008, Erickson,

2008). Moreover, the planar patch clamp method

enables simultaneous measurement of multi-point

ion channel currents and advanced 2-D bio-imaging.

We have developed an incubation type of planar

patch clamp device and demonstrated its operation

using TRPV1-expressing HEK293 cells and

capsaicin as a ligand molecule. However, detailed

investigation about the basic properties have not yet

been done.

The recently developed light-gated ion-channel

method is extremely suitable for the investigation of

neural cell and/or neural network functional analysis

due to its excellent time and space resolutions

(

Petreanu, 2007). It is also suitable to the application

for the investigation of the basic property of the

ionchannel biosensors. Concerning the application

of light-gated ion-channel in the planar patch clamp

method, however, no investigation has been done, in

spite of its extreme importance.

In this work, we have investigated the basic

properties such as noise and sensitivity of the

143

Urisu T., Uno H., Wang Z., Obuliraj S., Takada N., Aoyama M., Suzui M., Asano T., Ishizuka T. and Yawo H..

INCUBATION TYPE PLANAR PATCH CLAMP BIOSENSOR - Basic Performances.

DOI: 10.5220/0003764301430148

In Proceedings of the International Conference on Biomedical Electronics and Devices (BIODEVICES-2012), pages 143-148

ISBN: 978-989-8425-91-1

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

incubation type planar patch clamp biosensor.

Usefulness of light-gated ionchannel on the

incubation type planar patch clamp method was also

confirmed. Furthermore, the excellent performace of

this biosensor has been examined by detecting

capsaicin using TRPV1-expressing HEK293 cells.

2 MATERIALS AND METHOD

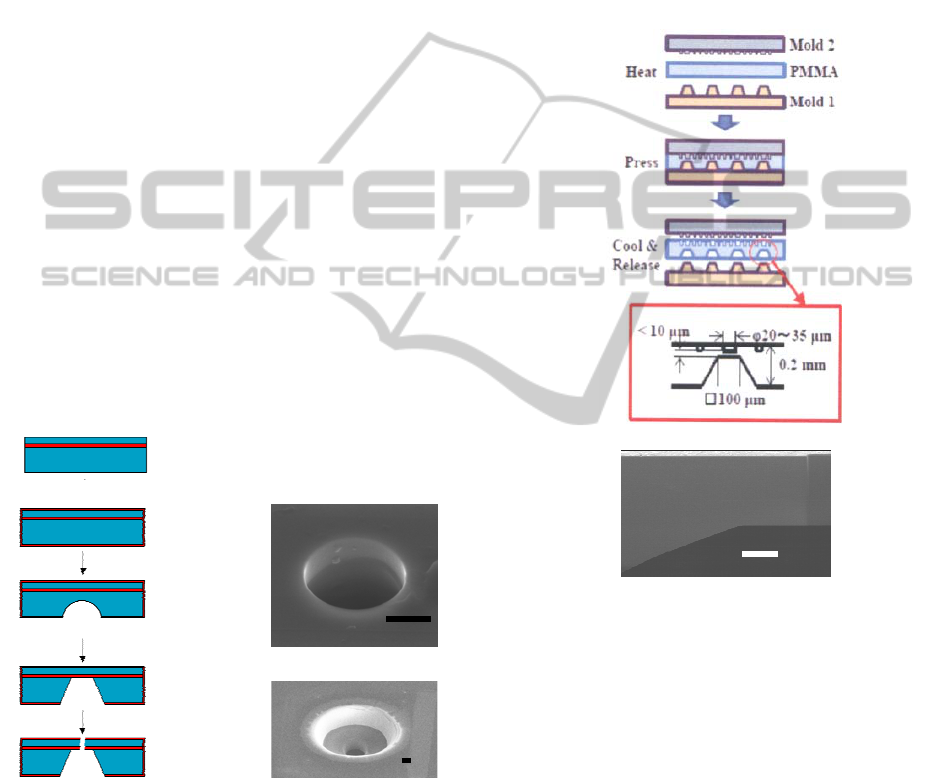

2.1 Fabrication of Biosensor Chip

2.1.1 Si Chip

Si on insulator (SOI) substrates were used to make

the Si sensor chip s. The fabrication process of the

chip is shown in Fig. 1. A thermal oxidation layer of

about 1μm thickness was formed on the substrate

surface by the wet thermal oxidation at 900°C using

a water-saturated O

2

flow, after which a large well

on the reverse surface was made by diamond

drilling. A pyramid-shaped hole that reached the

buried SiO

2

layer was formed by etching in 8% (v/v)

tetramethylammonium hydroxide (TMAH) at 90°C

for about 40 min. A micro-pore with a diameter of 1

~ 2 μm was made on the silicon membrane by

focused ion beam (FIB) milling from the reverse

side, as shown in Fig. 1.

Figure 1: Fabrication process of the Si chip (left) and the

top side (right upper) and back side (right lower) view of

the chip. Scale bar is 0.5 μm.

2.1.2 Plastic (PMMA) Chip

Plastic substrate has several advantages such as

lower cost, easiness in 3D micro structure

formation and in surface chemical

modifications. We have used PMMA for the

substrate material of multi-channel devices.

Fabrication process and the cross sectional view

of the chip are shown in Fig. 2a and b,

respectively. The basic structure of the

substrate was formed by both side hot

embossing, and the micropore was formed by

FIB. The micro fluidic structure was formed on

the upper surface of the substrate, and the

pipette solution well was formed at the lower

side.

a)

b)

Figure 2: Fabrication process of PMMA chip (a) and the

cross sectional view of the thin film region of the pipette

solution well part observed by scanning electron

microscopy (b). Scale bar is 5 μm.

The mold of brass for forming the pipette

solution wells (Mold 1 in Fig.2a), by which thin film

structures with 5~10 μm thickness were formed, was

fabricated by ultra-precision machining equipment

of Dr Omori’s group, RIKEN Japan . Upper mold

of nickel (Mold 2 in Fig.2a) for the micro fluidic

structure formation was fabricated by

electroforming, for which the master mold was

formed by the photolithography using positive resist

on the Si substrate.

Oxidation

Diamond

TMAH

etchin

BIODEVICES 2012 - International Conference on Biomedical Electronics and Devices

144

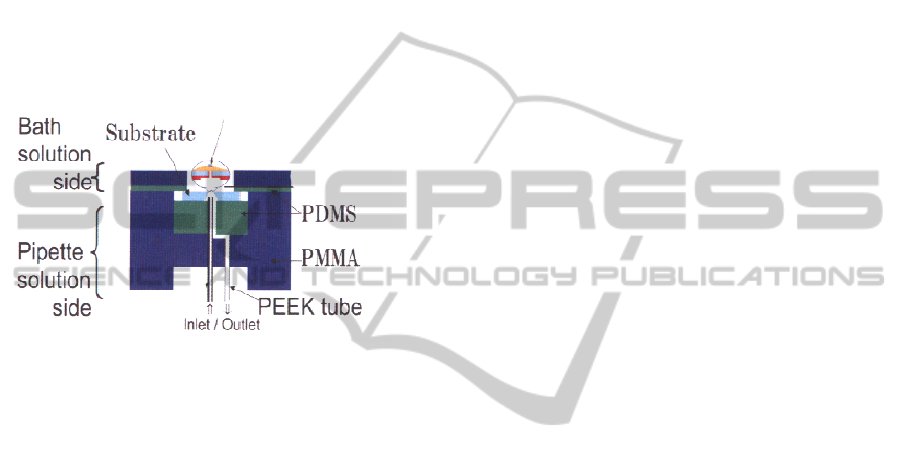

2.2 Biosensor Chamber and the Stable

Electrode

The 7 x 7 mm

2

(Si) or 11 x 11 mm

2

(PMMA) chip

was sandwiched by PDMS plates, and the sensor

structure was constructed as is shown in Fig. 3. We

fabricated the stabilized AgCl/Ag electrodes, where

the AgCl/Ag wire was inserted into glass tube of 1

mm inner diameter filled with the saturated KCl and

AgCl solution and the top of the glass tube was

sealed by the Vycor glass (Corning). We used these

stabilized electrodes for both upper side (bath

solution , ground) and lower side (pipette solution)

electrodes of the biosensor.

Cell

Figure 3: Schematic structure of the ion channel biosensor.

2.3 Expression of ChR2 and ChRWR

We used in this work channelrhodopsin 2 (ChR2)

and the chimeric channelopsin between chop1 and

chop2, which we call channelrhodopsin/wide

receiver (ChRWR), as light-gated ionchannel

molecules. HEK293 cells, which were a generous

gift from Mr. Minoru Wakamori at Tohoku

University, were cultured at 37℃ and 5% CO

2

in

Dulbecco’s modified Eagle’s medium (Sigma)

supplemented with 10% fetal bovine serum and

transfected with cDNA of channelrhodopsin-Venus

using Effectene transfection reagent (Qiagen, Tokyo,

Japan) according to the manufacturer’s instructions.

After cloning twice with the addition of G418 in a

10 cm dish, single colonies with bright Venus

fluorescence were selected by using a cloning

cylinder IWAKITE-32 (Asahi Glass Co., LTD,

Japan) and cultured in a medium containing G418

until they were confluent in the dish.

2.4 Culture in Biosensor

The surface of the sensor chip was coated with

extracellular matrixes (ECMs), collagen type 4

(BD), which was diluted using 1 mM HCl to 100

μg/ml. 50 μl of the solution was dropped on the

substrate surface, followed by incubation for 2 ~ 4 h

at room temperature. At this stage, the surface

densities of the ECM were about 3 ~ 5 μg/cm

2

. After

removing excess solution, the substrate was rinsed

with sterilized water, dried under a gentle nitrogen

stream, and kept sterile before use. HEK293 cells

were cultured in dishes filled with the medium under

the conventional incubating conditions, i.e., 37°C

and 5% CO

2

. The culture medium was supplemented

with DMEM to which 10% (v/v) FBS, 1% (v/v)

GlutamaxTM (Gibco), and 0.5% (v/v)

penicillin/streptomycin (Gibco) were added. After

cells were detached from the culture dishes, the cell

suspension was seeded at a density of 100 ~ 300

cells/mm

2

on the chip coated with ECM. Channel

current was measured after about 70% confluence

was reached in the biosensor.

2.5 Measurement of Light-gated

Ionchannel Current

The electrical measurement systems were almost the

same as those used in conventional pipette patch-

clamp experiments. The culture medium was

replaced with buffer. We used several of the buffer

solutions reportedly used in experiments on ChR2.

A typical bath solution in the upper chamber

contained (in mM): 140 NaCl, 3 KCl, 10 4-(2-

hydroxyethyl)-1–piperazineethanesulfonic acid

(HEPES), 2.5 CaCl

2

, 1.25 MgCl

2

, and 10 glucose at

pH 7.4 (with HCl). The lower chamber solution

(pipette solution) contained (in mM): 40 CsCl, 80

CsCH

3

SO

4

, 1 MgCl

2

, 10 HEPES, 2.5 MgATP, 0.2

Na

2

EGTA, (pH 7.4). All data were recorded using a

patch-clamp amplifier (Axopatch 200B) at room

temperature. Data were obtained at a 1-kHz cutoff

frequency and an output gain of 1 mV/pA, and they

were analyzed using pClamp 9.2 software. For

whole-cell current recordings, sub-nm conductive

pores through the cell membrane, which electrically

connected the inside of the cell to the lower

chamber, were formed by applying nystatin (Sigma)

solutions to the lower chamber. The nystatin stock

solution was prepared by dissolving nystatin in 1 ml

of methanol and successively adding 45 μl of HCl (1

M) and 45 μl of NaOH (1 M), which was then

diluted with the lower chamber solution to final

concentrations of 100-200 μg/ml before use. The

formation of the whole-cell arrangement was

confirmed by there being a capacitance increase of

about 6 pF in a time interval of 5-10 min after

addition of the nystatin solution to the lower

chamber. The laser beam from the semiconductor

laser with a 473-nm peak wavelength and 3.2-mW

INCUBATION TYPE PLANAR PATCH CLAMP BIOSENSOR - Basic Performances

145

maximum output power (Sumitomo Osaka Cement

Co.,Ltd) was guided by optical fiber and focused

with a micro lens with a 26.5 mm focusing length

under the fluorescence microscope’s objective lens

(OLYMPUS). The diameter of the laser beam at the

focusing point was 30 - 100 μm.

3 RESULTS AND DISCUSSION

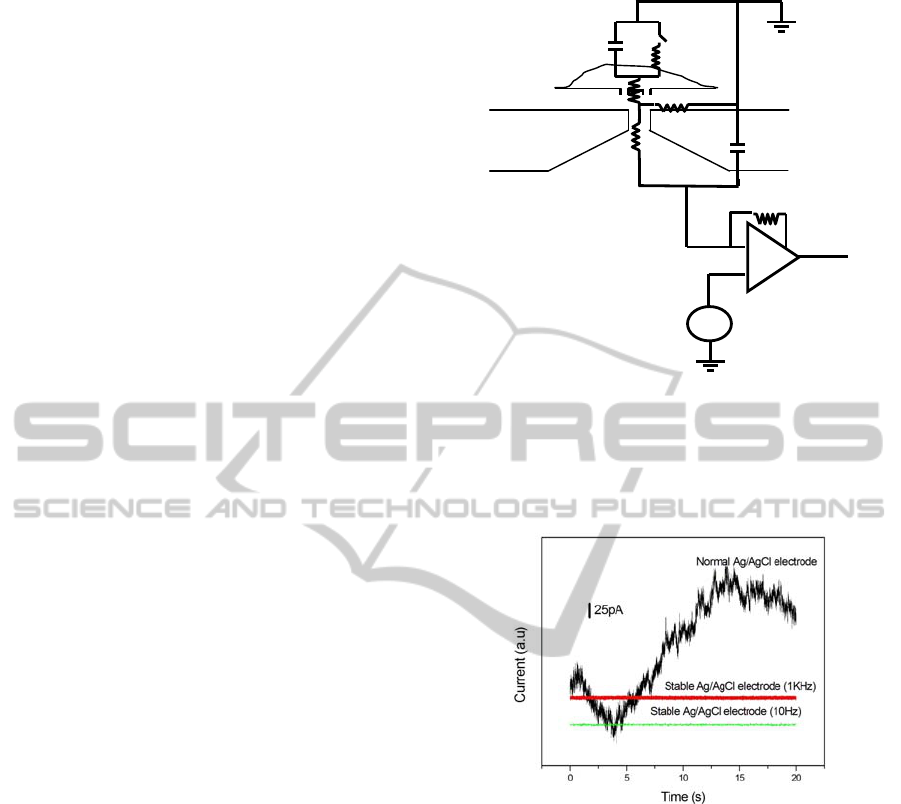

3.1 Noise Properties of Incubation

Type Planar Patch Clamp Biosensor

We consider the noise properties using the

equivalent circuit of the planar patch clamp

biosensor shown in Fig.4. The first noise source is

the current noise (I

h

) resulting from the interaction

of the head-stage input voltage noise (e

n

), the input

capacitance (C

t

) and the frequency bandwidth of the

circuit (B), described by eq. (1) (Mayer, 2003).

In

the following, all current noises are given by root-

mean-square (rms) values.

I

h

2

= (4/3)e

n

2

π

2

C

t

2

B

3

(1)

C

t

= C

m

+C

s

(2)

We used a value of e

n

= 2.3 x 10

-9

V Hz

-0.5

reported for the cooled type capacitor feedback

patch clamp amplifier (Axopatch 200B). C

t

is the

total input capacitance given by eq. (2), C

m

is the

membrane capacitance and Cs is the capacitance of

the substrate. The thermal voltage noises (Johnson

voltage noise) due to the access resistance R

a

and

seal resistance R

j

cause the current noise, I

Ra

and I

Rj

,

respectively as shown in eq. (3) (Mayer, 2003). The

resistances of the ion channels, R

m

and R

p

are usually

sufficiently larger than R

a

and R

j

, thus the

contribution to the thermal noise can be ignored. In

the incubation type planar patch clamp, contribution

of the seal resistance to the thermal noise often can’t

be ignored.

I

R

2

= 4kTB/R R = R

a

or R

j

(3)

where, k is the Boltzmann constant (k = 1.38 x 10

-23

J K

-1

), T is the absolute temperature.

In the case of the low seal resistance region, 1/f

noise called excess noise, which possibly is

generated by the current flowing at the narrow micro

pore region, becomes important. The spectral

density of the excess noise current, S

ex

2

, is given by

S

ex

2

= KI

2

/fR

a

2

(4)

Cm

Rm

R j

Ra

Rp

Vm

Cs

Sw

Figure 4: Equivalent circuit of the planar patch clamp

biosensor. C

m

: cell membrane capacitance, Sw:

ionchannel, R

m

, R

p

: resistance of corresponding ion

channel, R

j

: seal resistance, R

a

: access resistance, C

s

:

capacitance of the substrate, V

m

: applied membrane

voltage.

Figure 5: Observed current noise in the biosensor system

shown in Fig. 3 using PMMA substrate, for normal and

stabilized AgCl/Ag electrodes.

Where K is a constant and I is total current which is

approximately given by V

m

/(R

j

+ R

a

). The total rms

value of the current noise (I

t

) can be calculated

using eq. (5).

I

t

= ( I

h

2

+ I

Ra

2

+ I

Rm

2

+ I

ex

2

)

1/2

(5)

Other than these intrinsic noise, fluctuation of

the offset voltage (

Δ

V

m

) of the electrode, which

often becomes larger than 1 mV, causes the

significant fluctuation of the base line. So it is often

important to use the stablized electrode in the

incubation type planar patch clamp as shown in Fig.

5. Here we calculate the noise current for the typical

cases, C

t

= 20 pF, B = 10

3

Hz, R

a

= 2 MΩ and R

j

=

BIODEVICES 2012 - International Conference on Biomedical Electronics and Devices

146

10 MΩ, I

h

= 0.005 pA, I

Ra

= 2.8 pA, and I

Rj

= 1.2 pA

are obtained. So, if I

ex

2

is ignored, the total rms

value of the current noise is evaluated to be I

t

= 3.1

pA. This value is slightly smaller than the observed

value ~ 7 pA (1kHz) shown in Fig. 5. The

difference, ~ 4 pA, may be due to the excess noise,

since 1/f noise is dominant in the present seal

resistance region (data are not shown).

From these analysis, it is concluded that the

measurement of the whole cell mode which usually

gives the current level of several tens pA or larger

can be easily attained by using the stable electrode.

It is, however, necessary to increase the seal

resistance by about one order of magnitude (~100

MΩ) to realize the single channel recordings in our

system.

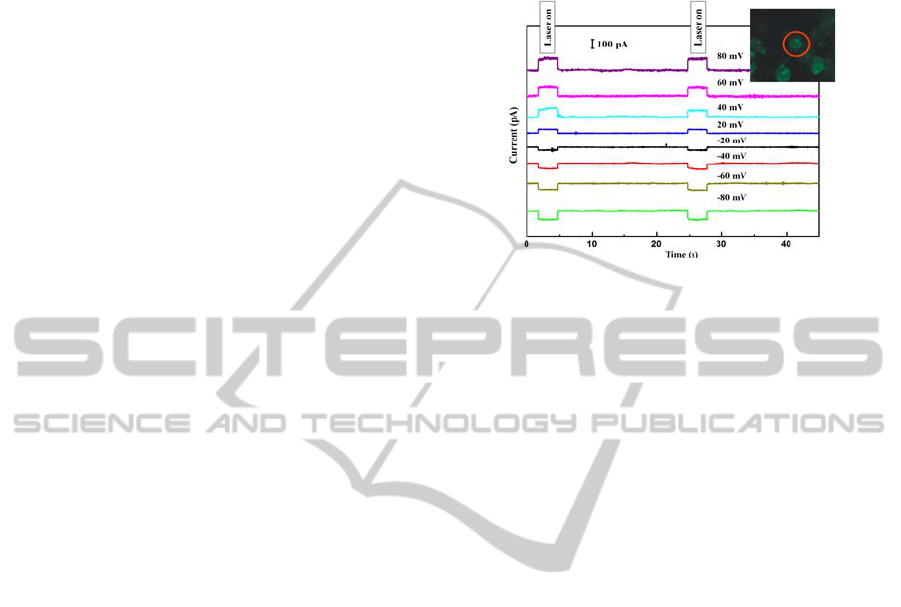

3.2 Light-gated Ion Channel Method in

the Incubation Type Planar Patch

Clamp Biosensor

The recently developed light-gated ion channel

method has brought a significant progress into the

neural network analysis field due to its temporal and

spatial high resolutions. Since the in vitro neural

network analysis and its application to the high

throughput screening is an important application of

the incubation type planar patch clamp method, here

we investigate the basic property of the light-gated

ion channel on the incubation type planar patch

clamp biosensor.

ChRWR-expressing HEK293 cells were seeded

on the chip of the incubation type planar patch

clamp biosensor. After the cells became almost

completely confluent, we observed the

characteristics of the laser stimulated channel

currents as shown in Fig. 6. The observed channel

current pulse signals were similar in shape and

signal to noise ratio to those observed in the pipette

patch clamp method, although the seal resistance

was much smaller than a giga-ohm. These data

suggest that light-gated method is useful not only in

the neural network analysis but also useful in the

performance test of the biosensor due to its

simplicity in handling.

3.3 Biosensor Operation using

TRPV1-expressing HEK293 Cells

The unique points of ion channel biosensor is highly

selective direct responses to various kind of ligand

molecules and also sensitive responses to physical

stimuli. Ion channels are also important drug targets

and the biosensor is a potentially unique device for

high throughput drug screening. It also finds its

application in the detection of biological warfare

agents (Bayley, 2001).

Figure 6: Observed ion channel current under voltage

clamp of 473-nm laser irradiation with ChRWR-

expressing HEK293. Ion channel current wave forms

depend on the applied membrane potentials.

TRPV1 receptor, a nonspecific cation channel

with preference for Ca

2+

, is mainly expressed in

sensory nerves from peripheral terminal to central

endings, which can be activated by vanilloids such

as capsaicin. Capsaicin is the pungent ingredient of

hot pepper, which elicits a sensation of burning pain

by selectively activating sensory neurons to transfer

the noxious stimuli to the central nervous system

(Caterina, 1997).

We have constructed ionchannel biosensor using

TRPV1-expressing HEK293 cells (gift from Prof.

Tominaga at National Institute for Physiological

Sciences) and applied to the capsaicin detection.

The surface of the SOI sensor chip were coated

with collagen type 4. After the cell covered on the

pore and spread, the resistance R

j

of the cleft

between the cell membrane and substrate surface

was measured (10.2 MΩ), then the perforated

whole-cell configuration was formed by the

application of nystatin to the pipette solution side.

Then, the whole-cell current of TRPV1-expressing

HEK 293 cell activated by capsaicin application was

recorded as shown in Fig. 7.

The concentration of capsaicin was 3.3 μM. The

desensitization was observed in the second injection

of capsaicin (Caterina, 1997). The noise level of our

experimental station was 7 pA using 1 kHz low pass

filter (Fig. 5). The magnitude of the single channel

current of TRPV1 is observed by pipette patch

clamp method to be about 4pA at the membrane

voltage +60 mV (Caterina, 1997). So we think that

single channel recording maybe realized even in our

incubation type planar patch clamp system by

several times increase of the seal resistance.

INCUBATION TYPE PLANAR PATCH CLAMP BIOSENSOR - Basic Performances

147

CAP

Figure 7: Whole cell channel current record of TRPVI

expressed on HEK293 cell by capsaicin stimulations

measured by ion channel biosensor based on the

incubation type planar patch clamp method.

4 CONCLUSIONS

Ion channel biosensor based on the incubation type

planar patch clamp method was developed and the

basic properties were investigated. Due to the

existence of ECM protein at the cleft between the

cell membrane and the substrate surface near the

miropore, it is not easy to realize the high seal

resistance (giga-ohm seal). In the present case using

collagen 4 as ECM, the seal resistance was usually

about 10 MΩ, and the noise level was 7 pA with the

1 kHz low pass filter. The main noise sources were

excess current noise and the thermal noise generated

at micro pore resistance (R

a

) and the seal resistance

(R

j

). All these noises can be reduced by increasing

the seal resistance. Operation of the light-gated ion

channel, ChRWR, was investigated by the

incubation type planar patch clamp method using

laser (λ = 473 nm) stimulations. The channel

current profile and its membrane potential

dependence well agreed to the reported data

measured by pipette patch clamp method. So we

think that light-gated method is also useful in the

neural network function analysis and high

throughput screening application based on the

incubation type planar patch clamp method, and also

useful in the simple performance check of these

devices. The biosensor operation was examined

using TRPV1-expressing HEK293 cells. Quite high

sensitivity was confirmed. But for the single channel

recording, more than several times improvement of

the seal resistance is required.

ACKNOWLEDGEMENTS

We appreciate Dr. Hitoshi OHMORI and Mr.

Yosuke HACHISU at RIKEN for their support in

making brass mold by ultra-precision machining

equipment.

REFERENCES

Bayley, H., Cremer, P.S., 2001. Nature 413, 226.

Caterina, M. J., Schumacher, M. A., Tominaga, M.,

Rosen, T. A., Levine, J. D., Julius, D., 1997. Nature

389, 816.

Erickson, J., Tooker, A., Tai, Y. C., Pine, J., 2008.,

Journal of Neuroscience Methods 175, 1.

Fertig, N., Blick, R. H., Behrends, J. C., 2002. Biophys. J.

82,3056.

Li, X. H., Klemic, K. G., Reed, M. A., Fred, J., Sigworth,

F. J. 2006. Nano Letters 6 , 815.

Matthews, B., Jack, W., 2006. J. Microelectromech. 15

214.

Mayer, M., Kriebel, J. K., Tosteson, M. T., Whitesides, G.

M., 2003. Biophysical J. 85, 2684.

Pantoja, R., Nagarah, J. M., Starace, D. M., Melosh, N. A.

Blunck, R., Bezanilla, F., Heath, J. R., 2004. Biosens.

Bioelectron. 20, 509.

Petreanu, L., Huber, D., Sobczyk, A., Svoboda, K., 2007,

Nature Neurosci. 10, 663.

Reska, A., Gasteier, P., Schulte, P., Moeller, M.,

Offenhäusser, A., Groll, J., 2008. Advanced Materials

20,2751.

Sett, A, Burkhardt, C., Weber, U., Stiphout, P.V., Knott,

T. 2003. Receptors and Channels 9, 59.

Sordel, T., Garnier-Raveaud, S., Sauter, F., Pudda, C., F.

Marcel, F., Waard, M. D., Arnoult, C., Vivaudou, M.,

Chatelain, F., Picollet-D’hahan, N., 2006. J.

Biotechnol. 125, 142.

Tao, H. W., Zhang, L. I., Bi, G., Poo, M., 2000. J.

Neurosci. 20, 3233.

Taylor, A. M., Dieterich, D. C., Ito, H. T., Kim, S. A.,

Schuman, E. M. 2010. Neuron 66, 57.

BIODEVICES 2012 - International Conference on Biomedical Electronics and Devices

148