SmarTTransfuser

A Biochip System for the Final ABO Compatibility Test

Karine Charrière

1

, Jean Sebastien Guerrini-Chappuis

1

, Bruno Wacogne

1,2

, Alain Rouleau

2

,

Celine Elie-Caille

2

, Christian Pieralli

2

, Lionel Pazart

1

, Pascal Morel

3

and Wilfrid Boireau

2

1

INSERM-CIT 808, Besançon University Hospital, Besançon, France

2

Institute FEMTO-ST, University of Franche-Comté, Besançon, France

3

French Blood Transfusion Center, Besançon, France

Keywords: Blood transfusion, Lab-on-chip, Microarray, Nanobiotechnology, Surface functionalization, Biosensor,

Bedside test, ABO compatibility, Crossmatch.

Abstract: Before each transfusion of red blood cell concentrate, a final ABO compatibility test is carried out at the

patient's bedside on a piece of card and interpreted visually. Despite this ultimate test, transfusion accidents

still occur due to group incompatibility, which can be lethal. In order to improve this test, we have

developed a specific device based on microarrays for the validation of a smart and safe transfuser in the

context of critical transfusional situations. This miniaturized device incorporates a biochip to analyze ABO

compatibility in order that the hemagglutination reaction of red blood cells with IgMs in solution be

replaced by specific capture and concentration of IgMs on microarrays. Results indicate that a specific

immunocapture is obtained with globular concentrates and with different total blood. Smarttransfuser is a

smart device developed in collaboration with the French Blood Transfusion Center for the optimization at

the patient’s bedside of an ultimate test prior to transfusion.

1 CONTEXT

A variety of blood components are available

including red cell concentrate (RCC), platelet

concentrate (PC) and plasma.

About 24 million components were transfused

and about 15 million whole blood or RCC were

transfused in the USA in 2008 (National Blood

Collection and Utilization Survey 2009). In France,

almost 3 million labile blood products, of which

79% are RCC, are distributed annually for just over

500.000 patients who are transfused.

In 2009 there were 3 patient deaths following a

reaction to ABO-incompatible blood in France, and

this reaction may have contributed to the deaths.

Last year, there were two major ABO-incompatible

reactions, one of which led to death (Afssaps, 2010).

In the UK, a total of 14 ABO-incompatible red cell

transfusions were given, 10 resulting from bedside

administration errors, 2 from wrong blood in tube

phlebotomy errors and 2 due to laboratory errors in

which the wrong sample was used for crossmatch

(SHOT, 2009). According to the Fatalities Reported

to the FDA following blood collection, in combined

fiscal years 2005 through 2010, ABO incompatibili-

ties account for 9% of the transfusion-related

fatalities reported. There was a decrease in ABO

haemolytic reactions from 4 in FY2009 to 2 in

FY2010 (FDA, 2010).

Attentive analysis of these attribution errors has

shown that these mistakes are often multiple,

occurring throughout the transfusional process.

2 ULTIMATE CONTROL

Before each transfusion of RCC in France, a final

ABO compatibility test is carried out at the patient's

bedside on a piece of card and interpreted visually.

The final test, carried out by nurses or doctors, aims

to verify the identity of the recipient (Figure 1). It

also aims to verify compatibility between ABO

grouping and the red blood cell units to be

transfused. This final compatibility test at the

patient’s bedside, the last security measure, is

frequently called into question and other countries

257

Charrière K., Sebastien Guerrini-Chappuis J., Wacogne B., Rouleau A., Elie-Caille C., Pieralli C., Pazart L., Morel P. and Boireau W..

SmarTTransfuser - A Biochip System for the Final ABO Compatibility Test.

DOI: 10.5220/0003852402570262

In Proceedings of the International Conference on Biomedical Electronics and Devices (BIODEVICES-2012), pages 257-262

ISBN: 978-989-8425-91-1

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

choose other identification methods before

administering red blood cells.

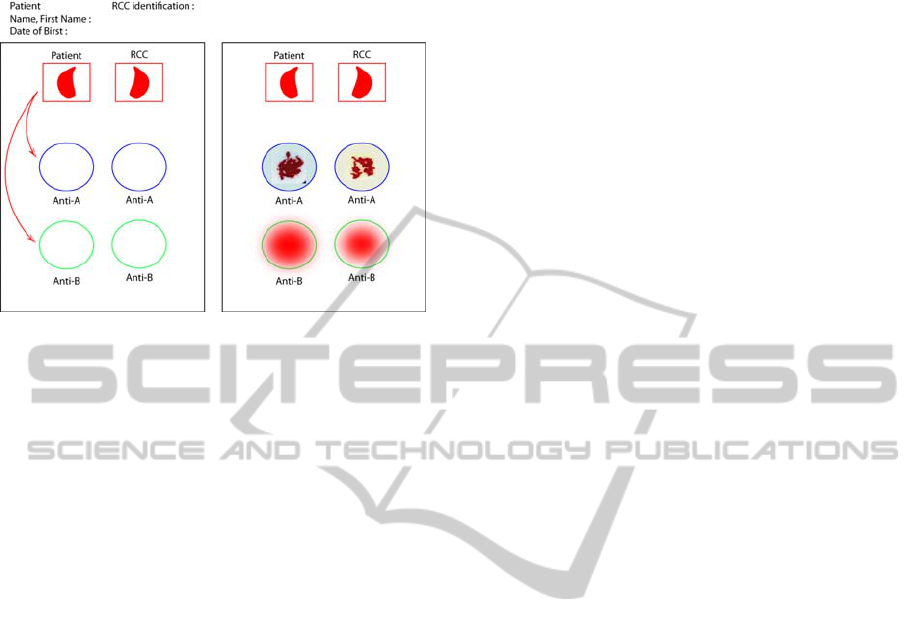

Figure 1: Representation of a bedside card. To use these

cards, it is necessary to rehydrate each reaction field with

one drop of isotonic saline solution (blue and red circles).

One drop of patient blood should be deposited on the

“patient field” and one drop of RCC on the “RCC field”.

Each drop should be deposited in the correspondents’

reaction fields, with a new spatula for each to avoid cross

reaction. The card should be shaken to see whether a

hemagglutination reaction occurs. Nurses should decide

whether RCC can be transfused according to this rule: for

circles of the same color (same antibody), a positive

reaction with blood cells and a negative reaction with the

patient’s blood forbid transfusions. In all other cases,

transfusion is allowed. In this example, transfusion is

allowed.

To eliminate these difficulties, the most

frequently studied solutions aim to ensure

compatibility between the information on the blood

product to be transfused and the recipient. The

technology developed consists of reproduced code

systems: bar codes which are read and radio

frequencies, to verify that the code attributed to the

patient (on a bracelet or in his/her file), corresponds

to the code attributed to the RCC (on a label) in

terms of ABO bulking (Aandahl et al., 2007). These

techniques constitute a higher level of transfusional

safety but nonetheless do not overcome human error,

for example when the bracelet is allocated or during

recipient grouping, etc. (Dzik, 2005). Dzick outlines

in a review some other obstacles: resistance to

change, confusion as to the best technology and

uncertainty concerning investment returns (Dzik,

2007).

In the UK, for example, the final administration

check must be performed at the patient’s side

immediately before administering the blood

component by matching the patient details attached

to the blood component with the details on the

patient’s identification band (or equivalent) (British

Committee for Standards in Haematology 2009).

None of these is entirely satisfactory at the

present time (Levy, 2008), and the frequency of

accidents is noticeably identical, no matter which

test device is used.

The studies described in this position paper aim

to demonstrate the benefit of applying

immunocapture techniques on microarrays to the

development of an “intelligent” blood transfusion

device.

3 IMMUNOSENSOR

ENGINEERING

A great challenge in biosensors and diagnostic

devices is “how to obtain relevant biological

mechanisms on the surface of microarrays and

which analytical tools are convenient for providing

accurate and rapid information on the structures of

captured biological entities of interest?”

To fulfill these aims, many skills must be

combined for a general approach. Successful

immobilization of biomolecules on a solid base

requires several critical factors to be controlled. The

biomolecule must be linked to the surface with

appropriate orientation, false positive signals must

be avoided by minimizing non-specific interactions

and ligands must remain active after binding (no

denaturation, folding, etc.). To control the chemical

functionalization of chips and the self-assembly

processes of chemical monolayers for a highly

controlled surface, biophysical investigations are

needed.

3.1 Design and Prodution of

Homemade Chips

Design and production of homemade chips

compatible with Surface resonance plasmons (SPR)

(from BiacoreTM) have been performed as

previously described with the help of the

MIMENTO technological platform, Besançon,

France (Boireau et al., 2009).

A 2-nm thick chromium (Cr) layer was deposited

on a SiO

2

wafer (width: 13 mm; thickness: 0.17 mm

from AGAR) with plasma sputtering technology to

optimize the adherence of gold to the substrate. The

40 nm thick Au layer was deposited onto the top of

the Cr layer using plasma-sputtering technology.

The deposition time and the argon flow pressure

were optimized to obtain a suitable gold surface. The

deposition time for the Cr and Au layers were

BIODEVICES 2012 - International Conference on Biomedical Electronics and Devices

258

respectively 5 and 21 s. For all depositions, the

argon flow pressure and current were 7 μbar and

0.3 A respectively.

With these deposition parameters, highly

efficient SPR biochips were produced (in terms of

complex optical thickness, surface roughness and

pseudo-periodic nano-structuration) as demonstrated

by Mangeat et al (Mangeat, 2009).

3.2 Chemical Functionalization and

SPR Experiments

Protein immobilization is a crucial point which

conditions the properties of specificity, stability and

usability of biosensors. Most of the macromolecular

coupling strategies on biosensor surface layers are

based on deposition, functionalization and activation

of polymer cushions with an expected high density

of probes. We chose to control the immobilization

and the homogeneity of the antibody layer on a

bidimensional surface. This was done by SPR

biophysical experiments in order to obtain

quantitative information (level of immobilization).

The homemade chips were chemically

functionalized as follows. The chemical

functionalization was obtained using a mixture of

11-mercapto-1-undecanol (11-MUOH) and 16-

mercapto-1-hexadecanoic acid (16-MHA)

(purchased from Sigma–Aldrich). The mixture of

11-MUOH/16-MHA (97/3 by mole) at 1mM in

absolute ethanol was sonicated for 10 min using an

Elma sonicator (power 90W, frequency 50/60 Hz).

Surfaces were rinsed by ethanol and ultra-pure

water. Then, the carboxyl groups were activated

using 240 µL of N-hydroxysuccinimide (NHS) at 10

mM and 1-Ethyl-3-(3-dimethylaminopropyl)

carbodiimide (EDC) at 48 mM (Amine Coupling Kit

from Biacore AB, Uppsala, Sweden) and incubated

for 30 min at RT. Surfaces were rinsed by ultra-pure

water. This procedure prepares the chips for the

immobilization step.

Biacore experiments were performed with the

Biacore™ 2000 apparatus at 25°C at a rate of 2

µL/min. The antibodies used were IgM anti-A or

IgM anti-B (DIAGAST, provided by the French

Blood Transfusion Center, Besançon). The running

buffer was saline phosphate buffer (PBS, 100 mM at

pH7.4 with NaCl 50 mM). The degree of protein

immobilization and the level of interactions in the

Biacore technology apparatus were plotted on a

sensorgram (response unit (RU) versus time (s)).

One thousand RU correspond to a shift in the

resonance angle of 0.1°. Calibration of the apparatus

gives a correlation between the shift in angle and the

surface mass density deposited on the biochip

surface, ranging from 0.1 to 1 ng/mm

2

(Stenberg,

1991). After exposure to the analytical solution, the

chips were removed from the Biacore unit via an

undock procedure with empty flow cell command.

We showed that after this chemical treatment of

the gold surface, it was possible to immobilize anti-

A and anti-B IgMs. First, different immobilization

pH were tested and the optimal pH conditions for

promoting functionalized antibody/surface

interactions were established. For each antibody, the

best immobilization was obtained with pH 4.65

(Figure 2). In this way, we were able to implement

efficient conditions for grafting IgM on biochips.

For each antibody, the surface was nearly saturated

after the first injection, showing that our grafting

conditions are optimized (Figure 3). The grafting

rate reaches 1500 IgM/µm

2

on average, which could

potentially involve 100 000 antibodies for each

captured red blood cell.

On these functionalized surfaces, we

demonstrated erythrocyte capture with Atomic Force

Microscopy. With erythrocytes from group A

globular concentrate, we achieved a specific

interaction with surface grafted with anti-A IgMs.

These initial results make way for an ex-vivo

development.

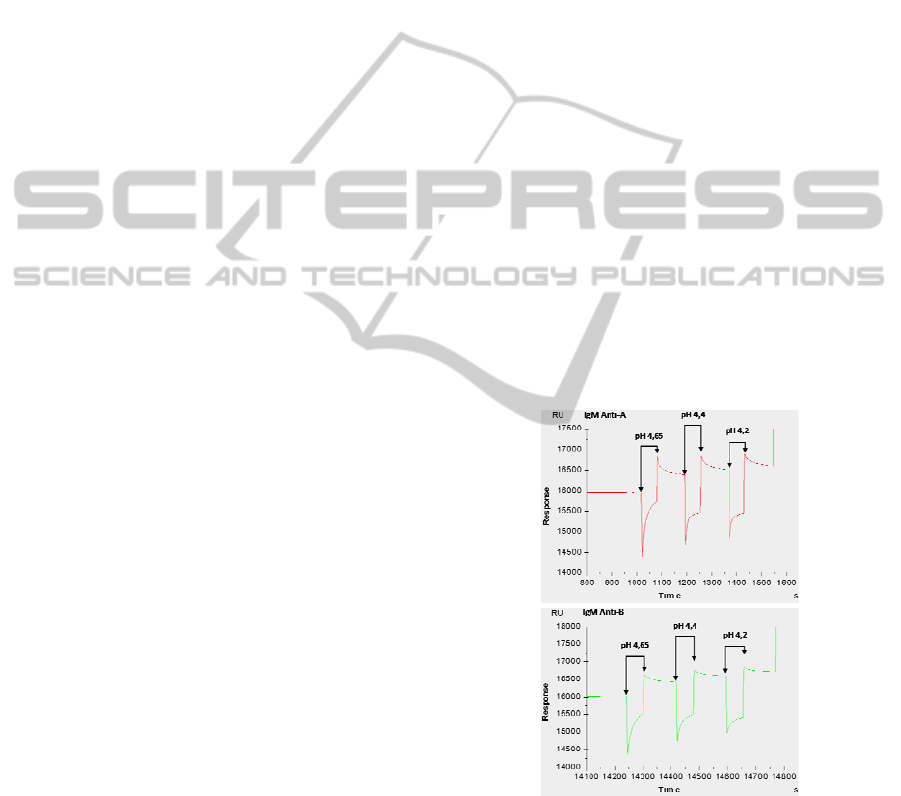

Figure 2: Immobilization of IgM anti-A and IgM anti-B

measured by SPR. Three pHs (4.65; 4.4; 4.2) were tested

and the resonance surface plasmon, expressed in units of

resonance (RU), was measured in real time. For each

antibody, optimum immobilization pH is 4.65.

SmarTTransfuser - A Biochip System for the Final ABO Compatibility Test

259

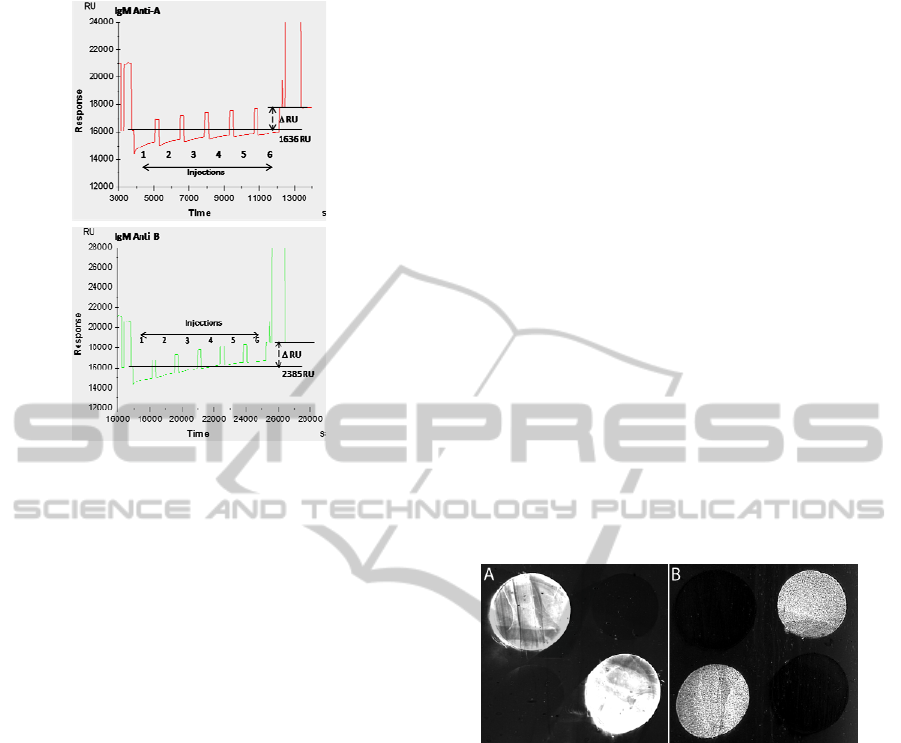

Figure 3: Immobilization of IgM anti-A and IgM anti-B

measured by SPR. Six successive injections were realized

and the resonance surface plasmon, expressed in units of

resonance (RU), was measured in real time. We observed

an echo variation of 1636 RU for the IgM anti-A and of

2385 RU for the IgM anti-B at the end of injections.

3.3 Feasibility Tests

After controlling functionalization of gold surfaces

and immobilization of erythrocytes, we checked the

ability of the biochips to work with other blood

groups. To do this, we conducted surface plasmon

resonance imaging (SPRi) experiments.

The chemical functionalization was performed as

described above. Four spots of IgM antibodies were

grafted onto the surface. Antibodies anti A or anti B

(purchased from Diagast) were diluted (1/10) in

acetate buffer (0.1 mg/mL, pH 4.5) and 2 spots of

each specy (2 µL/spot) were deposited on each

surface and incubated for 1 hour at room

temperature in a humid chamber. Then a blocking

agent (Rat Serum Albumine 40 µg/mL, pH 5.2) was

used to passivate the surface by incubation at room

temperature for 30 min. Incubation in ethanolamine

(0.2 M) was then used to target the free NHS entities

in order to desactivate the surface. Finally, the

biochips were rinsed with ultra pure water and used

for SPRi experiments. They were performed using a

SPRi-Plex imager (Horiba Scientific, France)

equipped with a 660 nm wavelength LED and a

CCD camera.

Experiments were carried out at room

temperature, in physiological serum (NaCl 0.9 %).

The flow rate in the chamber was 50 µl/min.

Ligands (red blood cell concentrate group A or

whole blood groups O, A, AB and B) were injected

(volume 200 µl) and the biochip surface was rinsed

to remove unbound ligands. Whole blood and red

blood cell concentrate were provided by the French

Blood Transfusion Center, Besançon).

The biochip was tested with different blood

groups in order to assess its specificity. Between two

measurements, the surface of the biosensor was

treated with PBS-n-Octyl-beta-D-glucopyranoside

for 1 min to dissociate the probe/target adducts

previously formed (regeneration of the surface

before a second injection). The system has proven to

be selective. Indeed, each target was bound only to

its corresponding antibody. No significant signal

was observed on the non-corresponding antibody

and reference spots. This shows the absence of

undesired non-specific binding (i.e., cross reactivity)

and/or adsorption on the surface. As seen in figure 4,

a very intense signal is observed on anti-A IgM

spots with whole blood group A (Figure 4A)

whereas no significant signal is observed on the two

other spots. In figure 4B, erythrocytes are

immunocaptured only by anti-B IgMs.

Figure 4: Different photographs of one biochip after

injection of whole blood group A (A) or whole blood

group B (B).

This high selectivity demonstrates that it is

possible to determine whole blood / red blood cell

concentrate groups by using a biochip in order to

replace the hemagglutination reaction of red blood

cells by IgM in solution.

4 TOWARD A MEDICAL DEVICE

The sensor should now be incorporated in the main

device, called “SmarTTransfuser” and developed for

clinical trials.

We have previously demonstrated that our

homemade biochips can specifically immunocapture

red blood cells of different blood groups. The next

step of the development of the SmarTTransfuser is

to design a medical device which could

automatically perform the compatibility test at the

BIODEVICES 2012 - International Conference on Biomedical Electronics and Devices

260

patient's bedside. Indeed, a mobile device is required

which contains the following elements: a fluidic

system, four biochips and an optical reading module.

4.1 General Concept

Our SmarTTransfuser system consists of a secure

patient blood sampling system combined with a

biochip and a mobile reader used to perform an

ultimate blood compatibility test at the patient’s

bedside (Pazart, 2010).

Immunocapture of red blood cells (patient and

RCC) is performed on 4 biochips (2 for the patient

and 2 for the RCC). These biochips are inserted into

a cartridge that includes fluidics arrangements used

to drive the patient’s blood and RCC towards the

chip surfaces. The cartridge is inserted into a mobile

reader/actuator that controls the flow of fluids, the

optical reading of the immunocapture reaction and

allows (or forbids) blood transfusion (Pazart et al.,

2011) (Figure 5).

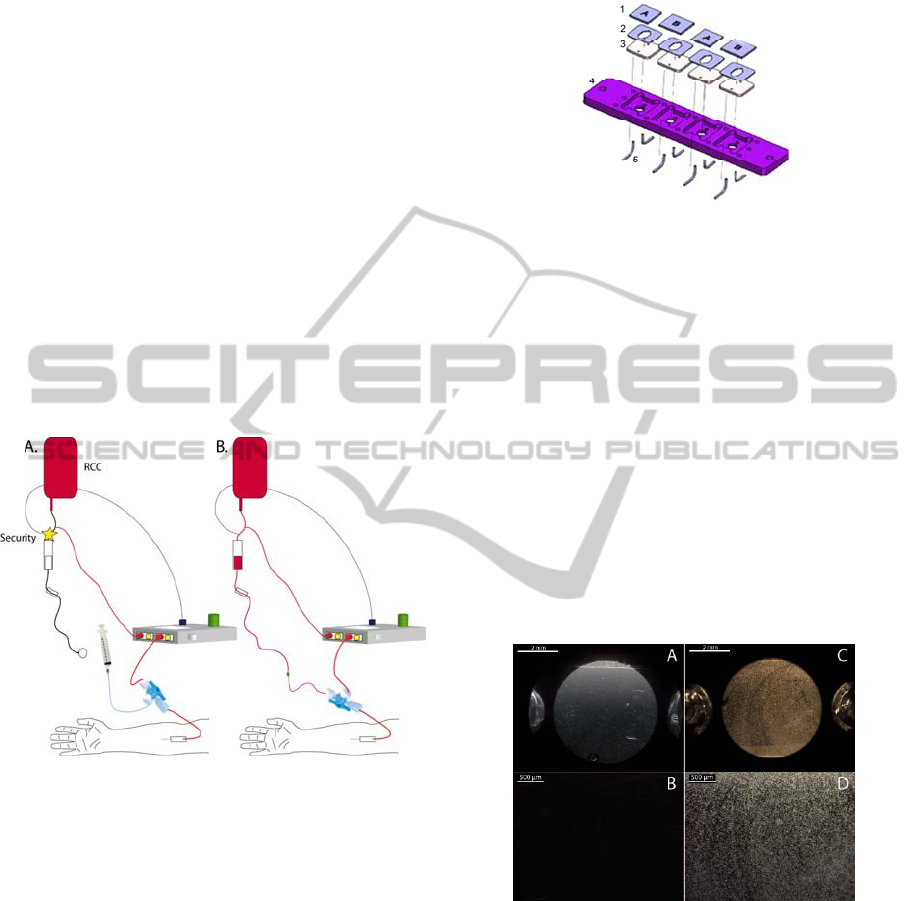

Figure 5: General concept of the SmarTTransfuser. The

SmarTTransfuser is on the transfusional line, and the

compatibility test is automatically realized (A). If the test

is correct, a green light comes on, the safety measure is

switched off and medical staff continue with the

transfusion as usual (B).

4.2 Immunosensor

The microsystem presented here and developed

under the coordination of the FEMTO-ST Institute is

an embedded detection device, which uses a

microsystem, including the surfaces, for detection of

blood group (biochips).

In order to design the medical device, the first

step was to determine which configuration will

allow for a specific immunocapture. Several

prototypes were designed. The best results were

obtained with the prototype presented in figure 6.

This configuration allows for a good blood flow,

with very little retention of red blood cells.

Figure 6: Representation of the reading zone of the

SmarTTransfuseur system. There are four biochips for the

ABO compatibility test: two for patient blood and two for

red blood cell concentrate (1). To ensure the system was

sealed with no retention of red blood cells, there is a two

part joint: a silicone sheet with a hexagonal window (2)

and a base in polycarbonate (3). All these parts are

inserted in a plastic base (4) and fluids can flow via part 5.

We tested immunocapture with this

configuration. The experimental design was as

follows: NaCl 0.9 % was used as course buffer (50

µL/min) and 250 µL of red blood cell group A

(dilution 1/4) was used (20 µL/min). We showed

that in these conditions, immunocapture is strong

and specific (Figure 7). Optical detection of the red

blood cells has been validated once and the result is

yet to be confirmed. We will therefore not describe

this issue in further detail in this position paper.

Figure 7: Photography of two biochips after

immunocapture reactions with red blood cell concentrate.

Very few red cells are observed on biochip graft with anti-

B antibodies (A and enlargement B). Almost all of the

surface of the biochip grafted with anti-A antibodies is

covered with red blood cells (C and enlargement D).

Detection of the red blood cell capture relies on

optical absorption. Blue LEDs and optical detectors

are positioned on each side of each reading zone.

Optical elements are parts of the mobile

reader/actuator. Optical detection of the red blood

cell trapping has been validated once and the result

SmarTTransfuser - A Biochip System for the Final ABO Compatibility Test

261

has yet to be confirmed. It is therefore too early to

describe this issue in further detail in this position

paper.

5 CONCLUSIONS

The ABO compatibility test is compulsory in

France. Studies led by the national hemovigilance

network show persistent attribution errors of blood

groups leading to transfusional accidents, with the

potential for death in each case (Afssaps, 2004). The

same observations have been made abroad

(Stainsby, 2005).The current procedure for

performing an ultimate pre-transfusional check is

not uniform. Although machines are sent to the

patient’s bedside for an automatic analysis of ABO

grouping, and technology has been developed to

attribute a code to the pouch of blood and to the

patient (Aandahl, 2007), these developments cannot

prevent human errors and transfusional accidents,

which can be lethal.

We have been working on a new system based

on biochips. We have shown through SPRi

techniques that these biochips are very selective and

can replace current hemagglutination test.

With our first tests with the SmarTTransfuseur,

we have shown that immunocapture is specific in

our conditions and that optical detection can be

carried out by absorption measurement. This

medical device could become a new uniform

procedure to carry out the ABO compatibility test.

Because tests will be carried out automatically,

human errors would be avoided and the additional

safety will involve only minor changes to current

practices.

We now need to repeat these tests in order to

cover all transfusional situations before clinical trials

in real-life situations.

The aim of this position paper is not only to

present the system we are developing, but also to

discuss the possibilities and techniques of ultimate

ABO compatibility tests outside France.

ACKNOWLEDGEMENTS

The authors would like to thank the French Blood

Transfusion Center, INSERM, the DGOS, the

CNRS, OSEO and the “innovative project

maturation” programme for their financial support.

REFERENCES

Aandahl, G. S., Knutsen, T. R., Nafstad, K., 2007.

Implementation of ISBT 128, a quality system, a

standardized bar code labeling of blood products

worldwide, electronic transfusion pathway: four years

of experience in Norway. Transfusion, 47(9), p.1674-

1678.

Afssaps, 2010. Rapport annuel hémovigilance. Available

at: http://www.afssaps.fr/.

Afssaps, 2004. Rapport annuel hémovigilance. Available

at: http://www.afssaps.fr/

Boireau, W. et al., 2009. Revisited BIA-MS combination:

entire «on-a-chip» processing leading to the proteins

identification at low femtomole to sub-femtomole

levels. Biosensors & Bioelectronics, 24(5), p.1121-

1127.

British Committee for Standards in Haematology, 2009.

Guideline on the Administration of Blood

Components. Available at: http://www.bcshguidelines.

com/documents/Admin_blood_components_bcsh_050

12010.pdf.

Dzik, W. H., 2007. New technology for transfusion safety.

British Journal of Haematology, 136(2), p.181-190.

Dzik, W. H., 2005. Technology for enhanced transfusion

safety. Hematology / the Education Program of the

American Society of Hematology. American Society

of Hematology. Education Program, p.476-482.

FDA, 2010. Fatalities Reported to FDA Following Blood

Collection and Transfusion. Available at: http://www.

fda.gov/downloads/BiologicsBloodVaccines/SafetyAv

ailability/ReportaProblem/TransfusionDonationFataliti

es/UCM254860.pdf.

Levy, G., 2008. [The pretransfusion bedside agglutination

test is not a «Gold Standard»]. Transfusion Clinique Et

Biologique: Journal De La Société Française De

Transfusion Sanguine, 15(5), p.318-321.

National Blood Collection and Utilization Survey, 2009.

The 2009 national blood collection and utilization

survey report. Available at: http://www.aabb.org/pro

grams/biovigilance/nbcus/Documents/09-nbcus-report.

Pazart L., Wacogne B., Pieralli C., Boireau W., Morel P.,

"Secure perfusion system", Patent WO 2011055031.

Pazart L., Wacogne B., Pieralli C., Boireau W., Morel P.,

"Device for taking a sample of a body fluid and

method for implementing same", Patent WO

2011055029.

SHOT, 2009. Annual Report. Available at: http://www.

shotuk.org/

Stainsby, D., 2005. ABO incompatible transfusions--

experience from the UK Serious Hazards of

Transfusion (SHOT) scheme Transfusions ABO

incompatible. Transfusion Clinique Et Biologique:

Journal De La Société Française De Transfusion

Sanguine, 12(5), p.385-388.

Stenberg, E., 1991. Quantitative determination of surface

concentration of protein with surface plasmon

resonance using radiolabeled proteins. Journal of

Colloid and Interface Science, 143(2), p.513-526.

BIODEVICES 2012 - International Conference on Biomedical Electronics and Devices

262