SURFACE PASSIVATION EFFECT IN SGOI NANOWIRE

BIOSENSOR WITH HIGH GE FRACTION

Kow-Ming Chang

1,2

, Chu-Feng Chen

1

, Chiung-Hui Lai

3

, Cheng-Ting Hsieh

1

, Chin-Ning Wu

1

,

Yu-Bin Wang

1

, Chung-Hsien Liu

1

and Kuo Chin Chang

4

1

Dept. of Elec. Engineering and Inst. of Elec., National Chiao-Tung University, No. 1001

University Rd., Hsinchu 300, Taiwan, R.O.C.

2

Department of Electronic Engineering, I-Shou University, No.1, Sec. 1, Syuecheng Rd., Kaohsiung 840, Taiwan, R.O.C.

3

Dept. of Electronics Engineering, Chung Hua University, No. 707, Sec.2, WuFu Rd., Hsinchu, 300, Taiwan, R.O.C.

4

Dept. MD Tse-An Clinic 319, Chung Cheng Rd., Tse Kuan District, Kaohsiung City, Taiwan, R.O.C.

Keywords: SiGe-on-insulator, Biosensor, Passivation, Sensitivity.

Abstract: The increase of surface to volume ratio results in the enhancement of the sensitivity of the nanowires. Our

previous studies have shown that the higher Ge fraction of Si

1-x

Ge

x

nano-wire improves the sensitivity of

the nanowire biosensor as a result of carrier mobility enhancement in strain-Si. Increasing the fraction of Ge

in SiGe-on-Insulator (SGOI) using Ge condensation by oxidation has obtained a significant enhancement in

hole mobility, further improving the sensitivity of SGOI nanowire. However, the sensitivity of SGOI

nanowire was degraded for exceeding a Ge fraction of 20% (i.e., high Ge fraction), resulting from the

unstable surface state. In this work, a top surface passivation SiO

2

layer was deposited on Si

0.8

Ge

0.2

nanowire and the sensitivity was about 1.3 times greater than nanowire sample without the top passivation

layer.

1 INTRODUCTION

The sensitivity of SGOI can be enhanced by

increasing the surface to volume ratio to condense

carriers in very thin conductivity layer. The

conduction is modified by the surface charges that

surround the nanowire surface (Li, 2005). In our

previous studies, the higher surface to volume ratio

was achieved by utilizing SiGe/a-Si stacking

structure (Chang, 2011). Moreover, an increase of a

Ge fraction of Si

1-x

Ge

x

improves the nanowire

biosensor sensitivity due to higher carrier mobility

(Chang, 2008). Ultrathin SGOI with high Ge

fraction was fabricated by utilizing Ge condensation

and Ge piling up at the SiO

2

/SiGe interface by

oxidation. However, the higher interface trap density

at the SiO

2

/SiGe interfaces was about 10

-12

cm

-2

after

oxidation (LeGoues, 1989). Besides, an unstable

surface state of semiconductor with free surface

which caused by a lot of dangling bond at free

surface and higher Ge fraction of Si

1-x

Ge has higher

surface state and results in fast oxidation rate

(Tanaka, 2008). Fast oxidation rate can create more

unstable surface state (Yang, 2008).To reduce

unstable surface state, a SiO

2

passivation layer is

introduced to suppress surface state less than 10

11

cm

-2

eV

-1

.The surface state of free surface is around

10

15

cm

-2

eV

-1

. In this work, SiO

2

layer is selected as

passivation layer to improve interface state and O

2

gas buffer layer to reduce oxidation rate for 20% Ge

fraction of SiGe nanowire sensors.

2 EXPERIMENT

An a-Si/Si

1-x

Ge

x

was deposited on the patterned 300-

nm-hight bottom oxide. The deposition thickness of

a-Si is 200Å, and Ge fraction of Si

1-x

Ge

x

splits in

this experiment is 7, 14, and 20 %, respectively. To

clarify the influence of passivation layer on the

nanowire sensitivity, nanowire sensors with and

without the passivation SiO

2

layer were fabricated.

The passivation SiO

2

was split in two thicknesses,

100 and 200 Å. The poly-Si nanowire was also

fabricated as control group to verify oxidation rate.

After the a-Si/SiGe layer formation, the samples

384

Chang K., Chen C., Lai C., Hsieh C., Wu C., Wang Y., Liu C. and Chang K..

SURFACE PASSIVATION EFFECT IN SGOI NANOWIRE BIOSENSOR WITH HIGH GE FRACTION.

DOI: 10.5220/0003875403840387

In Proceedings of the International Conference on Biomedical Electronics and Devices (BIODEVICES-2012), pages 384-387

ISBN: 978-989-8425-91-1

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

annealed in O

2

gas mixed with 13% N

2

gas ratio at

950

o

C for 180 sec, followed by the thermal

evaporation of Al films and the definition of the

electrodes by the mask process. The poly-Si and

SiGe nanowires were implanted in p-type nanowire.

To functionalize a-Si/Si

1-x

Ge

x

nanowires, the wires

were adopted the 3-aminopropyltri-ethoxysilance

(APTES) to modify the surface of the silicon oxide

around the nanowires. A hydroxyl functional group

on the surface of the oxide was replaced by methoxy

groups of APTES modules, and simultaneously, the

surface of the nanowire was terminated by amine

groups. From our earlier investigations (Chang,

2008), the amine groups were prone to deplete

positive carriers, reducing the conductivity of the p-

type nanowire. Next, bis (3-sulfo-N-

hydroxysuccinimide ester) sodium salt (BS3) was

used as a linker between APTES and IgG antibody.

BS3 was prone to becoming negatively charged,

increasing the conductivity of the p-type nanowire

because of the accumulation of the holes on the

surface of the nanowire.

The Hewlett Packard HP 4156A was used in this

study to measure the electric characteristics of

nanowire sensor. Drain voltage (V

D

) was varied

from -10 to 10V and 500 mV a step, and back gate

voltage was 0 V. The measurement of electric

characteristics was performed at every stage of

surface modification, and the average conductance

was then extracted from I

D

-V

D

characteristics with

V

D

= 3~6 V. The sensitivity (S) of a nanowire-based

sensor is defined as the ratio of the magnitude of

conductance change to the baseline conductance

value:

00

0

G

G

G

GG

S

(1)

where G

0

is the conductance before molecule

capture, G is the conductance after molecule capture,

and G is the different between G and G

0

.

3 RESULTS AND DISCUSSIONS

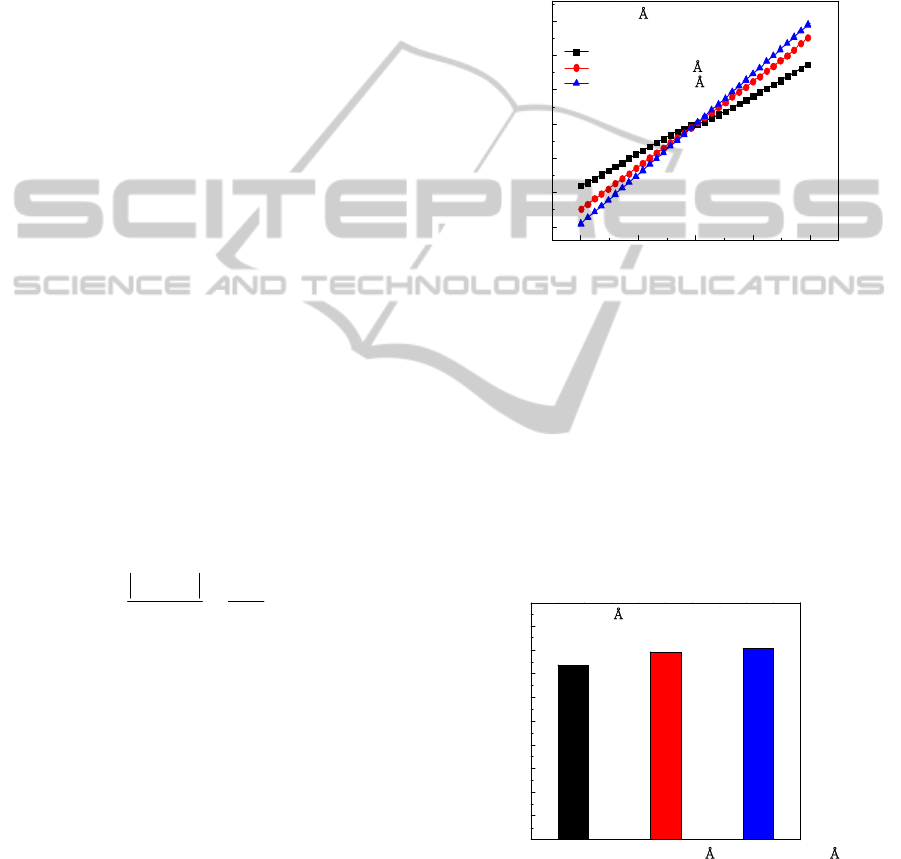

Figure 1 presents the characterization of I-V curve

of the a-Si=200 Å /Si

0.86

Ge

0.14

nanowires with and

without passivation SiO

2

layer. The nanowire with

200 Å passivation layer has higher conductance

compared with the ones with/without 100 Å

passivation layer. The nanowire sensitivity increases

with increasing the nanowire conductance. Figure 2

displays the sensitivity comparison of the nanowires

with/without the passivation oxide layer. Compared

with the nanowire without passivation layer, the

sensitivity increased about 7 and 10 % for 100 and

200 Å passivation layer condition, respectively. By

this way, we found the surface state could be

reduced by this capping layer and oxidation rate also

be reduced. Therefore, the sensitivity can be

improved owing to the lower interface state by

reducing the unstable surface sate and the oxidation

rate.

-10 -5 0 5 10

-1.5x10

-4

-1.0x10

-4

-5.0x10

-5

0.0

5. 0x10

-5

1. 0x10

-4

1. 5x10

-4

Oxidation time : 3min

Current (A)

Voltage ( V)

w/o Pasivation Oxide

Pasivation Oxide=100

Pasivation Oxide= 200

Amorphous 200

Si

0.86

Ge

0.14

Figure 1: The characterization of I-V curve of a-Si=200 Å

/Si

0.86

Ge

0.14

nanowires.

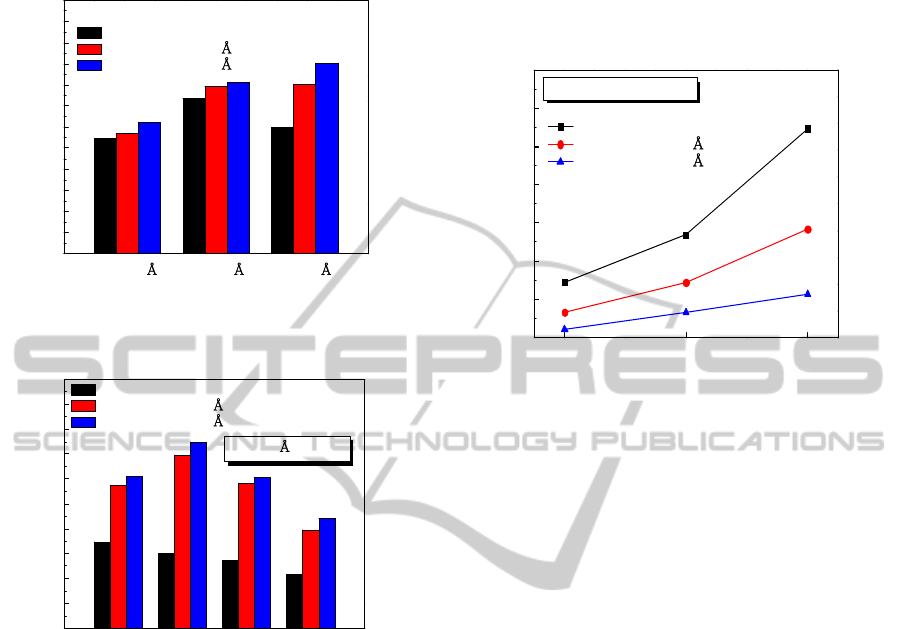

Figure 3 shows the sensitivity of SiGe nanowire

structure with different fraction of Ge. At 20 % Ge

group, the sensitivity has obvious improvement for

the ones with passivation SiO

2

. The sensitivity of 20

% Ge sample was degraded when passivation layer

did not cap on SiGe nanowire. In our previous work,

the sensitivity of SiGe nanowire degraded when the

fraction of Ge exceeded 14%. Therefore the higher

sensitivity of SiGe nanowire with high fraction Ge

was obtained by using a suitable capping layer.

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.

0

Amorphous 200

Si

0.86

Ge

0. 1 4

oxidation time: 3min

Sen sitivity (% )

w/o Passi vation Passivation Oxide= 10

0

Passivation Oxide= 20

0

Figure 2: The sensitivity comparison of the nanowires

with/without the passivation oxide layer.

Because the oxidation rate was reduced by the

deposition of the SiO

2

layer on the SiGe nanowire,

Ge condensation phenomenon was impacted. Hence,

oxidation time is also another factor to obtain

SURFACE PASSIVATION EFFECT IN SGOI NANOWIRE BIOSENSOR WITH HIGH GE FRACTION

385

maximum value of sensitivity in passivation

structure.

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

5.5

6.

0

Sensitivity (%)

w/o Passivation Oxide

Passivation Oxide= 100

Passivation Oxide= 200

Oxidaiton time: 3min

a-Si=200

a-Si=200 a-Si=200

Si

0. 9

3

Ge

0.07

Si

0. 8

6

Ge

0.1

4

Si

0.80

Ge

0.20

Figure 3: The sensitivity of SiGe nanowires structure with

different fraction of Ge.

0

1

2

3

4

5

6

7

8

9

1

0

Oxidation Time

a-Si=200 / Si

0. 8

Ge

0.2

3min 5min 7min 10min

w/o Passivation Oxide

Passivation Oxide= 100

Passivation Oxide= 200

Sensitiv ity (% )

Figure 4: The sensitivity of Si

0.8

Ge

0.2

nanowire structure

with different oxidation time.

Figure 4 presents the oxidation time effect in

different passivation conditions of Si

0.8

Ge

0.2

nanowire. The results show that a peak value existed

at the oxidation time of 5 min. The sensitivity was

about 1.3 times greater than the nanowire sample

without the top passivation layer. The sensitivity

degraded while oxidation time increased, resulting

from the poor Ge accumulation at surface when

diffusion effect started to dominated Ge distribution.

Finally, the lower oxidation rate of the sample

with capping layer was verified by the poly-silicon

nanowires. Figure 5 shows the sensitivity of the

poly-silicon nanowires with/without the SiO

2

passivation layer whose oxidation time was split into

three cases (3, 5 and 10 min). The sensitivity of the

poly-silicon nanowire without the SiO

2

passivation

layer was higher than the nanowire with the

passivation layer. This is because of the high

surface-to-volume ratio of poly-silicon without any

passivation layer to reduce oxidation rate. Hence, the

reduction of oxidation rate and unstable surface state

was realized by a suitable capping layer and the

sensitivity of high fraction Ge nanowire can be

improved.

0.6

0.7

0.8

0.9

1.0

1.1

1.2

1.

3

Oxidation Time

Poly silicon nanowire

3min 5min 10min

w/o Passivation Oxide

Passivation Oxide= 100

Passivation Oxide= 200

Sen sitivi ty (%)

Figure 5: The sensitivity of poly-silicon nanowire

structure with different oxidation time.

4 CONCLUSIONS

In our work, a SiO

2

passivation layer is proposed to

reduce the surface state and the oxidation rate for

suppressing the interface formation at the SiGe

surface. Hence, the sensitivity of the sample with a

high fraction Ge can be improved in Ge

condensation process. The maximum improvement

of the sensitivity of the Si

0.8

Ge

0.2

nanowire was

achieved at the oxidation time of 5 min for the

nanowire with 200 Å passivation oxide layer. The

maximum sensitivity enhancement of the passivated

nanowire is around 1.3 times higher than that

without the SiO

2

passivation.

ACKNOWLEDGEMENTS

The authors would like to thank the staff of the

National Nano Device Laboratory for their technical

help. They also acknowledge the financial support of

the National Science Council (NSC) under Contract

Nos. NSC 98-2221-E-009-174-MY3.

REFERENCES

Li, Z., Rajendran, B., Kamins, T. I., 2005. Silicon

nanowires for sequence-specific DNA sensing: device

BIODEVICES 2012 - International Conference on Biomedical Electronics and Devices

386

fabrication and simulation. Applied Physics a-

Materials Science & Processing, 80(6) 1257-1263.

Chang et al., 2011. 4th, 2011 IEEE INEC.

Chang et al., 2008. Higher drive current for SiGe

nanowires. 2

nd

IEEE International Nanoelectronics

Conference, 315-319.

LeGoues, F. K., Rosenberg, R., Nguyen, T., Himpsel, F.,

Meyerson, B. S., 1989. Oxidation studies of SiGe. J.

Appl. Phys, 65(4), 1724.

Tanaka, M., Ohka, T., Sadoh, T., Miyao, M., 2008.

Abnormal oxidation characteristics of SiGe/Si-on-

insulator structures depending on piled-up Ge fraction

at SiO2/SiGe interface. J. Appl. Phys, 103, 054909.

Yang, H., Wang, D., Nakashima, H., Gao, H., Hirayama,

K., Ikeda, K.-i., Hata, S., Nakashima, H., 2008.

Influence of top surface passivation on bottom-

channel hole mobility of ultrathin SiGe- and Ge-on-

insulator. Applied Physics Letters, 93(7), 072104.

SURFACE PASSIVATION EFFECT IN SGOI NANOWIRE BIOSENSOR WITH HIGH GE FRACTION

387