Development of a Self-regenerative Unit for Carbon

Dioxide Removal from Anaesthetic Circuits: Preliminary

Results using Hydroxide Solutions

Inês Pantaleão

1

, Joana Cabral

1

, Joaquim Gabriel

2

, José Sousa

1,3

and Adélio Mendes

1

1

University of Porto, Faculty of Engineering, Chemical Engineering Department, LEPAE,

Rua Dr. Roberto Frias, 4200-465 Porto, Portugal

2

IDMEC-Polo FEUP, University of Porto, Faculty of Engineering,

Rua Dr. Roberto Frias, 4200-465 Porto, Portugal

3

Chemistry Department, University of Trás-os-Montes e Alto Douro,

Apartado 202, 5001-911 Vila-Real Codex, Portugal

Abstract. Carbon dioxide (CO

2

) removal from anaesthetic circuits is currently

performed by soda-lime canisters. However, this procedure has many

drawbacks, being the most important its relation with post operative cognitive

decline and death in the first year after surgery. In this paper an alternative

technology is proposed based on a self-regenerative unit using hollow fiber

membrane contactors and amino acid salts for gas-liquid absorption of CO

2

.

This technology, is expected to overcome all the drawbacks associated with

soda-lime units. A preliminary experiment was evaluated under real conditions

for CO

2

removal, using hydroxide solutions. The system performed similarly to

soda-lime canisters, being able to remove CO

2

from 5 % to 0.5 % (in nitrogen)

during an hour, from a 10 L/min gas stream.

1 Introduction

In anaesthesia, when a low flow circle breathing circuit is used, the patient is

continuously ventilated with a gaseous mixture typically composed by nitrous oxide

(N

2

O), as carrier and anaesthetic gas, oxygen and 1 – 2 % fluorated additives

(sevoflurane/desflurane, being sevoflurane the most frequent). The carbon dioxide

(CO

2

) produced by the patient’s breathing must be removed since the gas flows in a

circle circuit.

Over decades, the use of hydroxide-based absorbents such as soda lime or

Baralyme® was accepted to be a safe and reliable method for removing CO

2

from

anaesthetic gas circuits. However, some evidences were found in recent years

regarding the hazardousness of this approach: bacteria, viruses and spores are

transmitted between patients [8], carbon monoxide can be generated, particularly

when desflourane is used [7] and there is a risk of explosion, since hydrogen is

formed and the temperature in the soda lime canisters is high [4]. The exhausted soda

lime canisters are solid waste which is dangerous and expensive to treat [5].

Moreover, the residual emission of N

2

O and flourinated anaesthetic compounds to the

atmosphere makes this process dangerous for the patient, medical staff and the

Pantaleão I., Cabral J., Gabriel J., Sousa J. and Mendes A..

Development of a Self-regenerative Unit for Carbon Dioxide Removal from Anaesthetic Circuits: Preliminary Results using Hydroxide Solutions -

Preliminary Results using Hydroxide Solutions.

DOI: 10.5220/0003883800690075

In Proceedings of the International Workshop on Veterinary Biosignals and Biodevices (VBB-2012), pages 69-75

ISBN: 978-989-8425-94-2

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

environment. But the worst side effect of the current CO

2

removal system is the

formation of neurotoxic compounds. The high temperatures developed during the

caustic absorption degrades sevoflurane [2], one of the most commonly used

anaesthetic, resulting in the so called compounds A, B, C, D and E [1], referred to as

neuro and nepho-toxic [3]. Their neurotoxicity is associated to the occurrence of post

operative cognitive decline (POCD) which increases exponentially after the age of 65.

Additionally, POCD is related to the occurrence of death in the first year after surgery

(Doherty, 2007).

Our proposal is to develop an alternative CO

2

removal method from anaesthetic

circuits, using hollow fiber membrane contactors and amino acid salts solutions. The

use of hollow fibers provides a large gas-liquid contact area, allowing the

development of a simple and compact unit. Being dense, the membranes block

microorganisms as well as virus transmission. The use of amino acid solutions grants

a biocompatible system and side-reactions of the anaesthetics are eliminated.

Furthermore, a self-regenerative unit will overcome environmental issues.

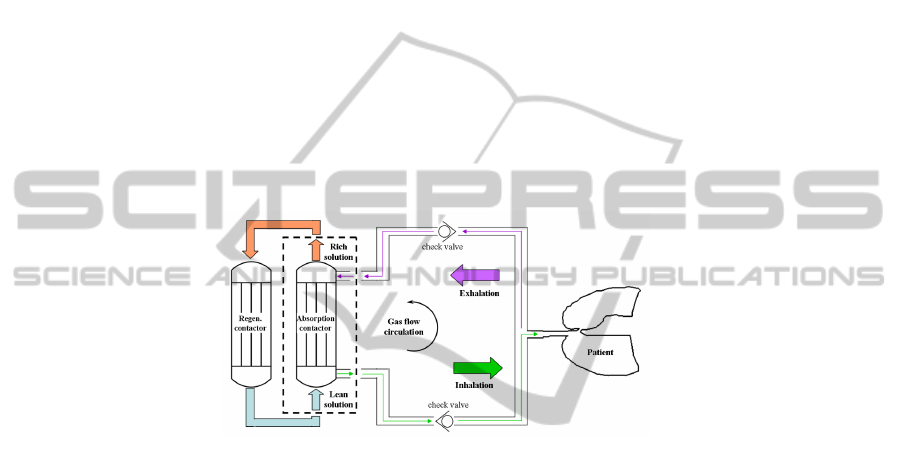

The unit will include two contactors (Fig. 1), one to absorb the CO

2

from the

patient’s breathing and the other to regenerate the absorbent solution.

Fig. 1. Sketch of an anaesthetic circuit and self-regenerative unit for CO

2

removal [6].

The absorbent must have a high cyclic absorption yielding, i.e., have a good

absorption rate and a high cyclic absorption capability. It should also be easily

regenerable under acceptable conditions (such as temperature), exhibit very low

volatility and present thermal and chemical stability while simultaneously having a

reasonable price. Since aqueous solutions of salts of most of the natural amino acids

fulfil these requirements, and simultaneously are biocompatible compounds, they

were chosen to be tested as absorbent solutions.

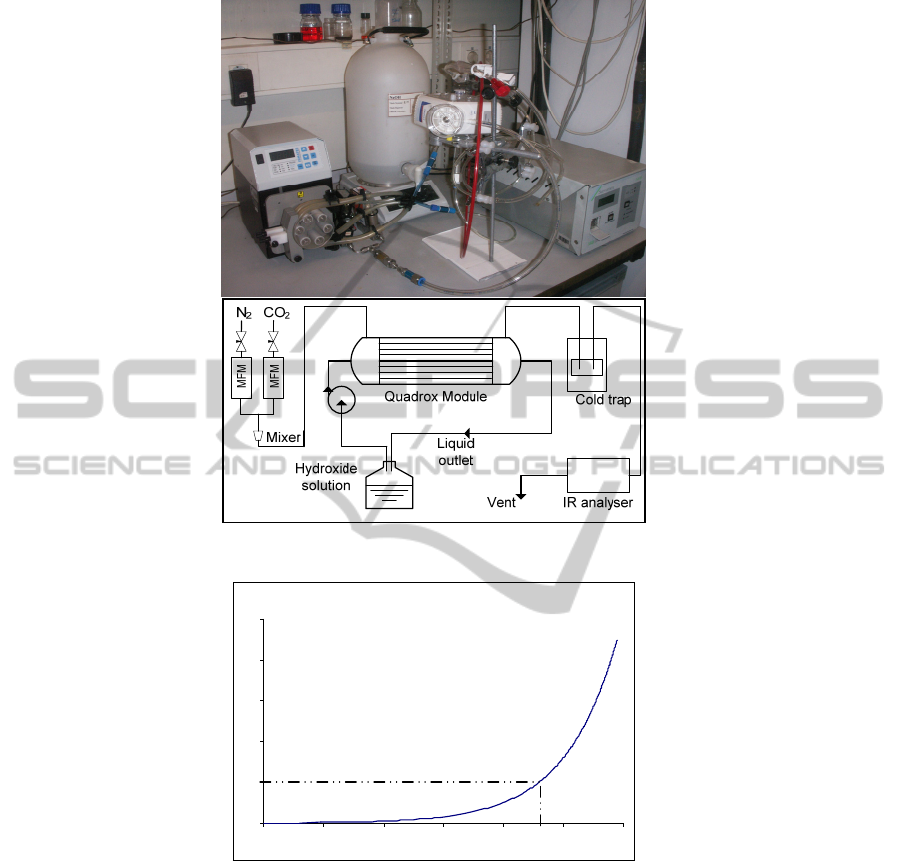

In the present study, the absorption step was studied using the same gas flow rates

as used in anaesthesia, and a commercial cross-flow membrane contactor (Quadrox,

Maquet cardiovascular, Fig. 2). As liquid absorbents, two hydroxide solutions were

tested to validate the concept and the set-up, since there was no need for the absorbent

to be regenerable. Moreover, alkaline solutions are commonly used for acid gas

absorption. The overall performance of the system for CO

2

removal from anaesthetic

gas circuits was evaluated in the laboratory.

70

2 Experimental Set-up

As a preliminary experiment, a commercial membrane module – Quadrox (Maquet),

blood oxygenator – was used with common gas flow rates and aqueous hydroxide

solutions as absorbents. The objective was to study the suitability of this commercial

membrane contactor for CO

2

removal from anaesthetic circuits, by chemical reaction

with a liquid absorbent.

The Quadrox module was adapted to be used in this set-up (Fig. 3). The original

blood circuit was used for the hydroxide solution. The blood outlet was blocked; the

recirculation exit was used instead. The internal heat exchanger shown in Fig. 2 was

not used. The original gas circuit was used for the gas current. The gas outlet was

divided into two tubes: one of them was directed to a CO

2

infrared gas analyzer

(Servomex) and the other to the atmosphere. This was necessary because the CO

2

analyzer used had a limit flow rate of 6 L/min.

The liquid absorbents flowed through the hollow fiber membranes with a flow

rate of 1 l/min. This was achieved using a peristaltic pump (Ismatec). The gas mixture

was made using thermal gas flow controllers (Bronkhorst).

Fig. 2. Flow directions of gas, blood and water (heat exchanger) in the Quadrox module

(retrieved from www.maquet.com).

3 Experiment

The hydroxide solution should be able to remove CO

2

from an anaesthetic gas current

of 10 L/min, with 5 % CO

2

, during a given period of time. The goal was to obtain, at

the exit of the contactor, a gas current with 0.5 % CO

2

.

In a hydroxide solution, CO

2

reacts with the hydroxide ions (HO

-

) according to

equation 1:

2

232

CO ( ) 2HO ( ) CO ( ) H O( )

g

aq aq l

−−

+↔+

(1)

To continuously remove CO

2

from a gas current of 10 L/min with 5 % CO

2

,

during an 8-hour surgery, the amount of HO

-

ions necessary is very high, what could

damage the membranes in the Quadrox module. Therefore, to protect the membranes,

a concentration of 0.2 mol/L was used, which corresponds to a pH of 13.3 (Fig. 4).

71

Fig. 3. Picture (a) and sketch (b) of the experimental set-up.

Fig. 4. pH as a function of hydroxide ion concentration [HO

-

], mol/l.

3.1 Test with a Saturated Salt Solution

To maintain the efficiency of the CO

2

removal process, the feeding solution should

have a constant concentration of at least 0.2 mol/L. Therefore, to reduce the volume

of solution necessary, a saturated solution of Barium hydroxide (Ba(HO)

2

) was used

since this salt produces a saturated solution with ca. pH=13. Reacting with CO

2

this

salt produces barium carbonate (BaCO

3

(s)) as a precipitate.

0

0.2

0.4

0.6

0.8

1

11.0 11.5 12.0 12.5 13.0 13.5 14.0

pH

[HO

-

], m ol/l

(b)

HO

-

solution

Peristaltic

pump

CO

2

analyser

Quadrox

module

(a)

72

Since the membrane module used (Quadrox-i) was made of microporous fibers,

precipitation had to be reduced to the minimum possible, since it could block the

membrane pores. Therefore a sodium hydroxide (NaHO) was used to prepare a

solution with concentration 0.215 mol/L, to which solid Ba(HO)

2

was added in order

to maintain the solution saturated. A magnetic stirring was used to keep the solution

homogenized and help the salt to dissolve, maintaining constant the amount of HO

-

ions in solution. Several goals are achieved with this procedure: the efficiency of the

process is maintained constant; HO

-

concentration is kept at the minimum possible;

precipitation is reduced to the minimum possible; the volume of solution necessary is

reduced to the minimum possible.

3.2 Test with Sodium Hydroxide

In this experiment, five litres of NaHO 0.25 M were prepared and used as absorbent

for the CO

2

in the gas current, flowing through the membrane module at 1 L/min. A

higher concentration solution – NaHO 2 M – was added to the liquid container,

whenever necessary, in small amounts of 150 ml, to give back to the solution the HO

-

ions it had already lost by chemical reaction with CO

2

.

4 Results and Discussion

The test with Ba(HO)

2

proved that it is not possible to use microporous fibers

whenever a precipitate is formed, since it blocks the membrane pores. The run lasted

only a couple of minutes, since the precipitate (BaCO

3

(s)) and Ba(HO)

2

itself started

blocking the membrane. The use of saturated solutions produced by insoluble salts

and accompanied by the formation of precipitates is therefore not suitable for CO

2

removal from anaesthetic circuits when using contactors made of porous membranes.

To use this set-up successfully with saturated salts solutions, a dense membrane

module should be considered – Quadrox-D instead of Quadrox-i.

Since the membrane module used was made of porous fibers, sodium hydroxide

(NaHO) was tested, as an alternative to Ba(HO)

2

. Sodium hydroxide is extremely

soluble, easy to handle and cheap. For an inlet gas current of 10 L/min, 5 % CO

2

in

N

2

, the composition of the outlet gas stream was 0.5 % CO

2

for ca. 7 minutes, after

what the CO

2

% started to rise. At this point, ca. 150 ml NaHO solution with

concentration 2 M were added to the plastic container. This highly concentrated

solution was able to give back to the original solution, the HO

-

ions it had already lost

by reaction with CO

2

. The process was repeated whenever necessary (every ca. 7

minutes): when the CO

2

% at the outlet of the module started to rise, the addition of

NaHO was able to maintain the overall efficiency.

This set-up was successfully tested at LEPAE for an hour. During this hour ca. 2

L of NaHO 2 M were added to the original solution in the plastic container. Further

consecutive additions of NaHO 2 M would make the experiment last as long as

necessary, within the life-time of the hollow fiber membranes under these harsh

experimental conditions.

73

This set-up will be ultimately validated by real anaesthesia experiments with

animals, and subsequently with humans.

5 Conclusions

The use of membrane contactors and amino acid salt solutions for CO

2

removal from

gas streams is an innovative approach that presents several advantages over current

absorbent systems used in anaesthetic machines. The technological innovation

introduced by the present work will bring a significant improvement. It will enhance

issues related to the patient’s health and well being, add economical advantages while

simultaneously originating a more environmentally friendly process.

This preliminary experiment with hydroxide solutions to remove CO

2

from

anaesthetic gas streams produced successful results. The set-up has proven capable of

removing CO

2

from 5 % (in a gas stream of 10 L/min) to 0.5 % for an hour. The

experiment could have lasted longer if further additions of NaHO solution were made,

assuming that the limiting factor is the life-time of the membranes, under the given

experimental conditions.

This set-up performs similarly to, and could therefore replace, soda lime canisters

(currently used for CO

2

removal). There is however a drawback which lies in the need

to keep adding NaHO solution to the container. This should no longer be an issue

when amino acid salt solutions are used. In this case, the absorbent solution will

absorb CO

2

and it will afterwards be regenerated in a separate membrane module, in a

cyclic process.

Acknowledgements

The authors wish to thank Maquet for kindly providing the Quadrox module. The

work of Inês Pantaleão and Joana Cabral is supported by the Portuguese Foundation

for Science and Technology (FCT), grant references SFRH/BDE/33802/2009 and

SFRH/BPD/64735/2009, respectively. The research is also supported by funds from

project PTDC/EQU-QUE/114944/2009.

References

1. Cunningham, D. D., Huang, S., Webster, J., Mayoral, J., Grabenkort, R. W., 1996.

Sevoflurane degradation to compound A in anaesthesia breathing systems” British Journal

of Anaesthesia, 77, 537-543.

2. Fang, Z. X. , Kandel, L., Laster, M. J., Ionescu, P., Eger, E. I., 1996. Factors Affecting

Production of Compound A from the Interaction of Sevoflurane with Baralyme® and Soda

Lime. Anesthesia & Analgesia 82, 775-781.

3. Konat, G. W., Kofke, W. A., Miric, S., 2003. Toxicity of Compound A to C6 Rat Glioma

Cells. Metabolic Brain Disease, 18, 11-15.

74

4. Lagorsse, S., Magalhães, F. D., Mendes, A., 2007. Xenon recycling in an anaesthetic

closed-system using carbon molecular sieve membranes. Journal of Membrane Science

301, 29-38.

5. Mendes, A., 2000. Development of an Adsorption/membrane Based System for Carbon

Dioxide, Nitrogen and Spur Gases Removal from a Nitrous Oxide and Xenon Anaesthetic

Closed Loop. Applied Cardiopulmonary Pathophysiology 2, 156-163.

6. Portugal, A. F., Magalhães, F. D., Mendes, A., 2009. Carbon dioxide removal from

anaesthetic gas circuits using hollow fiber membrane contactors with amino acid salt

solutions. Journal of Membrane Science 339, 275-286.

7. Struys, M. M. R. F., Bouche, M. P. L. A., Rolly, G., Vandevivere, Y. D. I., Dyzers, D.,

Goeteyn, W., Versichelen, L. F. M., Van Bocxlaer, J. F. P., Mortier, E. P., 2004. Production

of compound A and carbon monoxide in circle systems: an in vitro comparison of two

carbon dioxide absorbents. Anaesthesia, 59, 584-589.

8. Wilkers, A. R., 2005. Preventing the transmission of pathogenic microbes during

anesthesia. Expert Review of Medical Devices 2, 319-326.

75