A BIOMIMETIC AND BIOMECHANICAL

APPROACH FOR TISSUE ENGINEERING

Hybrid Nanomaterials and a Piezoelectric Tunable Bending

Apparatus for Mechanically Stimulated Osteoblast Cells Growth

Antonio Apicella and Raffaella Aversa

Material Lab, Dept. of Cultura del Progetto, Specialistic School of Industrial Design for Innovation,

Second University of Naples, Aversa, Italy

Keywords: Biomimetics, Biomechanics, Hybrid nanostructured biomaterials, Piezoelectric.

Abstract: The research develops and tests new hybrid biomimetic materials that work as mechanically stimulating

“scaffolds” to promote early regeneration in implanted bone healing phases. A biomometic nanostructured

osteoconductive material coated apparatus is presented. Bioinspired approaches to materials and templated

growth of hybrid networks using self-assembled hybrid organic-inorganic interfaces is finalized to extend

the use of hybrids in the medical field. Combined in vivo, in vitro and computer-aided simulations have

been carried out. Such multidisciplinary approach allowed us to explore many novel ideas in modelling,

design and fabrication of new nanostructured biomaterials and scaffolds with enhanced functionality and

improved interaction with OB cells. In vivo tests of Titanium screw implanted in rabbit tibiae have shown

that mechanical stimulation was induced by the presence of bioactive hybrid perimplantar scaffold resulting

in a differentiation and development of mesenchymal tissues. In order to investigate the relationship

between bone growth and applied mechanical loading (strain), a piezoelectically driven cantilever and a

computer-controlled apparatus for "in vitro" tests has been developed and presented.

1 INTRODUCTION

Developing innovative tissue engineering

biomimetic materials based on hydrophilic polymers

has been extensively studied in the past decades on

their physical, biological and mechanical properties.

Although hard in the dry state, such polymers swell

in water turning to soft and flexible materials used in

several biomedical applications such as ophthalmic

lenses, vascular prostheses, drug delivery system

and soft-tissue replacement (Montheard et al., 1992;

Apicella et al., 1993). Improved cytocompatibility in

terms of cell adhesion and metabolism for IPN of

HEMA and PCL was explained in terms of

increased surface hydrophobicity leading to

improvement of cell adhesion and spreading

(Schiraldi et al., 2004). Highly biocompatible novel

hybrid materials based on fumed silica and

hydrophilic poly-(hydroxy-ethyl-methacrylate)

(pHEMA) have been developed by the authors

(Schiraldi et al., 2004). The addition of fumed silica

is expected to improve the organization of the

polymeric network promoting hydrogen bonding of

the polymeric chains with the hydrophilic

nanoparticles. The resulting nanocomposites

consisted in more rigid transparent materials with

surprisingly improved mechanical strength and

cytocompatibility (Schiraldi et al., 2004) that

overcome one of the major drawbacks in hydrogels

applications associated with their poor mechanical

strength. Early studies confirmed that the nanofilled

hybrid composites possess biomimetic and

osteoconductive properties that can be useful in the

design of mechanically bioactive innovative

scaffolding systems for Osteobast (OB) growth

(Schiraldi et al., 2004). In healthy conditions,

modelling and remodelling collaborate to obtain a

correct shape and function of bones. This condition

is completely altered when bone is implanted with a

rigid prosthesis (Aversa et al., 2009; Sorrentino et

al., 2007). Loads on bones cause bone strains that

generate signals that some OB cells can detect and

respond to. Threshold ranges of such signals are

genetically determined and are involved in the

280

Apicella A. and Aversa R..

A BIOMIMETIC AND BIOMECHANICAL APPROACH FOR TISSUE ENGINEERING - Hybrid Nanomaterials and a Piezoelectric Tunable Bending

Apparatus for Mechanically Stimulated Osteoblast Cells Growth.

DOI: 10.5220/0003887902800285

In Proceedings of the International Conference on Biomedical Electronics and Devices (BIODEVICES-2012), pages 280-285

ISBN: 978-989-8425-91-1

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

control of modelling and remodelling (Sorrentino et

al., 2007; Frost, 1990; Wolff, 1892; Frost, 1964;

Frost, 1994). Early studies by Wolff (1892) stated that

mechanics could determine changes in the

architecture of bones (Wolff, 1892). In 1964 Frost

expressed mathematically the reactions of the bone

tissue to given stimuli to quantitatively assess bone

deformations (Frost, 1964). Remodelling processes

repair the damage removing and replacing the

damaged tissues with new bone. Moreover,

overloading (or under-loading) alters such

phenomenon (Frost, 1994). Mechanically compatible

hydrogels as scaffolding materials could increase

prosthesis adaptation mechanisms introducing active

interfaces that improve implant biomimetics while

reproducing cartilage and ligaments bio-mechanical

functions. Adaptive properties of bone benefit of use

of biomimetic (biomechanically compatible and

bioactive) scaffold bio-materials.

2 MATERIALS AND METHODS

Our Biomimetic and Biomechanical approach

resulted from a parallel mechanical and physical

characterization of new hybrid material coupled to

the bio-mechanical Finite Element analysis of the

biological system investigated (implanted bones).

The mechanics of the “in vitro dynamic bender

testing apparatus” were designed by using FEA

analysis utilising the material properties of the

swollen hybrid pHEMA based nanocomposites.

2.1 Materials

Commercial 2-hydroxyethyl methacrylate, was

purchased from Sigma-Aldrich Chemicals Co., (St.

Louis, MO, USA). Fumed silicon dioxide (Aerosil

300 Degussa, Germany) with a mean diameter of 7

nm and specific surface area of 300 m

2

⋅g

−1

was

utilized as the bioactive filler. The initiator, α-α’

azoisobutyrronitrile (AIBN), was purchased from

Fluka (Milan, Italy).

HEMA monomers were mixed with increasing

amount of fumed silica (4 to 30% by volume),

according to the procedures described in a previous

work. The resin was poured in 10 mm diameter

cylindrical moulds, polymerized in a forced air

circulation oven set at 60°C for 24 hrs and finally

postcured at 90°C for 1 h.

2.2 Sorption and Swelling Test

The cylindrical samples were used for the water and

isotonic saline (0.15 M NaCl) water solution

sorption and swelling experiments. The solution

uptakes were determined at equilibrium by

gravimetric measurements in a 0.1 mg Mettler

Toledo balance (Milan, Italy). The advancing

swelling fronts in the anomalous Case II (Apicella

and Hopfenberg, 1982) of the samples were

monitored measuring the thickness of the un-swollen

residual glassy core as a function of time.

The equilibrium sorption and swelling experiments

were performed at 37°C (thermostatic water bath)

until constant weight up-take was monitored (100 h).

2.3 Finite Elements Analysis

Finite Element Analysis (FEA) on models of the

Titanium implanted bones (human mandible

segment) and of the in vitro bender set-up was

performed according to the following procedures.

2.3.1 Models Set-up

Implanted bone (human mandible section)

The solid models were generated using Solidwork

2007 software. Titanium implant and the

surrounding part of a mandibular cortical and

cancellous bone were modelled. The average

anatomical dimensions of the maxillary bone were

generated according to literature data (Schwartz-

Dabney, 2003) as a cancellous core surrounded by

2.0 mm-thick cortical bone. The FE model was

obtained by importing the solid models into ANSYS

rel. 9.0 FEM software (Ansys Inc. Houston) using

IGES format. The volumes were meshed with eight

nodes brick with 3 degree of freedom per node,

resulting in a 3D FE model made up of 31,240

elements and 35,841 nodes. The model was

constrained at the top surface of the maxillary bone.

Accuracy of the model was checked by convergence

tests (Sorrentino et al., 2007).

Piezoelectric Bender

The geometry of the piezoelectric bender has been

measured on the commercial product (see section 2.5)

and transferred to the FE environment according to

the procedures described for the implanted bone. A 3

mm thickness symmetrical layers of rubber hydrogel

were modelled at the two piezoelectric bender

surfaces (simulating a thick coating of our swollen

pHEMA based hybrid composite)

2.3.2 Mechanical Properties of Materials

Orthotropic assumption for cortical bone was

adopted while the cancellous bone was considered as

isotropic linear materials. The Young’s modulus and

A BIOMIMETIC AND BIOMECHANICAL APPROACH FOR TISSUE ENGINEERING - Hybrid Nanomaterials and a

Piezoelectric Tunable Bending Apparatus for Mechanically Stimulated Osteoblast Cells Growth

281

Poisson’s ratio of isotropic materials used in the

models of the Titanium implanted bone and

piezoelectric bender are shown in Table 1

(Schwartz-Dabney, 2003).

Table 1: Isotropic mechanical properties of materials.

Young’s modulus Poisson’s ratio

Cancellous bone 0.91 (GPa) 0.30

Titanium 110 (GPa) 0.30

Piezoelectric ceramic 400 (GPa) 0.15

Swollen pHEMA Hybrid

nonocomposite

5 (MPa) 0.48

Cortical bone was divided into two sites, one on the

buccal side and one on the palatal side according to

the mechanical characterization reported for a

dentate mandible by Schwartz- Dabney and Dechow

(Schwartz-Dabney, 2003). Each area has its own

orthotropic constants values and orientation of the

maximum stiffness direction, the directions of the

maximum stiffness is referred to the occlusal plane.

E and G are expressed in GPa. Direction of

maximum stiffness are referred to the global

coordinate system. Orthotropic elastic constants and

orientation for buccal and palatal sides of cortical

bone are reported in Table 2.

Table 2: Orthotropic constants adopted for the cortical

bone on the buccal and palatal sides, respectively.

Max

stiff.°

E1 E2 E3 G12 G31 G23 _12 _31 _23

facial

39.9

11 15 18 4.5 4.7 5.7 0.21 0.25 0.42

buccal 4.4 12 18 19 4.9 4.9 5.1 0.16 0.31 0.43

Local orientation of the maximum stiffness (E3) and

the other two orthogonal stiffness directions (E1,

E2) have been reproduced dividing the shell of

external elements (compact bone structure) in

orientation sites according to the proposed

experimental mechanical characterization. The

orientation of the maximum stiffness has been

reproduced for each site by defining a local

coordinate system and by orienting the site’s

elements coordinate systems accordingly.

The maximum stiffness (E3) directions in degree

referred to the occlusal plane on buccal and palatal

side are reported in Table 2. E1 direction is normal

to the cortical surface.

2.4 Mechanical Characterization

Shear elastic modulus measurement on dry and

swollen p-HEMA Hybrid nanocomposites were

performed using a METTLERTOLEDO (Zurich,

Switzerland) dynamical mechanical tester operating

in shear mode (DMA). The elastic and viscous

components of the shear modulus were measured

under constant frequency loading in isothermal

condition. The samples were dried under vacuum at

a 60°C for 24 h before testing. In the shear test

mode, the 10 mm diameter and 2 mm thickness

sample disks are placed between three steel plates

forming a symmetrical sandwich. An isothermal

scan at 37°C in a dry Nitrogen purged environment

was performed. The deformation control was set to

10 μm and a force limitation of 0,9 N was applied at

an oscillating frequency of 10 Hz.

2.5 Mechanical Controlled Bender

57 mm piezoelectric benders (Quick-Mount 503,

PIEZO SYSTEMS, INC. Woburn, MA USA) were

used to build the oscillating dynamic scaffold

supports. A proprietary software and electronic

apparatus was used to drive oscillating output voltage

exit (0-100V). The deformations at the bender surface

were monitored by acquisition data software (System

4000 with 20 input channels by Vishay Measurements

Group Inc., NC, USA) at 2 points/s. The bender

operates with max displacement of 1.0 mm.

2.6 In Vivo Osteointegration Tests

2 implants for each rabbit tibia, in 6 rabbits (total of

24 implants in New Zealand White rabbits); each

rabbit has been implanted with 2 implants coated

with the nanostructured hybrid biomaterial on the

right tibia and 2 control implants in the left tibia.

Micro Computer Tomography with resolution 1

voxel=15 cubic micron has been performed on the

explanted tibiae after 1 week, 1, 2, 4 and 6 months.

BV/TV (Bone Volume/Total Volume), BS/TV

(Bone Surface), TbTh (Trabecular Thickness), TbSp

(Trabecular Separation), TbN (Trabecular Number)

have been used to evaluate the Total BIA (bone

implant apposition).

3 DISCUSSION

The aim of our research was to develop a

biomimetical/biomechanical approach for the design

of the experimental dynamic procedures (biological-

mechanical stimulus) finalized to favour adaptive

directionally organized OB growth in vitro scaffold

mineralization. In order to achieve this result, both a

proper biomimetic scaffolding material and an

externally driven mechanically straining apparatus

have had to be designed.

The biomimetic characteristic of our hybrid

materials have been investigated both for

BIODEVICES 2012 - International Conference on Biomedical Electronics and Devices

282

mechanical than osteoconductive properties.

3.1 Bio-mimetics: Hybrid

Nanocomposites Properties Design

Physiological bone material behaviour to be

mimicked by the bio-active scaffolding material

relates to the following aspects:

- mechanical properties (dry – swollen)

- bioactivity (in vivo tests)

In order to define the proper nanofiller/polymer ratio

of potentially idoneous the hybrid nanocomposites

The objective properties requirements are

- similar to bone rigidity (Elastic Modulus 6-15

GPa and shear modulus G 2-5 GPa) when dry

- similar to cartilage and ligament flexibility

(Halpin and Kardos, 1976) (high deformability -

Elastic modulus 2-20 MPa) when swollen.

3.1.1 Mechanical Properties

The dry Hybrid pHEMA nanocomposites with

compositions ranging from 4 to 30% by volume of

nanosilica were isothermally shear tested in a

Dynamic Mechanical Analyser operating at 10Hz

and at 37°C. The samples showed a predominantly

elastic behaviour (the viscous component was

negligible for all compositions). The values of the

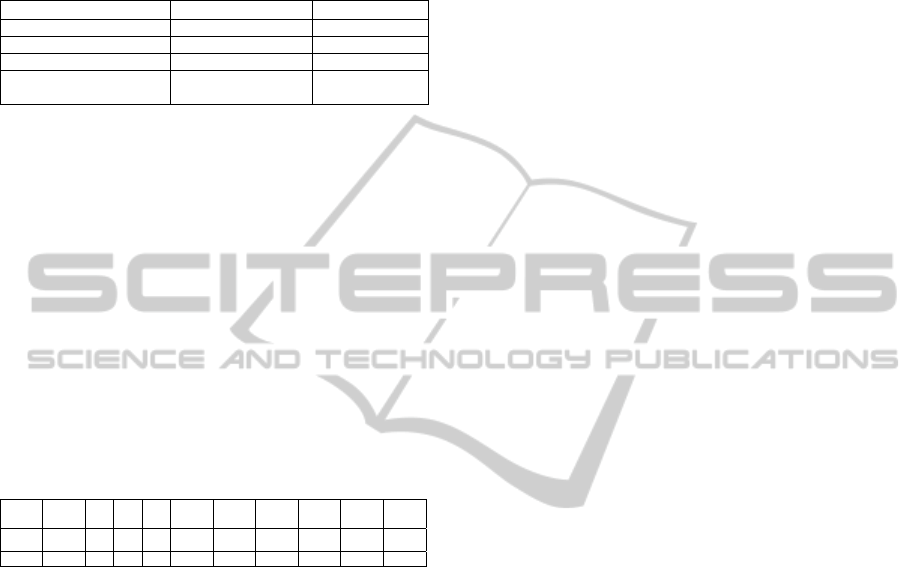

measured Shear moduli are reported in figure 1.

The compositional dependency of the shear

modulus of the nanocomposites does not follow the

ordinary Halpin-Tsai relationship utilized to describe

the elastic properties of particulate composites (red

line) (Töyräsa et al., 2001), while resembles to that

of a 3D oriented fibre mat (green line in figure 1),

indicating the formation of a continuous hybrid

ceramo-polymeric structure. Shear moduli

comparable to those of the cortical bone have been

measured for nano-silica volumetric fractions

ranging from 4 to 12%. A volume fraction of 5% has

been then chosen for the in vivo osteointegration

tests and for the FEA simlations.

Figure 1: Hybrid shear moduli (black), Halpin-Tsai (red)

and 3D fibres composite (silica glass fibres mat) (green).

3.1.2 Swelling and Sorption Behavior

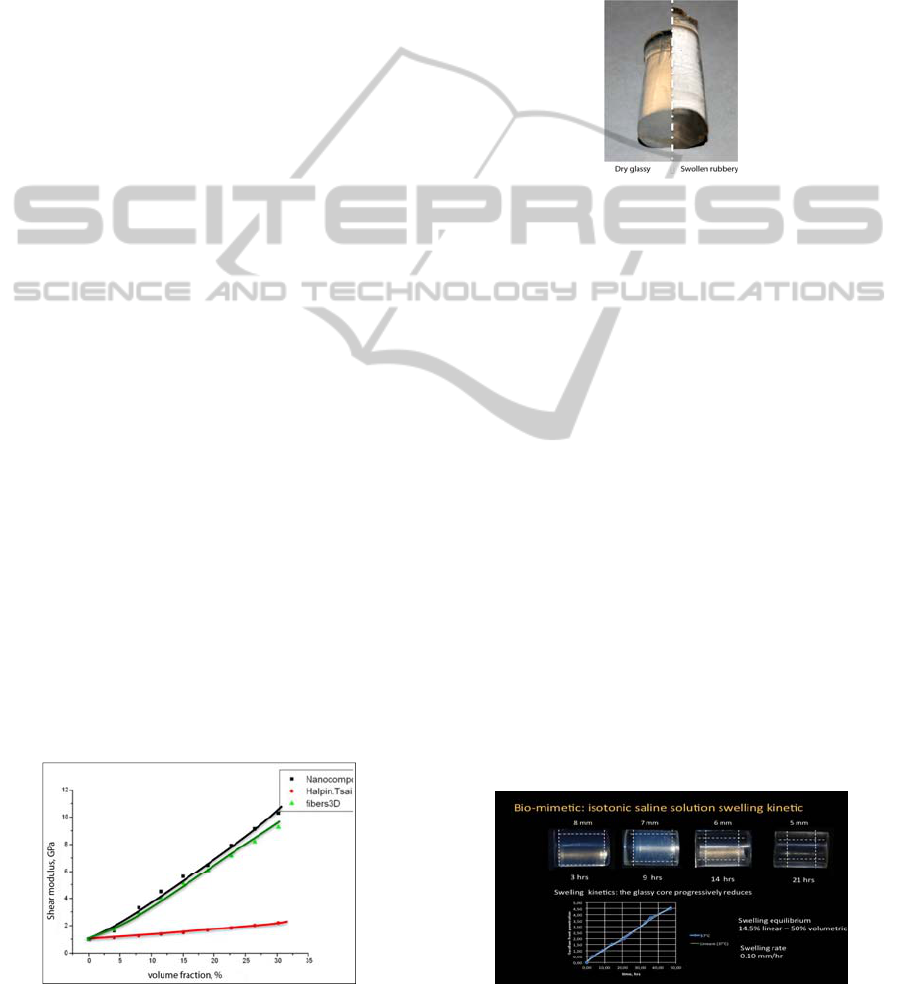

The 5% hybrid nanocomposites dramatically swell

in water solutions (figure 2) picking up 50% of its

dry weight and reducing its shear modulus to 2-3

MPa (measured in the DMA). Such phenomenon is

associated to the water induced polymer

plasticization that reduces the polymer glass

transition temperature below the test temperature

Figure 2: Swelling behaviour of the nanostructured hybrid

scaffold material.

This behaviour has been investigated in a

physiological isotonic 0.15 M NaCl solution held at

37°C for the 5% volume fraction sample both for

equilibrium and swelling kinetic. Once exposed to

the water solution, the initially dry and glassy

pHEMA composite starts to swell showing a clear

front dividing the rubber swollen external portion

and the unaffected glassy core. This glassy core

thickness progressively reduces as the swollen front

advance through the sample (upper part of figure 3).

A measure of the swelling kinetic is given by the

rate of reduction of the glassy core as a function of

the time (lower diagram in figure 3). The swelling

front advances at constant rate: this behaviour is

characteristic of a limiting relaxation controlled

sorption mechanism indicated as “Case II sorption”

(Apicella et al., 1993; Schiraldi et al. 2004; Aversa

et al., Sorrentino et al., 2007; Frost, 1990; Wolff,

1892; Frost, 1964; Frost, 1994; Apicella and

Hopfenberg, 1982). At equilibrium, when swelling

fronts meet, a 14.5% increase of the sample diameter

has been measured (about 50% of volume increase).

The resulting swelling rate is of 0.10 mm per hr.

Figure 3: Swelling kinetic of a 5% by volume hybrid

nanocomposite in 0.15M NaCl water solution (isotonic).

A BIOMIMETIC AND BIOMECHANICAL APPROACH FOR TISSUE ENGINEERING - Hybrid Nanomaterials and a

Piezoelectric Tunable Bending Apparatus for Mechanically Stimulated Osteoblast Cells Growth

283

3.2 Bio-mechanics: Adaptive

Properties of Bone

The use of biocompatible and biomechanically

active interface that can be “designed” to reproduce

bone compatible and biomimetic strain distribution

is discussed in the present paper. The ranges of the

physiological strains and related bone adaptive

properties according to (Frost, 1990; Frost, 1994) are

reported in figure 4. There are upper (>3000με) and

lower (< 50με) strain limits that do not favour

healthy bone growth.

Figure 4: Adaptive properties of bone: strain ranges for

bone resorption (< 50με blue), remodelling (50-1500

με light blue-green) and organized growth (1500-

3000με yellow-red), resorption (> 3000με).

The comparison between FEA simulation of

physiological strains in coated and uncoated

implants and bone volumes in the in rabbit tibiae

after two months of in vivo test is reported in figure

5. The FEA simulations of the strain distribution

reported of the same figure 5 have been run on a

mandibular bone section that presents comparable to

the rabbit tibia mechanical and dimensional

characteristics.

Figure 5: Osteointegration of Titanium implants with a

nanostructured hybrid biomimetic coating (left side) and

without (right). Micro-CT bone reconstruction and FEA

calculated physiological strain distributions are compared.

The Micro CT bone reconstructions of the

perimplantar areas of the hybrid nanostructured

biomaterial coated and of the “as received” implants

after two months are compared in figure 5: the

nanostructured biomaterial coated implant shows a

better osteointegration that can be related to the

osteoconductivity of the perimplantar biomimetic

hybrid coating.

The bone implant apposition or bone ingrowth

(COMERON, 1986), which is defined as the

percentage of osteointegrated implant length for the

biomimetically coated and uncoated implants in the

six months in vivo test show a significant

improvement of about 100% increase in the first two

months and 30% after 6 months.

The Osteoblast proliferation and bone growth in

the implanted tibiae is clearly favoured and

accelerated by the presence of the hybrid

nanostructured coating. The biomechanical approach

using the adaptive properties of bone well describes

the biomimetic behaviour of the proposed

perimplantar hybrid scaffold since it can predict

areas of bone resorption (FEA model elements with

strains below the physiological lower limits have

been removed in the image), as it occurs in the in

vivo tests at the neck of the implant (Micro CT

reconstruction on the right side of figure 5). The

proposed biomechanical model can predict areas of

bone growth (FEA model and micro CT

reconstruction compared in the left side of figure 5).

According to Frost:

1. Remodelling is triggered not by principal

stress but by ’strains’.

2. Repetitive dynamic loads on bone trigger

remodelling while static loads do not.

Dynamic factors have been accounted and

utilized to design a piezoelectric driven dynamic

scaffold deformation apparatus for in vitro adaptive

osteoblast cells growth. Biomimetic aspects are

invesigated by using the osteoconductive hybrid

nanocomposites bender thick swollen coating

coupled with a FEM modelling of the in vitro bone

adaptive growth. The piezoelectric dynamic bender

and control system are shown in figure 6.

Figure 6: Piezoelectric bender for dynamic OB cells

culture tests: calibration test configuration.

BIODEVICES 2012 - International Conference on Biomedical Electronics and Devices

284

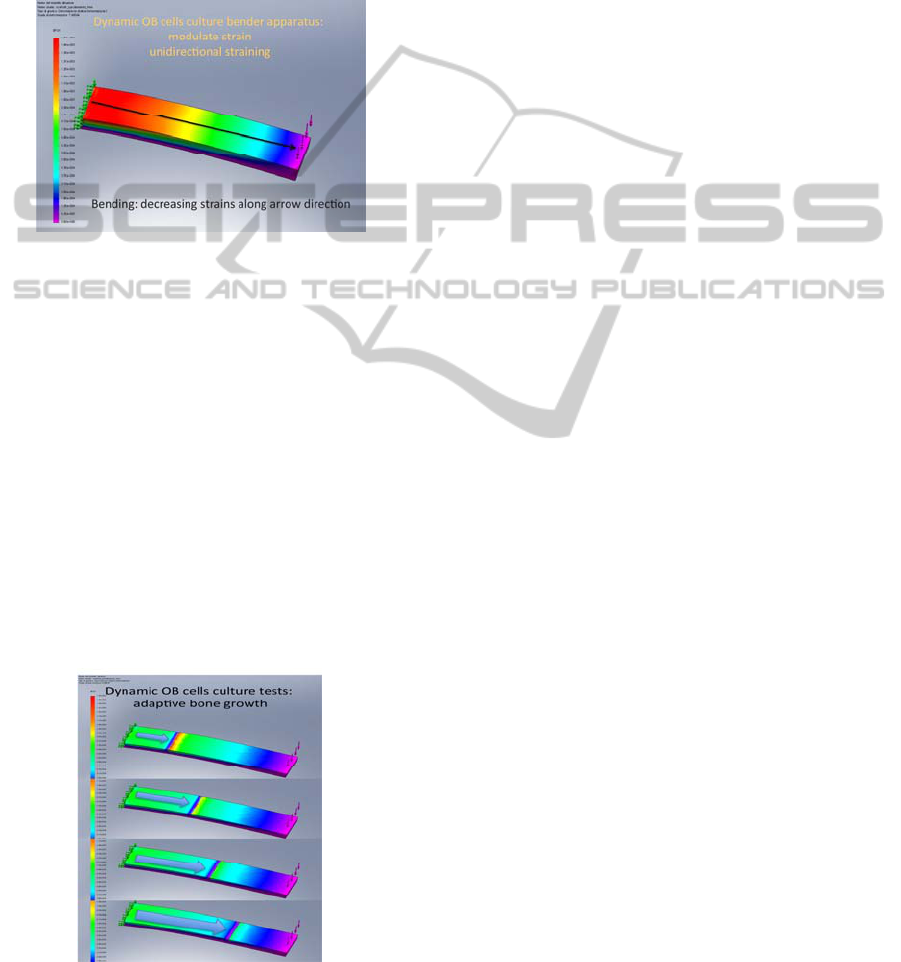

FEA results showing the distribution of the

unidirectional strains in the x direction (EPSX) in

the simulation of 1 mm oscillation at the free end in

the controlled bending test is reported in figure 7.

In the red-orange zone (1500 microepsilon), the

strains are compatible with those inducing organized

lamellar bone growth in healty bone. OB

colonization of the hybrid scaffold in the areas of

biologically compatible straining is the favoured.

Figure 7: FEA for the evaluation of the unidirectional

strains in the oscillation controlled bender.

The organized bone to growth in the red-orange

area causes a localized increase of the ossified

scaffold stiffness. Considering these localized time

dependent stiffening in the material highly strained

areas, a bone growing front moving in the direction

of the arrow (figure 8) is generated.

The rigid growing bone front lets a new area of

the scaffold to be bio-actively stimulated according

to the physiological strain for steady state

remodelling (50-1500 με - light blue and green

areas) and organized lamellar bone growth (1500-

3000 με - yellow-red areas). The oscillating

straining apparatus, than, can be used in in vitro

experiments to bone grow in thick scaffolds from

OB cell culture (figure 8).

Figure 8: Dinamic FEA simulation of the advancing bone

growth front under dynamic flexure straining conditions.

4 CONCLUSIONS

A biomimetical/biomechanical approach has been

pursued in designing the experimental dynamic

procedures (bio-mechanical stimuli) for in vitro

scaffold mineralization and ossification using

piezoelectric benders. The proposed material is a

Nanocomposites - Hybrid ceramo-polymeric poly-

Hydroxyl-Ethyl-Methacrylate (pHEMA) additioned

with nanosilica particles (4-6% by volume). This

biomimetic material swells in presence of

physiological solution (when in a biological aqueous

environment) picking-up to 50-30% by weight of

water. Mechanical behaviour in the glassy state is

comparable with bone while, in the swollen rubbery

state, is comparable with those of cartilage and

ligaments.

ACKNOWLEDGEMENTS

Funds from PRIN 2008 and FIRB (Funds for Base

Resarch) Futuro in ricerca 2008.

REFERENCES

Montheard JP, Chatzopoulos M, Chappard D. J Macromol

Sci Macromol Rev 1992;32:1–34.

Apicella A, et al. Biomaterials 1993;142:83–90.

Schiraldi C, D, Apicella A, Aversa R, De Rosa M (2004)

Biomaterials 25 (17):3645–3653.

Aversa R, Apicella D, Apicella A (2009). Dental materials

2009; 25: 678–690

Sorrentino R, Aversa R, Apicella A. Dent Mater 2007; 23:

983–93.

Frost HM. Anat Rec 1990; 226:403–13.

Wolff J. Das Gesetz der Transformation der Knochen.

Berlin: A Hirschwald; 1892.

Frost HM. Mathematical elements of lamellar bone

remodeling. Springfield: C. C Thomas; 1964. pp. 22–25.

Frost HM. Angle Orthod 1994; 64:175–88.

Apicella A, Hopfenberg Hb. Journal of Applied Polymer

Science, 1982; Vol. 27(4), P. 1139-1148, Issn: 0021-8995

Schwartz-Dabney, C.L. (2003) American Journal of

Physical Anthropology 120: 252-277.

J Töyräsa, et al., Journal of Biomechanics, Volume 34,

Issue 2, 2001, 251-256

J.C. Halpin and J. L. Kardos; Polymer Engineering and

Science, 1976, v16, N5, pp 344-352

H. U. COMERON, Clin. Orthop. 208 (1986) 81

A BIOMIMETIC AND BIOMECHANICAL APPROACH FOR TISSUE ENGINEERING - Hybrid Nanomaterials and a

Piezoelectric Tunable Bending Apparatus for Mechanically Stimulated Osteoblast Cells Growth

285