MANDIBLE PARAMETERIZATION USING A REFERENCE

LINE

M. J. Tsai

1

, C. L. Chen

2

, H. W. Lee

1

, C. H. Chao

3

and P. W. Hsu

1

1

Department of Mechanical Engineering, National Cheng Kung University, Tainan City, Taiwan

2

Medical College, National Cheng Kung University, Tainan City, Taiwan

3

Department of Electronic Engineering, Ming Chuan University, Taipei City, Taiwan

Keywords: Computer-assisted System, Mandibular Reconstruction, Parameterization.

Abstract: Using fibula flap for mandible reconstruction becomes a common method. Pre-surgical planning always

assumes a known removal portion of mandible to plan the cutting of fibula. Researchers have developed jig

or mechanism to assist doctors in measuring and guiding cutting locations of the mandible. However, the

true locations of mandible removal are never known. To ease the problem, standard mandible parameters is

required to locate the removal area. This paper aims to construct a reference line for parameterizing the

mandible. The reference line can be divided into four portions that are coincident with the anatomical

features areas of the mandible: Symphysis, Body, Angle, and Ramus. Each portion is then re-sampled into

10-15 sections, and these sections faithfully represent the mandible shape. Thus, all mandibles are re-

defined by these 101 sections. Using these mandible parameters, the removal area is recorded by numerical

addressable locations to compute the fibula cut, and the mandible and fibula can be aligned according to the

parameters for planning the reconstruction.

1 INTRODUCTION

Fibula flap is commonly used in mandibular

reconstruction because it has enough length for

large-defected reconstruction (Ferri, J., 1997).

However, there is no standard procedure for such

osteotomy since the shapes between fibula and

mandible are quite different. Doctors rely on their

own experience to decide a cutting strategy, and this

should be performed at the scene. Once the fibula

being cut into pieces, it is impossible to redo. For

releasing the doctors’ pressure and for aesthetic

purpose, computer-aided surgical planning are

employed recently; most of them used a stereo

model (Cohen, 2009; Hallermenn, 2006; Yeung,

2007), which is created based on tomography data so

that doctors can simulate the reconstruction.

However, the true removal locations of mandible

defected portion are still unable to know. Besides,

the alignment of fibula to the mandible for cutting is

performed manually, probably simulated by virtual

CAD environment for surgical planning. The cutting

planning may be useless if the discrepancy between

the true cut and the prediction is large. Some

researchers provided mechanisms (Strackee, 2004)

or paper models (Wang, 2009) to record dimensions

of the defect section to assist the osteotomy.

However, those approaches require assistantship

from technicians. The costing and time-consuming

processes are tedious and laborious that cannot be

automated in computer environment.

Until now, all of pre-surgical planning methods

eventually required manual measurement using jig

or paper models of mandible cut. Although some

researches provided successful examples of

rehabilitating defected mandible that were assisted

by CAD software (Yoo, 2011; Zachow, 2005), none

of them gave a complete solution of mandible

osteotomy. For the reason, this study aim to provide

a guide for addressing and registering the mandible

cutting locations in a computer assisted mandible

reconstruction planning. This approach is based on

numerical method of mandible feature extraction.

In order to make a standard yardstick, it is

necessary to parameterize mandible according to its

shape characteristic. In this paper, STL models of

mandible are used as an initial data. STL is a popular

file format used in CAD software. Most of the CT

scanned data can be easily converted into a STL

format via commercial available software packages.

548

Tsai M., Chen C., Lee H., Chao C. and Hsu P..

MANDIBLE PARAMETERIZATION USING A REFERENCE LINE.

DOI: 10.5220/0003891505480553

In Proceedings of the International Conference on Bio-inspired Systems and Signal Processing (MIAD-2012), pages 548-553

ISBN: 978-989-8425-89-8

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

However, finding 3-dimensional features of

mandible is difficult because of irregular and

complicated mesh surface.

In this research, we encoded the 3D mandible

STL file into 2D image format with two different

view angles and search their medial axes; by

integrating the information from the two medial

axes, a reference line that represents the profile of

the mandible in 3-D space is constructed. Then the

bending sections are searched from the reference

line. The mandible is then segmented into four

portions. Each portion is sliced into several sections.

After parameterization, the re-sampled mandible

model has standard format that consists 101 sections

distributed along the reference line. Each section

consists 40 structure points, with first 20 points

located in the lingua side and the last 20 points

located at the buccal side.

2 REFERENCE LINE

CONSTRUCTION

An ideal reference line for mandible should follow

three criteria. First, it must be inside a mandible that

is similar to a medial-axis. Second, it reflects the

shape of the mandible. Finally, it should be smooth

enough for parameterization along its shape. The

reference line distinguishes from a medial-axis in

that, due to rough STL digitization, the medial axis

may not be continuous to take derivatives.

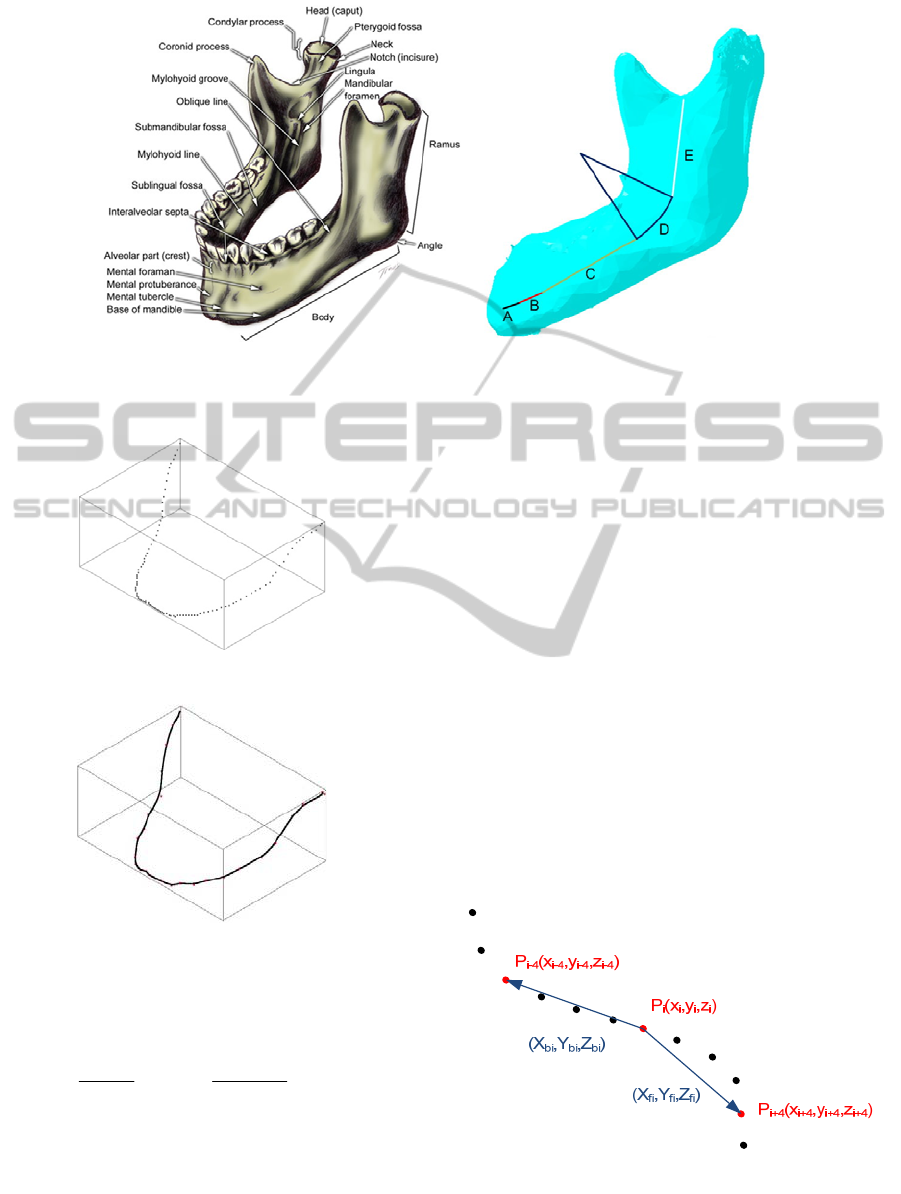

2.1 The Best Symmetrical Plane

Since the mandible STL models do not come in at

the same coordinate system, it is necessary to find a

conformable coordinate system to describe them.

Since the mandible is symmetrical in shape, it is

nature to find its symmetry plane first. Then a better

coordinate system can be constructed, and the

mandible can be re-oriented to the coordinate system

for subsequent processes. This step is fulfilled by

calculating its tensor of moment of inertia. From the

major axes of the inertia, the symmetric plane is

found and the shape of mandible can be observed in

a good view, as shown in Fig. 1.

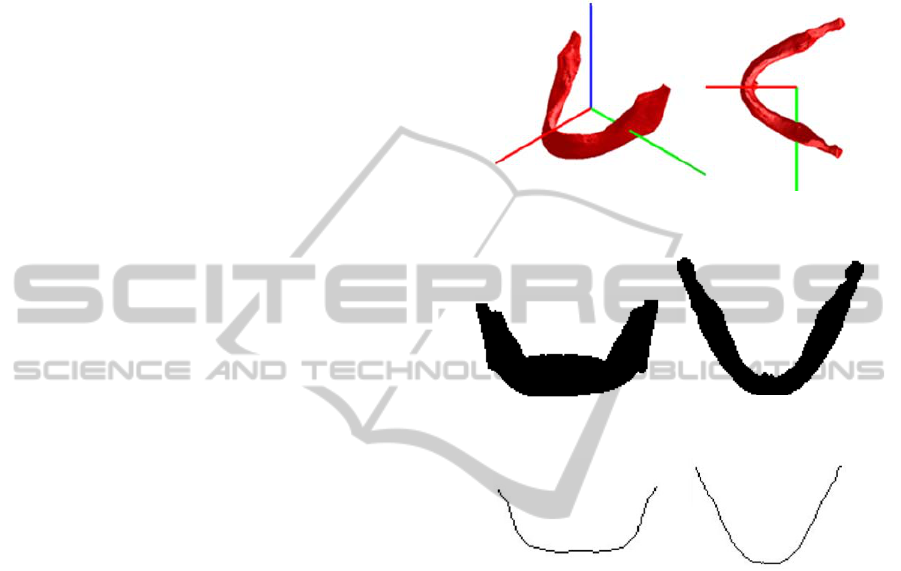

2.2 Two-dimensional Medial-axis

The vertexes of the mandible STL model are

extracted as 3D points which are then encoded into

2D images by projecting the points onto its principle

planes, the y-z plane (front view) and the x-y plane

(top view) with a proper scale factor, as shown

in

Fig. 2. Image processing technique is applied to find

the medial-axis in each image. The two 2D medial

axes can be obtained by a simple contour thinning

process. The medial-axes retain the profile and

shape of the mandible in the two principle planes

(Fig. 3).

Figure 1: Result of the best plane searching.

Figure 2: Mandible images. (L) Front view (R) Top view.

Figure 3: Medial-axis. (L) Front view (R) Top view.

2.3 Reference Line

Because a medial-axis contains two-dimensional

information, two medial axes in orthogonal view

preserve the 3D coordinates of the medial-axis.

Therefore, a 3D curve that passes through the points

of medial-axis can be constructed according to a

corresponding coordinate of both medial-axes. Fig. 4

shows such a 3D curve; it is a primary reference

line. Obviously, the primary reference line is very

rough and discontinuous caused by the image

resolution and digitization. In order to make a

smooth reference line, we reconstruct the 3D curve

by fitting it a B-spline function so that it is smooth

anywhere, as shown in Fig. 5.

MANDIBLE PARAMETERIZATION USING A REFERENCE LINE

549

Figure 6: (Left) Mandible anatomy, (Right) Reference line segmentation. The left figure is from http://withealth.net/en/

facial-bone-anatomy.

Figure 4: A primary reference line.

Figure 5: Reference line (B-spline).

A B-spline curve of p

th

order is defined as:

() ()

,

0

01

n

ip i

i

Cu N uP u

=

=≤≤

∑

(1)

() () ()

()

1

,,1 1,1

11

1

,0

1

0

ip

i

ip ip i p

ip i ip i

ii

i

uu

uu

Nu N u N u

uu u u

uuu

Nu

otherwise

++

−+−

++++

+

−

−

=+

−−

≤<

⎧

=

⎨

⎩

(2)

Where P

i

are control points, and N

i,p

(u) is the basic

function of the B-Spline. The further derivation is

described in (Tsai, 2011).

3 PARAMETERIZATION

According to the anatomical feature of the mandible,

the reference line can be simplified into arc and

straight-line portions for the left and right halves

(Fig. 7). We search for the bending portions of the

reference line using the 3D bending value that

extended from 2D (Wang, 1995), the 3D bending

value is defined by the following equations:

=

+

+

+

+

+

(3)

=

−

=

−

=

−

=

−

=

−

=

−

(4)

Where k is a step length indicates the number of

point forward and backward. Fig. 7 illustrates a case

of k = 4.

Figure 7: Bending value of P

i

with k equal to 4.

According to the bending values, high and low

curvature portions of the B-Spline curve can be

BIOSIGNALS 2012 - International Conference on Bio-inspired Systems and Signal Processing

550

distinguished by an appropriate threshold. We then

generate arc segments to replace the high curvature

portions, and straight-line segments to replace the

low curvature portions of the B-Spline curve. The

boundary condition between the arc and the straight-

line segments is continuous up to the first derivative,

i.e. they have the same slope. It is interested to

discover the segments are coincident to the

“Symphysis, Body, Angle, and Ramus” defined by

the anatomy features.

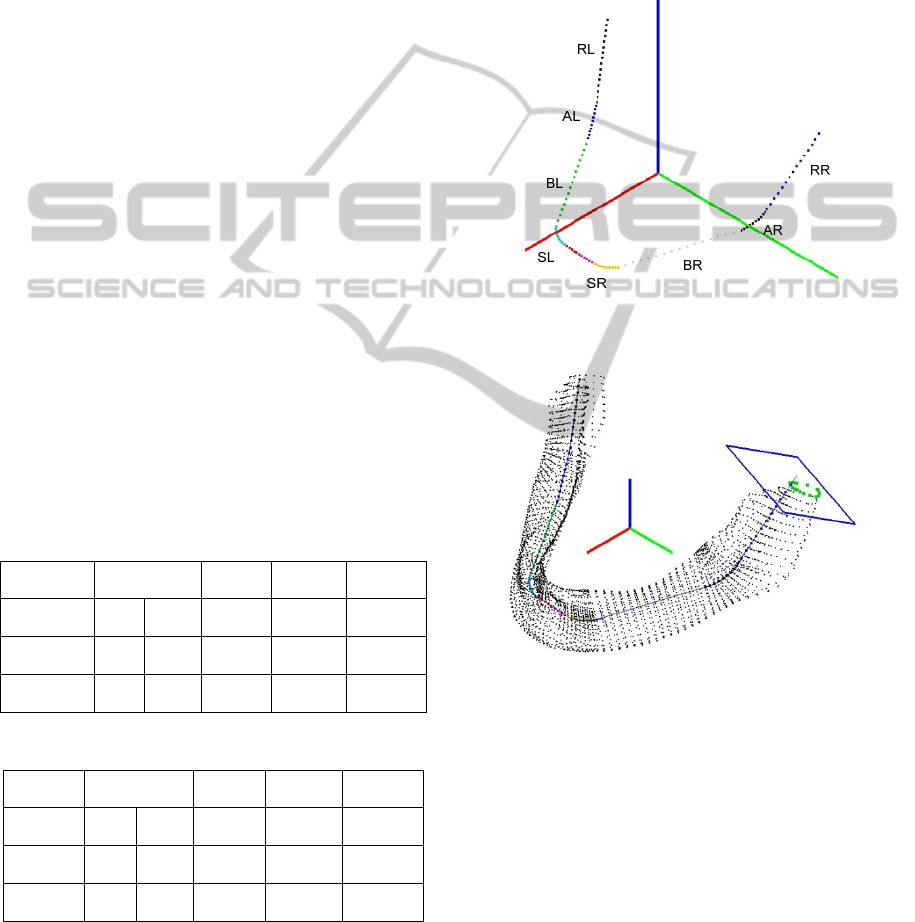

Then, non-dimensional parameters are specified

to each segment, and each segment is evenly divided

into 10 to 15 nodes according to the length. The

parameterization begins from the symmetric node,

then Symphysis, Body, Angle, and stop at Ramus.

For each left and right side, the Symphysis has ten

nodes, Body has 15 nodes, Angle has 10 nodes, and

Ramus has 15 nodes. Total of 101 nodes are

specified. Every node is given a non-dimensional

parameter (NDP). Each NDP contains two characters

and a number. The first letter is extracted from the

first character of the name of this mandible portion.

The second letter specifies the left or right half of the

section located. The last digit represents the order of

node in this segment (Fig. 8). For example, SL3

means the third node in the left side of

Symphysis

portion. Tables 1 and 2 list the left and right portions

of the NDP code, respectively. Besides, the data

structure of each node contains the position (x, y, z)

of the node on the reference line of the mandible and

the normal vector (I

x

, I

y

, I

z

) of the sectional plane

that passing through the node.

Table 1: The NDP codes (left half).

Mandible

portion

Left

Symphysis

Left

Body

Left

Angle

Left

Ramus

Line

segment

A B C D E

Number of

nodes

5+(1) 5 15 10 15

NDP SL0-5

SL6-

10

BL1-15 AL1-10 RL1-15

Table 2: The NDP codes (right half).

Mandible

portion

Right

Symphysis

Right

Body

Right

Angle

Right

Ramus

Line

segment

A B C D E

Number of

nodes

5+(1) 5 15 10 15

NDP SR0-5

SR6-

10

BR1-15 AR1-10 RR1-15

3.1 Sectional Contour of Mandible

The nodes on the reference line preserve the profile

of mandible but they alone cannot re-generate the

whole 3D mandible shape. Sectional contour at each

node is also required for reconstructing the mandible

model. In order to reduce the number of the data

point, we just recode the intersection points between

the original mandible triangular mesh and the 101

sectional planes. The normal vector of each plane is

defined by the direction of the straight-line segments

or the tangent of the arc portions. The resultant 101

sectional contours are shown in Fig. 9.

Figure 8: 101 nodes with codes.

Figure 9: 101 sectional contours of the mandible.

3.2 Structure Points

However, the number of contour point in a section is

not the same due to the original meshes of the

mandible STL models are not generated in the same

density. A normalized method is to re-sample the

contour points with equal spanning angle from the

node to the perimeter. The re-sampled contour points

are called the structure points to preserve the

mandible cross-sectional structure. For the contour

points in each section, the top and bottom crest

points are found first. Then 40 structure points are

re-sampled from the contour points; twenty are

located in the buccal side, and another twenty are in

MANDIBLE PARAMETERIZATION USING A REFERENCE LINE

551

the lingua side. Fig. 10 illustrates the definition of

the structure points. The lowest point is set as the

first point (P

0

), and the top crest point is set as the

twentieth (P

20

); the rest of points are generated by

interpolation. Based on the definition, the second to

the nineteenth point are located on the lingua (inner)

side of the mandible, and the twenty-first to the

thirty-ninth points are located on the buccal (outer)

side.

Figure 10: Definition of structure points of a section.

4 RESULT AND APPLICATION

The two mandible STL files in this paper were

provided by E-DA hospital (Kaohsiung, Taiwan); it

originally contains 44062 and 138564 polygons with

21981 and 68962 vertices, respectively. After

parameterization, they all reduced to a standardized

4400 structure points. Triangular meshes can be

easily built to reconstruct the mandible STL models.

4.1 Comparison

To evaluate the accuracy of reconstructed mandible

model, the differences between the original mandible

STL and the newly re-built one were measured.

Figure 11 shows a view that the two models are

overlapped. The maximum discrepancy between the

two models is measured about 0.2 mm, which is

precise enough for surgical planning and locating the

cutting area for reconstruction purpose. More cases

are going to be re-built to verify the algorithm by

checking the geometrical integrity and the accuracy

of the new mandible models.

Figure 11: Comparison of the original model (in red), and

the reconstructed one (in blue).

4.2 Mandible Reconstruction

Parameters

For the application of mandible parameterization, we

have also developed a user interface to cut the

mandible three-dimensionally according to the NDP.

Users can move a cutting plane along the reference

line, and rotate the plane about two axes defined by

the local coordinate of the line to range the defected

portion. There are three reconstruction parameters

for recording a cutting plane, which are the NDP

code of the section on the reference line, and two

rotation angles

α

and

β

. The rotation angles are,

respectively, about the normal and bi-normal vectors

of the local coordinate system along the reference

line. Fig. 12 illustrates a cutting process using NDP

as a guide. Of course, a real cutting guider can be

molded according to the NDP code using rapid-

prototyping technology.

To plan for the fibula cut, parameterization of

fibula based on the same strategy is also necessary. It

is easy to do so since the fibula is simply a

cylindrical shape. Once the orientation of fibula flap

is determined, then align the fibula cross section

with that of mandible can be done by using the NDP

code. The surgical planning can be accomplished in

computer by “placing” the fibula STL model onto

the mandible reference line and cutting the fibula

into segments. The length of fibula segment can be

determined by setting a tolerance between the

bended contour of the reference line and the

corresponding straight-line contour of the fibula.

Moreover, the fibula flap can be placed in a desired

orientation on the mandible since the number of

structure point indicates the top, lingua, bottom, and

buccal side. In all, this study established an

infrastructure for the computer assisted mandible

reconstruction using fibula flap. Without a standard

P

0

P

20

P

1

~P

19

P

21

~P

39

BIOSIGNALS 2012 - International Conference on Bio-inspired Systems and Signal Processing

552

parameterization, there would be no information for

the removal locations of the mandible, and fibula

bone would have no reference to align with the

mandible for cutting into segments.

Figure 12: Process of cutting a mandible. (a) Select cutting

position. (b) Rotateαdegree about x-axis. (c) Rotateβ

degree about y-axis. (d) Set up the first cutting plane. (e)

Result of the first cut. (f) Result of the second cut.

5 CONCLUSIONS

This paper postulates an idea and provides an

approach of mandible parameterization using a

reference line. The reference line represents the

profile of mandible. The reference line is divided

into four portions that represent the Symphysis,

Body, Angle, and Ramus. The new standardized

mandible model has 101 nodes that register as the

NDP code. Each section passing through the node

contains 40 contour points. These sectional structure

points can faithfully regenerate the true shape of

mandible. After parameterization, the removal nidus

portion of the mandible is indicated by the NDP

code and the defected portion can be reconstructed

by using the parameters as a guide. Besides, the

order of structure point also indicates the orientation

of the mandible cross-sectional direction, especially

the lingua and buccal sides, which facilitates the

placement of the fibula flap on the right orientation

of the mandible. The parameterization makes the

mandible reconstruction by numerical computation

possible. It is essential for surgical planning in a

CAD system, which is our future work to be done.

REFERENCES

Cohen, A., Lavev, A., Berman, P., Nashef, R., Abu-Tair, J.,

2009, “Mandibular Reconstruction Using Stereolitho-

graphic 3-dimensional Printing Modeling Technology”

Vol. 108, Journal of Oral and Maxillofacial Surgery.

Hallermann, W., Olsen, S., Bardyn, T., Taqhizadeh, F.,

Banic, A., lizuka, T., 2006, “A New Method for

Computer-Aided Operation Planning for Extensive

Mandibular Reconstruction”, Vol. 117, Plastic and

Reconstructive Surgery.

Ferri J., Piot B., Ruhin B., Mercier J., 1997, “Advantages

and Limitations of the Fibula Free Flap in Mandibular

Reconstruction”. Vol. 55, Journal of Oral and

Maxillofacial Surgery.

Strackee, S. D., Kroon, F. H., Spierings, P. T., Jaspers, J.

E., 2004, “Development of A Modelling and

Osteotomy Jig System for Reconstruction of the

Mandible with A Free Vascularized Fibula Flap”, Vol.

114, Plastic and Reconstructive Surgery.

Tsai M. J., Lee, H. W. Ann, N. J., 2011, “Machine Vision

Based Path Planning for a Robotic Golf Club Head

Welding System,” Robotics and Computer-Integrated

Manufacturing, 27, 2011, pp. 843-849.

Wang, M. J., Wu, W. Y., Huang, L. K., Wang, D. M.,

1995, “Corner detection using bending value”, Vol. 16,

Pattern Recognition Letters.

Wang, T. H., Tseng, C. S., Hsieh, C. Y., Ma, H., Shen, B.

H., Perng, C. K., Tiu, C. M., 2009, “Using Computer-

Aided Design Paper Model for Mandibular

Reconstruction: A Preliminary Report”, Vol. 67,

Journal of Oal and Maxillofacial Surgery.

Yeung, R. W., Samman, N., Cheung, L. K., Zhang, C.

Chow, R. L., 2007, “Stereomodel-Assisted Fibula Flap

Harvest and Mandibular Reconstruction”, Vol. 65,

Journal of Oral and Maxillofacial Surgery.

Yoo, D. J., 2011, “Three-dimensional Surface

Reconstruction of Human Bone Using A B-spline

Based Interpolation Approach”, Vol. 43, Computer-

Aided Design.

Zachow, S., Lamecker, H., Elsholtz, B., Stiller, M., 2005,

“Reconstruction of Mandibular Dysplasia Using A

Statistical 3D Shape Model”, Vol. 1281, International

Congress Series.

MANDIBLE PARAMETERIZATION USING A REFERENCE LINE

553