EXPERIMENTAL TESTS IN NON-DESTRUCTIVE

LABORATORY

On-line Experiment: Monitoring Sensors

Thamiles Rodrigues de Melo

1

, Marcus Marinho Bezerra

1

,

Jaidilson Jó da Silva

2

and José Sérgio da Rocha Neto

2

1

Laboratory of Electronic Instrumentation and Control, Federal University of Campina Grande,

Aprigio Veloso 882, Campina Grande, Brazil

2

Department of Electrical Engineering, Federal University of Campina Grande, Campina Grande, Brazil

Keywords: Hypertext, On-line Experiment, Labview, Sensors.

Abstract: In this paper the construction of hypertext which simulates a virtual laboratory (Non-Destructive

Laboratory) will be described. The hypertext was applied to on-line experiments associated to the study of

industrial automation processes, e.g., the monitoring of temperature, pressure and flow sensors. A test

platform and an HMI (Human Machine Interface), developed in the software LabVIEW, were used. The

HMI is published in the Web Server while the experiment is being executed. Thus, the students can assume

a hybrid role in the learning process, not only acquiring new knowledge in the study area, but also

producing it by means of this hypertext.

1 INTRODUCTION

The new technologies of information and

communication are changing the process of learning

and research. The computer is the main

technological element which enables these changes.

Today, the computer is a potentially capable tool to

start and diffuse new experiences and ideas in the

education (Tinio, 2002).

Another methodological tool that facilitates the

learning process is the hypertext (web site), which

allows the user to work in an interactive way:

exploring, importing and updating the present

content in a web page. This interactivity promotes

intellectual growth opportunities. Furthermore, the

skills and competencies developed help the users

solve quotidian problems more easily (Shapiro and

Niederhauser, 2002).

Many universities and colleges, throughout the

world, that deliver undergraduate programmes in

science and engineering are currently incorporating

virtual instruments as teaching, measurement and

analysis for student learning (Tiernan, 2010).

Industrial Automation is one of the large areas in

Electrical Engineering in which undergraduate

student needs to have knowledge about development

and usage of HMI's control. LabVIEW is a graphical

programming environment which implements

interfaces based on windowing using interactive

icons to issue commands and observe the operation

of the measurement systems. This software allows

the execution of on-line experiments using HMI's

published in the Web Server. Therefore, a student,

being anywhere in the world, can track the complete

execution of experiment in real-time (Consonni et al,

2004).

The students can view the obtained data in your

computer or any electronic equipment connected in

the Internet. Simultaneously it can research another

subjects related to the experiment and contributing

for the knowledge decentralization and enhance the

learning experience of undergraduate engineering

student using a computer.

In this context, the objective of this work is

presents a hypertext which simulates a virtual

laboratory for realization of on-line experiments

associated the study of industrial automation

process, e.g., the monitoring of temperature,

pressure and flow sensors. A test platform and an

HMI, developed over LabVIEW 2009, were used.

The HMI is published in the Web Server while the

experiment is being executed.

345

Rodrigues de Melo T., Marinho Bezerra M., Jó da Silva J. and Sérgio da Rocha Neto J..

EXPERIMENTAL TESTS IN NON-DESTRUCTIVE LABORATORY - On-line Experiment: Monitoring Sensors.

DOI: 10.5220/0003915003450348

In Proceedings of the 4th International Conference on Computer Supported Education (CSEDU-2012), pages 345-348

ISBN: 978-989-8565-07-5

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

2 MATERIALS AND METHODS

The hypertext was developed using the technology

Google Sites, which the HTML code is specified in

link: https://sites.google.com/site/nondestructivelab/

.

In the Non-Destructive Laboratory web page, the

sidebar was divided in three links:

• Home-page: There is a brief summary

about the purpose of creating the site.

• Experiments: There are the sub-links that

allow the student perform the on-line

experiments wanted.

• Comments: Is a placeholder where the

students can share another links or files

associated with the subject of the realized

experiment.

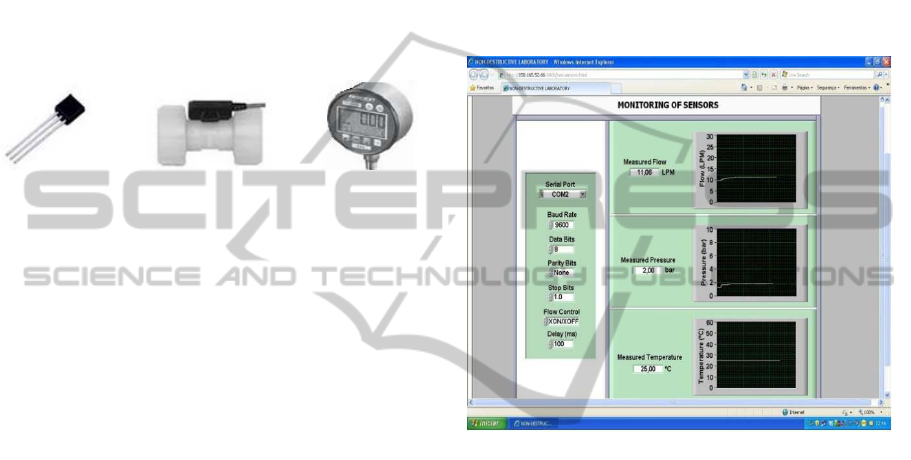

One of the screens of the site Non-Destructive

Laboratory can be observed on the Figure 1.

Figure 1: The screen of link “Experiments” of the Non-

Destructive Laboratory site.

Before the realization of the on-line experiment,

the student needs to have knowledge about the

industrial automation system in study. This system,

projected and built in the Laboratory of Electronic

Instrumentation and Control (LIEC) of the Federal

University of Campina Grande, is constituted by the

following elements:

• Test Platform: Set of galvanized iron tubes

interconnected, simulating a fluid transport

system. The flow and pressure sensors are

fixed in the tubes and the temperature

sensor is submerged in the fluid stored in

the tank (Figure 2, picture a).

• PLC (Programmable Logic Controller):

Is a device responsible for technology

integration between sensors and computer.

The PLC chosen for the information

processing of this system was SIMATIC

S7-200 Micro PLC from Siemens (Figure

2, picture b). This Micro PLC is a reliable,

fast and flexible controller for basic

automation tasks. The PLC is constituted of

a CPU 226 and a set of optional expansion

modules such as AD converter module

EM235 – 4 analog inputs and 1 digital

output. In addition, there is a PC/PPI cable

that allows establishing the communication

between RS-232 serial port of the computer

with the S7-200 CPU (Siemens, 2000).

• Computer: Device in which the PLC

programming will be realized by the

STEP7 Micro WIN software and the

monitoring of sensors using the HMI via

LabVIEW (Figure 2, picture c).

Figure 2: Industrial automation system in study. Picture a:

Experimental Test Platform; Picture b: S7-200 Siemens

PLC; Picture c: Computer with LabView.

As the main idea of the on-line experiment is the

monitoring of sensors. The main characteristics of

sensors are explained for a better understanding

about the interface exhibited in the hypertext. The

sensors used were:

• The LM35 temperature sensor (Figure 3a)

is a precision sensor which has a low output

impedance and voltage linearly with the

temperature measured at the time (10mV

equals 1°C) (National Semiconductor,

2000).

• The turbine flowmeter (Figure 3b), which

the frequency of pulses, generated due to

rotation of the propeller installed in the

direction of flow, is possible to measure the

speed the fluid. The sensor has a flow

CSEDU2012-4thInternationalConferenceonComputerSupportedEducation

346

transmitter to measure and a display panel

that supplies exact lectures in flow scale 3

to 38 LPM (FlowMeters.com LLC, 2003),

(Georg Fischer Signet LLC, 2011).

• The pressure sensor type Strain Gauge

(Figure 3c), based on the principle of wire

resistance change. It has the pressure

variation proportional to the elastic

deformation, traction or compression,

subjected to the wire. The sensor offers

digital display in 9 pressure units: psi,

mmHg, Pol Hg, ft H

2O, MPa, KPa, kgf/cm²

e Bar (Ashcroft, 2006), (Wilson, 2003).

a) b) c)

Figure 3: a) LM35 temperature sensor; b) Flow sensor

(Signet, model: 8550-1); c) Pressure sensor (Ashcroft,

model: 2274 XAO).

To execute the experiment, the student accesses

the Internet at the time scheduled with the teacher

and logs into his account in the Non-Destructive

Laboratory site. At LIEC, the experimental test

platform is turned on and the HMI developed in

LabVIEW 2009 is opened in the matrix computer by

the teacher.

During the execution of the experiment, the

student clicks at the link “HMI Sensors” present in

“Experiments” to display the HMI in the Web

Server. If the student does not have this graphical

software or this version used, it is necessary to

install the plug-in LabVIEW Run-Time Engine in

his computer in accordance with the operational

system used. The plug-in download can be done in

the “Experiments” page.

When the monitoring is finished, the student

closes the browser tab, so that the control of the page

will be released another student, and views the

measurements at the link “Measured Values”. If he

wants to share another links, files or doubts

associated to the subject of the realized experiment,

the student writes in the dialog box present at the

link “Comments”.

3 RESULTS AND DISCUSSIONS

The hypertext “Non-Destructive Laboratory” is still

in development phase. This page will be inserting in

the discipline of Electronic Instrumentation

Laboratory in the undergraduate degree in Electrical

Engineering from Federal University of Campina

Grande as e-learning. So that, the students learning

through contents is posed in the computer or Internet

and the teacher, use the Internet as means of

orientation, with intermediate classroom sessions.

The HMI presented in the site as shown in Figure

4 contains four frames: the frame at left hand side

refers to serial port configuration and the three

frames at the right hand side refer to the monitoring

of sensors, each one featuring a numeric indicator

associate the respective graphic.

Figure 4: The screen of the HMI developed at the link

“HMI Sensors”.

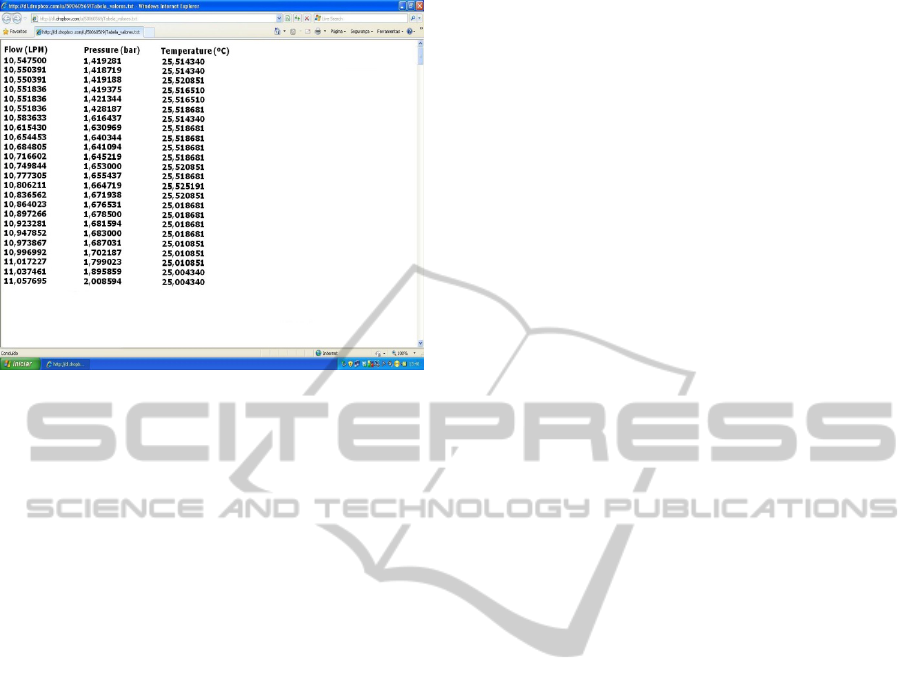

In addition, while the interface is running, it is

generated an n x 3 matrix, where the rows are the n

samples obtained and the 3 columns are the flow,

pressure and temperature measured, respectively.

The measurements, viewed at the link “Measured

Values”, can be used by students to make a further

analysis about experiment realized as shown in

Figure 5.

There are many advantages of deploying a

remote engineering laboratory in an educational

environment. Such a strategy provides a way to

provide more hands-on time for engineering students

in an efficient, flexible and cost effective manner. In

other words, since equipment can be used more

efficiently with a remote access strategy, fewer

instruments are required to serve the same number

of students. This is especially true for electrical

engineering departments that may have limited

access to laboratories and higher cost test equipment

in particular (Popescu and Odbert, 2011).

EXPERIMENTALTESTSINNON-DESTRUCTIVELABORATORY-On-lineExperiment:MonitoringSensors

347

Figure 5: The screen of the link “Measured Values”.

4 CONCLUSIONS

In this paper are presented the advisability of using

technology tools for auxiliary the process of distance

learning, for example, a hypertext which simulates

(emulates) a virtual laboratory for realization of on-

line experiments. In this case, the use of HMI’s

connected with Web Server is a way to bring

electrical engineering students to the reality of the

labor market in industrial automation: explore the

phenomena in study, visualize expected outcomes

and search possible solutions.

Also, the flexibility of iteration between students

and teacher provided by technology tools establishes

a new dynamic of teaching. The students can better

organize your questions and subjects under study

and they have the initiative to find their answers.

The innovative use of technology applied to

education, and more specifically, the distance

education, must be supported by a philosophy of

learning which provides the students the opportunity

to interact, to develop joint projects, to recognize

and respect different cultures and to build

knowledge.

ACKNOWLEDGEMENTS

The authors would like to thank CNPq for financial

support and all of the members of the LIEC,

especially to Rômulo Omena, who significantly

contributed to the development of this project.

REFERENCES

ASHCROFT Digital Industrial Gauge – Operating

Instructions. Ashcroft®, 2006.

Consonni, D. et al; “Applications of Virtual Instruments in

Electrical Engineering Education”, In International

Conference on Engineering Education and Research

"Progress Through Partnership", June 2004, pp. 1075

– 1088.

FlowMeters.com LLC (2003). “Turbine Flowmeters”;

available from: <http://www.flowmeters.com/ufm/

index.cfm?task=turbine>; accessed March, 2010.

National Semiconductor (2000). “LM35 Precision

Centigrade Temperature Sensors”; available from:

<http://www.national.com/ds/LM/LM35.pdf >;

accessed September, 2010.

Popescu, D.; Odbert, B. “Advantages Of Remote Labs In

Engineering Education”, In Agilent Educator’s

Corner – Agilent Technologies, 2011.

Shapiro, A.; Niederhauser, D. (2002). “Cap 23: Learning

from hypertext: Research issues and findings”;

available from: <http://www.aect.org/edtech/ed1/23.

pdf>; accessed November, 2011.

Signet 8550-1 Flow Transmitter (Manual). Georg Fischer

Signet LLC, 2011.

SIMATIC S7-200 Programmable Controller. System

Manual (Second Edition). Siemens AG, 2000.

Tiernan, P. “Enhancing the learning experience of

undergraduate technology students with LabVIEW

software”, In Computers & Education – An

International Journal (ELSEVIER), July 2010, pp.

1579 – 1588.

Tinio, V. L. (2002). “ICT in Education”; available from:

<http://www.saigontre.com/FDFiles/ICT_in_Educatio

n.PDF>; accessed November, 2011.

Wilson, Jon (2003). “Pressure Measurement: Principles

and Practice”; available from: <http://www.sensors

mag.com/sensors/pressure/pressure-measurement-prin

ciples-and-practice-969>; accessed March, 2010.

CSEDU2012-4thInternationalConferenceonComputerSupportedEducation

348