Flow Optimization for Iron Ore Reclaiming Process

Bruno Eduardo Lopes, José Pinheiro de Moura, Denis Anderson Ribeiro,

Fernando Henrique Costa e Borges and Marco Antônio de Souza

VALE, Av. dos Portugueses, 1000 Boqueirão, CEP 65085-580, São Luis, MA, Brazil

Keywords: Iron Ore Reclaimers, PID Control, Process Flow, Predictive Control.

Abstract: The purpose of the this paper is to demonstrate the optimization of the flow for the iron ore reclaiming

process by reclaimers over rails using implementation of PID control algorithms, identification techniques,

Predictive Control and a new effort-based learning method herein called reinforcement by difference

learning method and proportional reinforcement learning method. The outcome was an increase of

productivity, with reduction of the flow variability and on the amount of overflow occurrences.

1 INTRODUCTION

The need to control physical processes and systems

exist since remote times. The manual control, first

way for controlling used by man and still found in

many processes nowadays, shows the need of a

human operator that must know the system and have

reasonable experience and skills. With the

sophistication increase of human activities came

along the interest and necessity to automate or semi-

automate some processes, this was possible due to

the scientific and technological development that

among some several other knowledge brought us the

classical control theories. However, with the

advance of technology, systems and processes

became more complex making ineffective, or even

impossible, the usage of conventional controllers

obtained from classical theories. This initiated a

search for new methods and strategies for control

such as: multivariable control, adaptive control,

predictive control and intelligent systems control.

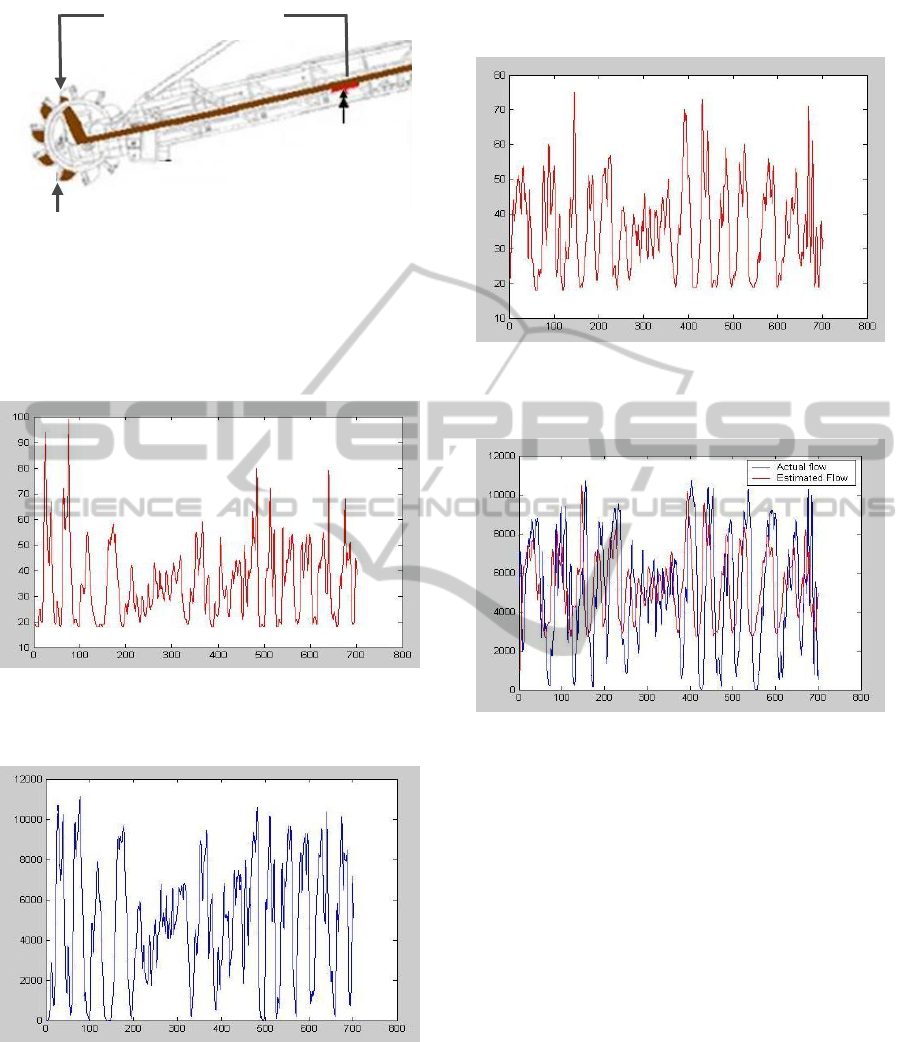

Figure 1: Stacker-Reclaimer at TMPM.

This paper demonstrates the application of

techniques for identification and process control n

stacker-reclaimers/reclaimers over rails located at

Terminal Maritimo Ponta da Madeira (TMPM).

The Terminal Maritimo Ponta da Madeira,

located in Brazil at the city of São Luis-MA, belongs

to VALE and is composed, currently, by 4 car

dumpers with nominal capacity of 8,000 tons per

hour, ten iron ore stock yards, conveyor belts and 10

yard machines divided in: 3 stackers, 3 reclaimers, 4

stacker/reclaimer and 4 ship loaders, all used to ship

iron ore.

2 OPERATIONAL MODES FOR

RECLAIMING

Reclaimers installed at TMPM can use 3 (three)

modes to control the reclaiming process:

Local

Manual

Semi-Automatic

The work for optimization was done to improve

the performance only for the semi-automatic

operation mode.

2.1 Local Mode

This mode purpose is for maintenance or testing and

will be executed through action from the

maintenance technicians on the command buttons

located nearby the equipments and respecting all the

security interlocks, not being possible in this mode

425

Eduardo Lopes B., Pinheiro de Moura J., Anderson Ribeiro D., Henrique Costa e Borges F. and Antônio de Souza M..

Flow Optimization for Iron Ore Reclaiming Process.

DOI: 10.5220/0003975404250432

In Proceedings of the 9th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2012), pages 425-432

ISBN: 978-989-8565-21-1

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

any productive process. All equipments are

commanded via the CLP.

2.2 Manual Mode

In order to characterize the manual mode, only is

needed to have selected on the HMI or in the SOS

(system operating station), the operation from

CABIN or CONTROL ROOM and, additionally,

have been selected the MANUAL mode. The

signaling will be through MANUAL OPERATING

ROOM or MANUAL CABIN written on the

operating screen.

The reclaiming will be under the command of

the operator through the usage of the levers at the

console. In this mode also the security and process

interlocks are respected, disallowing start them out

of sequence.

The translation movement will not revert

automatically and, the material reclaiming can be

done in any area of the stock yar d as long as the

operator detects it available.

The equipments will be commanded individually

via CLP, as long as the yard’s conveyor belt is on

(Start Conveyor of Spear and Start Bucket Wheel)

2.3 Semi-Automatic Mode

In this operating mode, the operator establish the

parameters of the process such as initial and final

landmark, set point for the reclaiming flow rate and

the time or distance for advancing and the angles for

the reversal of spear rotation.

Initially, through the rotation lever, the

movement is commanded and reversal points are

marked. The marked points are memorized and after

this marking, every time the rotation angle reaches

these points, there is a reversion of this movement.

Through the operating console it is possible to reset

the information of reversal points previously

defined, allowing a new preset for adjustment of the

reversal point.

In this mode, the backing movement and spear

descent for changing the reclaiming stand are done

manually, being necessary reinitiate de reclaiming

process, marking new reversal points for the spear

rotation.

The rotation speed is controlled through a PID

control loop and the time for the translation step is

determined by the operator as well as may be

adjusted automatically by a logic developed on the

CLP.

In order to preserve the flow measurement

without the interference of the material’s impact that

is being reclaimed to the spear conveyor belt, the

scale is mounted a reasonable distance from the

bucket wheel, generally in the middle of the spear’s

conveyor belt. This distance of the scale to the

bucket wheel causes an average delay of 10 seconds

and for this reason the flow measured by the scale is

not used as process variable.

3 STANDARD LOGIC FOR FLOW

OPTIMIZATION

The standard logic for flow optimization existing on

TMPM was developed aiming the control of the

following variables:

Rotation speed

Translation step

3.1 Rotation Speed Control

3.1.1 Mathematic Data Modeling

Due to the high elevated delay of the bucket wheel

in relation to the process scale according to figure 2,

which prevents the deployment of a flow control, it

was necessary develop a mathematic model to

estimate the reclaiming flow and eliminate this

delay, known as Dead Time (Smith, 1957; Astrom et

al., 1994; Hagglund, 1992).

Initially was analyzed the correlation of the flow

with the following process variables:

Current or pressure of the bucket wheel.

Current of the rotation engine.

Rotation speed

It was noted the existence of a high correlation

between the reclaiming flow and the current or

pressure of the bucket wheel and low correlation in

regards to the current and speed of the rotation. So,

only the current or pressure of the bucket wheel was

used for estimating the reclaiming flow.

In order to represent mathematically the

estimated reclaiming flow it was used the ARX

linear model which concepts are well demonstrated

in Aguirre (2007) and the extended minimum square

method (Aguirre, 2000) to estimate the parameters.

In order to determine the order of the model the auto

values analysis model, created by Lopes et al.

(2010), was utilized.

ICINCO 2012 - 9th International Conference on Informatics in Control, Automation and Robotics

426

Figure 2: Delay between bucket wheel and the scale.

In order to estimate the parameters of the ARX

model used data from current (input) and flow

(output) as shown in figures 3 (current of the bucket

wheel) and 4 (flow).

Figure 3: Data of current of the bucket wheel for

estimating the model parameters (Axis x=number de

samples / Axis y= current of the bucket wheel in Amper).

Figure 4: Data of flow for estimating the model

parameters (Axis x=number de samples / Axis y= flow in

Ton/h).

The 3° order model obtained was:

y(k) = 0,09y(k-3) - 0,76y(k-2) + 1,546y(k-1)

+ 12,11u(k-2) – 36,48u(k-1) + 43,238u(k)

(1)

For the model 1 validation it was used the data

from the current of the bucket wheel and flow shown

on the figures below.

Figure 5: Data of current of the bucket wheel for

validation of model 1 (Axis x=number de samples / Axis

y= current of the bucket wheel in Amper).

Figure 6: Comparison of actual flow with estimated (Axis

x=number de samples / Axis y= flow in Ton/h).

The obtained flow and the estimated flow for

current’s data as seen on figure 5 are shown on

figure 6. It can be noted that the estimated has a

good representation of actual data.

3.1.2 Reinforcement Learning

Due to a change on the behavior of the current of the

reclaimer’s bucket wheel over time, the model 1 did

not estimate the flow correctly any longer. The

problem is verified a month after the system was

modeled.

To fix this problem a new learning by

reinforcement method was created called

reinforcement by difference learning method and

proportional reinforcement learning method. The

procedure for utilizing this method is:

a. Analyze graphically the behavior of the real

data with the data estimated by the

mathematical model. Divide the graph in two

Scale

Bucket Wheel

TIME = +/- 10 Seconds

Flow Optimization for Iron Ore Reclaiming Process

427

or more areas, and these areas may be

divided in accordance with a possible change

in the behavior observed between actual and

estimated data. On this work, it was divided

in 3 areas: Area 1: Flow < 4000 t/h; Area 2:

Flow >= 4000 t/h e <=8000 t/h; Area 3:

Flow>8000 t/h.

b. Should the difference found between the

actual and estimated data are just a stationary

error choose the reinforcement by difference

learning method. Should it is an error of

proportionality use the proportional

reinforcement learning method. On this work

the reinforcement by difference learning

method was used.

c. Should the reinforcement by difference

learning method is opted, compare the

delayed estimated data (according to the

delay) with actual data, determine the

difference between them (Actual data –

Estimated data) and sum this difference to

the estimated data. This difference should be

calculated separately for each area

determined on item a.

d. Should proportional reinforcement learning

method is opted compare the delayed

estimated data (according to the delay) with

actual data, divide them (actual data /

estimated data) and multiply the obtained

value to the estimated value. This division

should the calculated separately for each area

determined on item a.

e. The calculation error between actual data and

estimated data should be done every n

seconds, being that the value of n will be

determined according to the problem to

solved. On this work it was used n=10

seconds.

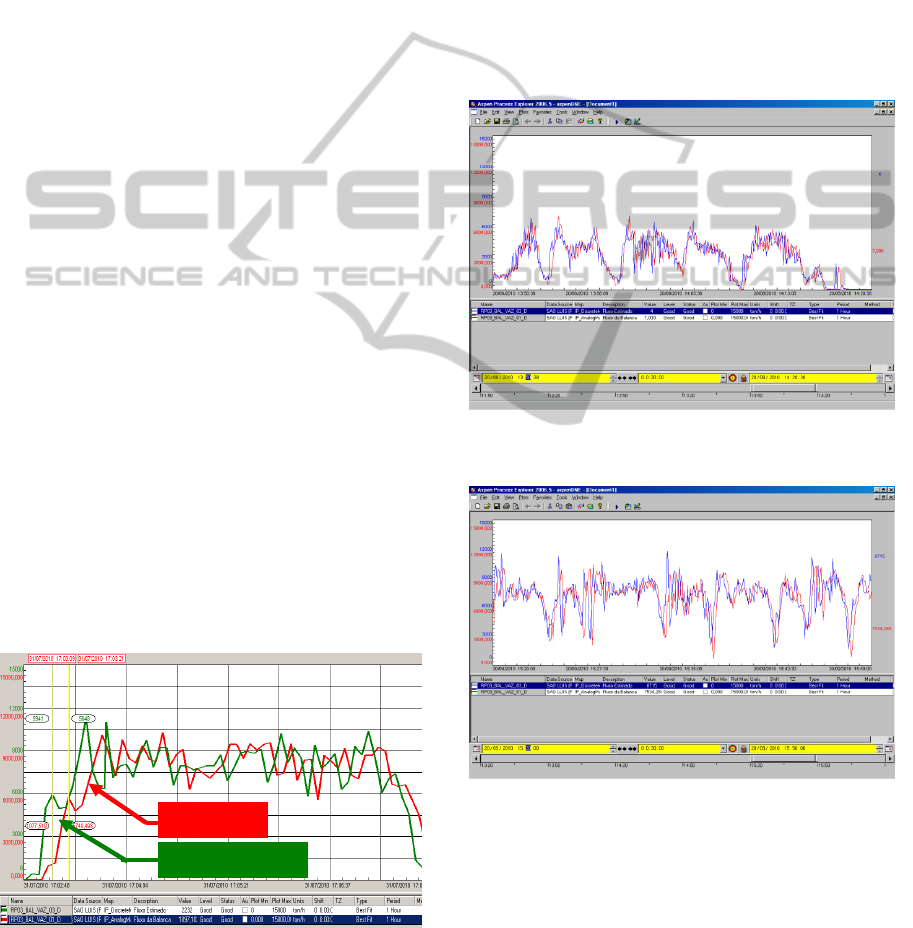

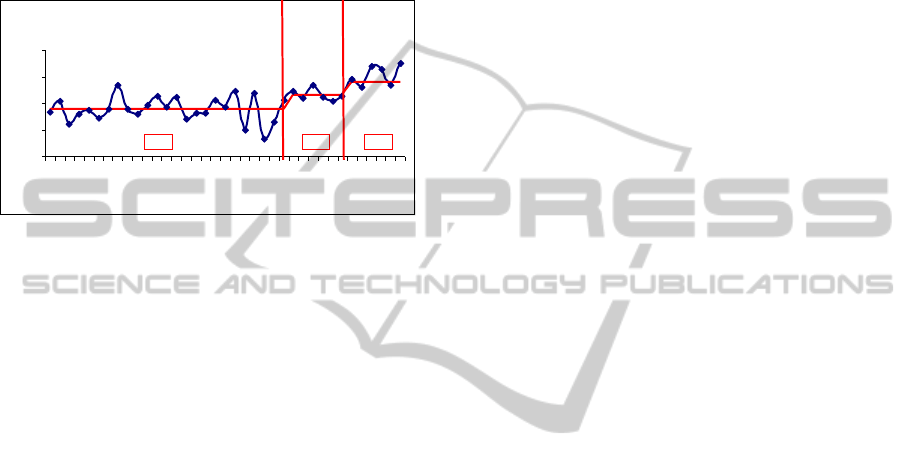

Figure 7: Estimated flow and actual flow comparison

(Axis x=Time / Axis y= flow in Ton/h).

The model 1 and the reinforcement learning

method was configured on the CLP of the reclaimer

and at figure 7, data extracted from the PIMS, can be

verified that the estimated flow has a good

representation of the actual flow.

By the usage of the reinforcement by difference

learning method on reclaimers and stackers-

reclaimers of TMPM was possible to ensure

accuracy of the estimated flow no matter the

difference of the behavior of the bucket wheel over

time. This accuracy can be verified on figure 8, 9

and 10 that during several months presented an

estimated flow (blue) very close the actual flow

(red) keeping the delay time.

Figure 8: Comparison of actual flow and estimated flow

on 08/20/2010 (Axis x = time / Axis y= flow in Ton/h).

Figure 9: Comparison of actual flow and estimated flow

on 09/20/2010 (Axis x = time / Axis y= flow in Ton/h).

Actual flow

Estimated flow

Delay = 12s

ICINCO 2012 - 9th International Conference on Informatics in Control, Automation and Robotics

428

Figure 10: Comparison of actual flow and estimated flow

on 11/20/2010 (Axis x = time / Axis y= flow in Ton/h).

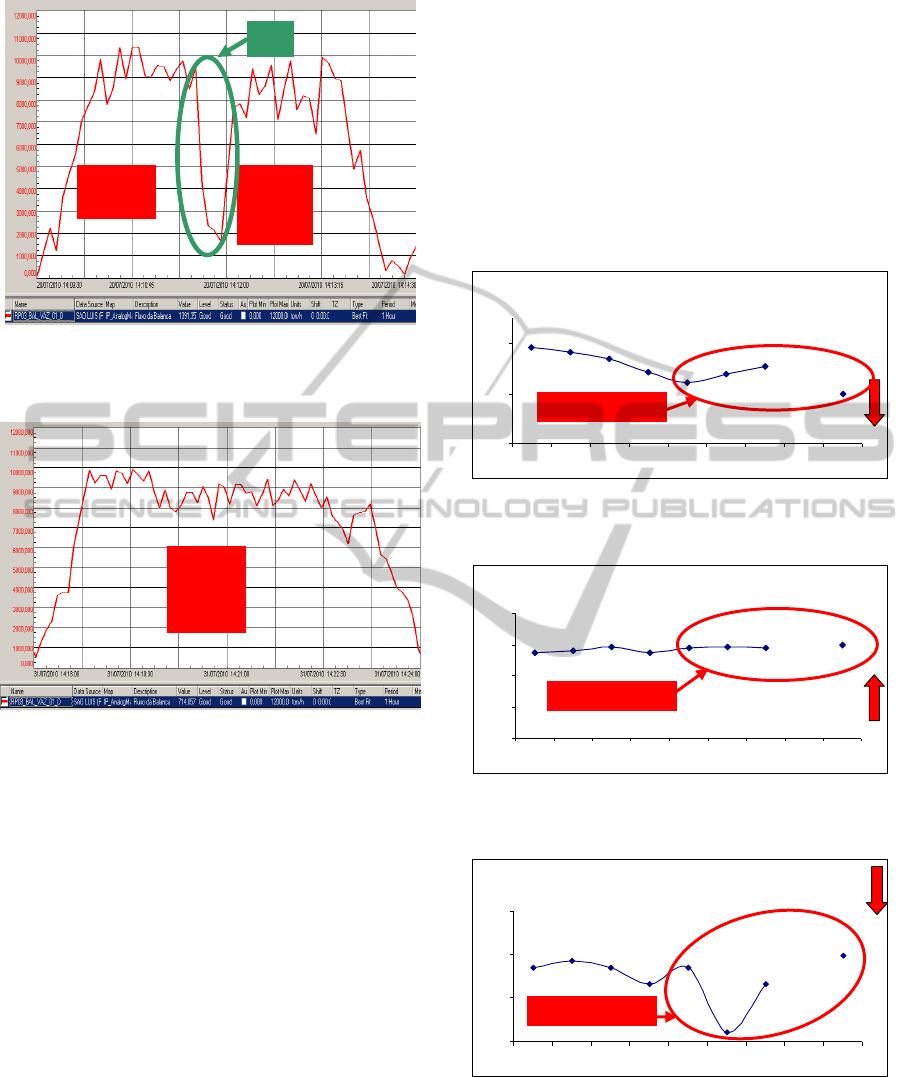

3.1.3 PID Control

The rotation speed - which interferes on the intensity

of the penetration of the bucket wheel in the pile – is

defined through a PID control loop that has as set

point (SP) the rate of the desired reclaiming flow

and as process variable (PV) the estimated flow

through the current of the bucket wheel’s engine.

The controlled variable (CV) is the Swing Speed

Boom. The control loop can be verified on figure 11.

Figure 11: Control loop of the flow.

As the method for tuning the PID was not the

purpose of this paper, it was used a practical tuning

method and the parameters found were kp Gain =

0.3; ki Gain = 0.2; Sample Period = 100

milliseconds.

Figure 12: Flow controlled at 8000 ton/h (Axis x = time /

Axis y= flow in Ton/h).

The PID control and the parameters found were

deployed on CLP of the reclaimer and the result is

demonstrated on figure 12 in which the operator has

established as set point value of 8000 t/h and the

PID controller adjusted the rotation speed until the

desired flow has been reached. For this PID was

setup a dead band of 500 t/h.

3.2 Translation Step

The initial translation step is manually defined by

the operator and individually each direction for the

rotation movement (clockwise and counter clock

wise). Its adjustment is made according to time or

distance for the translation in seconds or

centimeters.

If the operator chooses the automatic control of

the translation step, the ideal step is calculated

according of the average rotation speed that the

reclaimer needed to reach the setpoint value of the

flow during one of the rotation direction. If the

average speed of the rotation to achieve the desired

flow is elevated the time or distance of the

translation step is increase, if it is too low the time or

distance of the translation step is reduced.

The higher the translation step the lower will be

the rotation speed necessary for the reclaimer to

reach the set point and smaller will the loses caused

by the inversion of the rotation direction. On the

other hand, higher will be the possibility of overflow

occurrences and overloads on the bucket wheel. The

lower the translation step the higher will be the

rotation speed necessary for the reclaimer to achieve

the set point causing more loses due to the inversion

of the rotation direction. The idea is to adjust the

translation step in order to make the desired flow to

be achieved at a determined ideal speed in each

rotation.

The logic for translation step control was

configured on the CLP’s reclaimer and the result is

verified on figures 13 and 14. Before the

implementation of translation step control the

rotation in each direction, at base layer, has taken

about 2 minutes, as shown on figure 13. After the

implementation of the translation step control, the

rotation in each direction, at base layer, turned out to

take an average of 5 minutes, figure 14, reducing

loses due to changes on the direction of the rotation

and increasing productivity.

Flow controlled at 8000 ton/h

Controlled flow

Rotation speed reduction

Flow Optimization for Iron Ore Reclaiming Process

429

Figure 13: Time in each direction before implementation

of the translation step control (Axis x = time / Axis y=

flow in Ton/h).

Figure 14: Time in each direction after implementation of

the translation step control (Axis x = time / Axis y= flow

in Ton/h).

4 OUTCOMES

The purpose of this paper for optimization of

reclaimer flow control is the increase of productivity

along with decrease of variability and overflow

rates.

The variability or coefficient of variation (Cv) is

calculated dividing the standard deviation (σ) by the

flow average (µ):

Cv = σ / µ

(1)

At TMPM, overflow is considered as a

reclaiming flow over 10,000t/h during a period

higher or equals to 5 seconds.

In this paper will be demonstrated the results

obtained with the deployment of the optimization

work of flow control of the reclaimer RP-313K-03

and the Stacker-reclaimer ER-313K-04. The same

work was developed for the other yard machines of

TMPM and similar results were found.

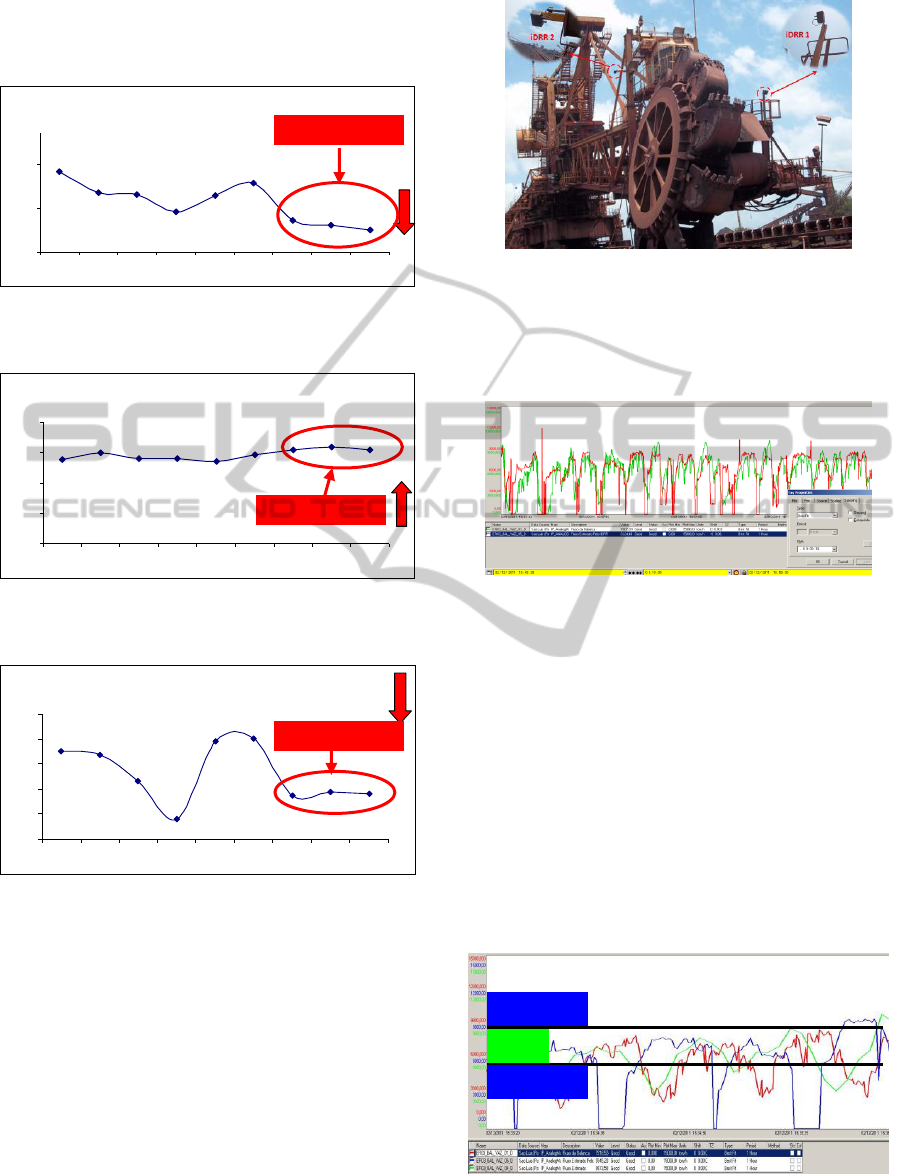

4.1 RP-313K-03

On figures 15, 16 and 17 it is possible to notice that

after the implementation of the flow control

optimization for RP-313K-03 was obtained an

average increase of 5% in productivity along with

average reduction of 10% in variability and 20% on

overflow occurrences.

Varibialidade - RP 313 - 03

0,35

0,44

0,43

0,42

0,39

0,39

0,37

0,40

0,25

0,35

0,45

mai/10 jun/10 jul/10 ago/10 set/10 out/10 nov/10 dez/10 jan/11

Figure 15: Variability evolution of RP-313K-03 (Axis x =

time / Axis y= variability).

Fluxo - RP 313 - 03

5791

5778

5867

5501

5846

5588

5452

5981

0

2000

4000

6000

8000

mai/10 jun/10 jul/10 ago/10 set/10 out/10 nov/10 dez/10 jan/11

Figure 16: Flow evolution of RP-313K-03 (Axis x = time /

Axis y= flow in Ton/h).

Sobrefluxo - RP 313-03

5,3

7,9

6,8

7,4

6,8

0,9

6,8

5,3

0,0

4,0

8,0

12,0

mai/10 jun/10 jul/10 ago/10 set/10 out/10 nov/10 dez/10 jan/11

Figure 17: Overflow evolution of RP-313K-03 (Axis x =

time / Axis y= overflow occurrences).

4.2 ER-313K-04

For the ER-313K-04 the result was even better, thus,

as demonstrated on figures 18, 19 and 20 there was

Clockwise

rotation

Counter

clockwise

rotation

Counter

Clockwise

rotation

Loses

New pattern

New pattern

New pattern

ICINCO 2012 - 9th International Conference on Informatics in Control, Automation and Robotics

430

an average increase of 9% in productivity along with

average reduction of 20% on variability and 39% on

overflow occurrences.

Varibialidade - ER 313 - 04

0,31

0,30

0,43

0,39

0,38

0,34

0,41

0,38

0,32

0,25

0,35

0,45

mai/10 jun/10 jul/10 ago/10 set/10 out/10 nov/10 dez/10 jan/11

Figure 18: Variability evolution of ER-313K-04 (Axis x =

time / Axis y= variability).

Fluxo - ER 313 - 04

6343

6149

5546

5997

5589

5630

5842

5412

6153

0

2000

4000

6000

8000

mai/10 jun/10 jul/10 ago/10 set/10 out/10 nov/10 dez/10 jan/11

Figure 19: Flow evolution of ER-313K-04 (Axis x = time /

Axis y= flow in Ton/h).

Sobrefluxo - ER 313-04

13,5

7,0

7,5

14,0

7,3

9,2

16,1

15,6

3,2

0,0

4,0

8,0

12,0

16,0

20,0

mai/10 jun/10 jul/10 ago/10 set/10 out/10 nov/10 dez/10 jan/11

Figure 20: Overflow evolution of ER-313K-04 (Axis x =

time / Axis y= overflow occurrences).

5 PREDICTIVE CONTROL

In order to improve the flow control in 2011 was

developed a solution that is based on predictive

control techniques (Camacho and Bordons, 1999).

To develop the predictive control, radar-like

sensors were installed alongside the bucket wheel, as

shown on figure 21.

Those sensors tell to the system the penetration

distance of the bucket wheel into the pile and the

height that is been reclaimed. By using this

Figure 21: Radar-like sensors installation localization.

information along with the spin speed data it was

possible to develop an estimator to predict the flow

to be reclaimed. The comparison of the expected

flow versus the actual one is shown on figure 22.

Figure 22: Comparison of actual flow (Green) and

expected flow (Red) on 02/12/2011 (Axis x = time / Axis

y= flow in Ton/h).

After the sensors were installed a logic was

developed to verify the expected flow values and

should it be higher or lower 15% of a desired flow a

predictive control action is triggered, in other words,

the PID flow controller is deactivated temporarily,

the ideal speed reference calculated by the predictive

control is written on the PLC and then the PID

controller is reactivated. It is important to mention

that the PID controls the flow that was estimated

using the current or pressure of the bucket wheel as

inputs. The action area covered by the controller is

demonstrated on figure 23.

Figure 23: PID and Predictive control action area.

Predicted flow (Blue). Estimated flow (Green) and Actual

flow (Red). (Axis x = time / Axis y= flow in Ton/h).

Predictive

Predictive

PID

New pattern

New pattern

New pattern

Flow Optimization for Iron Ore Reclaiming Process

431

The productivity gains with the implementation

of the predictive control can be seen on figure 24

where area 1 represents the productivity values for

the manual operation, area 2 represents the

productivity values using only the PID control and

area 3 represents the productivity obtained by using

the predictive control. The improvements obtained

are 11% over the manual operation and 6% over the

isolated usage of the PID control.

PRODUTIVIDADE

5787

6043

5825

6759

6691

6300

6458

6120

5707

6050

6339

5712

5875

6120

5812

6233

5645

6036

6187

5491

5804

5963

5889

5793

5612

5883

5928

6133

5916

6048

6334

6140

6330

6090

5315

5000

5500

6000

6500

7000

4-nov

6-nov

8-nov

11-nov

14-nov

21-nov

24-nov

26-nov

28-nov

30-nov

2-dez

4-dez

8-dez

12-dez

16-dez

19-dez

21-dez

23-dez

25-dez

5884

6157

6530

1

2

3

Figure 24: Productivity improvements with the utilization

of the predictive controller. (Axis x = time / Axis y= flow

in Ton/h).

6 CONCLUSIONS

The outcomes shown in this paper demonstrated that

the new pattern adopted by Vale for the iron ore

reclaiming process at TMPM, brought a significant

increase of productivity for its operations.

Additionally to the gain in productivity, it was

possible to obtain a reduction in operational loses on

the reclaiming process with reduction of overflow

occurrence.

Due to the obtained gains, this new pattern for

flow control developed at TMPM was established as

a standard to be used by the other Vale’s ports.

REFERENCES

Aguirre, L. A., 2000. A nonlinear dynamical approach to

system identification, IEEE Circuits & Systems

Society Newsletter 11(2): 10-23, 47.

Aguirre, L. A., 2007. Introdução a Identificação de

Sistemas. Técnicas Lineares e Não Lineares Aplicadas

a Sistemas Reais. Editora UFMG, Belo Horizonte -

MG. Brasil, 3a edição.

Lopes, B. E, Corrêa, M. V., Teixeira, R. A. and Moura, J.

P., 2010. Método de Análise dos Autovalores para

seleção de ordem de modelos lineares. Anais do 18º

Congresso Brasileiro de Automática, Bonito MS, pp.

498—504

Astrom, K., Hang C., Lim, B., 1994. A New Smith

Predictor for Controlling a Process with a Integrator

and Long Dead Time. IEEE Transaction on Automatic

Control 39(2): 343-345

Hagglund, T., 1992. A Predictive PI Controller for

Processis with Long Dead Time. IEEE, Control

Systems, pp57-60.

Smith, O. J. M., 1957. Closed Control of Loops With

Dead-Time, Chem. Eng. Progress; 53:217-219.

Astrim, K. J., Hagglund T., PID Controllers: Theory,

Design, and Tunning. 2ª Edition, Instrument Society of

America, 1995.

Camacho, E., Bordons, C., 1999. Model Predictive

Control. Springer Verlag.

ICINCO 2012 - 9th International Conference on Informatics in Control, Automation and Robotics

432