AN INTEGRATION PLATFORM FOR IT-FOR-GREEN

Integrating Energy Awareness in Daily Business Decisions and Business Systems

Barbara Rapp

1

, Jan Vornberger

1

, Fabian Renatus

2

and Henning G

¨

osling

2

1

Department of Computing Science, University of Oldenburg, Oldenburg, Germany

2

Chair of Production and Logistics, University of G

¨

ottingen, G

¨

ottingen, Germany

Keywords:

Green ICT, Energy Aware Production, CEMIS, Data Center, Energy Monitoring, Sustainability, Green

Logistics, Green Production.

Abstract:

Political parameters and guiding principles for environmental protection, sustainability and energy efficiency

demand for assistance from environmental management systems. Indeed, a high-capacity environmental man-

agement system has a need for multiple diverse and heterogeneous data in order to meet the requirements of

planning, controlling and assessing versatile environmental tasks within an organization and beyond organiza-

tional boundaries. This data has to be provided by so called corporate environmental management information

systems (CEMIS) for a goal oriented processing. But, looking into business practice shows that currently

implemented CEMIS do not cope with the requirements from the sustainability debate. Current software is

mostly used to manage the damage done, hence an energy efficient behaviour can not come to daily busi-

ness. Knowledge about the energy footprint of a product throughout its life-cycle is currently not properly

made accessible to business people, stakeholders or customers. For this reason, we plan a new CEMIS that is

able to take into account e.g. ICT for designing, building or selling, product related transport and production

processes, as well as web store energy costs for the whole product life.

1 INTRODUCTION

An organizational, technical system for systemat-

ically capturing, processing and publishing envi-

ronmentally relevant data within an organization is

called corporate environmental management informa-

tion system (CEMIS). The main idea of sustainability

is in the public eye and forces companies to report

on ecological, economical and social aspects. At this

point, the traditional concepts of CEMIS could have

been used, but this did not happen.

From today’s perspective, traditional systems

failed for any number of reasons. Mainly, current

CEMIS focus just on achieving legal compliance

or realizing standardized environmental management

systems like ISO 14001. In business terms, such sys-

tems are at an operational management level. All in

all, present CEMIS aim at avoiding or lowering the

costs of environmental impacts, which are already

caused by organizations. These systems are merely

output oriented. But, according to the current situa-

tions for companies and the requirements from differ-

ent stakeholders a proactive approach is required.

Energy has become a major cost impact for most

companies. Raising energy awareness, enabling en-

ergy efficiency and saving money in this way will be

one of the most important duties for newly imple-

mented CEMIS. When a system like the one proposed

in this paper is in action within a company, energy

awareness becomes part of daily business decisions

and helps saving energy in a proactive way.

In this position paper we present our thoughts on

how energy awareness will be integrated into next

generation CEMIS.

2 THE IT-FOR-GREEN

APPROACH

Besides satisfying stakeholder interests, it is the prime

objective of sustainable development to establish a

harmonic balance of economy and ecology, for ex-

ample by lowering costs through material and energy

efficiency. The reduction of material and energy con-

sumption in companies has a direct positive impact

on both the environment and the economy. However,

such beneficial effects can only be achieved by imple-

226

Rapp B., Vornberger J., Renatus F. and Gösling H..

AN INTEGRATION PLATFORM FOR IT-FOR-GREEN - Integrating Energy Awareness in Daily Business Decisions and Business Systems.

DOI: 10.5220/0003978202260231

In Proceedings of the 1st International Conference on Smart Grids and Green IT Systems (SMARTGREENS-2012), pages 226-231

ISBN: 978-989-8565-09-9

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

menting a new generation of more strategic CEMIS.

The term IT-for-Green aims at increasing the en-

vironmental friendliness of companies and their pro-

cesses by means of IT. In this context, CEMIS are to

be regarded essential for supporting the sustainability

integration. Conventional CEMIS are not sufficient to

achieve this objective, for they mostly serve the pur-

pose of ensuring legal compliance with relevant en-

vironmental laws and regulations, mainly in order to

avoid financial sanctions from state authorities. With

such a strong operational focus, the requirements en-

tailed by the concept of sustainable development can

only be fulfilled to a very limited degree. On the

other hand, companies may achieve profits by apply-

ing sustainable development measures: they reduce

costs through material savings and – becoming more

and more important – by implementing energy effi-

ciency and increase their turnovers through sustain-

able products and services, corporate image improve-

ment and advantages in competition.

Besides giving guidelines, the IT-for-Green

project aims at implementing a second generation

CEMIS. We are planning a system, that is based on

three building blocks. These modules correspond to

the life-cycle of products from input (measuring en-

ergy efficiency of the ICT used) to transformation (lo-

gistics and sustainable product development) to out-

put (corporate communication and sustainability re-

ports). The underlying architecture enables a collec-

tion of green web services. In future, they will pro-

vide a basis for a service platform (called green ser-

vice mall). To succeed in implementing a second gen-

eration CEMIS the expertise of different scientific and

industry partners is combined.

2.1 Goals

Second generation CEMIS will be located at the

strategic level of a company and provide relevant en-

vironmental information and algorithms for decision

support. Also, it will enable the evaluation of sus-

tainable development lines, of mission critical prices

of resources or of volatile energy markets. For this

reason related risks and system dynamical cause and

effects between economic, ecologic and social indica-

tors can be made visible.

Future CEMIS aim at using the company’s IT as

resource guiding, integrative system for intelligent

and strategic supervision. In this way a chance and

risk efficient, strategic environmental management

can be realized and sustainable shareholder value can

be generated. Such information systems will gain

broad importance for companies.

2.2 Planned Implementation

One result of the project will be a proof-of-concept

implementation. As mentioned above, three soft-

ware modules with corresponding services and pro-

cess models will be developed. The building blocks

will cover the complete product life-cycle from input

to transformation to output. The module ”Green IT”

(section 3) will provide services that deal with energy

efficiency of the ICT infrastructure. They can be used

stand-alone or as data source for other services and

modules. Section 4 focusses on ”Green Production

and Logistics”. This module provides services that

enable the reduction of energy and material flows.

The third module deals with sustainability reporting

and dialog-based communication. It provides ser-

vices, that for example enhance (external) data (e.g.

from module 1 or 2) and based on this, build reports

for different stakeholders.

The core system, that will finally make up the

next generation in the CEMIS, will be a service-

oriented platform that allows for loose coupling and

bundling of necessary methods. A green service mall

will provide a semantically enriched procurement of

CEMIS-functionality for individual embedding into

workflows. Embedding environmental considerations

into arbitrary (business) processes this way, allows for

an intermixed usage of specific functions from self-

hosted services, external service providers and non-

environmental services. Such architecture allows for

a highly flexible integration of environmental tasks

into traditional (already installed) information infras-

tructures with the new CEMIS as the integrating sys-

tem. For our prototype we will have to short-list the

functions that will be actually implemented.

With high priority, we will focus on energy aware-

ness and reduction as one of the most important use

cases for our first prototype. These services are cur-

rently implemented and tested with our industry part-

ners.

3 CAPTURING AND REPORTING

ICT ENERGY CONSUMPTION

The energy demand of ICT infrastructure is rising

continuously (Koomey, 2007). Looking at a typical

data center today, consumption has reached a point,

were the running costs of the ICT equipment is as

much an important factor as the investment costs in

the first place (Barroso, 2005).

Yet, many businesses do not have much informa-

tion about the energy requirements and consumption

ANINTEGRATIONPLATFORMFORIT-FOR-GREEN-IntegratingEnergyAwarenessinDailyBusinessDecisionsand

BusinessSystems

227

40 W

60 W

80 W

100 W

0 % 25 % 50 % 75 % 100 %

Active power

CPU utilization

Figure 1: Energy usage of a server in different load situa-

tions.

of their ICT equipment (BITKOM, 2008). It is there-

fore an important aspect of future CEMIS to support

companies in monitoring energy usage and attribute it

to the relevant business processes.

To tackle this problem, it is necessary to intro-

duce measuring hardware into the data center. A large

number of measuring points are required to reach

a high degree of detail in the reporting. To lessen

the burden of implementing this measuring infrastruc-

ture, our project will also look into ways to reduce the

number of measuring points needed.

One such approach consists of merely estimating

energy usage on the basis of equipment utilization

levels. Looking at the example of servers, this kind of

data – for example CPU utilization or network activ-

ity – is often readily available through software alone.

If this data can be used to accurately estimate power

usage, the implementation of a monitoring infrastruc-

ture can be simplified.

It will be a goal of the project to facilitate such

an approach by providing relevant services as part of

the green service mall. Preliminary work has started

to build reliable models that predict energy usage

based on server utilization. We validate these mod-

els through measurements performed in our lab server

environments as well as in larger data centers. Consis-

tent with other work in this area (Rivoire et al., 2008)

we see a strong influence of CPU activity on power

usage in our measurements (figure 1).

Even with a simple linear module based on CPU

utilization levels it is possible to attempt a power us-

age estimation. Figure 2 shows a screenshot of a soft-

ware module – which will be part of our prototype –

as it is estimating the power usage of a server. For

comparison, the actual measurements are tracked as

well and in our experiments this model achieves cor-

rect predictions with an average error of 6 %.

Of course there are many more components than

servers in a data center. Measuring points are also

required for the cooling infrastructure, for network

equipment and for the uninterruptible power supply.

Once all of these measurement points are in place,

the data can be fed into a model of the data center.

Such a model-based approach is helpful in two ways:

Firstly, it can be the basis for various reports and met-

rics (like PUE, power usage effectiveness) regarding

the current situation. Secondly, it becomes possible to

simulate the effect of changes to the data center and

thereby helps in the process of identifying power sav-

ing potentials.

Furthermore, a detailed understanding of the en-

ergy situation of the data center also helps in map-

ping business processes to the computing resources

they require and in turn the energy usage they cause.

Making this connection is a crucial part in making in-

formed decisions about the structure of these business

processes.

4 CAPTURING AND REPORTING

PRODUCTION AND

LOGISTICS PROCESSES

The ”Green Production and Logistics” module aims

at developing services, that allow small and medium-

sized enterprises (SMEs) for better analyzing the en-

vironmental impact of their production and/or logis-

tics processes. In both areas, international standard-

ized methodologies such as the Eco-Management and

Audit Scheme (EMAS), parts of the ISO 14000 se-

ries and the DIN EN 16258 are applied, in order to

ensure the comparability of results and long term us-

ability. However, one major obstacle is the difference

in those two process types. On the one hand, produc-

tion processes describe the physical transformation of

goods and can be very versatile depending on the in-

dustrial sector the enterprise is operating in. Logistic

processes, on the other hand, cover the transportation

of goods over space and time and are less industry-

specific, which means they require less customization

efforts after the installation of our tool.

4.1 Green Production

The module enables a SME to measure the environ-

mental performance of production processes. There-

fore, the first important step is to break down main

processes into subprocesses and further into single ac-

tivities. In this sense, it is not suitable to treat the en-

terprise as a whole (black-box) and just quantify its

in- and outputs, because thereby, potential improve-

ments can not be identified.

Each identified activity, specified by its core (e.g.

technical plant specification) and dynamic data (e.g.

material input), is used to create a basic material and

SMARTGREENS2012-1stInternationalConferenceonSmartGridsandGreenITSystems

228

Figure 2: Software tool to estimate power usage based on server utilization.

energy flow model. In order to ease data assessment

and to reduce manual user input, links to repositories

which contain this specific informations, are estab-

lished. It is necessary to obtain information cover-

ing the following aspects: energy efficiency, mate-

rial efficiency, water, waste, biodiversity and emis-

sions, as these are the six core environmental indi-

cators stated by the EMAS (European Parliament and

Council, 2009). On top of that, it is advised to publish

additional branch specific indicators.

However, for the management it might be hard

to interpret the gathered data, due to missing com-

parative values and metrics that allow for an evalua-

tion of the environmental performance. To solve this

and to give the management the possibility of a quick

evaluation, several impact assessment methods exist.

Methods like CML 2001 (Guine et al., 2002) and IM-

PACT2002+ (Jolliet et al., 2003) can be used to aggre-

gate the environmental performance into a few total

values.

Besides the ability to evaluate the performance

in a short amount of time and to validate the results

against target values, enterprises are enabled to spot

economic and/or ecologic weaknesses in their pro-

duction processes. For instance, processes with the

highest energy consumption could be highlighted in

the material and energy flow model, which could lead

to a further investigation. In that sense, the identifi-

cation of ecological improvements could also lead to

monetary benefits.

Unfortunately, several feasible improvements may

contradict each other. In these situations, the manage-

ment is supported by certain multi-criteria decision

aiding methods. Our tool allows the decision maker

to set up different alternatives (the possible improve-

ments), which will be ranked according to the identi-

fied criteria and the decision makers preferences.

4.2 Green Logistics

Besides the evaluation of the production processes, a

SME might be interested in an assessment of their

transportation processes as well. For the purpose of

publication, it should not matter whether they perform

the transportation on their own or assign them to a for-

warding agency. The second part of module 2 helps

enterprises with that task and is based on the DIN EN

16258 norm (Deutsches Institut f

¨

ur Normung, 2011).

The norm incorporates two major advantages. Firstly,

the evaluation of the transportation processes is inde-

pendent of the various means of transport (e.g. trucks,

trains, aircrafts, etc.). Secondly, there is no set re-

quirement for the data source, which is used in the

calculations (although, the more accurate the data, the

better the result).

The assessment of the transportation processes has

to cover two different areas, which are to some ex-

tend in relation to scope 1 and scope 3 emissions

mentioned in the green house gas (GHG) protocol

(WRI and WBCSD, 2004). Scope 1 emissions re-

fer to direct emissions that arise from enterprise con-

trolled sources, like the combustion of fuel in com-

pany owned vehicles. Scope 3 emissions contain in-

direct emissions, which do not originate from the en-

terprise itself, like the provision of fuel, but which are

needed to execute their business processes. The tool

is translating those scopes into Well-to-Tank (WTT)

and Tank-to-Wheel (TTW) processes, which stand for

scope 3 and scope 1 respectively. In order to en-

sure that results are comparable over various means

of transportation, two different units are calculated.

Energy consumption (e.g. consumption of gaso-

line, diesel, kerosene, electricity) will be measured

in megajoule (MJ) while GHG emissions will be de-

noted in carbon-dioxide equivalents (CO

2

e).

Calculation methods will vary depending on the

desired output format and the data source. Four dif-

ferent sources are possible: 1. specific measurements

for each vehicle used during the transport, 2. typi-

cal mean measurements based on vehicle type and/or

route, 3. measurement of the annual mean fleet con-

sumption, 4. default values found in scientific or gov-

ernmental publications. The first option is only vi-

able for enterprises, which have direct control over

the vehicles and can track their distances, load and

fuel consumption. The other three options can also be

ANINTEGRATIONPLATFORMFORIT-FOR-GREEN-IntegratingEnergyAwarenessinDailyBusinessDecisionsand

BusinessSystems

229

used by enterprises, which assign forwarding agen-

cies with the transportation of their goods and will

depend on the level of cooperation, because option

two and three may require access to external data.

After it is clear, which data is available, the cal-

culation itself is pretty straightforward. The trans-

port route needs to be divided into single parts which

are determined by the vehicles that were used. If a

good-specific assessment is desired and a vehicle did

carry other goods next to the one under investigation,

an allocation is required. Such an allocation can be

done in three different ways: 1. weight-dependent, 2.

volume-dependent or 3. a mixture of both. In that

fashion, TTW and Well-to-Wheel (WTW), which is

WTT plus TTW, can be calculated for each single part

of the route and then be aggregated into a total value

for the investigated good.

At the end, the results of both parts are submitted

to module 3, which may then lead to a publication in

a sustainability report.

5 INTEGRATION

We will now discuss the advantages of the integrat-

ing character of our planned platform approach in the

context of a possible use case. Every task, an end user

will be able to fulfill with the help of our new CEMIS,

is organized as a workflow and controlled by a new

workflow system. Let’s assume, we want to develop

a new product: A small portable device in need of

frequently downloading information from an online

store (like an e-book reader, portable media player).

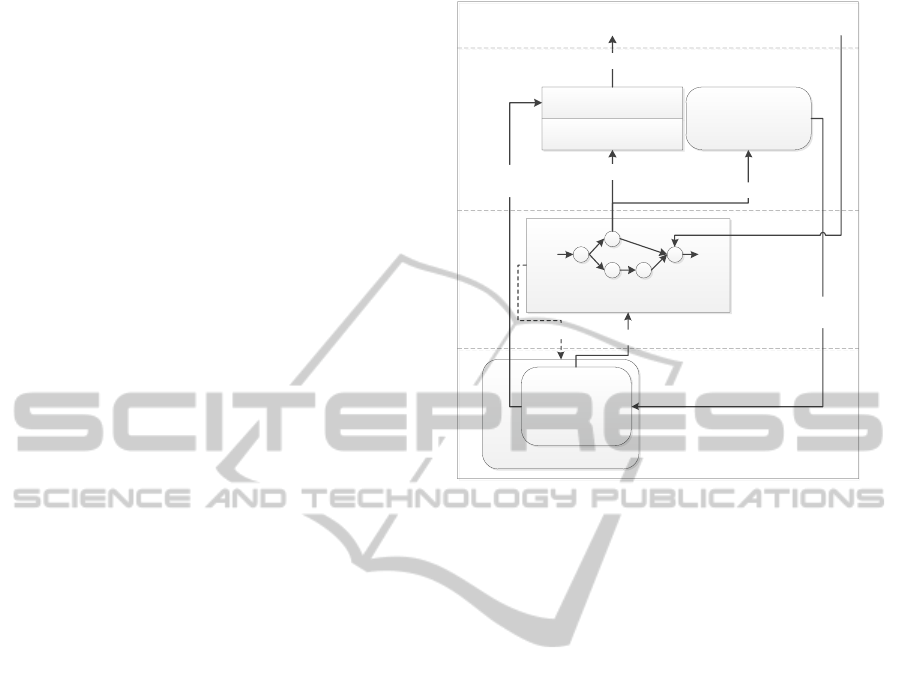

Figure 3 shows the information and control flow

during the execution of a single activity within a

CEMIS workflow. There are several perspectives on

such activities. We will start with a more generic look

on the whole system and then discuss it in the light of

raising energy awareness and efficiency.

From the user perspective there will be a client

application (planned as browser application) that vi-

sualizes the processing of a workflow, allows user in-

put and control flow interaction, presents intermediate

results, etc.

The technical perspective reflects the realization

of the services needed for fulfilling an activity. This

is so to speak the business logic of the whole system.

For the sake of an individually composed software

system that serves exactly the individual needs of dif-

ferent business and companies, we will have a set of

interoperable services for individual tasks. With this

modular design principle each company may compass

its own tailor made CEMIS. A high priority will be

given to the supply of energy related services.

CEMIS workflow context

CEMIS workflow context

activity business logic

activity interface

activity view

(5) store result in context

workflow engine

(1) get view

(3) signal: start activity

workflow view

activity view

with embedded

controls

controls

(6) signal: done

(2) embed

view

(4) make business

logic calls

(7) fetch

previous result

shared

universe

technical perspective task perspective user perspective

Figure 3: Integration scheme for energy aware product de-

velopment.

In the task perspective, a workflow represents

an executable arrangement of different activities that

guides an user during his work with the system. It will

be possible to define (or rather program) complex re-

lations and control flows within a workflow.

A workflow may comprise activities from sev-

eral (maybe external) sources and also from different

users. On a time scale, a workflow might be executed

in several phases (during product life-cycle) and be

saved to disc in the mean time. In order to share in-

formation among all these services and phases, a spe-

cialized context for information exchange is shared.

In the context of the mentioned new product, one

necessary activity might be to estimate later energy

consumption of the servers that host the web store.

In this case, the workflow engine will fetch all nec-

essary view information from the service and put it

into the user perspective for choosing an appropriate

server model and for parameterizing it.

Due to the design of our workflows, the engine

will continue with the appropriate activity based on

the model choice of the user and carry on with a view

that lets him use the model. All calculated results on

estimated energy consumption are stored to the con-

text for usage by further activities.

Necessary information about all entailed server

loads, when using the product, might be taken from

previously executed design activities and thus from

the CEMIS context. In this way, results from mar-

ket research on estimated product using profiles may

SMARTGREENS2012-1stInternationalConferenceonSmartGridsandGreenITSystems

230

be fed directly into the server model for transferring

product usage into an estimate of the energy load it

will entail on the server. In a similar way, energy

consumption for logistics related to the product can

be utilized. This might comprise upstream chains for

procurement of product parts as well as distribution

logistics.

Integrated in a workflow all these energy con-

sumption and estimation related activities may be ex-

ecuted multiple times with different parameters and

product configurations in order to take into account

production and product life-cycle energy costs for the

product design. The energy estimation data from the

design phase is stored in the CEMIS context, so it

will be still readily available when the workflow is

suspended and resumed later for a product redesign

phase. The context is part of the workflow and will

be stored to disk together with the workflow and its

execution state, if necessary.

Nevertheless, the energy data (as any other envi-

ronmental data in the platform) may also be saved

to an environmental data store and be used in any

other workflow that might accompany the product

life-cycle. All data will be transfered into an stan-

dardized CEMIS data format (development will start

soon) in order to ensure interoperability.

A frequent use case will be communication and

reporting. Communicating energy information in this

context refers to activities like including achieved

savings in product advertisements, fair and source-

related cost allocation or raising awareness for the

impacts of one’s own daily business decisions. Re-

porting on the other hand refers to an integration of

energy data into annual, official sustainability reports

that may be generated and published with our system

as well. New and interactive graph and gauge ele-

ments in this report will enable stakeholders to expe-

rience a versatile offer of energy information that is

exactly tailored to their specific needs.

6 CONCLUSIONS AND NEXT

STEPS

The development of the core integration platform has

just started out. The business concepts are developed

in close collaboration with our scientific and industry

partners, especially to confirm that they can benefit

from these concepts in daily business. Currently, we

are also facing the specification of a common, XML-

based data exchange format. The definition of ser-

vices, that implement different workflow activities is

yet another next step.

ACKNOWLEDGEMENTS

This work is part of the project IT-for-Green (Next

Generation CEMIS for Environmental, Energy and

Resource Management). The IT-for-Green project is

funded by the European regional development fund

(grant number W/A III 80119242).

REFERENCES

Barroso, L. A. (2005). The price of performance. ACM

Queue, 3:48–53.

BITKOM (2008). Energy Efficiency in the Data Center:

A Guide to the Planning, Modernization and Opera-

tion of Data Centers. Retrieved February 16, 2012,

from http://www.bitkom.org/files/documents/energy

efficiency in the data center volume 2.pdf.

Deutsches Institut f

¨

ur Normung (2011). Methode zur

Berechnung und Deklaration des Energieverbrauchs

und der Treibhausgasemissionen bei Transportdien-

stleistungen (G

¨

uter- und Personenverkehr). DIN EN

16258, Deutsches Institut f

¨

ur Normung e. V.

European Parliament and Council (2009). Regulation (EC)

No 1221/2009 of the European Parliament and of

the Council of 25 november 2009 on the voluntary

participation by organisations in a Community eco-

management and audit scheme (EMAS), repealing

Regulation (EC) No 761/2001 and Commission De-

cisions 2001/681/EC and 2006/193/EC. Technical re-

port, European Community.

Guine, J., Gorre, M., Heijungs, R., Huppes, G., Kleijn, R.,

Koning, A. d., Oers, L. v., Wegener Sleeswijk, A.,

Suh, S., Udo de Haes, H., Bruijn, H. d., Duin, R. v.,

and Huijbregts, M., editors (2002). Handbook on life

cycle assessment. Operational guide to the ISO stan-

dards. Part IIa: Guide. Kluwer Academic Publishers,

Dordrecht.

Jolliet, O., Margni, M., Charles, R., Humbert, S., Payet,

J., Rebitzer, G., and Rosenbaum, R. (2003). Impact

2002+: A new life cycle impact assessment method-

ology. International Journal of Life Cycle Assessment,

8(6):324–330.

Koomey, J. (2007). Estimating total power consump-

tion by servers in the U.S. and the world. Re-

trieved February 16, 2012, from http://sites.amd.com/

de/Documents/svrpwrusecompletefinal.pdf.

Rivoire, S., Ranganathan, P., and Kozyrakis, C. (2008).

A comparison of high-level full-system power mod-

els. In Proceedings of the 2008 conference on Power

aware computing and systems, HotPower’08, pages

3–3, Berkeley, CA, USA. USENIX Association.

WRI and WBCSD (2004). The greenhouse gas proto-

col. Technical report, World Resources Institute

and World Business Council for Sustainable Devel-

opment.

ANINTEGRATIONPLATFORMFORIT-FOR-GREEN-IntegratingEnergyAwarenessinDailyBusinessDecisionsand

BusinessSystems

231