Changing Concepts in Human-Computer-Interaction

in Real-time Enterprise Systems

Introducing a Concept for Intuitive Decision Support in SCM Scenarios

Christian Lambeck

1

, Dirk Schmalzried

2

, Rainer Alt

3

and Rainer Groh

4

1

Technical University Dresden, 01062, Dresden, Germany

2

OR Soft Jänicke GmbH, Geusaer Str., FH, 104, 06217, Merseburg, Germany

3

University Leipzig, 04109, Leipzig, Germany

2

Technical University Dresden, 01062, Dresden, Germany

Keywords: Visual Business Intelligence, Business Analytics, Real-time Supply Chain Management, Decision Support,

Radial Basis Functions, Scheduling.

Abstract: In current research, Enterprise Information Systems (EIS) are increasingly based on In-Memory-

Technologies, resulting in extremely fast response times for a multitude of typical system requests. In addi-

tion, up-to-date hardware configurations apply multi-core processing units, which lead to an availability of

immense computing power. Instead of a single result value, a whole result set is calculated within the same

period of time. Because of these dramatic changes in technology, many business processes, currently still

characterized by mask and dialog oriented user interfaces, will change to interactive and simulation based

approaches. This allows for the introduction of innovative, interactive and simulation based business pro-

cesses instead of conventional batch oriented ones. In the combination of the described interaction concept

in this contribution and the handing of result sets as described above, the authors expect a fusion of opera-

tional (e.g. supply chain management) and analytical (e.g. business intelligence) application systems. To

achieve this goal, the usage of assessment functions for weighting results, multi-dimensional result space

folding based on similarity measures and visualizations using 3D-landscapes based on radial basis functions

is suggested.

1 INTRODUCTION

Latest research on Enterprise Information Systems

(EIS) and their underlying production methods has

been manifold and primarily focused on perfor-

mance and real time issues (Plattner and Zeier,

2011), Service-Oriented Architectures (SOA)

(Ollinger et al., 2011) as well as sensor technologies.

Especially the consistent vertical interoperability of

these services and standards across the levels of

automation (ISA, 2012) and the application of the

Internet of Things to the production domain are

current challenges (Kortuem et al., 2010). New pro-

duction methods like modular 3F factories (Buch-

holz, 2010) as well as increasing complexity and

dynamic of supply chain processes themselves rein-

force the desire for extensive simulation enabled

supply chain planning with a focus on varying input

parameters and resulting outcome.

As a consequence of these changed conditions in

production logistics and new objectives in the field

of SCM a fundamental redesign of upcoming SCM

systems is required. Especially rapidly alternating

influential factors such as volatile raw material and

transportation costs, volatile exchange rates and

other volatile cost-influencing parameters have to be

taken into account. In order to derive a reliable and

suitable business conclusion, simulative “What-if”-

scenarios are more important than ever and have to

comprise these volatile parameters comprehensively.

By these risen claims, users demand for exten-

sive simulation based planning tools. Their ability to

vary input parameters and examine their effects on

the resulting outcome reveals a powerful potential.

Although simulative approaches in EIS exist, current

state of the art systems fail to fulfill those require-

ments sufficiently. Since they were designed in the

middle of the 90’s, stringent hardware limitations

had to be considered. In contrast, future RAM-based

139

Lambeck C., Schmalzried D., Alt R. and Groh R..

Changing Concepts in Human-Computer-Interaction in Real-time Enterprise Systems - Introducing a Concept for Intuitive Decision Support in SCM

Scenarios.

DOI: 10.5220/0003984201390144

In Proceedings of the 14th International Conference on Enterprise Information Systems (ICEIS-2012), pages 139-144

ISBN: 978-989-8565-10-5

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

computers with Multi-core support enable the user to

generate whole result sets instead of a single value in

a fractional amount of contemporary time consump-

tion. This trend allows the combination of opera-

tional and analytical processes. As a result, sophisti-

cated answers for a variety of complex SCM prob-

lems can be given in almost real time.

Attendant to the increased possibilities in han-

dling complex information sets, related user inter-

face principles have to change accordingly. Never-

theless, user interface design principles in the field

of EIS have been rarely subjected to research within

the last years. While multi-touch devices and corre-

sponding interface concepts are widespread in other

domains as illustrated in (Lima, 2012), enterprise

applications – especially in the upper levels of au-

tomation – are still dealing with transactional inter-

faces that consist of forms, tables and dashboards

and are meant to be controlled by mouse and key-

board (e.g. SAP R/3 UI- History in (SAP AG,

2012)).

Due to the novelty of visual and explorative sim-

ulation and interaction techniques in EIS, related

research on human-computer-interaction can be

rarely found. This contribution proposes a user inter-

face concept for the exploration of a three dimen-

sional landscape consisting of sampling points. The-

se “Data Landscapes” indicate a production plan’s

objective fulfillment through Key Performance Indi-

cators (KPI). Relevant challenges such as aggregat-

ed information presentation, real time interaction

and their preliminary considerations on performance

and algorithms are also addressed.

2 RELATED WORK

Nowadays, production and simulation related Enter-

prise Resource Planning Systems (ERP) – particular-

ly in Small and Medium Enterprises (SME) – are

customarily supported by Excel-sheets and are lim-

ited to textual or diagram output (Elizandro, 2008;

Gissrau and Rose, 2011). The majority of these tools

visualize the production plan as a Gantt-Chart, but

direct interaction is rarely supported at all. In addi-

tion, adequate presentations which give an insight to

complex correlations - like the simultaneous plan-

ning of material flows and the related resource con-

sumption - are often missing. In general, offered

visualizations are subjected to reporting in most

cases, whereas wide parts of the business process

remain textual. This might be one of the reasons for

current usability problems as described in (Topi et

al., 2005).

The research project Mind Map APS (DLR, 2010)

assumed an upcoming fundamental change in the

handling of enterprise applications within the next

years. Therefore, the three aspects Search Engine

based System Access, Interactive Business Process

Modeling and Zoomable User Interface Design were

taken into account to investigate their potentials. As

a primary goal, users should be able to interact with

the system more intuitively through map-based,

interactive and scalable process visualizations. Alt-

hough the estimated breakthrough could not be fully

achieved, several prototypes were conceived which

deal with 3D visualizations in oil industry, mobile

process assistance for healthcare scenarios or seman-

tic search paradigms to ease the user’s system ac-

cess.

Real-time EIS based on In-Memory technologies

allow response generation, which is faster by speed

decades. Therefore, many business processes, cur-

rently characterized by sequential and iterative dia-

logs, are changing to simulated ones with parallel

computations (Karnouskos et al., 2010). While ERP

systems facilitate the concept of simulation insuffi-

ciently, additional Advanced Planning and Schedul-

ing (APS) applications have been introduced (Stad-

tler and Kilger, 2008, p.109). The involved deficien-

cies that result from the split system landscape are

different data models and potential import/export

problems, time delays or problems while merging

simulation alternatives with real plans.

3 BUSINESS PROCESS

The proposed design causes some challenges in the

practical implementation. This primarily derives

from the vast amount of data to be processed (stor-

age issues), requirements on short response times

(performance issues) and finally the novel interac-

tion and its resulting user acceptance (interface is-

sues). In the following, challenges regarding con-

densed data as well as real-time interaction on these

consolidated information are discussed.

3.1 Benefits of Planning Processes

based on Simulative Result Sets

To bridge the before mentioned gap in current sys-

tems, standard and sequential ERP processes could

be redefined in a real-time EIS as follows:

After the adjustment of initial parameters for an

overall optimization objective in a first step, the

system generates a whole set of results at once. For

the step of computation, optimization methods as

ICEIS2012-14thInternationalConferenceonEnterpriseInformationSystems

140

well as heuristics are applicable. The emerging

planning alternatives are presented in a summarized

visualization instead of a series of individual results

in a sequential user dialog. The major benefit is an

explicit and direct comparability of the suggested

planning solutions.

The parameter variations in a production sched-

uling task might reach from different objective func-

tions (e.g. maximized profit margin; minimal profit

margin with restocking, meeting delivery dates) to

additional restrictions (stock clearance, enforcing

batch clearance). Thereby a combination of these

restrictions is also possible, so that a composite and

complex schedule optimization task is formed. Fi-

nally, specific production schedules arise which

would be typically presented as Gantt-Charts. How-

ever, comparing those Gantt-Charts – or even a

subset – is a challenging task for users and consti-

tutes the sequential and iterative dialog structure

mentioned before.

3.2 From Gantt-Charts to Key

Performance Indicators

A more convenient way than traditional Gantt-

Charts is the comparison of summarizing Key Per-

formance Indicators (KPI) for each generated plan-

ning alternative, which again can be used to evaluate

SCM objective satisfaction (e.g. quality, due dates,

margins, flexibility and demand fulfillment). In most

cases it is sufficient to choose the best fitting sched-

ule out of the sample space and proceed with the

business process. In other cases of composite result

evaluation functions it might be helpful to investi-

gate each component’s impact on the composite KPI

separately.

If none of the resulting production schedules sat-

isfies the business needs or if all resulting objective

functions are not satisfying, it could help to start a

new simulation run with better parameterization.

Therefore users have to slightly vary the parameters

specifically in those regions where already promis-

ing schedules have been found. In consequence, the

level of detail for this region would be increased by

any of these iterations until the identified result is

satisfying. To receive further reference points for

regions of favorable schedules and to fully use the

interactive and simulative potential of real-time EIS,

a suitable visualization technique is required. In the

following section, the established concept of Data

Landscapes is presented and gets adapted to the field

of EIS and SCM in particular.

3.3 From Key Performance Indicators

to Data Landscapes

The authors suggest a projection of the generated

schedules into a plane using folding algorithms

based on similarity criteria. This plane uses Time as

one dimension and Resource Utilization as the other.

Contrary to Gantt-Charts that use time and resource

allocation as well, this plane cannot provide a specif-

ic time or resource predication. Instead it is able to

illustrate the neighborhood and therefore the similar-

ity of production schedules. Hence, similar sched-

ules are projected closely to each other onto that

plane which is caused by the multidimensional fold-

ing algorithm.

One appropriate method for neighborhood pre-

serving multidimensional folding of production

schedules are Self-Organizing Maps - so called Ko-

honen Maps (Kohonen, 2001) - known from neural

networks. Each production schedule is uniquely

defined by the set of contained production orders,

which again define an unambiguous temporal alloca-

tion of resources and material flows. Thus, the pro-

posed folding delivers reproducible nodes in the

map.

This plane layer can be extended into a third di-

mension by applying an evaluation function on top

of these nodes. The evaluation function typically

results in KPIs to be used for measuring the fulfill-

ment of the SCM targets. The resulting sampling

points can be joined using radial basis functions, for

example, to form three dimensional Data Land-

scapes (see (Carr et al., 2001)). Despite the suggest-

ed radial basis functions, equivalent construction

techniques for Data Landscapes are also applicable,

of course.

Besides a uniform evaluation function, the use of

“mountain stacks” might be suitable, in which differ-

ent parts of the evaluation function (e.g. separated by

margin, demand fulfillment, deadlines) are added

consecutively. This allows for weighting certain input

parameters and also considering particular thresholds

(e.g. all schedules reaching a certain margin).

3.4 Exploring Regions of Interest

In regions around a local maximum, probably more

interesting production schedules can be found. By

recalculating with slightly modified parameteriza-

tion, the resolution of this designated area can be

increased and the user might detect more interesting

production schedules that are even closer to the

current objective. Due to the suggested method,

additional nodes will be located closely to the exist-

ChangingConceptsinHuman-Computer-InteractioninReal-timeEnterpriseSystems-IntroducingaConceptforIntuitive

DecisionSupportinSCMScenarios

141

ing one with a high probability. However, the fold-

ing of those multidimensional schedules into a two

dimensional plane cannot avoid the partial place-

ment of sampling points outside the current region

of interest. The following example illustrates the

effect that might occur:

The proposed method as described above would

create a landscape with 16 different sampling points

(16 CPUs could deliver those simultaneously),

which are distributed non-equidistantly across this

map. We assume that there are two sampling points

in region A and that their evaluation function (KPI)

has a significant maximum here. Hence they repre-

sent promising schedules and deserve closer atten-

tion. A next recalculation run on the same region

with slightly changed parameterization generates 16

additional sampling points. Due to the marginal

modification of the input parameters, the majority of

them would reside in this region, but some of them,

as a result of the folding, might reside in a totally

different region of the map. The resulting resolution

has increased again and would allow for a third

iteration. After three runs, 48 sampling points are

distributed across the Data Landscape where most of

them reside in the region of interest.

4 USER INTERFACE CONCEPT

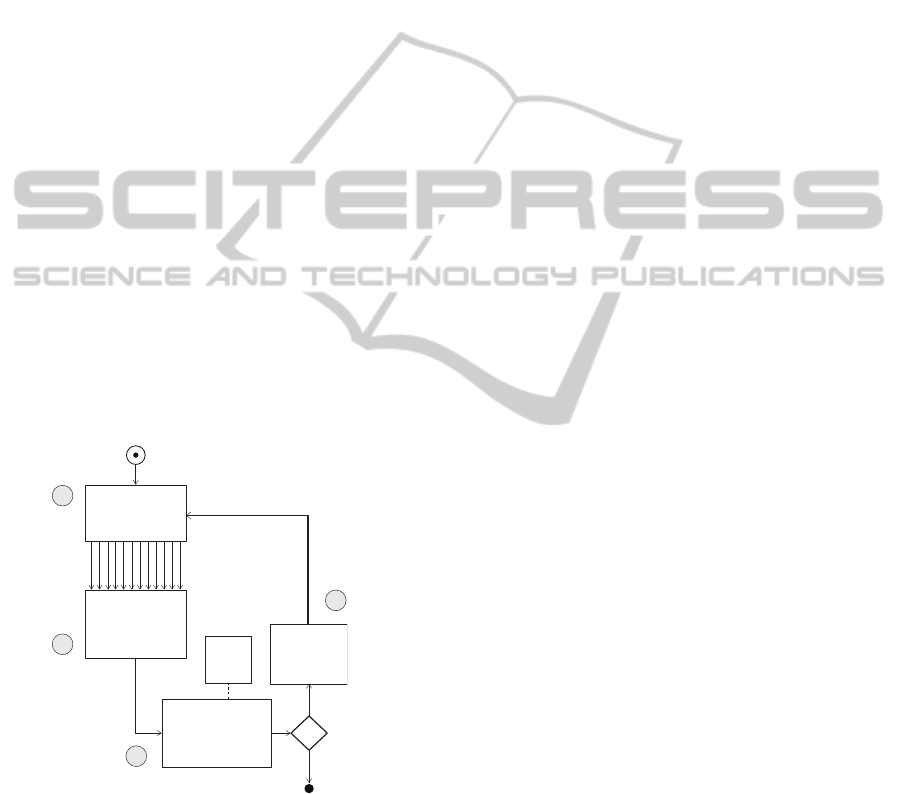

Figure 1: Business Process Dialog Model.

The preceding sections focused on the suggested

business process with its benefits compared to the

conventional approach. In this section, a concrete

user interface concept is described, which is meant

to be used on a touch-sensitive tabletop system. The

described process is split into four steps as illustrat-

ed in Figure 1.

In contrast to most existing applications, the whole

business process is controlled by a single view to

avoid usability problems as described in (Topi et al.,

2005) (identification of and access to the correct

functionality, transaction execution support, overall

system complexity etc.).

4.1 Selection of Calculation Parameters

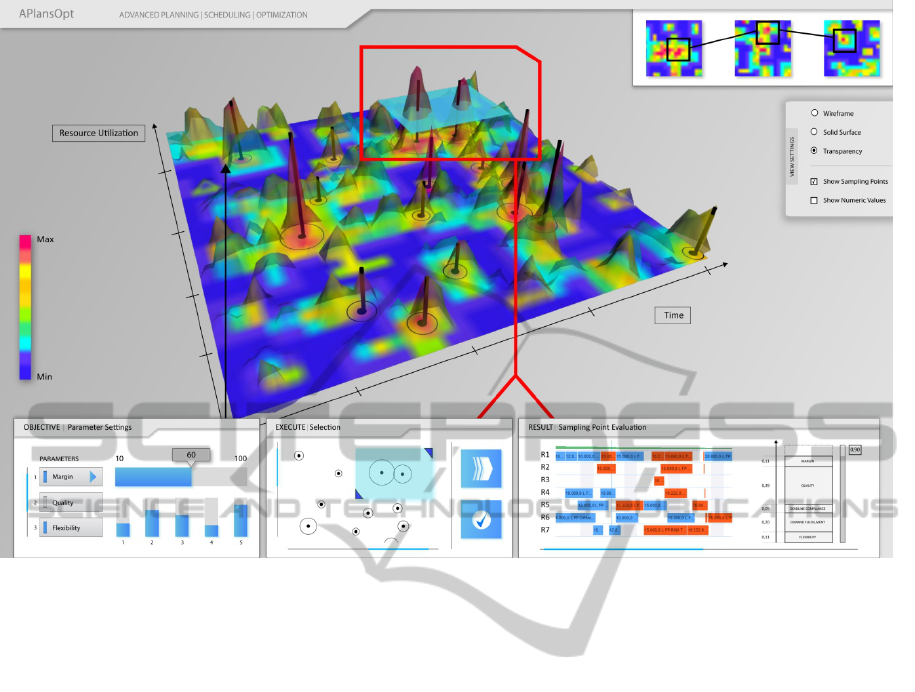

As a first step, the user has to set the initial parame-

ters (see section 3.1) which affect the selection of

the simulation algorithm and adjust it according to

the optimization objective. Therefore, parameters are

selected in the lower left area of the screen (see

Figure 2). On the right of the selection buttons, users

are able to adjust the influence of a selected item by

sliding the value between a minimum and maxi-

mum. Because the parameters partially affect each

other, their final composition is depicted below the

current slider. This way, users are always aware of

the consequences during their direct manipulation.

Once the parameters are selected and set as desired,

the system generates the result set as described in

section 3.1. Finally, a Data Landscape consisting of

several sampling points gives a first overall impres-

sion of the result set’s potential to satisfy the objec-

tive.

4.2 Result Presentation

Whereas conventional systems usually illustrate the

simulation results in a textual manner, the Data

Landscape approach has the ability to give an im-

pression of the result set’s quality at once. Each peak

represents a concrete production plan which is posi-

tioned according to the axis Resource Utilization and

Time. Therefore, plans with similar properties in

utilization and time can be found within the same

region. The height of the peak as an indicator for the

achievement of objectives is build upon the sum of

its Key Performance Indicators (KPI, see section

3.2). This means, that each KPI corresponds to a

particular SCM objective and represents its partial

fulfilment. Hence, the parts for quality, due dates,

flexibility et cetera add up to final height and form

the overall KPI for that designated production plan.

4.3 Region Selection and Drill-Down

In a next step, users might want to explore a promis-

ing area in more detail – a so called Drill-Down.

Therefore, a top view of the Data Landscape is illus-

trated in the middle part of the lower control view.

To select a region, users simply create a rectangle

Selecon of

Calculaon

Parameters

Visualisaon of

KPIs as Data

Landscape

Exploraon of

KPI Composion

and Prod. Plans

Detailed

Region

Selecon

Drill-

Down

Parallel Calculaon of

N Producon Plans

Explore Data

Mountain

Transformaon of Region to

a fine-grained Parameter Set

1

2a

3

2b

ICEIS2012-14thInternationalConferenceonEnterpriseInformationSystems

142

Figure 2: Suggested user interface concept with control views for parameter settings (bottom left: Objective), region selec-

tion with next iteration calculation (bottom centre: Execute) and Drill-Down with Gantt-Chart and KPI composition (bot-

tom right: Result). The overlay indicates the Drill-Down from a selected peak to its KPI composition and the related pro-

duction plan. The upper right series of snapshots illustrates the iteratively zoomed in regions in the manner of a detail-and-

context. View settings (e.g. wire-frame, solid, transparent) can be adjusted in the options menu at right of the screen.

and size it to the desired dimensions. Simultaneous-

ly, a plane with same dimensions is placed in the 3D

model to highlight the current area and its included

peaks. However, the selection of several independ-

ent regions is not possible at present. The details of

the current selection are illustrated in the lower right

part of the screen, where the KPI composition and

the corresponding plan’s Gantt-Chart are visualized.

After having examined the area peak by peak, the

former selection plane might be adjusted again to

restrict or enlarge the amount of included sampling

points accordingly. Once the identification of valua-

ble production plans is accomplished, a further itera-

tion can be started which is primarily focused on the

selected area. As described in section 3.2, the initial

parameters are getting slightly adjusted for the next

run and influence the upcoming iteration. Although

not all of the computed results might be located in

the area due to the parameter adjustment, its resolu-

tion is permanently increased by each iteration. In

the end, the selected region gets more and more fine-

grained in detail whereas the surrounding region

remains widely coarse-grained. If a satisfying pro-

duction plan is found, the recursive workflow ends

up by applying the final production plan.

5 CONCLUSIONS

The suggested user interface concept with its related

adapted business process allows for the intuitive

presentation of different production schedules and

their corresponding KPIs. In addition, the compari-

son of these schedules as well as the iterative ap-

proximation to more promising production plans is

supported in a visual way.

Changing the conventional usage concept of En-

terprise Applications as described in this contribu-

tion could exploit the potential of novel real-time

EIS. Business analytics, business intelligence and

operational design would fusion and could form a

comprehensive insight into simulative information

spaces. The concept of planning is transferable to

other domains of operational systems, such as blend

optimization, make-or-buy decisions, variations on

raw material costs as well as the strategic simulation

of material portfolios, geographical locations or

capacity extensions. For those domains, different

ChangingConceptsinHuman-Computer-InteractioninReal-timeEnterpriseSystems-IntroducingaConceptforIntuitive

DecisionSupportinSCMScenarios

143

simulative derived variations can be compared very

rapidly and with ease. The approach of increasing a

result area in resolution and its further exploration is

therefore widely applicable.

6 FUTURE WORK

Although the described concept is still in a prototyp-

ical status, its potential benefits are already obvious.

In further research and development, considerations

on appropriate touch-sensitive hardware as well as

user studies are planned. Especially the paradigm of

Drill-Down with the help of multi-touch gestures on

a tabletop system will be subjected to research in the

future. Concerning the projection type for the 3D

Data Landscape, a comparison of the current per-

spective projection and an isometric perspective

seems to be reasonable. To support the comparabil-

ity of peaks even more, the isometric projection

might be more suitable. The upcoming user studies

will evaluate the introduced concept by a survey

with experienced users to state the major deficien-

cies. Due to the great demand for mobile solutions in

EIS in general, further research will also have an eye

on possible scenarios on mobile devices. With their

numerous built-in sensors, new interaction meta-

phors are imaginable. One example might be the use

of G-sensor abilities for suitable Drill-Down or re-

finement interactions.

ACKNOWLEDGEMENTS

Christian Lambeck would like to

thank the European Union and the

Free State of Saxony, Germany for

supporting this work. Special thanks

are due to Thomas Lambeck and

Frank Förster for their enthusiastic

participation.

REFERENCES

Buchholz, S., 2010. Future manufacturing approaches

in the chemical and pharmaceutical industry. Chemical

Engineering and Processing: Process Intensification,

49(10), pp.993–995.

Carr, J. C. et al., 2001. Reconstruction and representation

of 3D objects with radial basis functions. In Proceed-

ings of the 28th annual conference on Computer

graphics and interactive techniques. SIGGRAPH ’01.

New York, NY, USA: ACM, pp. 67–76. Available at:

http://doi.acm.org/10.1145/383259.383266.

DLR, 2010. Mind Map APS - Project Fact Sheet.

Available at: http://www.pt-it.pt-dlr.de/_media/ Infob-

latt_MindMap_APS.pdf [Accessed December 12,

2011].

Elizandro, D., 2008. Simulation of industrial systems :

discrete event simulation using Excel VBA, New York:

Auerbach Publications.

Gissrau, M. & Rose, O., 2011. A DETAILED MODEL

FOR A HIGH-MIX LOW-VOLUME ASIC FAB. In

Proceedings of the 2011 Winter Simulation Confer-

ence. Winter Simulation Conference 2011. Arizona,

pp. 1953–1963.

ISA, 2012. ISA | The International Society of Automa-

tion. Available at: http://www.isa.org/ [Accessed Feb-

ruary 14, 2012].

Karnouskos, S. et al., 2010. Real-world Service Interac-

tion with Enterprise Systems in Dynamic Manufactur-

ing Environments. In Artificial intelligence techniques

for networked manufacturing enterprises management.

London; Heidelberg: Springer.

Kohonen, T., 2001. Self-organizing maps, Berlin; New

York: Springer.

Kortuem, G. et al., 2010. Smart objects as building

blocks for the Internet of things. IEEE Internet Com-

puting, 14, pp.44–51.

Lima, M., 2012. visualcomplexity.com | A visual explo-

ration on mapping complex networks. Available at:

http://www.visualcomplexity.com/vc/ [Accessed Feb-

ruary 10, 2012].

Ollinger, L., Schlick, J. & Hodek, S., 2011. Leveraging

the Agility of Manufacturing Chains by Combining

Process-Oriented Production Planning and Service-

Oriented Manufacturing. In Proceedings of the 18th

IFAC World Congress. World Congress of the Inter-

national Federation of Automatic Control (IFAC-

2011), August 28 - September 2, Milan, Italy. Elsevier

Science Ltd.

Plattner, H. & Zeier, A., 2011. Desirability , Feasibility,

Viability – The Impact of In-Memory, Berlin ; Heidel-

berg ; New York : Springer.

SAP AG, 2012. SAP Design Guild - R/3 History in

Screen Shots. Available at: http://www.

sapdesignguild.org/resources/r3_history.asp [Accessed

December 2, 2011].

Stadtler, H. & Kilger, C., 2008. Supply chain manage-

ment and advanced planning concepts, models, soft-

ware, and case studies, Berlin : Springer,.

Topi, H., Lucas, W. T. & Babaian, T., 2005. Identifying

Usability Issues with an ERP Implementation. In

Pro-

ceedings of the International Conference on Enter-

prise Information Systems (ICEIS). ICEIS’05. pp.

128–133.

ICEIS2012-14thInternationalConferenceonEnterpriseInformationSystems

144