How to Use an Adaptive High-gain Observer in Diagnosis Problems

Fr´ed´eric Lafont

1,2

, Jean-Franc¸ois Balmat

1

, Nathalie Pessel

1,2

and Jean-Paul Gauthier

1,2

1

Universit´e du Sud-Toulon-Var, LSIS, UMR CNRS 7296, B.P 20132, 83957 La Garde Cedex, France

2

Institut Universitaire de Technologie de Toulon, B.P 20132, 83957 La Garde Cedex, France

Keywords:

Observer, Diagnosis, Sensor.

Abstract:

This paper explains how to use an adaptive High-Gain observer in sensor diagnosis problems. This type of

observer allows to switch between a classical Extended Kalman Filter and High-Gain observer according to

an innovation function. Combined with a standard technique of residual generation, this approach is very

efficient to determine fault occurence in the non-linear dynamical systems. We present the obtained results on

a wastewater treatment system.

1 INTRODUCTION

Nowadays, systems are more and more automated in

order to reduce the human intervention. So, these sys-

tems are composed of sensors and actuators. There-

fore, it involves to define a structure enable to detect

a sensor fault or a failing actuator. The aim of such

equipment is the diagnosis of failure to avoid the eco-

nomic losses and/or the environmental risks.

The present work deals the sensor diagnosis with

an observer for non-linear dynamical systems ap-

plied to a wastewater treatment system. There is a

lot of works on the synthesis of non-linear observers

for (bio)chemical processes (Alcaraz-Gonzalez et al.,

2002; Assis and Filho, 2000; Dochain, 2008; Meth-

nani et al., 2011; Nejjari et al., 2008; Sotomayor et al.,

2002). In this study, we choose an adaptive high-

gain observer, developed already as software sensor

(Boizot et al., 2010; Lafont et al., 2011), to solve a

sensor diagnosis problem. Transition from High-Gain

(HG) mode to Extended Kalman Filter (EKF) mode

is performed via an adaptation procedure based upon

the level of innovation. In the context of large transi-

tions, the HG observer guarantees theoretical conver-

gence with arbitrary rate, under certain observability

assumptions. For small enough error of initial esti-

mation, classical EKF is more or less optimal w.r.t.

noise.

Usually a changing coordinates is necessary in or-

der to obtain an observability canonical form. In some

cases, this change of coordinates is very complicated.

To avoid this step, we write our observer in the natural

coordinates. However, the counterpart of this choice

is that the Riccati equation of the Kalman filter has

not the standard form (Lafont et al., 2011).

A such observer is “robust” compared with ini-

tial conditions and measurement noises. Although the

generation of residues is standard, we show the capa-

bility of adaptive HG-EKF observer to detect a sensor

fault.

Section 2 summarizes sensor diagnosis problems

and observer-based residual generation. In Section 3,

we recall the structure of the adaptive high-gain ob-

server, which is the multi-output version developed in

the paper (Boizot et al., 2010). Also, the crucial con-

cept of innovation, which is used in order to switch

between the EKF and HG-EKF modes, is presented.

Section 4 is devoted to the application: A wastewater

treatment plant. Finally, in Section 5, we show simu-

lation results.

2 SENSOR DIAGNOSIS AND

OBSERVER

2.1 Sensor Diagnosis

We are interested at the problem of the bias and the

drift faults. These two faults are the most common

and the most repetitive.

An output with a bias fault is defined by:

y

i

= y

r

+ b, (1)

with y

i

is the measured output, y

r

the real output and

b the constant offset value.

185

Lafont F., Balmat J., Pessel N. and Gauthier J..

How to Use an Adaptive High-gain Observer in Diagnosis Problems.

DOI: 10.5220/0003984501850190

In Proceedings of the 9th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2012), pages 185-190

ISBN: 978-989-8565-22-8

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

An output with a drift fault is defined by:

y

i

= y

r

+ d(t), (2)

with y

i

is the measured output, y

r

the real output and

d(t) the time varying offset factor. d(t) can be rep-

resented by the function: d(t) = a t + b with a and b

two constant terms.

2.2 Observer-based Residual

Generation

The main problem for the diagnosis based on ob-

servers is to find the residues. They are neglectable

in the absence of fault and significantly affected when

some faults occur. One difficulty is to make the robust

observer w.r.t. disturbances which are no faults.

So, a non-linear system can be written:

dx

dt

= f (x, u),

y = h(x) = Cx,

(3)

where x is the state vector, y the measured outputs

and u the control variables.

The corresponding observer is defined by:

d ˆx

dt

= g( ˆx,u),

ˆy =

ˆ

Cˆx,

(4)

The output estimation error is used to residual

generation. The residual is analysed to determine

fault occurence. We apply a standard method:

r

i

= |y

i

− ˆy

i

|. (5)

The output has a fault if r

i

> δ

i

. For each out-

put, we simulate off-line in nominal operating (with-

out fault) to determine the threshold level δ

i

. Then,

the method is applied on-line.

3 SYSTEMS UNDER

CONSIDERATION AND

OBSERVER EQUATIONS

3.1 The Observability Canonical Form

We consider a smooth non-linear system of the form

(3) which is mapped by a diffeomorphism ψ into the

following system:

dξ

dt

= F (ξ, u) = A(t)ξ + b(ξ, u),

y = Cξ,

(6)

where ξ ∈ R

n

is the state vector in observable co-

ordinates (n the system order), where u are the control

variables belonging to a certain bounded subset of R

p

(p the number of the control variables) and the output

y ∈ R

d

0

(d

0

the number of the outputs).

The matrices A(t), C and the vector b(ξ, u) have

a following form (all details can be found in (Boizot

et al., 2010)):

A(t) =

0 a

2

(t) 0 ··· 0

0 0 a

3

(t)

.

.

.

.

.

.

.

.

. ·· ·

.

.

.

.

.

.

0

.

.

. ·· · ·· · 0 a

k

(t)

0 0 ·· · ·· · 0

,

C = (a

1

(t), 0, ··· , 0) = (Id, 0, ·· · , 0),

(7)

where Id is an identity matrix of order d

0

.

b(ξ, u) =

b

1

(ξ

1

, u)

b

2

(ξ

1

, ξ

2

, u)

.

.

.

b

n

(ξ

1

, · ·· , ξ

k

, u)

. (8)

The state vector ξ(t) is assumed to have a “block”

structure ξ =

ξ

′

1

ξ

′

2

·· · ξ

′

k

′

, where ξ

i

∈ R

d

i

−1

(d

i

the

size of i+ 1

th

“block”) with d

0

≥ d

1

≥ · · · ≥ d

k−1

. The

matrices a

i

(t) have dimension d

i−1

×d

i

and belong to

a compact subset K

i

of the set of d

i−1

× d

i

matrices of

maximum rank d

i

.

The f (x, u), a

i

(t) and b

i

(ξ, u) are assumed

smooth w.r.t. ξ, u and t. The b

i

depend on ξ in a

“block” triangular way and are compactly supported.

3.2 Observer Structure

Let Q (n × n) , R (d

0

× d

0

) be symmetric positive

definite matrices. Let θ be the high-gain parameter,

θ ≥ 1. For θ = 1 the observer will just be an ordinary

EKF.

Set ∆ = BD

1,

1

θ

, · ·· ,

1

θ

k−1

, the block diagonal

matrix with diagonal blocks Id

d

0

,

1

θ

Id

d

1

, · ·· . Set Q

θ

=

θ∆

−1

Q∆

−1

, R

θ

= θ

−1

R.

The equations of the system in observable coordi-

nates are:

dξ

dt

= Tψ

ψ

−1

(ξ)

f

ψ

−1

(ξ), u

,

dξ

dt

= F (ξ, u) .

(9)

The equations for the HG-EKF in the observable

coordinates are:

d

ˆ

ξ

dt

= F(

ˆ

ξ, u) + PC

′

R

−1

θ

(y−C

ˆ

ξ), (10)

dP

dt

= TF(

ˆ

ξ, u) P+ P TF(

ˆ

ξ, u)

′

+ Q

θ

−PC

′

R

−1

θ

CP.

(11)

ICINCO2012-9thInternationalConferenceonInformaticsinControl,AutomationandRobotics

186

In the natural coordinates we have ˆx = ψ

−1

(

ˆ

ξ) =

Φ( ˆx), where ˆx denotes the estimate of x. As shown in

(Lafont et al., 2011), the equations for the HG-EKF

become:

d ˆx

dt

= f( ˆx, u) + pC

′

( ˆx, u)R

−1

θ

(y− h( ˆx)), (12)

dp

dt

= T f ( ˆx, u)p+ pT f( ˆx, u)

′

+ q

θ

( ˆx)

−pC

′

R

−1

θ

Cp

+Tψ( ˆx)

−1

D

2

ψ( ˆx)

n

pC

′

R

−1

θ

(h( ˆx) − y)

o

p

+pD

2

ψ( ˆx)

n

pC

′

R

−1

θ

(h( ˆx) − y)

o

′

Tψ( ˆx)

−1

′

,

(13)

where

p = TΦ

ˆ

ξ

P TΦ

ˆ

ξ

′

(14)

and

q

θ

( ˆx) = (Tψ( ˆx))

−1

Q

θ

(Tψ( ˆx))

−1

′

. (15)

TF denotes the tangent mapping to the mapping

F : x → F (x), R

n

→ R

n

i.e. its Jacobian matrix in co-

ordinates. Accordingly T

2

F denotes the double tan-

gent, a skew-symmetric bilinear mapping, R

n

-valued,

and for any u ∈ R

n

we define the matrix D

2

F (x){u}

by T

2

F (u, v) = D

2

F (x){u} · v.

3.3 Innovation

The function In

d

, introduced below, is called the inno-

vation. This function reflects the quality measurement

of the estimation error on a small moving time inter-

val of size d. The strategy is to adapt the High-gain

parameter θ according to In

d

. Due to the observabil-

ity properties of our system, if the ˆy is far from y then

θ will increase to High-gain mode. Contrarily, if ˆy

is close to y, the innovation will be small and θ will

decrease to 1 (Kalman filtering mode). For this, the

variable θ will be subject to the differential equation

(19) defined just below.

Let F

o

(θ) be defined as follows:

F

o

(θ) =

1

∆T

θ

2

if θ ≤ θ

1

,

1

∆T

(θ− 2θ

1

)

2

if θ > θ

1

,

(16)

where θ

1

=

1

2

θ

max

and ∆T small enough is a constant.

The value θ

max

depends of the studied system and is

obtained by an heuristic approach. It is bounded and

the observer remains stable.

The innovation In

d

(t), with forgetting horizon d,

is:

In

d

(t) =

Z

d

t− d

ky(τ) − ˆy(τ)k

2

dτ, (17)

where ˆy(τ) is the prediction from the initial state

ˆx(t − d).

Let us define

F (θ, In

d

) = µ(In

d

)F

o

(θ) + (1− µ(In

d

))λ(1− θ),

(18)

for a λ > 0 and with µ(In

d

) a sigmoid function,

µ : ]−∞;+∞[→] 0;1[ , In

d

→

1

1+e

−β·

(

In

d

−m

)

. The equa-

tion for the HG parameter θ is:

˙

θ = F (θ, In

d

). (19)

4 APPLICATION

The process under consideration is a real small-size

wastewater treatment plant (WWTP) composed of a

unique aeration tank equipped with surface aerators

which provide oxygen and mix the influent wastewa-

ter with biomass (Figure 1).

Figure 1: Wastewater treatment plant.

The model used is based upon the Activated

Sludge Model N

1

(ASM 1) (Henze et al., 1987). Then

the biodegradation model consists of 12 state vari-

ables (Table 1). Actually, we consider only biodegra-

dation.

The state variables describing the total alkalinity

being not included. The values of stoichiometric and

kinetic parameters, as well as the influent concentra-

tions can be found in (Lafont et al., 2011).

The complete set of equations and influent con-

ditions can be found on the International Water As-

sociation task group on benchmarking of control

strategies for wastewater treatment plants website

(http://www.benchmarkwwtp.org/, 2011).

The model is of the form ˙x = f (x, u), where the

control u consists of the state u

b

of the turbines and

the value Q

in

of the influent average flow. The input

u

b

in (20) is a binary sequence switching between 0

and 1 and representing the state of turbines (off/on)

that aerate the plant. We make here the reasonable as-

sumptions of three measurements: S

O

, S

NO

and S

NH

.

Although the WWTP with these three outputs is ob-

servable, it is too complicated for our purpose. We

use a simplified model of lower dimension that has

been developped in (Chachuat, 2001).

4.1 The Reduced Model

The author proceeds as follow:

HowtoUseanAdaptiveHigh-gainObserverinDiagnosisProblems

187

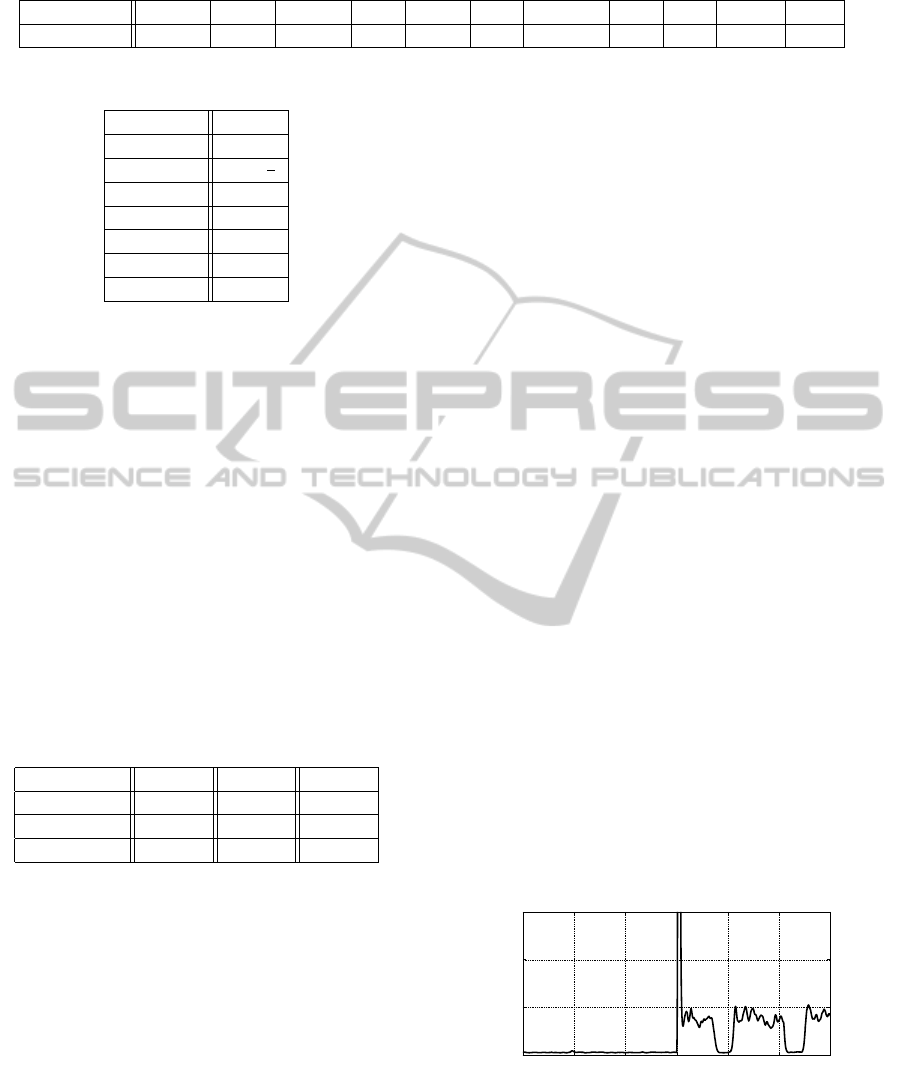

Table 1: List of variables.

Definition Notation

1. Soluble inert organic matter S

I

2. Readily biodegradable substrate S

S

3. Particulate inert organic matter X

I

4. Slowly biodegradable substrate X

S

5. Active heterotrophic biomass X

B,H

6. Active autotrophic biomass X

B,A

7. Particulate products arising from biomass decay X

P

8. Oxygen S

O

9. Nitrate and nitrite nitrogen S

NO

10. NH

+

4

+ NH

3

nitrogen S

NH

11. Soluble biodegradable organic nitrogen S

ND

12. Particulate biodegradable organic nitrogen X

ND

- A single organic compound, denoted X

DCO

(DCO for “chemical oxygen demand”), is formed

by adding soluble and particulate organic compound

concentrations X

DCO

= S

S

+ X

S

,

- It is considered that the dynamics of X

BH

, X

BA

and X

ND

are slow w.r.t. the others.

By removing the three unobservable variables X

P

,

X

I

and S

I

, we obtain a simplified model with 5 state

variables S

O

, S

NO

, S

NH

, X

DCO

and S

ND

. The three

variables S

O

, S

NO

and S

NH

are observables. All these

simplifications provide the following reduced model:

˙

S

O

=

Q

in

V

S

in

O

− S

O

+ α

1

X

DCO

K

DCO

+X

DCO

·

S

O

K

O,H

+S

O

+ er

1

(y) + u

b

· k

L

a·

S

max

O

− S

O

(20)

˙

S

NO

=

Q

in

V

S

in

NO

− S

NO

+ α

3

X

DCO

K

DCO

+X

DCO

·

K

O,H

K

O,H

+S

O

S

NO

K

NO

+S

NO

+ er

2

(y)

(21)

˙

S

NH

=

Q

in

V

S

in

NH

− S

NH

+ α

5

X

DCO

K

DCO

+X

DCO

·

S

O

K

O,H

+S

O

+ η

NO,g

K

O,H

K

O,H

+S

O

S

NO

K

NO

+S

NO

+ er

3

(y) + α

6

S

ND

(22)

˙

X

DCO

=

Q

in

V

X

in

DCO

−

K

S

K

DCO

X

DCO

+α

7

X

DCO

K

DCO

+X

DCO

S

O

K

O,H

+S

O

+η

NO,g

K

O,H

K

O,H

+S

O

S

NO

K

NO

+S

NO

+ α

8

(23)

˙

S

ND

=

Q

in

V

S

in

ND

− S

ND

− α

6

S

ND

+ α

9

·

X

DCO

K

ND

+X

DCO

S

O

K

O,H

+S

O

+ η

NO,h

K

O,H

K

O,H

+S

O

·

S

NO

K

NO

+S

NO

(24)

K

DCO

= K

S

X

DCO

S

S

K

ND

= K

X

X

DCO

X

S

X

B,H

(25)

er

1

(y) = α

2

S

NH

K

NH,A

+S

NH

S

O

K

O,A

+S

O

er

2

(y) = α

4

S

NH

K

NH,A

+S

NH

S

O

K

O,A

+S

O

er

3

(y) = −α

4

S

NH

K

NH,A

+S

NH

S

O

K

O,A

+S

O

(26)

The constant k

L

a is the oxygen transfer coef-

ficient

k

L

a = 10 h

−1

and S

max

O

is the dissolved

oxygen saturation concentration

S

max

O

= 8 mgl

−1

.

The volume of the aeration tank (V) is equal to

6000 m

3

. The settler is a cylindrical tank where

the solids are either recirculated to the aeration tank

Q

rs

= 18446 m

3

day

−1

or extracted from the system

Q

w

= 385 m

3

day

−1

. The parameter values α

1

, α

2

,

α

3

, α

4

, α

5

, α

6

, α

7

, α

8

, α

9

, K

ND

and K

DCO

are given

in Table 2.

4.2 Change of Variables

We apply the developed observer to a simplified

model (five states, three outputs). The change of vari-

ables Ψ which relates natural coordinates to observer

coordinates is trivial. It consists of setting just :

]

X

DCO

=

X

DCO

K

DCO

+ X

DCO

. (27)

The state vector x = (S

O

S

NO

S

NH

X

DCO

S

ND

)

′

is

changed for ξ =

S

O

S

NO

S

NH

]

X

DCO

S

ND

′

, therefore

our system is almost naturally in observable coordi-

nates. The inverse Jacobian is trivial to compute.

The choice of parameters for the adaptation of in-

novation is presented in Table 3.

5 RESULTS

Simulations with the perturbed outputs are carried

out by an additive Orstein-Uhlenbeck process. The

ICINCO2012-9thInternationalConferenceonInformaticsinControl,AutomationandRobotics

188

Table 2: Constant coefficients.

Coefficient α

1

α

2

α

3

α

4

α

5

α

6

α

7

α

8

α

9

K

DCO

K

ND

Value - 5892 - 875 - 1648 191 - 957 150 - 17855 830 561 574 296

Table 3: Parameters for the adaptation.

Parameter value

θ

max

300

β 1664

π

e

m 1

∆T 0.01

λ 200

δ 0.01

d 0.1

alternative control u

b

has been chosen: “On” dur-

ing 15 minutes and “Off” during 5 minutes. The

simulations cover 14 days and the value of the in-

put flow rate Q

in

come from the benchmark file

(http://www.benchmarkwwtp.org/, 2011). We have

three files: One for the dry weather, one for the storm

weather and one for the rain file.

To evaluate the performances of our observer we

have compared an ordinary EKF with our adaptive

HG-EKF presented in (Lafont et al., 2011). Consider-

ing the obtained results for this system, we propose to

use this adaptive HG-EKF observer for the diagnosis.

5.1 Threshold Level for each Output

For each output, we simulate the three files, without

fault, to determine the threshold level δ

i

(Table 4).

Table 4: Threshold level.

File/Output S

O

S

NO

S

NH

Dry 0.2505 0.9453 0.2466

Rain 0.2440 0.9306 0.2247

Storm 0.2576 0.9605 0.2200

We have selected one threshold level by output.

For S

O

, the taken threshold is 0.3, for S

NO

, 1.0 and for

S

NH

, 0.3. These levels must be valid for whatever file.

5.2 Faults

The bias and the drift faults are simulated. The bias

value is equal to 1.5 and 2. The drift fault is simulated

with two curve slopes: (t −t

f

) and 2∗(t−t

f

), t

f

is the

fault time and t is the simulation time.

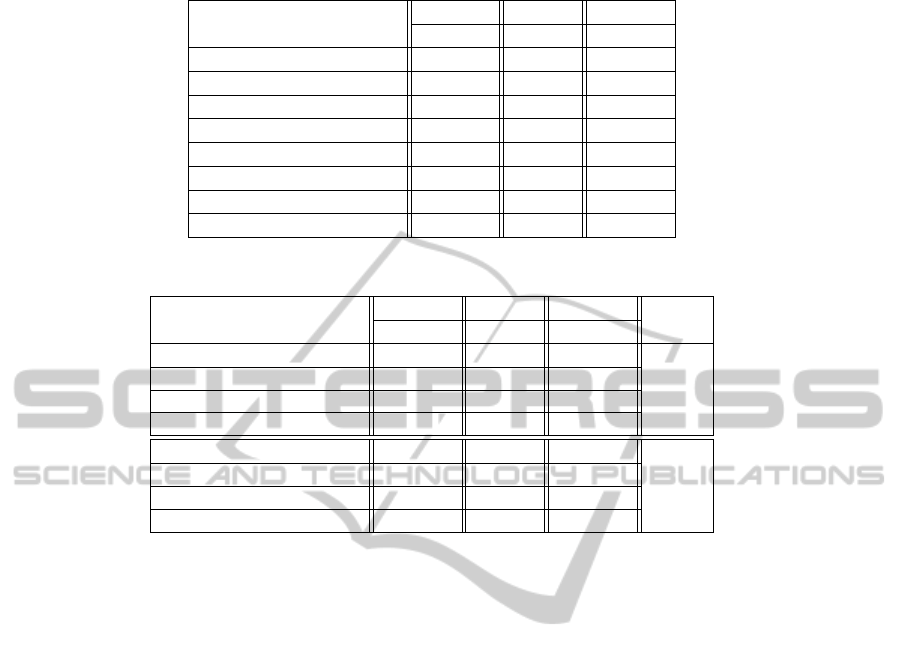

Results are presented in Tables 5 and 6 where t

d

is

the detection time. Only the results for the fault time

equal to 3 with the dry file are presented in Table 5.

Indeed, the three files have the same seven first days.

Moreover, Tables 5 and 6 present two interesting re-

sults:

- Whatever the fault time t

f

, the various faults are

detected,

- If the fault is more important, it is detected

quickly.

6 CONCLUSIONS AND FUTURE

WORKS

6.1 Conclusions

We have shown that an adaptive HG-EKF observer

is efficient to detect sensor faults such as bias and

drift. The proposed method imposes to determine the

threshold levels with no fault. Thanks to the “robust-

ness” (compared with noise and initial conditions) of

this observer and thethreshold choice for the residues,

the adaptive HG-EKF observer is an interesting ap-

proach for the sensor diagnosis. Moreover, the resid-

ual generation is very easy.

To improve the method, we can work with the

eigenvalues of the matrix p. The calculation of the

trace permits to give a confirmation:

Trace(p) =

n

∑

i=1

V

i

, (28)

where V

i

are the eigenvalues. When there is a sensor

fault, the trace has an abrupt change (Figure 2). This

result is a complementary information but it is not sat-

isfactory, because if the value Q

in

increases, the trace

becomes very big and the algorithm indicates a false

alarm.

2.97 2.98 2.99 3 3.01 3.02 3.03

0

1

2

3

x 10

10

Day

Trace

Figure 2: Trace with a fault at t

d

= 3 days.

6.2 Future Works

To improve this method, we can use the trace prop-

erties. The trace value is compared with the influ-

HowtoUseanAdaptiveHigh-gainObserverinDiagnosisProblems

189

Table 5: Faults detection for the dry file.

Fault/Sensor S

O

S

NO

S

NH

t

d

t

d

t

d

Bias +1.5, t

f

= 3 3.0002 3.012 3.0004

Bias +1.5, t

f

= 12 12.0001 12.158 12.0004

Bias +2, t

f

= 3 3.0001 3.009 3.0003

Bias +2, t

f

= 12 12.0001 12.028 12.0002

Drift (t − t

f

), t

f

= 3 3.222 4.455 3.215

Drift (t − t

f

), t

f

= 12 12.150 12.739 12.197

Drift 2∗ (t −t

f

), t

f

= 3 3.092 3.539 3.090

Drift 2∗ (t −t

f

), t

f

= 12 12.067 12.959 12.115

Table 6: Faults detection for the rain and storm file.

Fault/Sensor S

O

S

NO

S

NH

File

t

d

t

d

t

d

Bias +1.5, t

f

= 12 12.0001 12.189 12.0004

Bias +2, t

f

= 12 12.0001 12.013 12.0003 Rain

Drift (t −t

f

), t

f

= 12 12.176 13.528 12.189

Drift 2∗ (t −t

f

), t

f

= 12 12.086 12.933 12.084

Bias +1.5, t

f

= 12 12.0001 12.201 12.0005

Bias +2, t

f

= 12 12.0001 12.012 12.0003 Storm

Drift (t −t

f

), t

f

= 12 12.175 13.813 12.203

Drift 2∗ (t −t

f

), t

f

= 12 12.089 12.941 12.084

ent flow rate by developing a “black box” (neural net-

works for example) which select the peak level to no-

tify a fault.

REFERENCES

Alcaraz-Gonzalez, V., Harmand, J., Rapaport, A., Steyer, J.-

P., Gonzalez-Alvarez, V., and Pelayo-Ortiz, C. (2002).

Software sensors for highly uncertain wwtps : a new

approach based on interval observers. Water Research,

36:2515–2524.

Assis, A. and Filho, R. (2000). Soft sensors development

for on-line bioreactor state estimation. Computers and

Chemical Engineering, 24:1099–1103.

Boizot, N., Busvelle, E., and Gauthier, J.-P. (2010). An

adaptive high-gain observer for nonlinear systems.

Automatica, 469:1483–1488.

Chachuat, B. (2001). Methodology of dynamic optimisa-

tion and optimal control of small-size activated sludge

wastewater treatment plants. PhD, Institut National

Polytechnique de Lorraine, Nancy.

Dochain, D. (2008). Bioprocess control. volume ISBN

9781848210257. ISTE.

Henze, M., Grady, C., Gujer, W., Marais, G., and Matsuo, T.

(1987). Activated sludge model n1. In IAWQ, editor,

Technical Report 1. London.

http://www.benchmarkwwtp.org/ (2011).

Lafont, F., Busvelle, E., and Gauthier, J.-P. (2011). An

adaptive high-gain observer for wastewater treatment

systems. Journal of Process Control, 21:893–900.

Methnani, S., Gauthier, J.-P., and Lafont, F. (2011). Sen-

sor fault reconstruction and observability for unknown

inputs, with an application to wastewater treatment

plants. International Journal of Control, 84.4:822–

833.

Nejjari, F., Puig, V., Giancristofaro, L., and Koehler, S.

(July 6-11, 2008). Extended luenberger observer-

based fault detection for an activated sludge process.

Proceedings of the 17th World Congress The Interna-

tional Federation of Automatic Control, Seoul, Korea,

pages 9725–9730.

Sotomayor, O., Park, S., and Garcia, C. (2002). Software

sensor for on-line estimation of the microbial activ-

ity in activated sludge systems. ISA Transactions,

41:127–143.

ICINCO2012-9thInternationalConferenceonInformaticsinControl,AutomationandRobotics

190