Modeling Dynamic Systems for Diagnosis

PEPA/TOM4D Comparison

I. Fakhfakh

1

, M. Le Goc

2

, L. Torres

2

and C. Curt

1

1

IRSTEA, 3275 route de C

´

ezanne - CS 40061, Aix-en-Provence, France

2

Aix-Marseille Univ, LSIS, 13397 Marseille, France

Keywords:

Multi Modeling, Model Based-reasoning, Dynamic System, Process Algebras, Timed Observation Theory.

Abstract:

Researchers have long been seeking the most suitable formalism and method to build models of dynamic

systems for diagnostic tasks. In this paper, we claim that the main difficulty stems from the lack of global

formalism capable of taking into account structural, functional and behavioral knowledge. To illustrate this

point, we propose a comparison between two modeling approaches.

1 INTRODUCTION

In the last two decades model-based diagnosis has

been an important area of research in which numerous

new methodologies and formalisms have been pro-

posed, studied and subjected to experiments (Con-

sole et al., 2000) and (Le Goc et al., 2008). This

is motivated by the practical need for ensuring the

correct and safe operation of large complex systems.

Since (Reiter, 1987), most of frameworks have been

based on logic formalism. Despite major contribu-

tions in the domain of temporal logic, a difficulty re-

mains in taking observation time into account in di-

agnosis reasoning. Therefore many works have been

proposed to define more or less specific formalisms

to overcome this limit to the logical representation

of timed knowledge, such as the discrete event sys-

tem (D.E.S) formalism and the multi-modeling ap-

proach of (Chittaro et al., 1993). Moreover, these

approaches have seldom been used in the context of

diagnosis. More recently, PEPA formalism (Perfor-

mance Evaluation Process Algebra) (Console et al.,

2000) and the TOM4D methodology (Timed Obser-

vation Modeling for Diagnosis) (Le Goc et al., 2008)

have been proposed to provide expressive languages

to enable efficient modeling of dynamic systems for

diagnosis, comprising a component centered model-

ing paradigm.

The goal of this paper is to bridge research into

process algebras and timed observation modeling

(Le Goc et al., 2008) by providing a comparison be-

tween PEPA and TOM4D. This comparison is per-

formed with a concrete example(Section 2).

2 A HYDRAULIC SYSTEM

The dynamic system studied in (Console et al., 2000)

is described in Figure 1. We use this example to com-

pare PEPA and TOM4D.

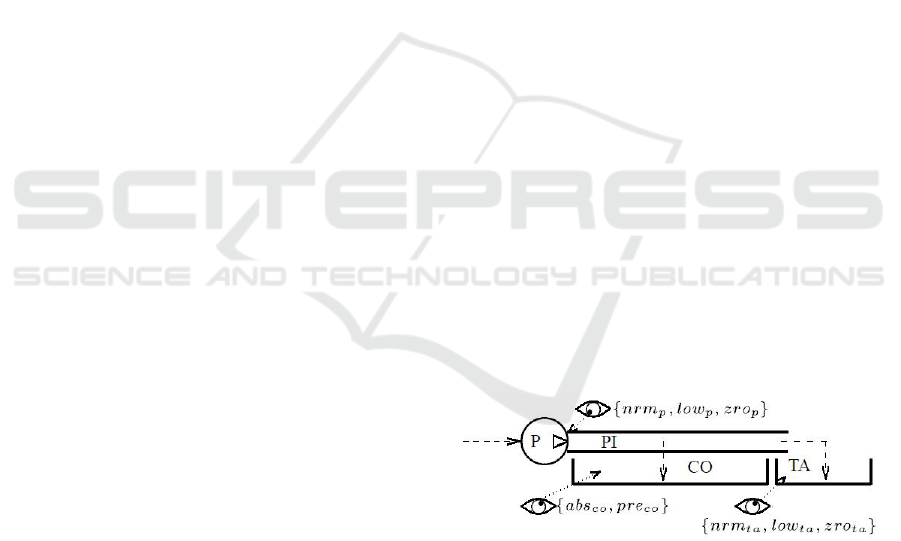

Figure 1: Hydraulic system of (Console et al., 2000).

” The system is formed by a pump P which deliv-

ers water to a tank TA via a pipe PI; another tank CO

is used as a collector for water that may leak from the

pipe. For the sake of simplicity, we assume that the

pump is always on and supplied with water. Pump P

has three modes of behavior: OK (the pump produces

a normal output flow), leaking (it produces a low out-

put flow), and blocked (no output flow). Pipe PI can

be OK (delivering the water it receives from the pump

to the tank) or leaking (in this case we assume that

it delivers a low output to the tank a when receiving

a normal or low input, and no output when receiving

no input). Tanks TA and CO are always in OK mode,

i.e., they simply receive water. We assume that three

sensors are available (see the eyes in Figure 1): flowp

measures the flow from the pump, which can be nor-

mal (nrm

p

), low (low

p

), or zero (zro

p

); level

TA

mea-

sures the level of the water in TA, which can be normal

(m

ta

), low (low

ta

), or zero (zro

ta

); level

co

records the

183

Fakhfakh I., Le Goc M., Torres L. and Curt C..

Modeling Dynamic Systems for Diagnosis - PEPA/TOM4D Comparison.

DOI: 10.5220/0003987201830186

In Proceedings of the 14th International Conference on Enterprise Information Systems (ICEIS-2012), pages 183-186

ISBN: 978-989-8565-10-5

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

presence of water in CO, which can be either present

(pre

co

) or absent (abs

co

)”.

3 PEPA MODEL

The PEPA model is based on classical process alge-

bras enhanced with timed information. Process al-

gebras are abstract languages based on a component

oriented approach (Console et al., 2000) where each

component is modeled in isolation and then each of

the models of the components is composed using the

operators provided by the calculation in order to ob-

tain the entire model. In PEPA, the model of a physi-

cal system is usually divided into two parts: A behav-

ioral model(BM) and a structural model(SM).

3.1 Structural Model

SM describes the structure of the system in terms of

its components. Each component is represented as an

instantiation of generic model. In the example stud-

ied (cf. Figure 1), four generic behaviors are defined:

the ”P” behavior (Pump), the ”PI” behavior (Pipe),

the ”TA” behavior (TA tank) and the ”CO” behavior

(CO tank); also four component instances can be de-

clared: P

(1)

: P; PI

(1)

: PI; TA

(1)

: TA; CO

(1)

: CO.

P

(1)

: P means that the component P

(1)

is an instance

of a component whose behavior is P. The connection

between them is ensured by the cooperation operator

L

i

where the sets L

i

define the activities on which the

components must cooperate. Equation SD

1

describes

the SM of the hydraulic system. The SM of the exam-

ple is:

SD

1

de f

= (P

(1)

L

1

∪{end}

(PI

(1)

L

2

∪{end}

(TA

(1)

{end}

CO

(1)

) )

where L

1

= {nrm

p

, low

p

, zro

p

}, L

2

= {nrm

1

, low

1

,

zro

1

, abs

2

, pre

2

}, H = {nrm

0

, nrm

1

, low

1

, zro

1

, abs

2

,

pre

2

}. The TA

(1)

tank, for example, cooperates with

the CO

(1)

tank with the ”end”

3.2 Behaviour Model

The behavior of each component type is described

as a nondeterministic choice between the various

modes. For example, the BM of the pipe is the

following: PI = PIok

1

+ PIlk

1

+ End;

PIok

1

= nrm

p

.PIok

2

+ low

p

.PIok

3

+ zro

p

.PIok

4

;

PIok

2

= nrm

1

.abs

2

.PI ;

PIok

3

= low

1

.abs

2

.PI;

PIok

4

= zro

1

.abs

2

.PI;

PIlk

1

= nrm

p

.PIlk

2

+ low

p

.PIlk

2

+ zro

p

.PIlk

3

;

PIlk

2

=low

1

.pre

2

.PI; PIlk

3

= zro

1

.abs

2

.PI;

End = end.End

For each behavior, a set of equations is defined

to specify the relations between the component vari-

ables. In particular, the actions of PEPA are used

to express conditions on input, output and state vari-

ables. PI = PIok

1

+ PIlk

1

+ End means that the com-

ponent PI may either be in OK behavior (PIok

1

) or

in leaking behavior (PIlk

1

). The additional identifier

End allows the component to evolve into a final state.

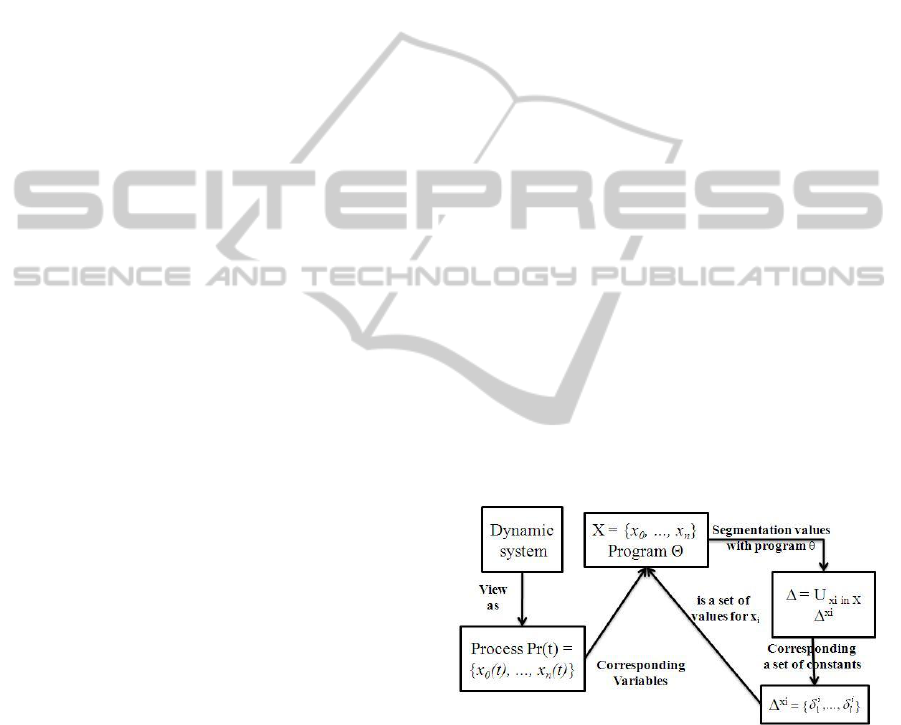

4 TOM4D MODEL

TOM4D is a multi-model approach that combines

CommonKads templates with the conceptual frame-

work proposed in (Zanni et al., 2006) and the tetrahe-

dron of states (T.O.S), (Chittaro et al., 1993). These

elements are merged according to the Timed Obser-

vations Theory (cf Figure 2 more details in (Le Goc,

2006)). In this theory, it is usual to define an observa-

tion class C

i

={(x

i

, δ

i

j

)} as a singleton to associate one

variable x

i

with a constant δ

i

j

. The concept of obser-

vation class is close to the notion of discrete event in

the D.E.S domain. Figure 3 describes the three main

steps of the TOM4D modeling process: The Knowl-

edge Interpretation step uses a CommonKADS tem-

plate to interpret and organize available knowledge

(an expert, a set of documents, etc.) of a dynamic

system.

Figure 2: Timed Observation Theory: abstract.

The scenario model M(ω)= < SM(ω), FM(ω),

BM(ω)> of the system is consistent with knowledge

available on its evolution over time. This model

is necessary to provide, by using the tetrahedron of

states, a physical and a logical interpretation of the

terms used (variables, constants, etc.). In the exam-

ple studied two physical dimensions are given for the

variables: volume (m

3

) and flows of water (m

3

.s

−1

)

(leaking and normal output). This leads to using the

Hydraulic T.O.S. where no pressure (Pr), no resistiv-

ity (R) or pressure moment (Pp) are evoked in the

ICEIS2012-14thInternationalConferenceonEnterpriseInformationSystems

184

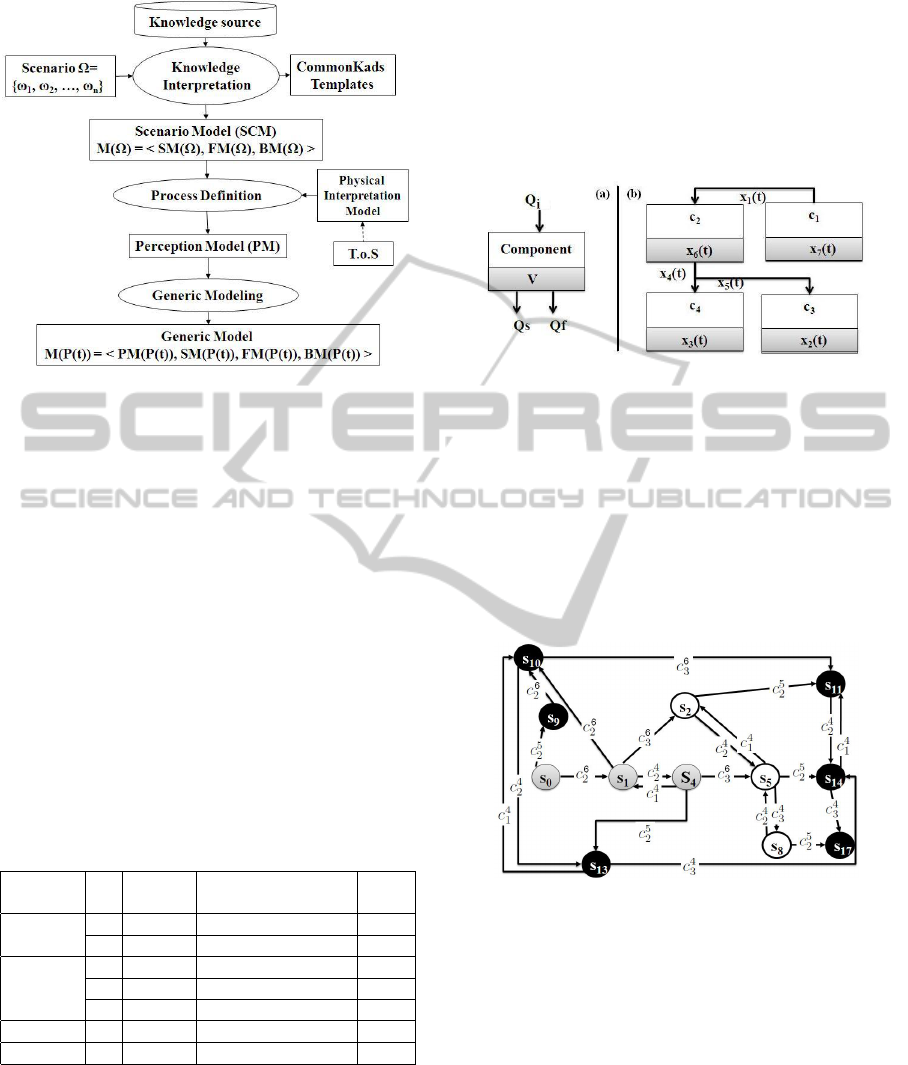

Figure 3: TOM4D Modeling Process.

available knowledge. Thus it is easy to design an ab-

stract generic hydraulic component forming a relation

between an input flow Qi(t), an internal volume V (t)

and two output flows, a normal output flow Qs(t) and

an uncontrolled output flow Q f (t) (Figure 4a). Such a

component is generic because it can be used to model

all the components of the system.

4.1 Perception Model: PM

The abstract generic hydraulic component is sufficient

to define the role of each variable of the system and

the associated concrete components.

Table 1 shows the component-variable-value as-

sociation that can be made according to the abstract

generic hydraulic component.

Table 1: component-variable-value association.

COMPS X dimen- Action ∆

sion (PEPA)

c

1

x

7

V nrm

0

, low

0

,zro

0

2,1,0

x

1

Qs nrm

p

,low

p

,zro

p

2,1,0

c

2

x

6

V nrm

pi

,low

pi

,zro

pi

2,1,0

x

4

Qs nrm

1

,low

1

,zro

1

2,1,0

x

5

Q f pres

2

,abs

2

1,2

c

3

x

2

V nrm

TA

low

TA

,zro

TA

2,1,0

c

4

x

3

V pres

CO

, abs

CO

1,2

4.2 Structural Model

A TOM4D structural model SM(P(t)) is a 3-tuple <

COMPS, R

p

, R

x

> (cf. Figure 4) where:

• COMPS={c

1

, c

2

, c

3

, c

4

} is the finite set of con-

stants denoting the system components,

• R

p

is a set of equality predicates defin-

ing the interconnections between the compo-

nents. R

p

={out(c

1

)=in(c

2

), out

1

(c

2

)=in(c

3

),

out

2

(c

2

)=in(c

4

)}

• R

x

is a set of equality predicates linking each vari-

able. R

x

={ out(c

1

)=x

1

, out(c

3

)=x

2

, out(c

4

)=x

3

,

out

1

(c

2

)=x

4

, out

2

(c

2

)=x

5

}.

Figure 4: Structural Model SM(P(t)).

4.3 Behavioral Model

The behavior model BM(P(t)) is a 3-tuple < S,C, γ >

where S = {s

i

}

i=1...l

is a set of states (s

0

for example

corresponds on x

6

=0 ∧ x

4

=0 ∧ x

5

=1), C is a set of

timed observation classes C

i

={(x

i

, δ

i

j

} (C

6

1

= {(x

6

,0)}

for example) and γ: S × C → S is the state transi-

tion function that implements the state evolution in

the system modeled (i.e. γ(s

1

,C

6

3

) = s

2

).

Figure 5: Behavioral Model of the Pipe.

The ok and leaking PEPA modes of the pipe cor-

respond to the grey and black states in Figure 5, re-

spectively.

4.4 Functional Model: FM

A functional model FM is a 3-tuple < ∆, F, R

f

>

where ∆ is the set of values assumable by the differ-

ent variables (∆

x

1

= {2, 1, 0} for example), F is a set of

functions (The result of the T.o.S and structural model

denotes 7 functions ) and R

f

is a set of equality pred-

icates defining a variable as a function of the others.

The graph of FM(P(t)) is shown in figure 6).

ModelingDynamicSystemsforDiagnosis-PEPA/TOM4DComparison

185

Figure 6: Functional Model of the hydraulic system.

5 DISCUSSION AND

CONCLUSIONS

The example studied shows that the TOM4D struc-

tural model plays the same role as the declaration of

generic component instances, the connection equa-

tions and the activities declaration in PEPA formal-

ism.

The functional TOM4D models play the same role

as the so called ”behavioral” model of components in

Reiter’s theory. There is no equivalent in PEPA be-

cause the process algebras are centered with the de-

scription of the behavioral properties of the connected

components. In this perspective, the value of a vari-

able at a particular time depends on the different ac-

tivities at work in the process. Consequently, the FM

cannot be modelled in the modeling process.

Process algebras define the set of states through

a set of symbols corresponding to an expert’s lan-

guage items, contrary to TOM4D where the states

are anonymous: their meanings are provided with the

value of the whole set of variables used when the sys-

tem enters a state. The set of PEPA actions plays the

same role as the set of timed observation classes and

the behavior definition is similar to the set of transi-

tion relations of the TOM4D behavioral models. Such

a behavioral model is not covered by Reiter’s theory.

In other words, a diagnosis model built according to

Reiter’s theory is formulated with a structural model

and a functional model in the TOM4D meaning. A di-

agnosis model built according to PEPA is formulated

with a structural model and a behavioral model.

On the other hand, the TOM4D methodology

obliges the experts to define the way they ”see” the

system in order to model in terms of perception.

There is no equivalent in PEPA because it consid-

ers the diagnosis model as a consequence of both the

system structure and the behavior of its components.

This was one of the reason for proposing TOM4D.

An important property of the TOM4D methodol-

ogy is the use of T.O.S. T.O.S. facilitates the introduc-

tion of a physical interpretation to model behaviors

having a physical meaning.

From the technical viewpoint, the PEPA model is

more compact than TOM4D models. A compact rep-

resentation is an advantage for the modeler since the

lower the number of symbols there are to be defined,

the better the model will be.

One the advantages of TOM4D is precisely that

its makes explicit the different relations between the

terms used by an expert to formulate their knowledge

(variable, value, state transition condition, etc). In

other words, TOM4D obliges experts to clarify their

knowledge when analyzing the system to be modeled

according to four points of view: perception, struc-

ture, function and behavior. From this standpoint,

the graphical representations of TOM4D models are

clearly an advantage for interpreting and validating

them.

Finally, TOM4D methodology provides concepts

and tools to help the modeler to define the correct

level of abstraction for efficient diagnosis. The ex-

periments we performed with TOM4D methodology

show that this level of abstraction corresponds to that

used by an expert to formulate their knowledge of di-

agnoses applied to dynamic systems.

We are now investigating these approaches to

characterize the properties of their diagnosis algo-

rithms (computational and pertinence properties).

ACKNOWLEDGEMENTS

The authors would like to thank the PACA region and

FEDER for their funding.

REFERENCES

Chittaro, L., Guida, G., Tasso, C., and Toppano, E. (1993).

Functional and teological knowledge in the multi-

modeling approach for reasoning about physical sys-

tems: A case study in diagnosis. IEEE Transactions

on Systems, Man, and Cybernetics 23(6), 1718-1751.

Console, L., Picardi, C., and Ribaudo, M. (2000). Diag-

nosing and diagnosability analysis using pepa. Paper

presented at the 14th European Conference on AI.

Le Goc, M. (2006). Notion d’observation pour le diagnostic

des processus dynamiques : application Sachem et la

dcouverte de connaissances temporelles. Universit

´

e

Aix-Marseille III - FST.

Le Goc, M., Masse, E., and Curt, C. (2008). Modeling pro-

cesses from timed observations. (ICSoft 2008).

Zanni, C., Le Goc, M., and Frydmann, C. (2006). A con-

ceptual framework for the analysis, classification and

choice of knowledge-based system. In International

Journal of Knowledge-based and Intelligent Engi-

neering Systems, 10, pages 113–138. Kluwer Aca-

demic Publishers.

ICEIS2012-14thInternationalConferenceonEnterpriseInformationSystems

186