A Service-based Integration for an improved Product Lifecycle

Management

Stefan Silcher

1

, Max Dinkelmann

2

, Jorge Minguez

1

and Bernhard Mitschang

1

1

Graduate School advanced Manufacturing Engineering (GSaME), University of Stuttgart, Stuttgart, Germany

2

Institute of Industrial Manufacturing and Management (IFF), University of Stuttgart, Stuttgart, Germany

Keywords:

Product Lifecycle Management, Service-oriented Architecture, Modular IT Integration.

Abstract:

The continuously changing environment is nowadays a major challenge for companies. The tough compe-

tition, growing customization of products and environmental regulations forces companies to continuously

adapt their business processes. In order to manage the complexity and reduce the effort for developing prod-

ucts and production, many IT systems are indispensable. Despite Product Lifecycle Management Technology

(PLM) the growing heterogeneous IT landscapes lack of a continuous support for business processes and get

quickly unmanageable. In this paper PLM technology is extended by a service-based integration approach.

Therefore, a modular service-based architecture was developed which will be presented in detail. The archi-

tecture describes how the whole product life cycle can be integrated more efficiently. The characteristics and

findings of our approach are presented as well as a first prototype covering the production planning.

1 INTRODUCTION

Manufacturing companies face several challenges

nowadays. Firstly, in some industry sectors there ex-

ists an overcapacity of produced goods, like in the au-

tomobile industry. There is a tough competition be-

tween companies for market share, price and qual-

ity of products. Secondly, the trend for customiza-

tion is growing. Companies deliver highly individu-

alized products to customers in order to increase their

competitiveness. This results in an increasing com-

plexity when developing the products and planning

their production. Thirdly, environmental regulations,

like reducing energy consumption and greenhouse gas

or replacement of harmful materials, force producing

companies to be highly innovative in developing new

technologies, materials and processes.

These challenges lead together with a highly vola-

tile market to new requirements for manufacturing

companies. To consolidate or increase the market

share, they have to enhance the adaptability of their

company in many ways. Their production has to be

as flexible as possible to produce highly customizable

products in the same production line. Changes of the

factory layout have to be performed in a very short

time and often with increasing frequency in order to

get shorter production times. Therefore, the exchange

of data between the digital and physical factory has to

be improved. This means, the actual state of the phys-

ical factory should be reflected in the model of the

digital factory at any time. This enables a faster reac-

tion on appearing problems or failures in the physical

factory. Additionally, the organization has to be adap-

tive as well. Hence, changes in the business processes

have to be smoothly performed (Jovane et al., 2009).

The first approaches to organize and provide the

product data over their whole life cycle came with the

Product Data Management (PDM). Introducing PDM

systems enormously reduces the effort to handle prod-

uct data, but the systems do not consider the processes

in the product life cycle. Therefore, the concept of

PDM was extended to monitor and manage these pro-

cesses and Product Lifecycle Management was intro-

duced (PLM). The goal is to optimize and standardize

the processes to execute them efficiently and there-

fore save time and money (Saaksvuori and Immonen,

2008), (Stark, 2004).

Additionally, the tasks within a process are sup-

ported by software applications. This leads to a faster

execution of single tasks and consequently reduces

the execution time of the process. However, several

problems arise when a high number of applications

are installed. One of these problems is the emergence

of information silos. The characteristic of such an

IT landscape is often distributed, heterogeneous and

proprietary. Coupling applications by implementing

38

Silcher S., Dinkelmann M., Minguez J. and Mitschang B..

A Service-based Integration for an improved Product Lifecycle Management.

DOI: 10.5220/0003996100380047

In Proceedings of the 14th International Conference on Enterprise Information Systems (ICEIS-2012), pages 38-47

ISBN: 978-989-8565-10-5

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

point-to-point interfaces reduces the problem of in-

formation silos, but such solutions get quickly very

complex and hard to manage and maintain.

The motivation of our work is to build an archi-

tecture, which provides the needed flexibility in the

IT landscape of manufacturing companies. The pro-

cesses within PLM have to be continuously supported

by IT systems, these systems have to be loosely cou-

pled to provide the needed flexibility. Existing ap-

plications should be integrated into the new architec-

ture. Additionally, the management and maintainance

effort of the infrastructure has to be reduced and the

availability of data within the product life cycle im-

proved.

To realize such an architecture, a flexible solu-

tion is needed to flexibly integrate the applications of

the product life cycle. A commonly used paradigm

today is the Service-oriented Architecture (SOA).

SOA provides a flexible integration of applications

by loose coupling and reusing services, which are

self-contained, platform-independent and discover-

able (Erl, 2005). The use of standardized technology

like Web services to implement services allows easily

maintaining, extending or exchanging of an interface.

Moreover, Web services can be composed to work-

flows, which are modeled in standardized languages

like Business Process Execution Language (BPEL)

(OASIS, 2007) or Business Process Model and Nota-

tion (BPMN) (OMG, 2011). These workflows can be

executed by corresponding workflow engines to sup-

port the business processes.

The flexible composition of Web services within

workflows enables a flexible IT support of business

processes, which is necessary to quickly adapt the

business processes in a highly volatile environment.

The platform-independence of Web services allows

exchanging data and information between heteroge-

neous applications. Relying on standards and loosely-

coupled applications simplify maintaining, changing

and extending the IT infrastructure (Weerawarana

et al., 2005).

A common middleware solution to integrate Web

services is the Enterprise Service Bus (ESB) (Chap-

pell, 2004). The ESB handles the routing of messages

to enable a loose coupling of applications. Most ESB

solutions possess a BPEL engine, which is able to ex-

ecute BPEL workflows. Additionally, the ESB can

offer functionality such as message queuing capabili-

ties or monitoring services.

This paper presents a service-based integration ap-

proach for PLM. The developed architecture is based

on an ESB hierarchy to integrate the product life cycle

in a modular way. The results of the implemented pro-

totype for the digital factory demonstrate the benefits

of the service-based solution. The benefits include the

flexible composition of IT tasks, implemented as Web

services, in workflows. The workflows support the

planner of the factory by automating recurring tasks

and saves therefore time and money. Additionally,

the management and extensibility effort of the imple-

mented prototype is enormously enhanced compared

to the previous solution with customized scripts.

The remainder of the paper is structured as fol-

lows: In Section 2, the challenges in PLM and the

problems of inadequate integration of applications are

discussed. Furthermore, the service-based approach

for PLM integration is presented and the current so-

lutions in application integration are described. The

implemented prototype for the integration of produc-

tion planning tools is depicted in Section 3 and ben-

efits and problems as well as further extensions are

discussed. In Section 4, related work is presented be-

fore summary and outlook are given in Section 5.

2 SERVICE-ORIENTED PLM

ARCHITECTURE

An efficient and effective IT support of PLM pro-

cesses is one of the major challenges in today’s man-

ufacturing companies. Using IT systems, especially

in the product development and production planning

phase, can reduce the time-to-market of new products

tremendously. At the same time failures and ramp-up-

time of production are reduced as well as the quality

of products is improved. Today, the time between de-

ciding to develop a new product and its production

start can be further reduced by a seamless integration

of the various tools in the product life cycle. These IT

systems are often legacy applications or information

silos difficult to integrate. In order to enhance the ef-

ficiency of production, the challenge is to enable an

efficient exchange of information within the plethora

of heterogeneous and distributed IT systems used dur-

ing the product life cycle.

The adoption of the SOA paradigm eases the

needed information exchange between heterogeneous

applications by using standardized interfaces like

Web services and decoupling service functionality

from its implementation. Hence, a modular integra-

tion of the various product life cycle phases is pre-

sented in Subsection 2.2. Modularity reduces the im-

plementation and maintenance effort of the IT infras-

tructure. Data exchange between the Web service

as well as their compositions is accomplished by an

ESB. Workflows are capable of automatically execut-

ing recurring tasks within PLM and therefore save

valuable time, as well as reducing errors.

AService-basedIntegrationforanimprovedProductLifecycleManagement

39

Distribution

& Support

Concept

Design &

Development

Production-

planning

Production

Retire &

Dispose

Phase 1 Phase 2 Phase 3 Phase 4 Phase 5 Phase 6

CAD

Wiki

PDM Machine

Control

Unit

CRM …

Simulation PDA… …

Digital Factory

Tools

MESBlog

…

Figure 1: Phases and Tools of the Product Life Cycle.

In Subsection 2.1, the separation of the product

life cycle in six phases, which is used in this paper,

is presented. The service-based PLM architecture is

described in Subsection 2.2. The ideas of a service-

based PLM integration to production networks are ex-

tended in Subsection 2.3. Subsequently, the motiva-

tion for an improved data exchange between the dig-

ital and physical factory and the current state of the

production planning are introduced in Subsection 2.4

and 2.5.

The first implementations within the Learning

Factory’s digital learning shell of the Institute of In-

dustrial Manufacturing and Management (IFF) are

presented in Section 3. This prototype realizes a

seamless service-based integration of systems in the

production planning and eases the data management

thanks to automating the data exchange between the

applications by implementing the process in a BPEL

workflow.

2.1 Product Life Cycle

The product life cycle is heterogeneous in many ways.

Therefore, it is split in different phases, each of them

represent a characteristic activity. In Figure 1, the dif-

ferent phases of the product life cycle can be seen.

The separation of the product life cycle considers not

only the different activities in each phase, but also the

support with tools and the management of data.

In the first phase, the ’concept’ phase (C), ideas

for new products are generated and market analyses

are prepared. Therefore, wikis, blogs or social net-

works are used and often unstructured data has to be

handled and interpreted.

The ’design & development’ phase (DD) is de-

termined by developing and designing the various

parts of the products. Tools like Computer-aided De-

sign (CAD) and Product Data Management systems

(PDM) manage the high volume of data within this

phase.

In the next phase, the ’production planning’ (PP)

is carried out, where process and resource data are

added to the product data and linked among each

other. This data is linked into Digital Factory Tools,

which generate a plan for the factory. The planned

production processes are simulated with simulation

tools to verify the sequence. The data volume, which

has to be handled, increases enormously in this phase

compared to the design and development phase.

Having the product development and production

planning completed, the production can start in phase

four, the ’production’ phase (P). Here, Manufactur-

ing Execution Systems (MES) are responsible for ap-

plying the production orders in the production. The

control unit provides a real-time control of the man-

ufacturing facilities. Feedback of the manufacturing

facilities is gathered and stored by the production data

acquisition unit (PDA) for later analysis.

Selling the products, their maintenance and the

customers comprise are the main tasks of phase five,

the ’distribution & support’ phase (DS). Customer

Relationship Management Systems (CRM) are used

for the linking of sold products and customers for any

kind of complaints or warranty issues.

The ’retire & dispose’ phase (RD) deals with the

disposal of the product. Information about assembly

and material composition of the product can help re-

gain valuable material or simplify the separation of

material for recycling.

2.2 Service-oriented Integration

PLM extends the concept of PDM by adding man-

agement and control of business processes for the

whole life cycle. The problem today is that IT sys-

tems poorly support business processes. Especially

the flexible IT support of business processes is of

great importance (Papazoglou et al., 2007). There-

fore, a service-based architecture is needed, which al-

lows to implement a continuous IT support along the

whole product life cycle. Additionally, business pro-

cesses must be adapted in an easy manner as part of

the IT infrastructure.

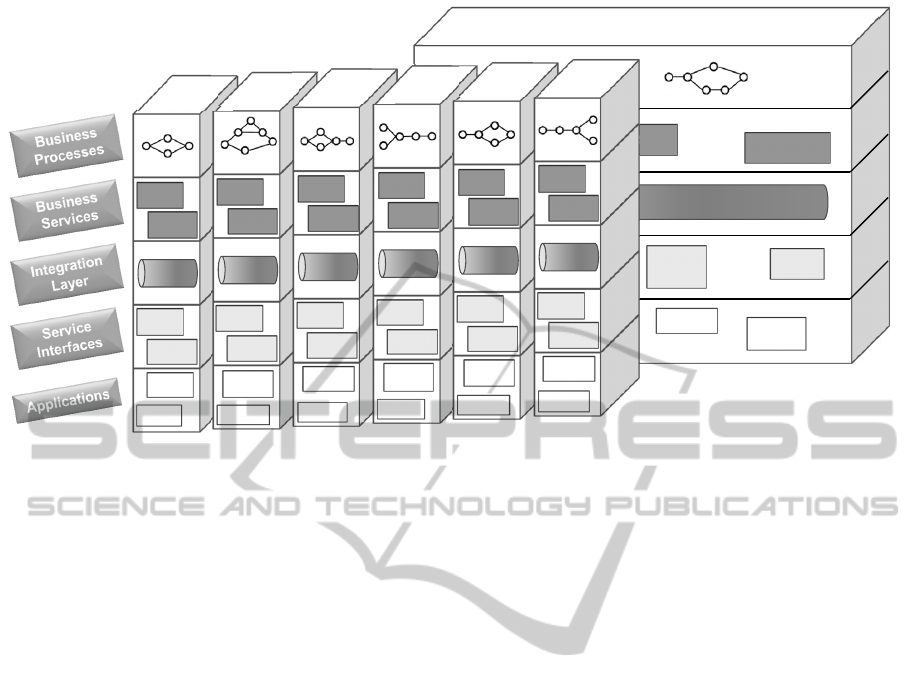

Therefore, a modular service-based architecture

ICEIS2012-14thInternationalConferenceonEnterpriseInformationSystems

40

© GSaME, Universität Stuttgart

17

Ergänzungsprogramm Technik

Stefan Silcher

0

1

2

3

4

Product Lifecycle Management

App

PLM

1

App

PLM

2

WS

PLM

1

WS

PLM

2

BS

PLM

1

BS

PLM

2

PLM-Bus

Layered PLM Architecture

App

C

2

App

C

1

WS

C

2

WS

C

1

BS

C

2

BS

C

1

ESB

C

App

DD

2

App

DD

1

WS

DD

2

WS

DD

1

BS

DD

2

BS

DD

1

ESB

DD

App

PP

2

App

PP

1

WS

PP

2

WS

PP

1

BS

PP

2

BS

PP

1

ESB

PP

App

P

2

App

P

1

WS

P

2

WS

P

1

BS

P

2

BS

P

1

ESB

P

App

DS

2

App

DS

1

WS

DS

2

WS

DS

1

BS

DS

2

BS

DS

1

ESB

DS

App

RD

2

App

RD

1

WS

RD

2

WS

RD

1

BS

RD

2

BS

RD

1

ESB

RD

0

1

2

3

4

Phase 1

Phase 2

Phase 3

Phase 4

Phase 5

Phase 6

Figure 2: Service-based Integration Architecture for Product Lifecycle Management.

was developed with different integration layers, to ef-

ficiently integrate the plethora of applications, used in

the product life cycle, as well as to flexibly support

the business processes. The developed architecture,

which is presented in Figure 2, uses a pillar for every

phase of the product life cycle. Furthermore, the six

phases are integrated with an additional pillar for the

overall PLM (Silcher et al., 2011).

Each pillar is represented by a phase-specific ESB

that integrates all the applications of the correspond-

ing phase. These phase-specific characteristics can

be supported directly. A distinction is made between

phase-specific ESBs and the phase-overlapping PLM-

Bus. This solution with multiple ESBs builds a hier-

archy to efficiently manage all the processes in the

whole product life cycle.

The vertical integration of each product life cy-

cle phase is clearly structured by distinguishing dif-

ferent levels of abstraction (Minguez et al., 2010).

Hence, the functionality and data, provided by each

application, is exposed as Web service in small, func-

tional units. These units can be composed to work-

flows, which support the execution of business pro-

cesses. The five layers are explained in Subsection

2.5 in more details.

The horizontal, phase-overlapping integration is

performed by the PLM-Bus, which connects the

phase-specific ESB’s as a central backbone. The sep-

aration of phase-specific integration and holistic PLM

integration contains several advantages (Silcher et al.,

2011). Particularly, the possibility of adapting the

ESB to the requirements of each phase like availabil-

ity, data throughput and time requirements are of great

importance.

The PLM-Bus is responsible to manage the phase-

overlapping data exchange, tasks and processes. The

PLM-Bus should provide information about available

Web services of all phases as well as authorization

and authentication as a single sign-on service. Pro-

cesses like change and failure management have to

be coordinated by the PLM-Bus. Additionally, En-

terprise Resource Planning systems and other appli-

cations, which cannot be assigned to a specific phase,

should be directly integrated by the PLM-Bus.

2.3 SOA for Production Networks

Previously not considered was the fact, that most

companies are not involved in the whole product life

cycle. Only the Original Equipment Manufacturers

(OEM’s) treat the product life cycle from the devel-

opment to the recycling of the product. Small and

Medium-sized Enterprises (SMEs), in particular sup-

pliers of OEMs, focus their work on one or two phases

of the presented product life cycle. Therefore, a

phase-specific integration is often sufficient to cover

their whole business area. This is not only profitable

for the SMEs, which benefit from the advantages of

a service-based IT infrastructure. Especially for the

OEM’s, the change of the SMEs IT landscape to an

SOA can be valuable.

A service-based communication improves the

quality of the data exchange, due to standardized Web

service interfaces, workflow definition or data ex-

change formats. Additional, asynchronous commu-

nication eases the loose coupling systems of the com-

AService-basedIntegrationforanimprovedProductLifecycleManagement

41

panies.

Therefore, the integration of SMEs in the business

process of an OEM is useful to have a defined way of

communication between the companies. E.g. changes

in the design of a product, made by an SME, can be

necessary due to inconsistencies in assembly tests of

the OEM. The OEM can describe the problems and

send them to the SME, where automatically an ex-

posed process is triggered to solve the resulting prob-

lem.

Therefore, the presented architecture can be easily

extended to manage data and processes in production

networks covering all involved companies, e.g., from

OEM to all suppliers. The challenge would be to con-

vince all suppliers and customers of a company to mi-

grate their IT infrastructure to SOA. Beside the tech-

nical challenge it poses an organizational challenge.

2.4 Digital and Physical Factory

Today, one key to a more efficient factory is the cou-

pling of the digital and physical factory. The vision

is to have available an up-to-date digital copy of the

physical factory at any time. Based on the current

state, different simulations could be executed to fore-

cast the short and medium term development of the

factory and its production.

The problem is to provide status information of

the production environment in real-time to the digi-

tal factory in order to automatically run a simulation

model out of that data (K

´

ad

´

ar et al., 2010). The pre-

sented architecture improves the availability of data

in the production environment by exposing Web ser-

vice interfaces and loosely coupling of applications in

the infrastructure, which allows a faster data exchange

between the digital and physical factory.

The IFF at the University of Stuttgart has built a

Learning Factory, which contains a digital learning

shell and a physical factory. The digital learning shell

contains many tools for planning and optimizing the

digital model of the factory. The central application

is a database to store product, process and resource

(PPR) data, also called PPR-Hub. Around this PPR-

Hub, there are several tools for the factory optimiza-

tion. Amongst others, there is a layout planning table,

where a group of people can cooperatively optimize

the factory layout (Kapp et al., 2005). The most im-

portant tool in a digital factory is a simulation applica-

tion. Additionally, a logistic simulation tool is used to

verify the planned production processes and various

simulated scenarios (Kapp et al., 2003).

The presented tools and others can exchange data

with the PPR-Hub by executing (Visual Basic) scripts.

These scripts are customized point-to-point connec-

0

1

2

3

4

Digital

Factory

Tools

Layout Planning

Table Service

PPR-Hub

Service

ESB

PP

Layout Planning

Service

Layout

Planning

Table

Production

Planning

Figure 3: Integration Pillar for the Production Planning

Phase.

tions. Therefore, the inclusion of new tools or sub-

stitution of an existent tool is associated with a great

effort. Substituting a tool leads to a complete reim-

plementation of the script.

The physical factory of the IFF, called iTRAME,

consists of modular manufacturing units, which are

connected with a universal plug-and-play mechanism

and can be easily exchanged (Dinkelmann et al.,

2011).

Currently, the factory layout of the physical fac-

tory can be automatically detected and copied with a

script to the digital planning environment. Due to the

high effort for implementing these scripts, no further

information is used in the planning environment, e.g.

process data and time information of the production.

This information would help to understand the cur-

rent situation in the production, when planning and

real data are compared, and thus would enhance the

planning accuracy, but also increases the planning ef-

fort.

The goal of implementing an SOA is to replace the

tight coupling of the applications with scripts by Web

service interfaces, which can be flexibly composed

into workflows. The workflows can support the plan-

ner by automatically or semi-automatically executing

recurring tasks in the product life cycle, e.g. when

new products are introduced, changes in the product

mix are detected, or machine failures appear.

ICEIS2012-14thInternationalConferenceonEnterpriseInformationSystems

42

PPSB

Access-DB

Planning

Table

PPR-

Hub

Workflow

Engine

MSMQMSMQ

Content-

based

Router

MSMQ

Workflow Management Portal Layout Planning Table

Figure 4: Architecture of Integrated IT systems.

2.5 Production Planning

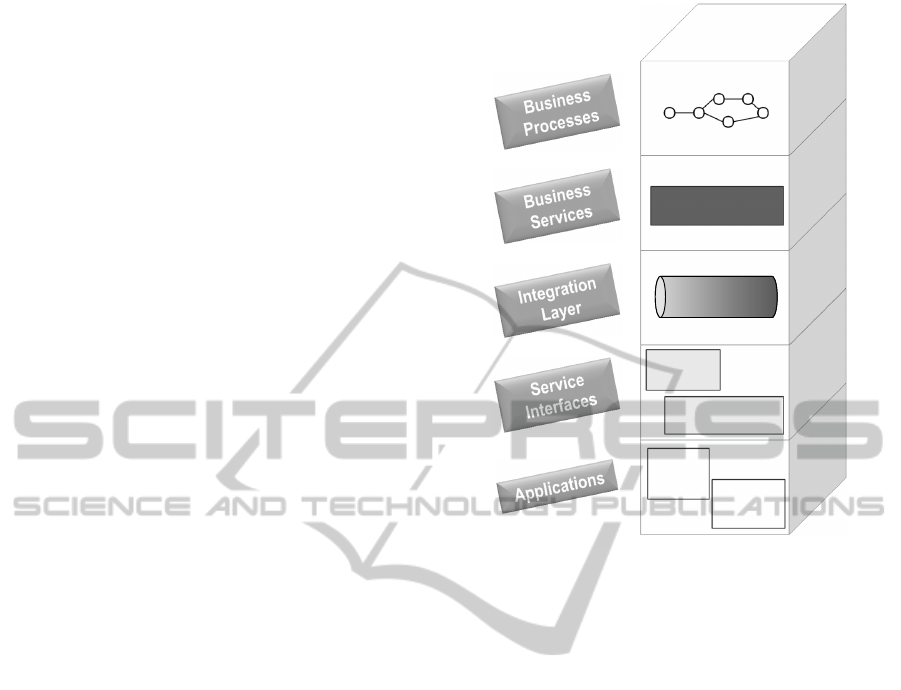

Implementing the presented service-based architec-

ture for PLM in the production planning is figured out

in Figure 3.

Layer 0 contains the various applications of the

production planning, e.g. digital factory tools, layout

planning table, simulation tools. The data and func-

tionality of the applications is exposed to other tools

by means of Web service interfaces, which are placed

in Layer 1. The ESB in the integration layer (Layer 2)

routes the messages sent and received by the Web ser-

vice interfaces to the desired destination. Addition-

ally, it performs the data transformations from propri-

etary data formats to a canonical data format of the

ESB, which is described in Subsection 3.3. The busi-

ness services in Layer 3 compose the Web services to

small processes, which manage the data exchange be-

tween two applications. The business process layer at

the top of the pillar (Layer 4) represents the IT imple-

mentation of the business processes.

Web service technologies are platform indepen-

dent, which is a great advantage when integrating pro-

prietary heterogeneous systems like the current IT in-

frastructure at the IFF. In the implemented prototype,

the messages are exchanged over Message Queues

(MQ), which allow a reliable, asynchronous commu-

nication between the participating applications and

improve the loose coupling of applications (Hohpe

and Woolf, 2003). More details on our prototype im-

plementation will be given in the subsequent chapter.

3 IMPLEMENTATION OF

SERVICE-BASED

INTEGRATION FOR

PRODUCTION PLANNING

To show the benefits of the service-based approach,

some applications of the Learning Factory’s digital

learning shell were integrated by the presented ap-

proach and architecture. Therefore, the databases of

each application were equipped with Web service in-

terfaces and a web-based portal was developed to con-

trol and manage workflows executed in the production

planning environment.

3.1 Prototype of Service-based

Production Planning

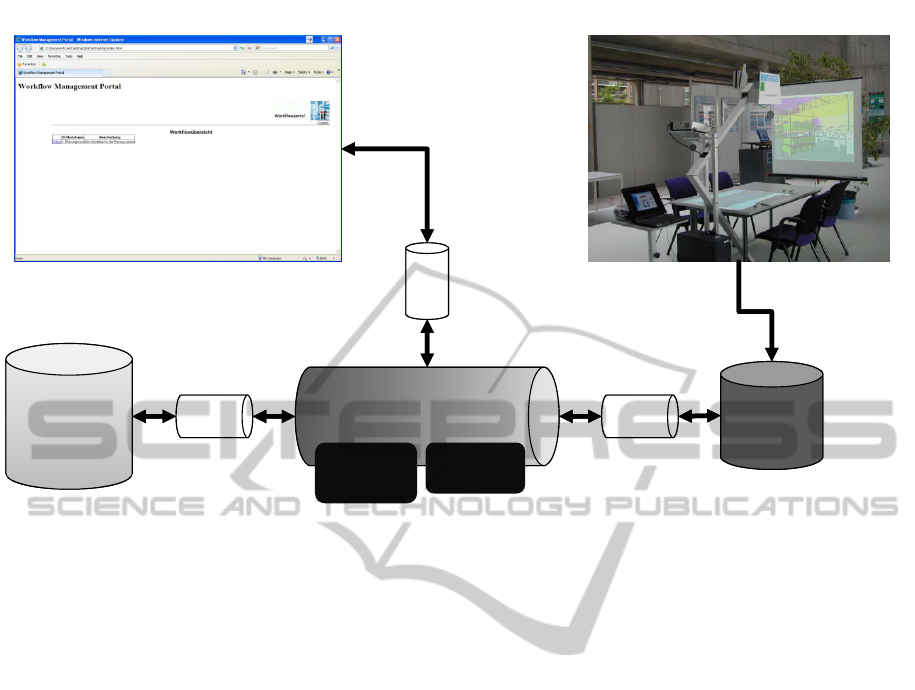

In the first phase of the implementation, the central

data hub, which stores the PPR data, should be inte-

grated with a layout planning tool (Kapp et al., 2005).

The developed architecture is shown in Figure 4.

The core of this architecture is the Production

Planning Service Bus (PPSB), which is based on the

OpenESB, an open source implementation of an ESB

(OpenESB, 2010). BPEL workflows can be executed

AService-basedIntegrationforanimprovedProductLifecycleManagement

43

Load

Projects

Select

Project

Load Resource

Data to

Planning Table

Perform

Layout

Planning

Store

Resource

Data in

PPR-Hub

Load Projects Select Project

Load Resource Data

to Planning Table

Perform Layout

Planning

Store Resource

Data in PPR-Hub

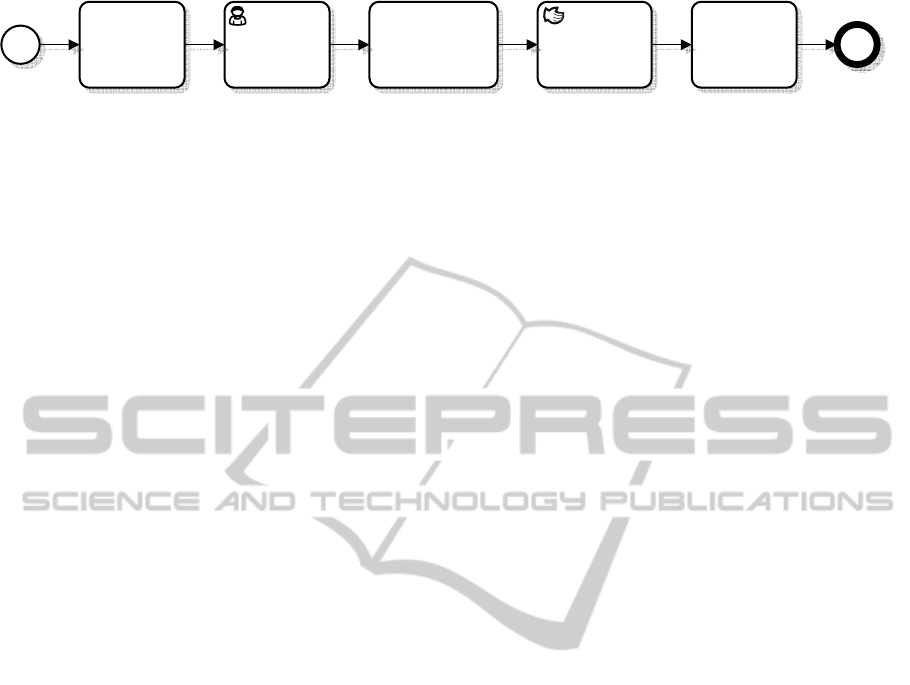

Figure 5: BPMN Workflow for Layout Planning.

in the workflow engine of the OpenESB. To adminis-

trate the workflows, the Workflow Management Por-

tal was developed, where the production planner can

start, control and if necessary restart or stop the avail-

able workflows. The usage of the implemented plan-

ning workflow is described in Section 3.2.

Using asynchronous communication improves the

loose coupling between the applications. They don’t

communicate directly with each other; instead the

messages are sent over MQs. A MQ enables a reliable

communication between the participants by receiving

messages and storing them persistently until the MQ

has successfully delivered the message to the receiver.

This means, the receiver can be temporarily unavail-

able without disrupting the whole system or blocking

the sender of a message. Therefore, the usage of MQs

makes the system more robust against network or ap-

plication failures and improves the loose coupling of

the applications.

In the presented prototype, Microsoft Message

Queuing (MSMQ) is used to connect the systems with

the OpenESB. To enable the OpenESB to communi-

cate with the MSMQs, a MSMQ Binding Component

is provided by the developers of the OpenESB.

To integrate the applications within the architec-

ture, Web service interfaces were developed to en-

able the exchange of messages with other applica-

tions. For the Workflow Management Portal, PPR-

Hub and Layout Planning Table a Web service inter-

face was implemented for each. Due to the fact, that

no source code was available for the Layout Planning

Table, the only way to exchange data with this tool

was an interface to its access database.

All the messages exchanged in the system rely on

the same canonical data format. Thus, all the mes-

sages have the same structure and don’t have to be

transformed between the different systems. The only

effort is to generate a correct message, including the

data provided by the database. To reduce the effort, a

common library that automatically generates the mes-

sages in the correct format is implemented to be used

by all Web services.

The loose coupling of the integrated applications

is ensured by using a content-based router (Hohpe and

Woolf, 2003). This means, an application must not

know the network address or endpoint of the desti-

nation system of a message. The message can just be

sent to the ESB, where the content-based router deter-

mines the destination by inspecting the content of the

message. Therefore, the endpoint can be looked up

in a database, when the destination system is known.

This allows transferring applications to other servers

or changing their endpoints without affecting other

applications. The only thing to do is to change the

corresponding endpoint in the database of the content-

based router and all other applications can communi-

cate again with the changed application. The purpose

of the content-based router is to decouple applications

and to enhance adaptability.

3.2 Layout Planning Workflow

The workflow implemented for the prototype controls

the data flow between the systems presented in the

previous subsection. A BPMN model of this work-

flow is presented in Figure 5.

The first task ”Load Projects” of the workflow

sends all projects, which are stored in the PPR-Hub,

in a message to the Workflow Management Portal.

The message is extracted and the projects are pre-

sented in the portal.

The user is asked in the second task ”Select

Project”, to select the project he wants to modify in

the Layout Planning Table. The human icon in the

top left corner of the task indicates that a human in-

teraction is necessary in this task.

After selecting a project, the third task ”Load Re-

source Data to Planning Table” is started, which sends

a message containing the selected project to the PPR-

Hub. The resource information of this project is there-

upon sent over the ESB to the Layout Planning Table

and stored in its database.

In the fourth task ”Perform Layout Planning”, the

user can perform the layout planning to optimize the

material flow, the logistic processes, and so forth. The

hand icon in the top left corner of the task indicates

that this task has to be performed manually by the

user.

When the user finished the layout planning, the

last task ”Store Resource Data in PPR-Hub” is exe-

cuted. This task generates a message to send the op-

timized planning data over the ESB back to the PPR-

Hub, where they are stored and are now available for

other systems in the production planning.

ICEIS2012-14thInternationalConferenceonEnterpriseInformationSystems

44

3.3 Message Format

To efficiently exchange messages between the differ-

ent applications, an application-independent canoni-

cal data format was defined. Using a canonical data

format is best practice in integration, because it re-

duces the complexity of data formats when integrat-

ing new applications into the infrastructure (Chappell,

2004). Thus, the data of each application has to be

transformed to and from the canonical format, instead

of one transformation from each to every application.

This reduces the complexity of integration and im-

proves the extensibility and scalability of the integra-

tion approach.

The defined message format consists of two parts

and is based on XML. The first part contains infor-

mation about the message type and the routing. The

content-based router derives the destination of the

message from the message type and writes them in

the routing information part of the message.

The second part of the message contains the data

of a project. Currently, this part entails information

about the production resources, but can be easily ex-

tended with product, process and order information in

the future, when more applications are integrated into

the architecture.

<?xml version="1.0" encoding="utf-8"?>

<ProjectMessage xmlns:xsi="...>

<CommonInfos xmlns="http://tempuri.org/ESB">

<RoutingInfos>

<OriginSystem>PPR-Hub</OriginSystem>

<DestinationSystem>

<SystemID>WP</SystemID>

<SystemURI>http://localhost:9007/

PortalService/</SystemURI>

</DestinationSystem>

</RoutingInfos>

<MessageType>0</MessageType>

. . .

</CommonInfos>

<Projects xmlns="http://tempuri.org/ESB">

<Resources>

<ModuleTypes>

<ModuleID>1</ModuleID>

<Modulename>modulename</Modulename>

<Type>1</Type>

<FileName>test.cad</FileName>

<BitmapName>test.bmp</BitmapName>

<Module>

<ObjectID>1</ObjectID>

<Objectname>objectname</Objectname>

<Position>

<Position_X>300</Position_X>

<Position_Y>80</Position_Y>

<Position_Z>0</Position_Z>

<Rotation_X>0</Rotation_X>

<Rotation_Y>0</Rotation_Y>

<Rotation_Z>0</Rotation_Z>

</Position>

</Module>

<Module>

. . .

</Module>

</ModuleTypes>

</Resources>

<ProjectID>1</ProjectID>

<Projectname>test project</Projectname>

</Projects>

</ProjectMessage>

The messages are generated by the Web services,

which read the data from the database of the source

system and fill them into the XML schema. After

completing the message, it is sent to the router of the

PPSB, where the destination is derived from the mes-

sage content and forwarded to the destination Web

service interface. After receiving the message, the

information is extracted from the XML message and

stored in the database of the destination system.

3.4 Review and Extension of the

Prototype

For the manageability of our IT infrastructure ap-

proach, this prototype demonstrates great advantages

compared to the previously implemented point-to-

point interfaces between the applications:

• The ESB as central integration backbone eases the

connection of the heterogeneous applications to

this prototype.

• The use of a canonical data format reduces the

number of different transformations, which leads

to a better extensibility and scalability of the in-

frastructure.

• The content-based router enables the loose cou-

pling of the applications to the ESB by introduc-

ing a central database for the registration of appli-

cation endpoints.

• The implementation of MQs boosts the loose cou-

pling at the connectivity layer. Additionally, the

robustness of the complete infrastructure is im-

proved due to temporarily failures of networks or

applications.

• Changing from a synchronous to an asynchronous

communication increases the performance by

reducing unnecessary blocking of applications

when waiting till a message is send or is available

to receive.

The presented prototype allows the production

planner to manage the data of the integrated appli-

cations at a single point, the Workflow Management

AService-basedIntegrationforanimprovedProductLifecycleManagement

45

Portal. In the portal, the planner can see the available

workflows and start, stop or restart them.

Proprietary applications can be integrated in var-

ious ways into an SOA. To access the functionality

of a program, an available interface can be used or a

new one can be implemented, provided that the source

code is available. If neither is available, the func-

tionality of a program cannot be easily integrated in

a workflow, as in our case. Nevertheless, the data can

be accessed by an interface over the program logic or

directly over the database of a program. In the pro-

totype the databases of the integrated programs were

equipped with an Web service interface which lead to

an enhances data exchange between the applications.

To fully automate the planning processes, functional-

ity has to be exposed as Web services to be able to

execute them within a workflow activity.

Extending the prototype with a simulation tool

like the logistic simulation tool would make sense.

The optimized layout could be verified by simulating

the production processes and the throughput can be

measured. Therefore, the simulation tool has to be

equipped with a Web service interface to receive the

necessary data for the simulation.

The canonical message format has to be extended

to include beside the resource data also product and

process data. In the currently used data format, this

extension is already provided and can be easily per-

formed. Additionally, the Web service interface of

the PPR-Hub has to be extended to read and write

the product and process data. On the other hand, the

Web service interface of the Layout Planning Table

remains unchanged. Now, there are two alternatives

to integrate the simulation tool in a workflow. The

presented layout planning workflow can be extended

to include the simulation tool or a new simulation

workflow can be implemented to control the data ex-

change between the PPR-Hub and the simulation tool.

In the second case, the layout planning workflow and

the new simulation workflow have to be executed con-

secutively.

4 RELATED WORK

In the last few years, the main PLM vendors like Das-

sault Syst

`

emes, PTC and Siemens PLM Software ex-

tended their PLM solutions with a service-based ap-

proach to get the desired continuous integration of

the product life cycle (CIMdata, 2006). However,

they adopt their proprietary integration middleware

and thus resulted in restricted interoperability prop-

erties: lacking to integrate systems of other vendors,

missing flexibility in business process support, and

applications are not loosely coupled to the integration

middleware. Furthermore, the interfaces are not open,

so it is hard or impossible for other software vendors

to connect their applications to these middleware sys-

tems.

Rantzau et al. implemented a Data Change Prop-

agation System called CHAMPAGNE for heteroge-

neous information systems (Rantzau et al., 2002).

The CHAMPAGNE platform manages dependencies

between the schemas of different distributed applica-

tions. Compared to the presented prototype in this pa-

per, CHAMPAGNE implements a tight coupling to the

participating applications. Hence, changes in a sys-

tem can only be made when the propagation scripts

are changed accordingly, which my become quite

some hassle.

5 CONCLUSIONS AND

OUTLOOK

Highly volatile markets and growing competition

force companies to continuously increase their effec-

tiveness. Their flexibility has to be improved to adapt

to the constantly changing environment. This can be

achieved by a more flexible support of business pro-

cesses and the IT infrastructure. Additionally, the

applications, which support a business process task,

have to be better integrated to improve the data and

information flow. The vision is a continuous integra-

tion of all applications used in the product life cycle

to accelerate the data exchange.

The paper presents a service-based architecture to

integrate the different phases of the product life cy-

cle. The phase-overlapping integration is performed

by the PLM-Bus, which allows exchanging data and

coordinating processes between the phases. The ben-

efits of this architecture are a clear separation between

different levels of abstraction as well as the possibility

to adapt each ESB to the requirements of each phase

like availability, data throughput and time require-

ments. Possible extensions to integrate customers and

suppliers in this infrastructure to get a consistent in-

formation exchange in the production network were

discussed.

Furthermore, the developed prototype based on

the Production Planning Service Bus performs a

service-based integration of the production planning

environment at the IFF. The benefits and problems of

the prototype and the integration of proprietary appli-

cations are discussed and an outlook on useful exten-

sions of the implementation in the production plan-

ning is given.

The next step in the service-based integration of

ICEIS2012-14thInternationalConferenceonEnterpriseInformationSystems

46

PLM is the implementation of the PLM-Bus to effi-

ciently couple the production planning and produc-

tion phase. The goal is to establish a bidirectional

communication between the digital and physical fac-

tory to automatically adopt the current production sta-

tus for the planning and to accomplish an optimized

planning in the production environment.

ACKNOWLEDGEMENTS

The authors extend their sincere thanks to Fabian

Laux, who contributed in developing and implement-

ing the prototype of the service-based production

planning integration.

Furthermore, the authors would like to thank the

German Research Foundation (DFG) for financial

support of this project as part of the Graduate School

of Excellence advanced Manufacturing Engineering

(GSaME) at the University of Stuttgart.

REFERENCES

Chappell, D. A. (2004). Enterprise Service Bus: Theory in

Practice. O’Reilly Media, 1st edition.

CIMdata (2006). Service-oriented architecture for plm - an

overview of ugs soa approach. Technical report, CIM-

data, Inc.

Dinkelmann, M., Riffelmacher, P., and Westkmper, E.

(2011). Training concept and structure of the learn-

ing factory advanced industrial engineering. In

ElMaraghy, H. A., editor, Enabling Manufactur-

ing Competitiveness and Economic Sustainability,

Proceedings of the 4th International Conference

on Changeable, Agile, Reconfigurable and Virtual

Production (CARV2011), pages 624–629. Springer

Berlin Heidelberg.

Erl, T. (2005). Service-Oriented Architecture: Concepts,

Technology, and Design. Prentice Hall International,

illustrated edition edition.

Hohpe, G. and Woolf, B. (2003). Enterprise Integration

Patterns: Designing, Building, and Deploying Mes-

saging Solutions. Addison-Wesley Longman, Ams-

terdam.

Jovane, F., Westk

¨

amper, E., and Williams, D. (2009). The

ManuFuture Road: Towards Competitive and Sus-

tainable High-adding-value Manufacturing. Springer,

Berlin, 1st edition.

K

´

ad

´

ar, B., Lengyel, A., Monostori, L., Suginishi, Y., Pfeif-

fer, A., and Nonaka, Y. (2010). Enhanced control of

complex production structures by tight coupling of the

digital and the physical worlds. CIRP Annals - Manu-

facturing Technology, vol. 59(1):437–440.

Kapp, R., Le Blond, J., and Westk

¨

amper, E. (2005). Fab-

rikstruktur und logistik integriert planen: Erweiterung

eines kommerziellen werkzeugs der digitalen fabrik fr

den mittelstand. wt Werkstattstechnik online, vol. 95

(2005), No. 4:191–196 (german).

Kapp, R., L

¨

offler, B., Wiendahl, H.-H., and Westk

¨

amper, E.

(2003). Der logistik-pr

¨

ufstand: Skalierbare logistik-

simulation von der lieferkette bis zum arbeitsgang. wt

Werkstattstechnik online, vol. 93 (2003), No. 1/2:31–

38 (german).

Minguez, J., Ruthardt, F., Riffelmacher, P., Scheibler, T.,

and Mitschang, B. (2010). Service-based integration

in event-driven manufacturing environments. In WISE

2010 Workshops, volume 6724 of Lecture Notes in

Computer Science, pages 295–308. Springer.

OASIS (2007). Web services business process execution

language version 2.0.

OMG (2011). Business process model and notation

(BPMN) version 2.0.

OpenESB (2010). http://www.logicoy.com/esb.php (last

visited: November 2011).

Papazoglou, M., Traverso, P., Dustdar, S., and Leymann, F.

(2007). Service-oriented computing: State of the art

and research challenges. Computer, vol. 40(11):38–

45.

Rantzau, R., Constantinescu, C., Heinkel, U., and Mei-

necke, H. (2002). Champagne: data change prop-

agation for heterogeneous information systems. In

Proceedings of the 28th international conference on

Very Large Data Bases, VLDB ’02, pages 1099–1102.

VLDB Endowment.

Saaksvuori, A. and Immonen, A. (2008). Product Lifecycle

Management. Springer, Berlin, 3rd edition.

Silcher, S., Minguez, J., and Mitschang, B. (2011). Adopt-

ing the manufacturing service bus in a service-based

product lifecycle management architecture. In Pro-

ceedings of the 44th International CIRP Conference

on Manufacturing Systems: ICMS ’11; Madison, Wis-

consin, USA, pages 1–6. Online.

Stark, J. (2004). Product Lifecycle Management: 21st Cen-

tury Paradigm for Product Realisation (Decision En-

gineering). Springer, Berlin, 1st edition.

Weerawarana, S., Curbera, F., Leymann, F., Ferguson, D. F.,

and Storey, T. (2005). Web Services Platform Ar-

chitecture: Soap, WSDL, WS-Policy, WS-Addressing,

WS-Bpel, WS-Reliable Messaging and More. Prentice

Hall International, USA.

AService-basedIntegrationforanimprovedProductLifecycleManagement

47