Substations Optimization

Foundations of a Decision Making System

Luiz Biondi Neto

1

, Pedro H. G. Coelho

1

, Francisco Soeiro

1

, Osvaldo Cruz

1

and

David Targueta

2

1

State University of Rio de Janeiro, Av. Maracanã, 524, Rio de Janeiro, RJ, Brazil

2

São Simão M. S. Ltda, Mal Camara 160, Sala 1808, Rio de Janeiro, RJ, Brazil

Keywords: Decision Support System, Substations Optimization.

Abstract: The optimization of building processes for a power substation is based on the adopted configuration

structure and includes a simulation of the methods for the mechanical, civil and electrical processes. Thus it

is necessary to know the scope of the service area, the substation load and its connected transmission lines,

the terrain topography, and the environmental impact, issues that will be only known after the choice of the

area and the project details. The purpose of this work was to bring the foundations of a decision support

system regarding the reduction of the structure weight and its concrete volume. A laboratory reduction

model validated the work.

1 INTRODUCTION

For an electric utility, changes in legislation and

the growth of energy use require the need for new

tools and techniques, to achieve the highest level of

quality of power supply to the consumer at the

lowest cost and always preserving the environment.

For this reason, the research carried out, combines

mechanical civil and electrical engineering, and

therefore makes use of different methodologies,

depending on the area in which one seeks to

optimize envisioning a decision support system

(D’Ajuz, 1985).

The main objectives of this research aimed to

develop possible solutions for optimization of

construction of substations and consisted of:

1. Model and simulate the investigated metallic or

composite structures by estimating their weights,

aiming their reduction in the optimized Electrical

System (ES).

2. Shape the foundations of the pillars concerned to

the investigated metal or composite structures in

order to .reduce the concrete volume.

3. Model, simulate and test the Electrical System on

a reduced scale.

2 METHODOLOGY

2.1 Reducing the Weight Structure

Studies were undertaken in order to minimize the

weight of the structure with three different

situations, from the most traditional to the most

innovative on the market with technical

characteristics that meet the preliminary optimized

substation. Three structures were investigated:

1. Lattice-like structures (traditionally used).

2. Tubular structures (used in our proposal).

3. Centrifuged Concrete Structures (steel and

concrete).

These structures must be sized appropriately in order

to resist traction forces, self weight, weight of

equipment and wind acting on them.

For the calculations is necessary to know precisely

the topography of the region adjacent to the land and

own land for the construction, the angular

distribution lines related to the substation, and the

climatic characteristics of the region, especially in

relation to the wind, which at this stage project are

not yet defined.

The computational tool (Bhati, 2005) used to

model, simulate, analyze and estimate parameters in

the three cases studied, was the Finite Element

Method (FEM).

330

Biondi Neto L., H. G. Coelho P., Soeiro F., Cruz O. and Targueta D..

Substations Optimization - Foundations of a Decision Making System.

DOI: 10.5220/0004001603300333

In Proceedings of the 14th International Conference on Enterprise Information Systems (ICEIS-2012), pages 330-333

ISBN: 978-989-8565-10-5

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

2.1.1 Lattice-like Structures

Lattice Systems are those consisting of

undeformable elements joined together by hinges,

considered perfect, and subject only to loads applied

to the joints or nodes. Thus the elements or bars are

only subject to normal efforts, traction or

compression. In the plane lattice, the set of

construction elements, e.g. round bars, flat or angles,

are interconnected under triangular form geometry,

by pins, welding, rivets or bolts, designed to form a

rigid structure in order to withstand only the normal

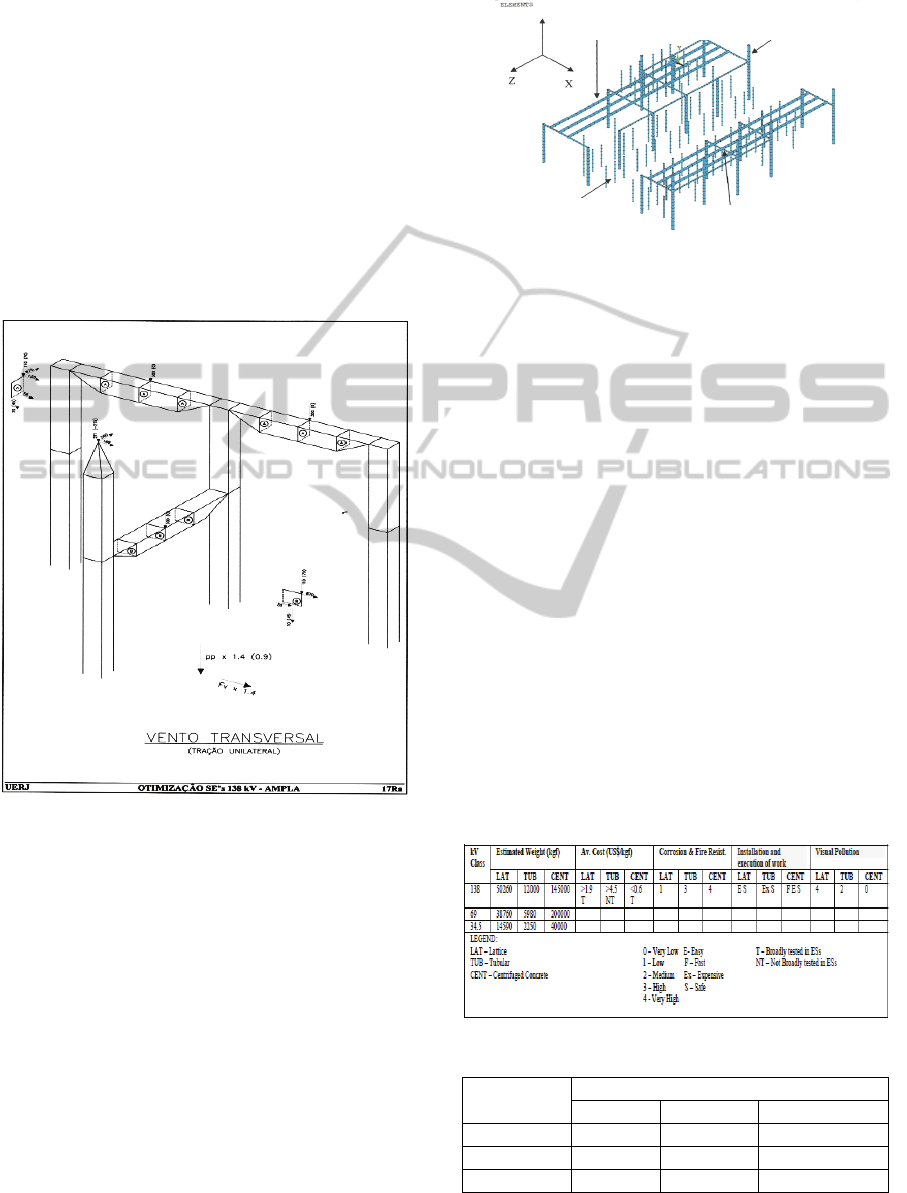

efforts. Figure 1 shows part of the plant that was

used for calculating the unilateral drift due to

crosswind for a 138 kV Electrical Substation.

Figure 1: Unilateral drift due to crosswind for a 138 kV

SE.

2.1.2 Tubular Structures

Tubular profiles can have three different geometries:

circular, rectangular and square. The geometry of

these profiles is their main advantage, because its

closed section allows a significant increase in

resistance. Besides, the effective reduction of the

foundations structure yields huge savings for these

buildings, and shows good integration to the

environment.

The circular profiles provide a better distribution

of stresses on the tube due to their geometry, in

which all cross-sectional points are equidistant and

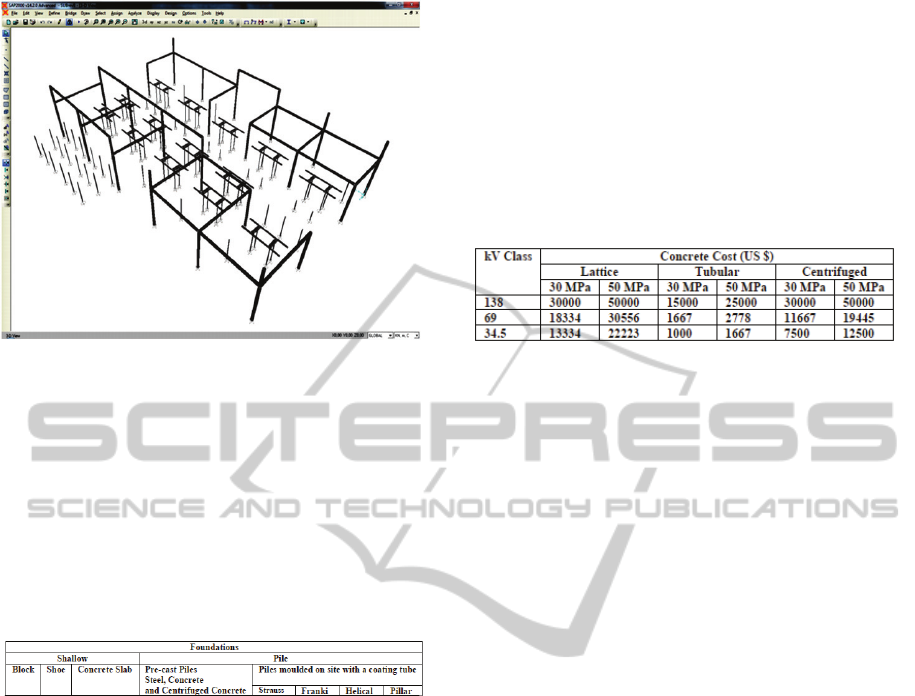

therefore were investigated in our research. Figure 2

shows the FEM used in the 138 kV ES having

tubular structure.

Figure 2: FEM modelling used for tubular structure.

2.1.3 Centrifuged Concrete Structures

The excellent visual integration with the urban

environment, given the texture of the concrete and

the elegance of the structure, allows the installation

of centrifuged reinforced concrete in any area,

minimizing the impact on the environment and

landscape. Throughout this work simulations using

FEM were performed indicating that the weight of

the centrifuged reinforced concrete structure is much

larger than that of the tubular steel and the same

occurred with the lattice one. Consequently, the

amount spent on concrete foundations using

centrifuged concrete is much larger than the

structures used in tubular steel and the same

occurred with the lattice structure. Figure 3 shows a

brief view of a 138 kV Electrical Substation with

centrifuged concrete.

Tables I and II summarize some specifications,

technical and economic characteristics and important

peculiarities in these types of structures.

Table 1: Structures operational characteristics.

Table 2: Costs of the investigated structures.

kV Class

Structure Cost (US $)

Lattice Tubular Centrifuged

138 94935 54000 80556

69 72214 26910 111112

34.5 27559 10125 22223

Aluminum bus

φ

141,3 mm Larger columns φ 141,3 mm

Smaller columns

φ 60.3mm

Beams

φ 73 mm

SubstationsOptimization-FoundationsofaDecisionMakingSystem

331

Figure 3: Centrifuged concrete structure for a 138 kV ES.

As far as the cost is concerned, the tubular

structure is also very attractive, as evidenced in

Table 2.

2.2 Simulation of the Concrete Volume

Generally, the foundations of substations can be

classified as shown in Table 3

Table 3: Foundations of substations types.

To accurately estimate the type and volume of

concrete foundations it is basically required to know

the loads to be transferred to the foundations of the

investigated structures, and evaluate the reports of

the land survey for the construction of the ES. It is

undeniable that there is an inevitable link between

the geological conditions and the design of the

foundations (Groenewald, 2009). Mentioned below

are some needs which must be fully met during the

detailed design of the project.

1. Definition of the loads to be transferred to

foundations;

2. Important developments in geomorphology;

3. Geotechnical local site;

4. Data on slopes and hillsides on the ground;

5. Data on erosion, occurrence of soft soil on the

surface;

6. Need to make cuts and embankments on the

ground;

7. Compressibility and resistance in the survey;

8. The level of groundwater;

9. Executive feasibility;

10. Economic viability.

It can be seen, through simulation, that the tubular

steel frame weighs less than 10% of the centrifuged

concrete structure and less than 25% of the lattice

structure, fact which would lead directly to its

choice. The lighter the structure, the lower the

concrete volume to be used, resulting in lower cost,

as shown in Table 4.

Table 4: Cost of concrete.

2.3 Reduced Model Testing

The choice of the reduction coefficient of the

reduced model was based taking into account not

only the physical limitations found in the Laboratory

of Structures and Materials (LEM) at PUC-Rio,

where tests were performed, but also the equipment

and instrumentation required to the tests, which

followed a high technical accuracy required in these

experiments and available on the LEM.

For the tests of the prototype scale model were

considered reductions in the dimensions of the parts,

taking into account the equivalence of physical

resistance to the tubes easily available for purchase

on the market. The height of the prototype is

decisive for the calculation of the reduction

coefficient under the penalty of exceeding the limits

permitted in the laboratory tests, which led to the

ratio of 1:6 (one to six).

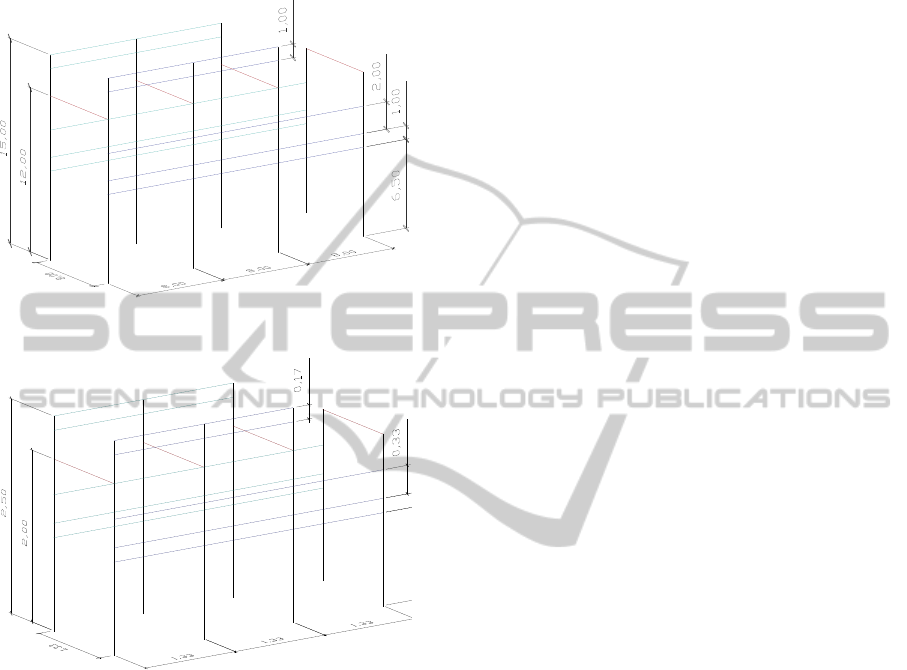

The calculations of the reduced model were

based on the original study design. The values of the

geometric properties of the prototype, such as

length, width and height of the structure, and

external diameter and wall thickness of tubular

profiles were taken from the design of the 69 kV ES

performed using the structural analysis program

SAP2000. Figure 4 shows the model with the actual

dimensions.

All profiles are circular tubes with the following

dimensions:

Columns

• - outside diameter of 219.1 mm and 12.7 mm

thickness;

• - crossbeams - outside diameter of 219.1 mm and

12.7 mm thickness.

Longitudinal Beams

• - outside diameter of 101.6 mm and thickness 5.7

mm.

ICEIS2012-14thInternationalConferenceonEnterpriseInformationSystems

332

As explained earlier, the reduced model was

constructed using a reduction factor of 1:6. Figure 5

shows a schematic drawing of the dimensions of the

reduced model.

Figure 4: Actual dimensions of the 69 kV ES in meters.

Figure 5: Reduced Model Dimensions of the 69 kV ES

3 CONCLUSIONS

Under the specific viewpoint of optimization of

power substations, object of this research, the

obtained results seem very promising. For future

work it is intended to give more depth to the tubular

steel structures and their respective founding,

simulating more cases using finite element software,

in addition to those already made in this research.

The test results of the reduced model indicate

that the integrity of the structure was confirmed,

considering the details of the boundary conditions of

the investigated structures, loading and material,

where there was no need for any reinforcement or

modification of the original structure.

Finally, it was found that the optimized SEs were

actually efficient from the studied viewpoint.

REFERENCES

D’Ajuz, A., 1985. Electrical Equipments – Specifications

and Applications in High Voltage Substations,

Furnas/UFF Ed., in Portuguese.

Bayliss, C. and Hardy, B., 2007. Transmission and

Distribution Electrical Engineering, Newness Ed.

Bhatti, M. A., 2005. Fundamental Finite Element Analysis

and Applications with Mathematica and Matlab

Computations, John Wiley & Sons.

Groenewald, A., J., S., 2009. The Use of Tubular

Conductors in the Design of High Voltage

Substations. In CIBRE 6

th

S. Africa Regional Conf.,

2009.

Carneiro, F., L., 1996. Dimensional Analysis and

Similarity and Physical Models Theory, UFRJ Ed., in

Portuguese.

SubstationsOptimization-FoundationsofaDecisionMakingSystem

333