Business Process Development for Industrial Cluster

Taivo Kangilaski

Department of Computer Control, Tallinn University of Technology, 5, Ehitajate tee, Tallinn, Estonia

Keywords: Industrial Cluster, Partner Network, Enterprise Architecture Management, Business Process Management,

Quality Management System.

Abstract: Small production companies frequently have only limited amount of customers, especially in country sides.

To have more orders and to be more competitive, they need to cooperate and form Industrial Clusters. To

manage Industrial Cluster, there should be firm Quality Management System. The current article proposes

approach about handling that complicity, which is related to the Industrial Cluster Management.

1 INTRODUCTION

In Eastern Europe countries, there are lot of small

and middle size (SME) companies in manufacturing

domain. In most cases they have only few

customers, they have quite weak sales team if any,

thus they dependent on their own existing contacts.

As these companies have limited possibilities in

production (which mostly related with bench and

personnel skillsets) it’s also limits their availability

to grow. Thus, the initiatives to the join these

production companies as capability centre into the

umbrella of Industrial Cluster (IC) are very

important.

According to our research group understanding

IC is formed by some production company or

sometimes by some group of people acting as a

broker. Company or this group of people, which

creating such IC can be viewed as the IC Focal

Players (FP). The core of IC has been developed in a

way that it would be able to respond quickly to

market needs and there would be no need to invest

too much time to develop necessary network

competencies and processes for each new business

opportunity. These networks are mostly long term

strategic alliances. In addition to the strategic

alliances, there are also goal-oriented networks,

which can be considered as extensions of the

strategic alliances when needed competences /

resources are missing or are not reachable, or they

are not of a sufficiently high quality (Kangilaski,

2010a).

Current paper contributes to the IC planning

phase focusing on business services, process

management and related artefact identification.

2 PREVIOUS RESEARCH

IC research topic is also known as Virtual

Enterprise, Virtual Organization, Virtual

Organization in Breeding Environment, Virtual

Corporation, Extended Enterprise, Collaborative

Networks, Business Ecosystem etc and there are

many research projects supporting that field.

Well-known are EU level projects in the

Framework Programmes for Research and

Technological Development – ECOLEAD,

SPIKE9, GloNet, but there are lot of others

initiatives in level of universities, companies, etc.

3 ENTERPRISE ARCHITECTURE

As known, quite often small companies fail to create

an integrated vision about how business process

should work across the company and how

information, applications, and the technologies

should enhance or even perform these processes.

This means that it is a challenge also for FP forming

the IC, as it will compose from several companies

which do not have much cooperation experiences.

Thus, to develop such IC, the Enterprise

Architecture (EA) based approach is very usable.

EA serves as a ready reference that enables the

535

Kangilaski T..

Business Process Development for Industrial Cluster.

DOI: 10.5220/0004004705350538

In Proceedings of the 9th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2012), pages 535-538

ISBN: 978-989-8565-22-8

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

organization to assess the impact of the changes on

each of the EA components (Kangilaski, 2010b).

From theory point of view, there are more than

20 different EA frameworks available (Kangilaski,

2010c), which mostly are oriented to the single

organization. Thus, when there is a need to create IC

then there are only few frameworks which support it,

including SCOR, ARCON, VERAM, GLOBEMEN

etc. Those frameworks will cover different aspects

of IC lifecycle management. The main problematic

related with these frameworks lies on the too high-

level abstraction, which makes them implementation

quite challenging.

4 FORMING INDUSTRIAL

CLUSTERS

To be more attractive for companies, which

potentially will join to IC, the FP has to provide

surplus value for them. Thus FP must work out most

critical services to be provided to the IC. According

to our experiences, these services have to be as

minimum of following:

Communication as a service – FP is a former of

IC, which means that it has to perform actions to

identify IC members impacts and needed

competences, which have to be represented. In

addition, it has to improve communications among

companies belonging into IC. Having a cluster

newsletter seems to be one option.

Purchasing as a service – this is one of the most

frequently used services. Companies, merging their

material purchase orders over IC, will get most

probably lower price from market than purchasing

independently. In addition, such cooperation will

also strengthen buyer-supplier linkages.

Marketing as a service – to have better business

opportunities, FP could collect IC companies’

capabilities and promote the IC products or services

domestically and even abroad.

Research and development as a service – FP

having overview about IC companies’ capabilities

may conduct the research and development activities

inside IC to develop new products and services that

IC could provide.

Learning as a service – from FP’s point of view,

it is important that IC companies’ employees are

well educated (e.g. having needed certificates,

modern skillsets). Thus, FP should analyse

companies’ needs and should prepare needed

educational activity and training. To motivate

companies to belong into IC, it is reasonable that

these programs are sponsored by FP.

IT as a service – the small production companies

have only limited possibilities to invest into the ICT.

In most cases we have seen that the production

planning is supported by MS Excel, and production

processes are supported only by paper documents if

any. The quite powerful approach is if FP could

provide for IC companies in light weight mode

production planning functionalities, inventory

management functionality and work order

management functionality. The functionality should

be simplified, to minimize the implementation costs

and time for IC members. Using such IT solution

with analytical functionality will most likely extend

company production effectiveness.

In addition, the FP provides an IT environment,

where IC members could communicate.

Quality management as a service – to be more

competitive, the companies, especially in production

domain, should have to implement Quality

Management System (QMS) and Environmental

Management System (EMS). This is the reason why

the companies have to meet the prerequisite

demanded by FP to implement QMS and EMS to

belong into the IC (ISO 9001, ISO 14001). In some

cases also OHSAS 18001 is demanded.

4.1 Business Process Management

To manage IC, the FP has to establish policies for

process management. As already described, FP

proposes Quality Management as a service, thus it is

reasonable to have an IT environment for process

modelling. Process modelling environment gives

major effect for QMS and EMS management.

Mostly, the companies have process models for

three proposes:

1. to have an overview for an external observer

who wants to understand how business

processes are performed and to determine the

improvement points

2. to define the desired processes and how

company should/could/may perform its

activities

3. to provide explanations about the rationale of

processes, establishing link between business

requirements and process models

Our research group has from previous projects

good Software AG tool ARIS usage experience,

together with its modelling methodology. This is the

reason why we also implemented this approach in

our current analyses.

4.1.1 ARIS House Approach

Commercial ARIS toolset supports several standards

ICINCO2012-9thInternationalConferenceonInformaticsinControl,AutomationandRobotics

536

such as Business Process Execution Language

(BPEL), Business Process Modelling Notation

(BPMN) 2.0, Event-driven Process Chains (EPCs),

Unified Modelling Language (UML), ArchiMate etc

(Business Process Trends, 2007).

In addition to the notations, the ARIS framework

not only describes processes but also includes other

important information related to the process flow,

such as Organisation and organisational structures,

Business objectives and strategies, IT-systems and

software applications, Data and data structures,

Resources (e.g. people and materials), Information

flow, Costs, Products and services related to the

process, Skills and knowledge.

To handle such complicacy, the ARIS

methodology provides an ARIS House structure to

organize the different model types, objects and to

define their relation to each other. This structure

helps to organize all of the data and reduces

complexity by offering five views – Organization

View, Data View, Function View, Product/Service

View and Process (Control) View.

By itself, the ARIS framework does not provide

a detailed method for way how to perform business

re-engineering or designing the IT systems

necessary to support a business. The major focus

areas should be products and services that IC plans

to market, business processes, roles, documents and

data in critical value chains.

4.1.2 Processes for Industrial Cluster

To put IC in operation, the FP with its strategic

alliance partners should develop process architecture

for IC (Fig. 1). The process architecture is a

structure that describes the way the business will

operate by determining clear responsibilities.

Process

archiecture

management

ProcessDesign

Process

implemen‐

tation

Process

Controlling

Process

optimization

Figure 1: Process lifecycle.

After the process architecture has been

established, the determined processes should be

carefully designed. The first priority should be to

have processes that are related to IC management.

When there is an agreement in these processes, the

companies may start to model their own processes to

adapt additional demands accrue from IC

management processes. The biggest change for IC

companies is that they need the Broker role. This

role should identify new collaboration opportunities

both inside and outside the IC.

During the process design, the ARIS toolset as

well as methodology was quite valuable, as it gives

us systematic way to communicate the agreed

processes and principles via FP web environment

which is opened for IC members.

When processes are designed, the process

implementation phase is started. According to our

approach, during this phase the FP’s production

planning environment, work order management and

inventory management functionality should be

implemented. As the IT solution is rather light-

weight, the implementation process is quite short.

After process implementation, the process

controlling activities should be started. Information

for controlling can be collected by FP and provided

by IC members. Basing on analyses, the IC FP may

initiate with strategic partners process changes to be

more effective or to adapt to changing market

demands.

According to our experiences, the main processes

that should be focused in level of IC are: Develop

and manage Industrial Cluster; Design and manage

products provided by Industrial Cluster; Purchasing;

Marketing and selling products; Delivering products

(incl. logistics); Managing customer services;

Manage IT; Manage knowledge, improvement and

change.

In level of IC companies, the main focus should

be on the following processes: Information exchange

within IC; Manufacturing process and Manage

environment safety.

What is not listed is Risk management process.

According to our understanding, it is important to

emphasize it separately as it minimizes risk to be

unsuccessful. It is not listed, because we have seen

that small companies will do risk management quite

casually during project preparation phase.

4.1.3 Information Management

Having modelled all needed business processes, it is

possible to determine most critical artefacts that

companies need to exchange in IC. Based on that

information, the FP can consider extending its IT

environment, to offer wider functionality to the IC

members.

Our research group has access to the IC that

covers more than 20 SME-s, which are also mostly

small companies operating in Estonia as well as in

neighbour countries.

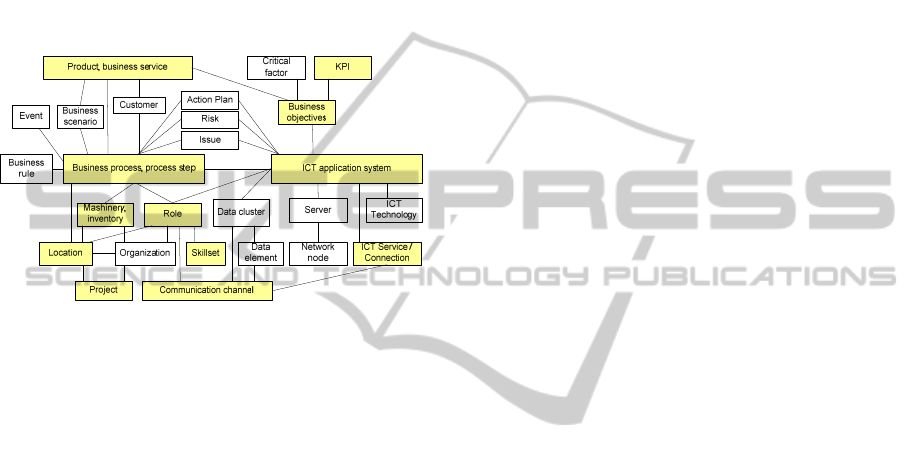

Based on performed analyses, we have

determined the major artefacts describing IC,

BusinessProcessDevelopmentforIndustrialCluster

537

presented in Fig. 2. To make an architectural

description, these artefacts are also interconnected

via many-to-many connections. Amount of

interconnections should be minimized to keep the

documentation as simple as possible. One option is

proposed in Fig. 2, where most critical artefacts are

emphasized.

These emphasized elements should be also

modelled in processes, because then it forms

analysable set of information for FPs and gives the

possibility to propose processes reengineering if

needed.

Figure 2: Key artefacts modelling IC.

The degree of simplification and abstraction of

process model depends on the interest of the target

audience and business uncertainty levels.

4.2 Major Risks for Focal Player

Forming Industrial Cluster

To start to form IC, risk management is a significant

topic. According to our team experiences, the

following risk categories should be taken into

account – luck of trust; companies’ economic

stability; quality management; companies’

production capacity management; and lacking of

technology and product development innovation.

In Eastern Europe, the major risk category is luck of

trust. Companies are developing in the first phase of

IC lifecycle. When their economic situation has been

strengthened, they may start to extend their market

share by their own, excluding the IC and overtaking

the customers. This will influence IC microclimate

and minimize the trust inside the IC.

Weak whole set capacity is the bottleneck and has

resulted in difficulty in improving the overall size,

economic effects and competitive power.

5 CONCLUSIONS

There are numerous small production companies in

production field in Eastern Europe.

Our team is convinced that the key approach to

establish working IC is to start from business

modelling and have to process based approach for

quality management as well as for controlling the

cooperation inside IC. Thus the FP should form

Process Office for IC (Kangilaski, 2010b), and based

on this unit contribution to concentrate to develop IT

solutions for critical processes support. Our team has

successfully managed the pilot projects using ARIS

toolset as working environment for that.

The current research is supported from Estonian

Ministry of Education and Research for targeted

financing scheme T113A and Grant ETF9460.

REFERENCES

Business Process Trends, 2007. ARIS Platform Products,

http://www.bptrends.com/publicationfiles/04-08-PR-B

PM-Tools%20Report-IDS%20Scheer.pdf

Kangilaski, T., 2010a. Challenges for SMEs Entering into

the Virtual Organization Partner Network. In DAAAM

2010, 7th International Conference of DAAAM Baltic

Industrial Engineering: 7th International Conference

of DAAAM Baltic Industrial Engineering, Tallinn

University of Technology, 352-357.

Kangilaski, T., 2010b. Communication as a Crucial

Element for Enterprise Architecture Management in

Virtual Organization. In EAI2N, IFIP TC 5

International Conference, Enterprise Architecture,

Integration and Interoperability, Held as Part of

World Computer Congress, 66-77.

Kangilaski, T., 2010c. Enterprise Architecture

Management in Virtual Organization. In ICIT 2010 -

USB Proceedings, International Conference on

Industrial Technology, 1006-1011.

ICINCO2012-9thInternationalConferenceonInformaticsinControl,AutomationandRobotics

538