A Fault-Tolerant Controller for an SP-100 Space Nuclear Reactor

Ju Hyun Kim, Dae Seup Kim and Man Gyun Na

Department of Nuclear Engineering, Chosun University, 309 Pilmun-daero, Dong-gu, Gwangju, Korea

Keywords: Fault Detection and Diagnostics, Fault-Tolerant Control, Fuzzy Model, Model Predictive Control, Space

Reactor Power Control, Sequential Probability Ratio Test.

Abstract: The control system is a key element of space reactor design to meet the space mission requirements of

safety, reliability, survivability, economics, and autonomous action. The objectives of the proposed model

predictive control are to minimize both the difference between the predicted TE power and the desired

power, and the variation of control drum angle that adjusts the control reactivity. A genetic algorithm is

used to optimize the model predictive controller. The model predictive controller is integrated with a fault

detection and diagnostics algorithm so that the controller can work properly even under input and output

measurement faults. Simulation results of the proposed controller show that the TE generator power level

controlled by the proposed controller could track the target power level effectively even under measurement

faults, satisfying all control constraints.

1 INTRODUCTION

The SP-100 space nuclear reactor was designed to

provide a realistic and reliable source of very long-

term power for space exploration and exploitation

activities. The SP-100 system is a fast spectrum

lithium-cooled reactor system with an electric power

rating of 100 kW. The control functions needed for

SP-100 can be ensured only by an autonomous

control system, which assumes the responsibilities

for normal control, abnormal event response and

fault tolerance, and provides interface with operators

on earth for high-level decision-making.

In order to optimize the reactor power control

performance, methods for the optimal power control

of nuclear reactors have been presented extensively

in the past two decades. But it is very difficult to

design optimized controllers for nuclear systems of

the SP-100 space reactor. This work employs the

model predictive control (MPC) method, which has

received increased attention as a powerful tool for

the control of industrial process systems. The

dynamics of the SP-100 reactor system are highly

non-linear. Therefore, a nonlinear MPC

methodology has to be applied to predict the future

behavior of the plant based on a nonlinear model of

the process. In this work, the nonlinear model

development is conducted by a fuzzy model because

fuzzy models are simpler in structure and easier to

develop compared to other nonlinear models. Thus,

the on-line optimization problem is solved using a

genetic algorithm, which guarantees the feasibility

of all the generated potential solutions.

2 MODEL PREDICTIVE

CONTROL COMBINED WITH A

FUZZY MODEL

In this work, the MPC is combined with the fuzzy

model based on the subtractive clustering approach.

The model predictive controller combined with a

fuzzy model is called a fuzzy model predictive

controller. The MPC method is to solve an

optimization problem for a finite future at current

time and to implement the first optimal control input

as the current control input. The procedure is then

repeated at each subsequent instant. A performance

index for deriving an optimal control input is

represented by the following quadratic function:

[]

2

2

11

1

ˆ

(|)() ( 1)

2

LM

kk

yt k t wt k R ut k

==

+−++ Δ+−

⎡⎤

⎣⎦

∑∑

(1)

subject to constraints

min max

max

(1)0 for

()

()

ut k k M

uutu

ut u

⎧

Δ+−= >

⎪

≤≤

⎨

⎪

Δ≤Δ

⎩

452

Kim J., Kim D. and Na M..

A Fault-Tolerant Controller for an SP-100 Space Nuclear Reactor.

DOI: 10.5220/0004006704520457

In Proceedings of the 9th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2012), pages 452-457

ISBN: 978-989-8565-21-1

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

2.1 Output Prediction using a Fuzzy

Model

In this work, a fuzzy model based on subtractive

clustering (SC) is used to predict the future output of

the model predictive controller. The

i

-th fuzzy rule

for

t

-th time instant data is described as follows:

()

,1

,

,1

,

If ( 1) is ( )

( ) is ( )

(1)is ()

( ) is ( ),

ˆ

then ( ) is

( 1), , ( ), ( 1), , ( )

y

y

yu

i

yin

in

uinn

i

iyu

yt d A t AND

AND y t d n A t

AND u t A t AND

AND u t n A t

yt

f

ytd ytdn ut utn

+

+

−−

−−

Δ−

Δ−

−− −− Δ− Δ−

L

L

LL

(2)

The input vector to the fuzzy model consists of

y

and

uΔ

which are past values of output and

control input move, respectively, and can be

indicated as a vector consisting of a total of

m

elements (

y

u

mn n=+

, a total number of input

variables to the fuzzy model):

() ( 1) ( ) ( 1) ( )

yu

t yt d yt d n ut ut n

⎡⎤

=−− −−Δ−Δ−

⎣⎦

x LL

(3)

When the SC method is applied to a collection of

input/output data, each cluster center is in essence a

prototypical data point that exemplifies a

characteristic behavior of the system and each

cluster center can be used as the basis of a fuzzy rule

that describes the system behavior. The number of

n

fuzzy rules can be generated, where the premise

parts are fuzzy sets, defined by the cluster centers

that are obtained by the SC algorithm. The

membership function value

(())

i

A

tx of an input data

vector

()tx to a cluster center

()i

∗

x

can be defined

as follows:

()

2

2

4() ()

() , 1, 2, ,

tir

i

A

te i n

α

∗

−−

==

xx

x L

(4)

The fuzzy model output

ˆ

()yt

is calculated by the

weighted average of the consequent parts of the

fuzzy rules as follows:

()()

()

1

1

() ()

ˆ

()

()

n

ii

i

n

i

i

A

tf t

yt

At

=

=

=

∑

∑

xx

x

(5)

where the function

()

()

i

f

tx

which is an output of a

fuzzy rule is a polynomial in the input variables and

represented by the first-order polynomial of inputs

as follow:

()

,

1

() ()

m

iijji

j

f

tqxtr

=

=

+

∑

x

(6)

2.2 Control Input Optimization by a

Genetic Algorithm

Conventional optimization techniques for solving

the cost functions of (1) cannot be easily applied due

to the peculiarity of a fuzzy model that is basically a

nonlinear model. Therefore, the on-line nonlinear

optimization problem is solved using a genetic

algorithm, which guarantees the feasibility of all the

generated potential solutions.

A chromosome which is a candidate solution of

the optimization problem is represented by

g

s

,

whose elements consist of present and future control

inputs and has the following structure:

() ( 1) ( 1)

, 1, ,

gg g g

sutut utM

gG

⎡

⎤

=++−

⎣

⎦

=

L

L

(7)

The genetic algorithm proceeds according to the six

steps: initial population generation, fitness function

evaluation, selection operation, crossover operation,

mutation operation, and repeat or stop.

The fuzzy model is optimized by a genetic

algorithm, combined with a least-squares method.

That is, the genetic algorithm is used to optimize the

cluster radius,

r

α

, for the subtractive clustering of

numerical data, and the least squares algorithm is

used to calculate the consequent parameters,

,ij

q

and

i

r .

3 FAULT-TOLERANT CONTROL

USING FAULT DETECTION

AND DIAGNOSTICS

Since the human access for fixing the faults is

almost impossible in an outer space and also, the

maintenance to use robots is very difficult, the SP-

100 space nuclear reactor must supply the stable and

reliable power source even under the measurement

faults related to the control system to support the

space exploration and exploitation activities in the

outer space. Fault detection and diagnostics is an

important module in fault-tolerant control systems

and it is desirable to provide diagnostic information

AFault-TolerantControllerforanSP-100SpaceNuclearReactor

453

as soon as faults develop, so that the controllers are

automatically reconfigured and the further

deterioration is prevented.

In this work, a fault detection and diagnostics

algorithm is developed to estimate the input and

output measurements using a fuzzy model based on

the subtractive clustering method and to check the

operability of existing hardware sensors using a

sequential probability ratio rest (SPRT) so that the

FTC can handle the fault situations of the input and

output measurements or partial loss of actuators. In

this work, a fuzzy model is used to estimate the

input and output measurement signals. This fuzzy

model is another fuzzy model which is different

from the fuzzy model that predicts the system output,

which is needed to minimize the control objective

function.

The objective of sensor fault detection and

diagnostics is to diagnose sensor health as soon as

possible with a very small probability of making a

wrong decision. The SPRT uses the residual

(difference between the measured value and the

estimated value,

ˆ

() ()yt yt−

). Normally the residual

signals are randomly distributed, so they are nearly

uncorrelated and have a Gaussian distribution

function

(, , )

it i i

Pm

ε

σ

, where

t

ε

is the residual

signal at time instant

t

, and

i

m and

i

σ

are the mean

and the standard deviation under hypothesis

i

,

respectively. The sensor degradation or fault can be

stated in terms of a change in the mean

m

or a

change in the variance

2

σ

. Therefore, the SPRT

detects sensor health by sensing the alteration of the

probability distribution. If a set of samples,

i

x

,

1, 2, ,ik= L , is collected with a density function

describing each sample in the set, an overall

likelihood ratio is given by

11 1 12 1 13 1 1 1

01 0 02 0 03 0 0 0

(|)(|)(|) (|)

(|)(|)(|) (|)

k

k

k

PHPHPHPH

P

HP HP H P H

εεε ε

γ

εεε ε

⋅⋅⋅⋅⋅

=

⋅⋅⋅⋅⋅

(8)

where

0

H

represents a hypothesis that the sensor is

normal and

1

H

represents a hypothesis that the

sensor is degraded.

By taking the logarithm of the above equation

and replacing the probability density functions in

terms of residuals, means and variances, the log

likelihood ratio can be written as the following

recurrent form:

22

00 1

1

22

1

01

()()

ln

22

kk

kk

mm

σε ε

λλ

σ

σσ

−

⎛⎞

−−

=+ + −

⎜⎟

⎝⎠

(9)

This ratio is used for deriving the sensor drift

detection algorithm. For a normal sensor, the log

likelihood ratio would decrease and eventually reach

a specified bound

A

, a smaller value than zero.

When the ratio reaches this bound, the decision is

made that the sensor is normal, and then the ratio is

reinitialized by setting it equal to zero. For a

degraded sensor, the ratio would increase and

eventually reach a specified bound

B

, a larger value

than zero. When the ratio is equal to

B

, the decision

is made that the sensor is degraded. The specified

bounds

A

and

B

are important in determining the

sensor faults. The decision boundaries

A

and

B

are

chosen by a false alarm probability

α

and a missed

alarm probability

β

;

ln

1

A

β

α

=

−

⎛⎞

⎜⎟

⎝⎠

and

1

lnB

β

α

−

=

⎛⎞

⎜⎟

⎝⎠

.

The input signal is the control drum angle to

regulate the reactivity and the output signal to be

controlled is the TE power. Also, to handle the sensor

faults, the input and output signals of the control

system are estimated by using a fuzzy model for

signal estimation from the measurements of the SP-

100 reactor system. If the input or output sensors are

normal, the measured values are used to predict the

future control system output. But if they are

determined to be degraded or faulty, the faulty sensors

are isolated and the estimated sensor signals instead

of the measured values are used to predict the future

system output. The schematic block diagram of the

proposed FTC is illustrated in Figure 1.

Figure 1: Block diagram of the proposed FTC for an SP-

100 space reactor.

4 APPLICATION TO THE SP-100

SPACE REACTOR

The reactor system of the SP-100 space reactor is

made up of a reactor core, a primary heat transport

ICINCO2012-9thInternationalConferenceonInformaticsinControl,AutomationandRobotics

454

loop, a TE generator, and a secondary heat transport

loop to reject waste heat into space through

radiators. The reactor core is composed of small

disks of highly enriched (93%) uranium nitride fuel

contained in sealed tubes. Figure 2 shows a

schematic of one loop of the reactor system. The

heat generated in the reactor core is transported by

liquid lithium and is circulated by electromagnetic

(EM) pumps. The energy conversion system uses the

direct TE conversion mechanism.

Figure 2: Schematic of TE SP-100 space reactor system.

4.1 SP-100 System Description

The individual modules of the integrated model, as

shown in Figure 3, include a model of reactor

control mechanism, a neutron kinetics model, a

reactor core heat transfer model, and a heat

exchanger model coupled with the TE conversion

model.

Figure 3: Integrated model of the SP-100 system.

The point reactor kinetics model with six delayed

neutron groups is used to describe the dependence of

nuclear reactor power on the reactivity change. This

is given by the following equations:

6

1

() ()

() ()

()

() ()

ii

i

ii

ii

dP t t

Pt C t

dt

dC t

Pt C t

dt

ρβ

λ

β

λ

=

−

=+

Λ

=−

Λ

∑

(10)

A simplified reactor core heat transfer model is

developed to calculate the fuel temperature, the

cladding temperature, and the average core coolant

temperature. The fuel temperature

f

T

, the cladding

temperature

clad

T and the average core coolant

temperature

c

T are described by the following

ordinary differential equations:

(

)

()

()

f

clad f

f

f

PTT UA

dT t

dt C

−−

=

(11)

(

)

(

)

() ()

()

f

clad f clad c clad

clad

clad

T T UA T T UA

dT t

dt C

−−−

=

(12)

(

)()

()

()

clad c clad c P ex in

c

c

TTUA mCTT

dT t

dt C

−−−

=

&

(13)

where the parameters have their usual meanings.

Electric power is generated by 3 loops × 12

primary heat exchangers × 30 channels × 480 TE

cells. Each TE cell consists of two semiconductors,

one P-type and one N-type. Because there is a

temperature gradient between the hot shoes and the

cold shoes of TE cells, when heat is conducted from

the hot shoe of a TE cell to its cold shoe, electric

power will be generated due to the Seebeck effect.

4.2 Applications

The FTC for the TE power control is subject to

constraints as follows:

(1)0forut j j M

Δ

+− = >

0()180

oo

ut≤≤

() 1.4

o

ut TΔ≤

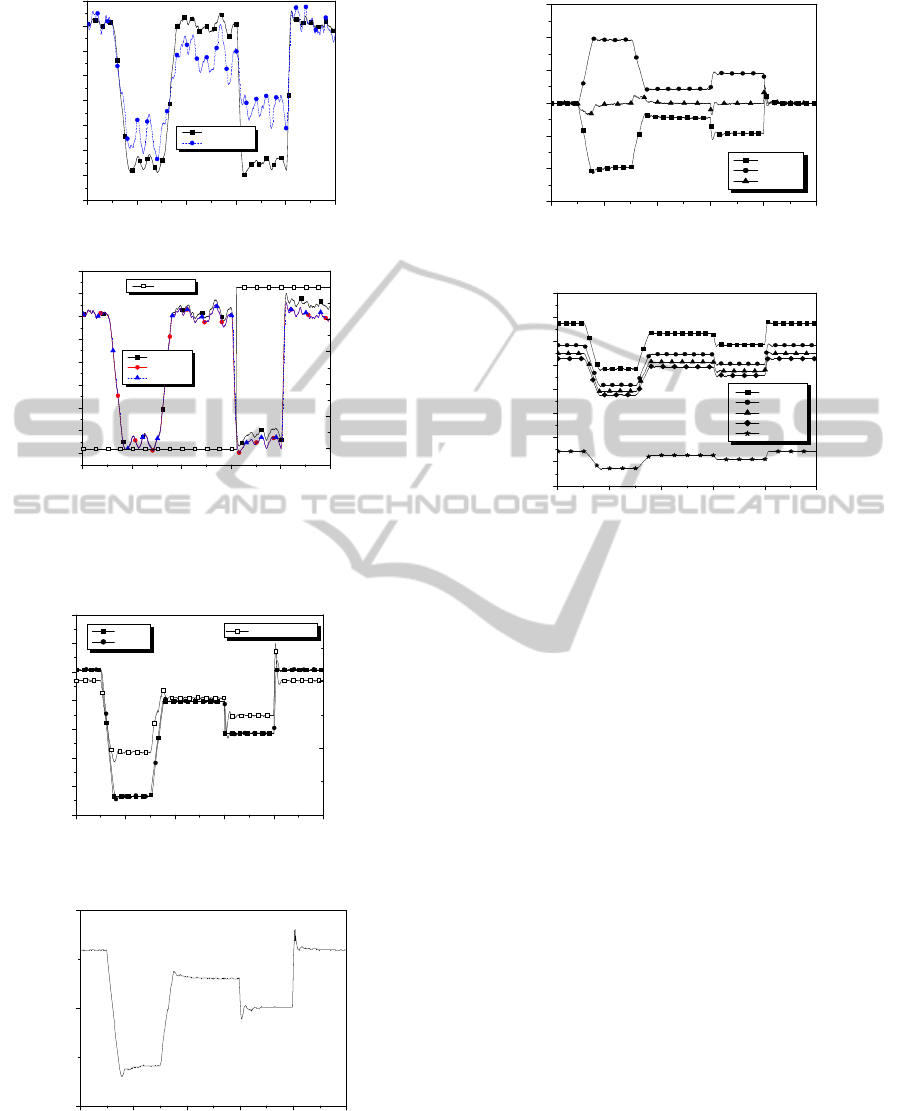

Figure 4 describes the performance of a

developed fault detection and diagnostics algorithm.

Figure 4(a) shows the training and test data used to

design and test the algorithm. Figure 4(b) shows the

fault detection and diagnostics performance when

the output measurement is assumed to begin to be

gradually degraded artificially from 300 sec. The

signals used to estimate the output measurement are

the reactor core thermal power, control drum angle,

core inlet and outlet temperatures, and cold shoe and

hot shoe temperatures, which is a total of 6 signals.

Since the output signal of the control system is

important above all, the output measurement fault

was simulated. The gradual degradation of the

output measurement is detected at 321 sec since the

beginning of the gradual degradation.

Figure 5 shows the performance of the proposed

FTC for normal transients such as the setpoint

change of TE power. The setpoint starts to change

AFault-TolerantControllerforanSP-100SpaceNuclearReactor

455

(a) training data and test data

(b) fault detection and diagnostics

Figure 4: Performance of a fault detection and diagnostics

algorithm.

(a) TE power and thermal reactor power.

(b) control drum angle

Figure 5: Performance of the proposed FTC for normal

transients.

(c) reactivity

(d) temperature

Figure 5: Performance of the proposed FTC for normal

transients (cont.).

by ramp at 100 sec and 300 sec, respectively and

also changes by step at 600 sec and 800 sec. The

performance of the proposed controller was checked

with a roughly adjusted factor of

1=

ω

. It is shown

that the TE generator power follows its desired

setpoint change very well. It was known that the

proposed controller meets several constraints very

well and accomplishes the fast and stable responses.

5 CONCLUSIONS

In this work, the fault-tolerant controller combining

a model predictive controller and the fault detection

and diagnostics algorithm was developed to control

the nuclear power in the SP-100 space reactor

system. Based on a fuzzy model consisting of the

control drum angle change and the TE power, the

future TE power is predicted by using the fuzzy

model identified by a subtractive clustering method

of a fast and robust algorithm. Another fuzzy model

combined with the sequential probability ratio test

estimates the input and output measurement signals

and diagnoses the health of input and output

measurements. The genetic algorithm was used to

optimize the model predictive controller and both

the fuzzy models. With the presence of faults, the

0 200 400 600 800 1000

40

50

60

70

80

90

100

110

120

TE power (kW)

time (sec)

training data

test data

0 200 400 600 800 1000

50

60

70

80

90

100

110

120

130

trip flag

TE power (kW)

time (sec)

measured

actual

estimated

0.0

0.2

0.4

0.6

0.8

1.0

trip flag

0 200 400 600 800 1000

60

70

80

90

100

110

120

130

TE power (kW)

time (sec)

setpoint

actual

1.0

1.5

2.0

2.5

thermal reactor power (MW)

thermal power

0 200 400 600 800 1000

110

120

130

drum angle (deg)

time

(

sec

)

0 200 400 600 800 1000

-0.6

-0.4

-0.2

0.0

0.2

0.4

0.6

reactivity (dollar)

time

(

sec

)

control

feedback

total

0 200 400 600 800 1000

700

800

900

1000

1100

1200

1300

1400

1500

temperature (

o

K)

time

(

sec

)

fuel

core outlet

core inlet

hot shoe

cold shoe

ICINCO2012-9thInternationalConferenceonInformaticsinControl,AutomationandRobotics

456

control law is reconfigured using online estimates of

the measurements. The simulation result of the fault-

tolerant controller shows that the TE generator

power follows its desired setpoint change very well.

Also, the proposed controller meets several

constraints very well and accomplishes the fast and

stable responses.

REFERENCES

S. F. Demuth, 2003, SP-100 Space Reactor Design,

Progress in Nuclear Energy, Vol. 42, No. 3, pp. 323-

359.

Y. B. Shtessel, 1998, Sliding Mode Control of the Space

Nuclear Reactor System, IEEE Trans. Aerospace and

Electronic Systems, Vol. 34, No. 2, pp. 579-589.

M. G. Na and B. R. Upadhyaya, Aug. 2006, Model

Predictive Control of an SP-100 Space Reactor Using

Support Vector Regression and Genetic Optimization,

IEEE Trans. Nucl. Sci., Vol. 53, No. 4, pp. 2318-2327.

M. G. Na and B. R. Upadhyaya, Nov./Dec., 2006,

Application of Model Predictive Control Strategy

Based on Fuzzy Identification to an SP-100 Space

Reactor, Annals of Nuclear Energy, Vol. 33, Nos. 17-

18, pp. 1467-1478.

M. G. Na, B. R. Upadhyaya, X. Xu, and I. J. Hwang, Nov.

2006, Design of a Model Predictive Power Controller

for an SP-100 Space Reactor, Nucl. Sci. Eng., Vol.

154, No. 3, pp. 353-366.

S. L. Chiu, 1994, Fuzzy Model Identification Based on

Cluster Estimation, J. Intell. Fuzzy Systems, Vol. 2,

pp. 267-278.

H. Sarimveis and G. Bafas, 2003, Fuzzy Model Predictive

Control of Non-linear Processes Using Genetic

Algorithms, Fuzzy Sets Systems, Vol. 139, pp. 59-80.

M. G. Na and I. J. Hwang, 2006, Design of a PWR Power

Controller Using Model Predictive Control Optimized

by a Genetic Algorithm, Nucl. Eng. Tech., Vol. 38,

No. 1, pp. 81-92.

W. H. Kwon and A. E. Pearson, 1977, A Modified

Quadratic Cost Problem and Feedback Stabilization

of a Linear System, IEEE Trans. Automatic Control,

Vol.22, No. 5, pp. 838-842.

J. Richalet, A. Rault, J. L. Testud, and J. Papon, 1978,

Model Predictive Heuristic Control: Applications to

Industrial Processes, Automatica, Vol.14, pp. 413-

428.

C. E. Garcia, D. M. Prett, and M. Morari, 1989, Model

Predictive Control: Theory and Practice – A Survey,

Automatica, Vol. 25, No. 3, pp. 335-348.

AFault-TolerantControllerforanSP-100SpaceNuclearReactor

457