Development of Robust Learning Control and Application

to Motion Control

Meng-Shiun Tsai, Chung-Liang Yen and Hong-Tzong Yau

Department of Mechnaical Engineering and Advanced, Institute of Manufacturing with High-tech Innovations,

National Chung-Cheng Unviersity, 168, University Rd, MinHsiung, Chiayi, Taiwan

Keywords: Iterative Learning Control, Motion Control, Nurbs Curves, Robust H

∞

Control.

Abstract: In this paper, the error dynamic equation of the ILC algorithm is derived with consideration of parameter

uncertainties and noise. The H

∞

frame work is utilized using the derived error dynamics to design the robust

learning controller. The proper learning gain is designed based on an optimization process to ensure that

both tracking performance and convergence condition can be achieved. Simulation and experiments are

conducted to validate the robust learning algorithm and the system is stable ever under high payload

uncertainty.

1 INTRODUCTION

Iterative learning control (ILC) is a technique to

control the system when it operate same tasks

repetitively. The ILC can be applied to robot

manipulators (Tayabi and Islam, 2006), chemical

batch process (Lee and Lee, 2007), and so on. Many

schemes of the ILC including the 2D theory method

(Geng et al., 1990), stochastic method (Wang and

Afshar, 2009), inverse system (Ye and Wang, 2005),

and feedback learning operators (Goldsmith, 2002;

Chin et al., 2004) have been proposed. Technical

review on the methodologies and applications of the

ILC is referred to (Ahn et al., 2007).

System robustness is generally a major concern

in the implementation of ILC to either linear or

nonlinear systems. The adaptive iterative learning

control was proposed (French and Rogers, 2000).

The Lyapunov method was adopted to prove the

convergence of the algorithm. Other adaptive ILC

algorithms were proposed to handle system with

time-varying parameters using a positive-definite

Lyapunov-like sequence (Kuc et al., 1991). Another

approach to ensure system robustness is to utilize the

H

∞

theory to formulate the general design

framework for the ILC algorithm (Padieu and Su,

1990). In these papers, only the performance and

robustness analysis of ILC schemes are considered.

In this paper, two steps design process is

proposed. The first step is to design the H∞

controller without consideration of the system

uncertainty. But the noise effect is included in the

design process. The second step is to iterate the

learning gain such that the convergence condition is

satisfied even under large system uncertainty. The

learning gain served as the performance weighting

which is the loop optimization variable to further

minimize system performance. Simulations and

experiments are conducted to demonstrate the design

philosophy.

2 MODELLING OF SERVO

CONTROL SYSTEM

In this paper, the command-based ILC is applied to a

CNC milling machine tool (Tsai et al., 2006). The

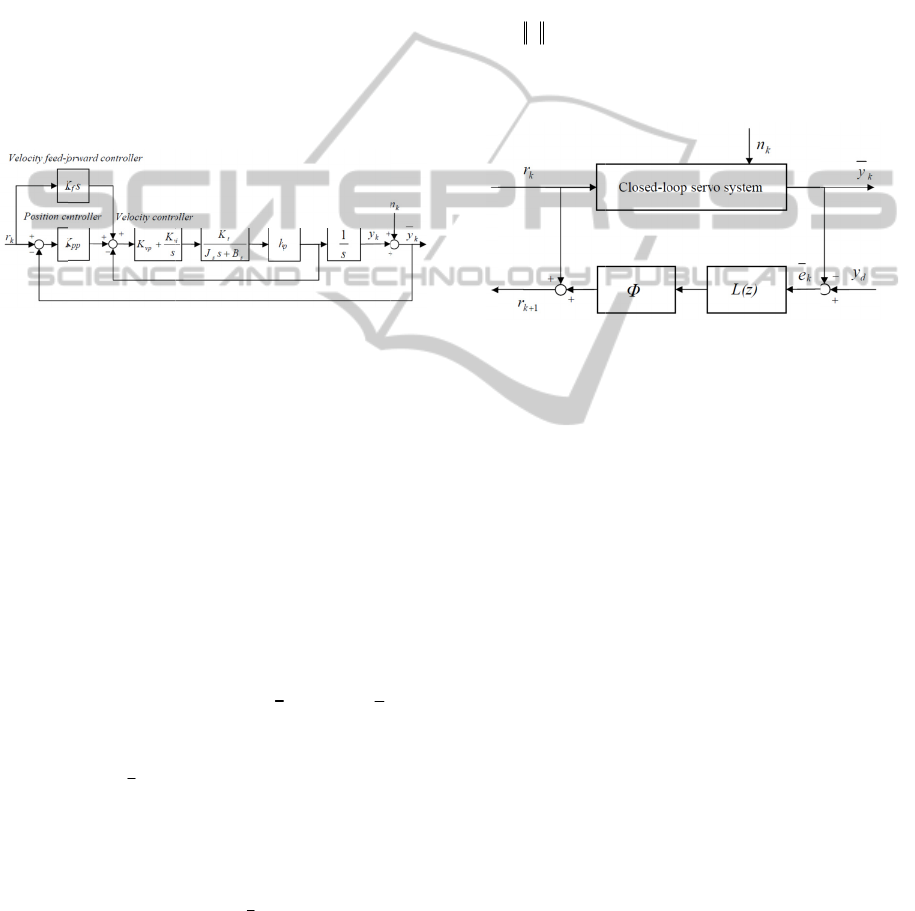

general servo control system as shown in Fig. 1

which includes the linear dynamic model of the

servo system, the velocity and position loops with a

velocity feedforward controller F(s). The function

)s(F

is designed as

sK

f

where

f

K

is the

feedforward gain. The J

s

, B

s

, K

t

and h

p

are the

moment of inertia, viscosity, torque constant and

pitch of lead screw. The parameters

vp

K

and

vi

K

in

the velocity loop can be designed by specifying the

damping ratio and bandwidth of the closed-loop

transfer function of the velocity loop. The position

gain

pp

K

in the position loop is determined by the

designed bandwidth of the position loop. The

148

Tsai M., Yen C. and Yau H..

Development of Robust Learning Control and Application to Motion Control.

DOI: 10.5220/0004008601480152

In Proceedings of the 9th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2012), pages 148-152

ISBN: 978-989-8565-21-1

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

feedfor

w

optimiz

a

the ma

g

various

f

function

s

referenc

e

)s(n

k

a

r

y

Bec

a

discrete

-

discrete

-

techniq

u

y

k

Figure 1

measure

m

3 O

P

In the

p

servo c

o

the erro

r

method

o

3.1

E

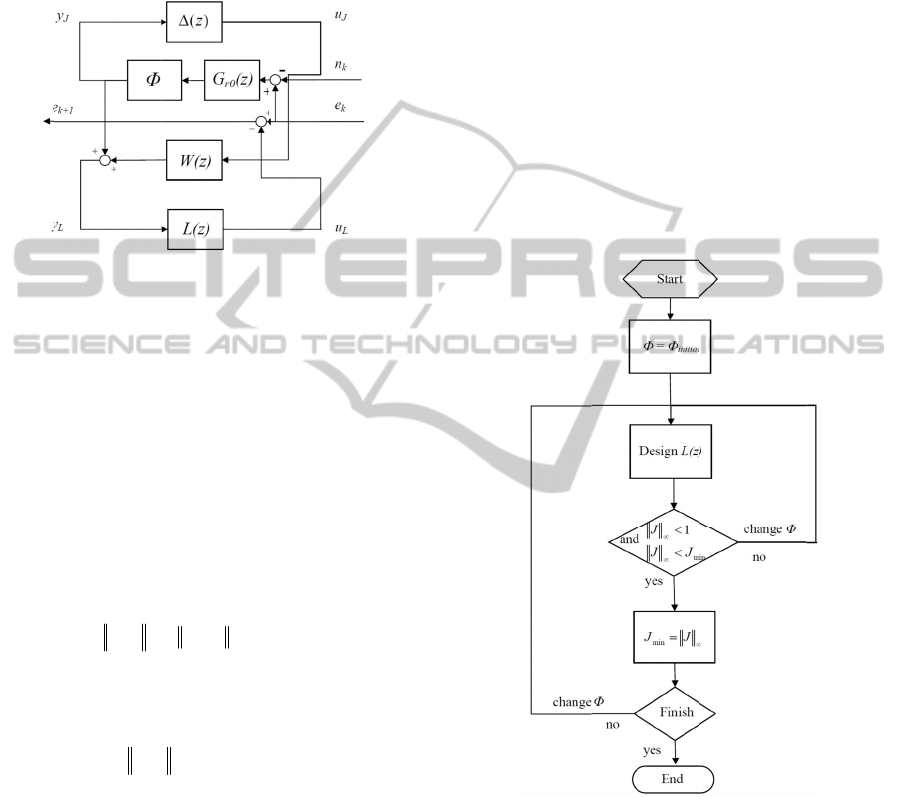

Figure

2

b

ased I

L

at the k

t

h

the des

i

denote t

h

the trac

k

tracking

L(z) an

d

comma

n

r

k+1

. Th

e

can be r

e

r

Afte

r

b

e simp

l

w

ard gain

K

a

tion approac

h

g

nitudes of

t

f

requencies.

A

s between

e

command

r

e givens as:

r)s(G)s(

y

k

rk

=

a

use the lear

n

-

time domain

-

time model

u

e and is give

n

r)z(G)z(

k

r

k

=

: Architectur

e

m

ent noise.

P

TIMIZA

T

p

revious sect

i

o

ntrol system

r

dynamics e

o

logy is propo

E

rror D

y

n

a

2

illustrates

t

L

C where r

k

a

n

h

and the (k+

1

i

red trajector

y

h

e measurem

e

k

ing error

w

error

k

e

p

r

o

d

learning ga

i

n

d

r

k

to obta

i

e

complete le

a

e

presented by

)

z(r)z(

r

k1k

=

+

y)z(e

dk

=

r

derivation,

t

l

ified as:

f

is design

e

h

, which min

i

t

he error tra

n

A

ccording to

F

the output

)s(r

k

, and

n)s(G)s(

k

n

k

+

n

ing process i

, E

q

. (1) is

using the

n

as:

n)z(G)z(

n

k

+

e

of servo c

o

T

ION PR

O

i

on, the gen

e

is develope

d

quation is d

e

sed.

a

mics Equ

a

t

he architect

u

n

d r

k+1

are th

e

1

)

th

iteration,

r

y

,

)z(n

k

,

y

e

nt noise, the

w

ith measure

m

o

cessed by a

i

n Φ is adde

d

i

n the new

u

a

rning proces

s

the followin

g

z(e)z(ΦL

)

k

+

)z(y)z(

k

−

t

he error dyn

a

e

d by usin

g

i

mizes the su

m

n

sfer functio

n

F

ig. 1, the tra

n

)s(y

k

and

the sensor

n

)s(

k

s implement

e

converted to

zero-order

h

)z(

k

o

ntrol system

O

CESS

ral model o

f

d

. In this sec

t

e

rived and d

e

a

tion

u

re of comm

a

e

input comm

a

r

espectively.

y

)z(

y

k

and

e

k

output signal

m

ent noise.

learning co

n

d

to the refer

e

u

pdated com

m

s

shown in F

i

g

equations.

)

a

mic equatio

n

g

an

m

of

n

at

n

sfer

the

n

oise

(1)

e

d in

the

h

old

(2)

with

f

the

t

ion,

e

sign

and-

a

nds

y

d

is

)z(

k

l

and

The

n

trol

e

nce

m

and

i

g. 2

(3)

(4)

n

can

p

er

f

fun

rep

r

the

W(

z

to

b

ex

p

k

e

Fig

u

me

a

3.

2

Af

t

ca

n

dy

n

for

m

dia

g

eq

u

b

y

t

wh

e

gai

n

opt

i

of

fun

out

p

Eq

u

fol

l

=

L

1k

(

1

e

=

+

Equation (

3

f

ormance is

s

ction

r

LG

Φ

.

U

r

esentation, t

h

nominal pla

n

z

) and given

a

G

r

(z)=

Here

△

(z) i

s

b

e 1

<

∞

Δ

.

T

p

ressed as:

r

0

1

k

GΦL1[

−

=

+

u

re 2: Archit

a

surement nois

e

2

Robust

er developin

g

n

be designe

d

n

amics into a

l

m

(Zhou et a

l

g

ram corres

p

u

ation (12). T

h

t

he following

⎢

⎢

⎢

⎣

⎡

−

−

=

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎣

⎡

+

L

1k

J

W

0

0

y

e

y

Φ

Φ

e

re P

A

is the

n

which is

i

mization pro

the augmen

ction L(z), i

n

p

ut of the l

e

u

ation (6) c

a

l

owing form:

=

⎥

⎥

⎦

⎤

⎢

⎢

⎣

⎡

L

y

Z

~

The relation

b

L

(z)y

L

. The au

g

kr

Φ

e)ΦLG-

1

+

3

) indicates

s

trongly infl

u

U

sing the m

u

h

e G

r

can be

n

t G

r0

(z) and

t

s:

G

r0

(z)(1+W

(z

s

the small p

e

T

he errors dy

n

k

0

Φ

L

e])W(I

+

+

Δ

e

cture of co

m

e

.

ILC usin

g

g

the error dy

n

d

by first t

r

l

inear fractio

n

l

., 1996). Fig

u

p

onding to

h

e block diag

r

LFT form gi

v

−

0r0r

0r0r

0GG

II0

0GG

Φ

Φ

Φ

Φ

a

ugmented p

l

the design

c

ess, y

J

, y

L

, u

J

t

ed plant, i

n

n

put to the

e

arning funct

i

a

n be furthe

r

⎢

⎢

⎣

⎡

⎥

⎦

⎤

⎢

⎣

⎡

=

2221

1211

u

W

PP

PP

b

etween the

y

g

mented syst

e

kr

n

Φ

LG

that the

u

enced by th

e

u

ltiplicative u

n

further repre

s

t

he weightin

g

(

z)

△

(z))

e

rturbation n

o

y

namics can

b

k

0r

n]WΔI[

Φ

LG +

m

man

d

-

b

ased

H

∞

Contr

o

n

amics, the

H

r

ansforming

n

transformat

i

ure 3 shows

the error

r

am can be re

p

v

en as:

⎥

⎥

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎢

⎢

⎣

⎡

=

⎥

⎥

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎢

⎢

⎣

⎡

⎥

⎥

⎥

⎦

⎤

L

k

k

J

A

L

k

k

J

u

e

n

u

P

u

e

n

u

I

l

ant,

Φ

is th

e

n

ed variable

J

and u

L

are

t

n

put to the

augmented

p

i

on L(z), res

p

e

r represente

d

⎥

⎥

⎦

⎤

L

u

W

~

y

L

and u

L

is g

i

e

m can be ex

p

(5)

tracking

e

transfer

n

certainty

s

ented by

g

function

(6)

o

rmalized

b

e further

k

(7)

ILC with

o

l

H

∞

control

t

he error

i

on (LFT)

t

he block

dynamic

p

resented

(8)

e

learning

for the

h

e output

learning

p

lant and

p

ectively.

d

by the

(9)

i

ven as u

L

p

ressed as

DevelopmentofRobustLearningControlandApplicationtoMotionControl

149

a stand

a

shown b

Figure 3

consideri

n

With th

e

p

erturbe

d

the robu

the tw

o

learning

and

W

~

c

T

It is no

t

design c

r

And

ILC alg

ensure t

h

Equ

a

should

b

conditio

n

3.3

O

By obse

r

found t

h

algorith

m

uncertai

n

p

rocess,

conside

r

follows.

a

rd form for

elow:

1k

J

e

y

z

~

=

⎥

⎦

⎤

⎢

⎣

⎡

=

+

2

1

L

Py =

: Architecture

n

g measureme

n

e

developed

m

d

system mo

u

st H

∞

control

o

Riccati eq

u

function L, t

c

an be repres

e

⎢

⎣

⎡

−

−

=

W

~

Z

~

LW

0

T

Φ

t

ed that the

f

r

iteria in sele

c

∞

W

~

Z

~

T

the sufficien

t

g

orithm (Roo

v

h

at

T

W

~

Z

~

a

tion (12) im

p

b

e set in or

d

n

.

O

ptimizati

o

r

ving the clo

s

h

at the stabilit

y

m

are str

o

n

ties. Before

the H

∞

cont

r

r

ing the pla

n

designing t

h

L1211

uPW

~

P +

=

L22

1

uPW

~

+

of ILC synt

h

n

t noise

m

odels by Eq

s

del can be u

s

ler can be de

s

u

ations. Af

t

e

he closed lo

o

e

nted as the f

o

−

−

0r

0r0r

LG

1LG

GG

Φ

Φ

ΦΦ

f

ollowing eq

u

c

ting the lear

n

∞

≥

0r

ΦG

t

convergenc

e

v

er, and Bo

s

1

W

~

≤

∞

p

lies that the

c

d

er to satisfy

o

n Process

s

ed loop tran

s

y

and perfor

m

o

ngly infl

u

introducing

r

oller designe

d

n

t uncertain

t

h

e H

∞

contro

h

esis problem

s

. (8) and (9)

,

s

ed for desig

n

s

igned by sol

v

e

r designing

o

p between t

h

o

llowing:

⎥

⎦

⎤

0r

G

u

ation provid

n

ing gain

Φ

.

e

condition o

f

s

gra, 2000) i

c

ondition of

Φ

the converg

e

s

fer function,

m

ances of the

enced by

the optimiz

a

d

process wit

h

t

ies is give

n

o

llers

(10)

(11)

with

, the

ning

ving

the

h

e

Z

~

(12)

d

es a

(13)

f

the

i

s to

(14)

1

Φ

<

e

nce

it is

ILC

the

a

tion

hout

n

as

wh

e

au

g

for

m

tra

n

fol

l

Fig

u

lea

r

lea

r

sat

i

ini

t

des

p

la

n

co

n

of

t

inc

l

=

⎥

⎥

⎦

⎤

⎢

⎢

⎣

⎡

L

1

y

Z

~

e

re

⎢

⎣

⎡

=

21

11

2A

P

P

P

g

mented syst

e

m

for H

2

/H

∞

c

k

L

e

y

z

~

⎢

⎣

⎡

=

With the d

e

n

sfer functi

o

l

owing:

[

1

1

W

~

Z

~

LG

PT

1

Φ

=

=

u

re 4: The flo

w

r

ning controlle

r

The design

p

r

ning gain

Φ

i

sfied. The p

r

ial value of

Φ

ign the cont

r

n

t. The secon

n

troller L(z) s

h

t

he converge

n

l

uded.

⎢

⎢

⎣

⎡

⎥

⎦

⎤

⎢

⎣

⎡

=

2221

1211

u

W

~

PP

PP

⎥

⎦

⎤

22

12

P

P

is the

e

m can be e

x

c

ontroller desi

111

1

k

J

P

W

~

P

y

+=

⎥

⎦

⎤

+

signed contr

o

o

n can be

]

0r0r

2

2

12

1

1

LG1

G

LPI(P

Φ

−

−+

w

chart of des

i

.

p

rocess is to

and ensure t

h

r

ocedure start

s

Φ

and then a

p

oller L(z)

b

a

s

d

step is to e

n

h

ould satisfy

t

n

ce where t

h

⎥

⎥

⎦

⎤

L

1

u

W

~

augmented

p

x

pressed as a

i

gn as shown

b

L12

u

P

o

ller, the cl

o

represented

]

21

1

2

LP)

−

igning learnin

g

start by sel

e

h

e stability c

o

t

s by first ch

o

a

pply the H

∞

s

ed on the a

u

n

sure that the

t

he sufficient

h

e plant unc

e

(15)

p

lant. The

standard

b

elow:

(16)

o

sed loop

as the

(17)

g

gain and

e

cting the

ndition is

o

osing an

theory to

u

gmented

designed

condition

e

rtainty is

ICINCO2012-9thInternationalConferenceonInformaticsinControl,AutomationandRobotics

150

4 E

X

To vali

d

and exp

machine

machine

MHMD

0

servo d

r

each ax

i

(RTX) (

V

control

output

d

the Ad

v

p

aramet

e

approac

h

a linear

s

1 Volt t

o

1000 H

z

Transfe

r

1999).

T

velocity

1.0 and

5

of positi

o

251.33

r

f

K

is s

e

To

e

applied

t

curve is

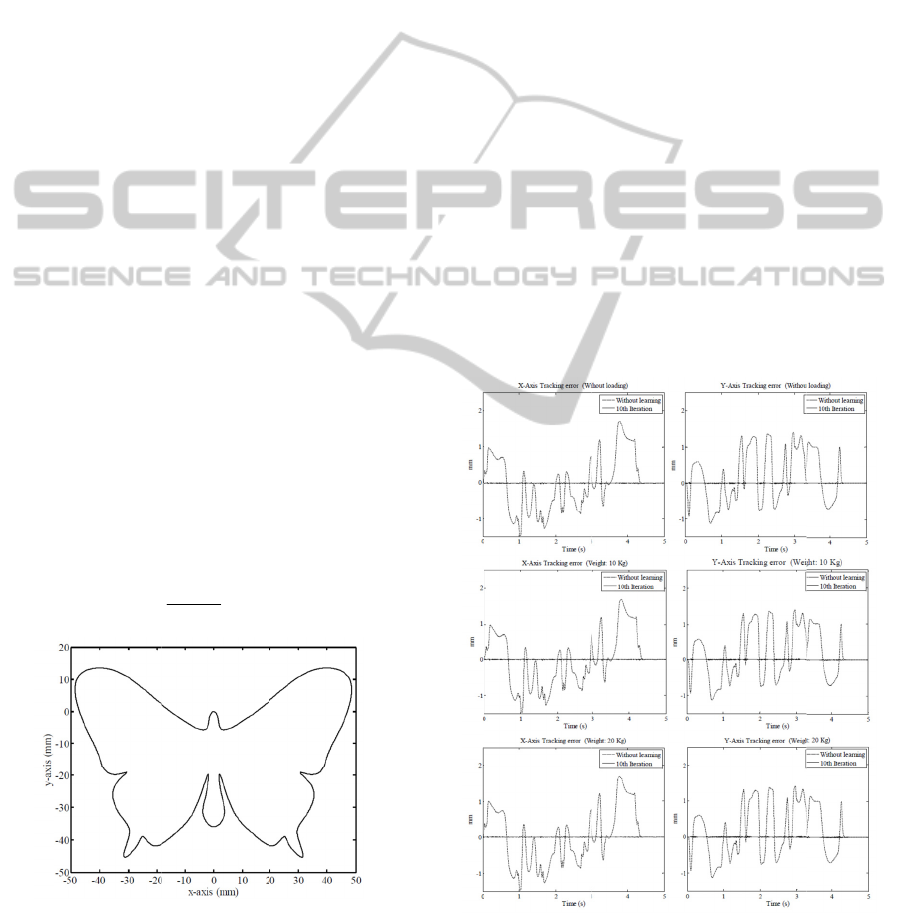

Fig.5. T

h

tested i

n

p

ayload

to devi

a

corresp

o

uncertai

n

After ap

p

is foun

d

range o

f

X

PERIM

E

d

ate the desi

g

eriments are

tool system

.

tool ar

0

42S1S serv

o

r

ives. The re

s

i

s is equal to

V

enturCom I

n

system with

d

ata from the

v

antech 178

4

e

rs are identi

f

h

. The nomin

a

s

wep

t

-freque

n

o

1 Volt and

t

z

, and ident

i

r

Function Es

t

T

he damping

r

close

d

-loop

t

5

02.65 rad/se

o

n closed-loo

r

ad/sec and

t

e

lected to 0.9

5

e

nsure that t

h

t

o a complex

used as a

w

h

ree payload

s

n

the moving

changes can

c

a

te about 8

%

o

nding weigh

t

n

ty bounds is

)s(W

=

Figure 5:

p

lying the de

s

d

that the lea

r

f

0.3 and 0.

5

E

NTAL V

A

g

n process, si

m

performed

u

.

The x, y,

a

e driven

o

motors an

d

s

olution of th

1μm. The r

e

n

c., 2006) is

u

real-time

p

linear scale

4

encoder

c

f

ied using a

f

a

l plant G

r0

(s)

n

cy signal at t

h

t

he frequenci

e

i

fied by usi

n

t

imate (ETF

E

r

atio and the

t

ransfer funct

i

c, respectivel

y

p transfer fu

n

t

he velocity

5

.

h

e proposed

a

trajectory, a

w

orking exa

m

s

given as 0,

1

platform. T

h

c

ause the mo

m

%

and 16%,

r

t

ing function

given as:

200s

s5.0

+

=

The butterfly c

s

ign process

s

r

ning gain

Φ

5

3 to satisfy

A

LIDATI

O

m

ulation ana

l

u

sing a three

-

a

nd z axes o

f

by Panas

d

MHMD04

2

e linear scal

e

e

al-time exte

n

u

sed to ensur

e

p

erformance.

are processe

d

c

ard. The

p

f

requency do

m

is measured

w

h

e magnitud

e

e

s from 0.1

H

n

g the Empi

r

E

) method (Lj

u

bandwidth o

f

i

on are chos

e

y

. The band

w

n

ction is chos

e

feedforward

a

lgorithm ca

n

b

utterfly NU

R

m

ple as show

n

1

0, and 20 K

g

h

e 10 and 2

0

m

ent of inert

i

r

espectively.

W(s) to cove

r

u

rve.

s

hown in Fig.

should be i

n

the converg

e

O

N

l

ysis

-

axis

f

the

s

onic

2

S1S

e

for

n

sion

e

the

The

d

by

p

lant

m

ain

with

e

of -

H

z to

r

ical

ung,

f

the

e

n as

w

idth

e

n as

gain

n

be

R

BS

w

n in

g

are

0

Kg

i

al J

s

The

r

the

(18)

4, it

n

the

e

nce

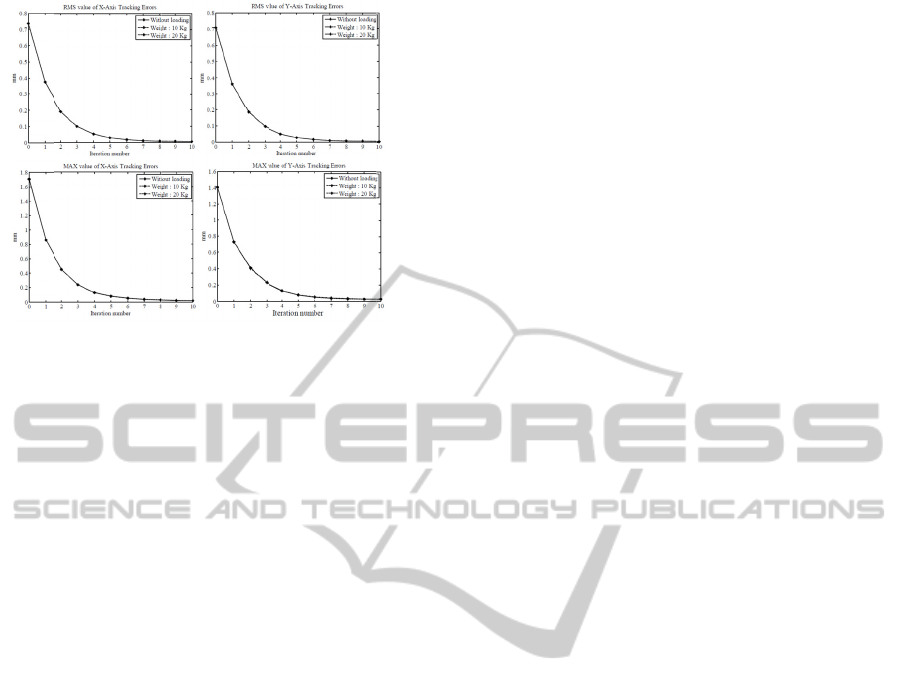

co

n

to

b

too

l

res

p

b

et

w

lea

r

an

d

the

the

val

u

co

n

we

i

99.

4

val

u

co

n

we

i

99.

3

ma

x

un

d

10

k

98.

Th

e

sat

i

out

p

loa

d

Fig

u

cas

e

n

dition. The

o

b

e 0.53.

Experiments

l

with the

p

a

y

p

ectively. T

h

w

een the c

a

r

ning after th

e

d

7. From the

r

x-axis and t

h

conditions

u

es of x-axi

s

n

ditions of t

h

i

ght and loa

d

4

0% and 99.

4

u

es of y-axi

s

n

ditions of t

h

i

ght and loa

d

3

0% and 9

9

x

imu

m

value

s

d

er the condit

i

k

g weight a

n

16%, 98.71

%

e

results illu

s

i

sfies the syst

e

p

ut tracking

d

ings.

u

re 6: The co

m

e

s of without le

o

ptimal learni

are conduct

y

loa

d

equal t

o

h

e comparis

o

a

ses of with

o

e

10th iteratio

r

esults, the tr

a

h

e y-axis are

of different

s

output trac

k

h

at without l

d

ing 20 kg

w

4

1% after 1

0

s

output trac

k

h

at without l

d

ing 20 kg

w

9

.12% after

s

of the x-axi

s

i

ons of that w

i

n

d loading

2

%

and 98.77

%

s

trate tha

t

n

o

e

m robustnes

s

errors are s

i

m

parisons of tr

a

a

rning and the

l

i

ng gain is d

e

t

ed on the

m

o 0, 10 kg a

n

o

ns of track

i

o

ut learning

o

n are shown

i

a

cking perfor

m

much impro

v

loadings.

T

k

ing errors

u

l

oading, load

i

w

eight reduce

0

iterations.

T

k

ing errors

u

l

oading, load

i

w

eight reduce

10th iterat

i

s

output track

i

w

ithout loadin

g

2

0 kg weig

h

%

after 10th

o

t only the

c

s

but also the

i

milar under

a

cking error b

e

learning.

e

termined

m

achining

n

d 20 kg,

i

ng error

and the

i

n Figs. 6

m

ances of

v

ed under

he RMS

u

nder the

i

ng 10kg

99.40%,

T

he RMS

u

nder the

i

ng 10kg

99.33%,

i

on. The

i

ng errors

g

, loading

h

t reduce

iteration.

c

ontrolle

r

trends of

different

e

tween the

DevelopmentofRobustLearningControlandApplicationtoMotionControl

151

Figure 7:

the tracki

n

5 C

O

A modi

f

this pap

e

choosin

g

learning

method

o

learning

Experi

m

with dif

f

reductio

n

iteration

s

compari

s

p

ayload

s

achieve

d

ACK

N

The aut

h

Affairs,

to this s

t

SE - 10

1

REF

E

Ahn, H.

S

learn

i

Tran

s

1121.

French,

M

learn

i

Inter

n

Geng, Z.

,

mode

The trends for

ng errors.

O

NCLUS

I

f

ied H

∞

opti

m

er

to provid

e

g

the learni

n

function.

o

logy, the a

p

function ca

n

m

ents are con

d

f

erent loading

n

of trackin

g

s for the no

m

s

ons betwee

n

s

demonstrate

d

.

N

OWLE

D

h

ors are grate

f

R. O. C. for

t

t

udy under co

n

1

, and 100-E

C

E

RENCES

S

., Chen, Y. Q.

i

ng control: bri

e

s

. on Systems,

M

., and Roge

r

i

ng by an

n

ational Journ

a

,

Carroll, R., a

n

e

l and algorit

h

the RMS and

m

I

ONS

m

ization proc

e

e

a systemati

c

n

g gain an

d

According

p

propriate le

n

be designe

d

d

ucted on th

e

conditions. I

t

g

error is o

v

m

inal plant.

n

the plant

s

that system

r

D

GEMEN

T

f

ul to the Min

i

t

he financial

s

n

tract 98 – E

C

C

-17-A-05-S1

-

, and Moore,

K

e

f survey and c

Man, and Cy

b

r

s, E., 2000,

adaptive Ly

a

a

l of Control, 7

3

nd

Xie, J., 199

0

h

m analysis fo

m

aximum valu

e

ss is propos

e

c

methodolog

d

designing

the prop

o

arning gain

d

simultaneo

u

e

machining

t

t

is shown tha

t

v

er 97% afte

r

Furthermore,

s

with diff

e

r

obustness ca

n

T

S

i

stry of Econ

o

s

upports prov

C

– 17 – A –

0

-

189, respecti

K

. L., 2007, Iter

ategorization,

I

b

ernetics, 37, 1

Nonlinear iter

a

punov techn

i

3

, 840-850.

0

, Two-dimens

i

r

a class of iter

a

u

es of

e

d in

g

y in

the

o

sed

and

u

sly.

t

ools

a

t the

r

10

the

e

rent

a

n be

o

mic

v

ided

05 –

i

vely.

r

ative

I

EEE

1

099-

r

ative

n

ique.

i

onal

a

tive

Ku

c

Lee

Lju

n

Pa

d

Ta

y

Tsa

i

Ve

n

Wa

n

Ye,

Zh

o

learning contr

o

c

, T. Y., Nam,

learning contr

o

Robot. Autom.

,

, J. H., and Le

e

applied to b

a

Engineering P

r

n

g, L., 1999,

User. Prentice

d

ieu, F., and S

control syste

m

Processing, 4,

y

abi, A, and Isl

a

control for ro

b

Control Engin

e

i

, M. S., Li

n

Development

control algo

disturbance, a

n

Syst. Technol.,

n

turCom Inc.,

Documentatio

n

n

g, H., and

Structure Con

t

in Stochastic

S

Trans. on Aut

o

Y. Q., and

inversion lear

n

1556.

o

u, K., Doyle,

J

Optimal Contr

o

o

l systems. Int.

J

K., and Lee,

o

l of robot m

a

,

7, 835–841.

e

, K. S., 2007,

t

ch processes:

r

actice, 15, 13

0

System Identi

f

Hall.

u

, R., 1990,

H

m

s, Int. J.

A

465–474.

a

m, S., 2006,

A

b

ot manipulato

e

ering Practic

e

n

, M. T., a

n

of comman

d

-

b

r

ithm with c

o

n

d noise effec

t

14, 511-518.

2006, Vent

u

n

. Cambridge.

A

fsha

r

, P., 2

0

t

roller Design

f

S

ystems Using

matic control,

5

Wang, D.

W

n

ing control la

w

J

. C., and Glo

v

o

l. New Jersey

,

J. Control, 52,

J. S., 1991,

A

a

nipulators. IE

E

Iterative learn

i

An overvie

w

0

6-1318.

fication: Theo

r

H

∞

approach t

A

daptive Con

t

A

daptive iterati

v

o

rs: Experimen

t

e

, 14, 843-851.

nd

Yau, H.

b

ased iterativ

e

o

nsideration o

ts. IEEE Tran

s

u

rCom RTX

009, ILC-Bas

for Output PD

g

LMI Techni

q

54, 760-773.

W

., 2005, Cle

a

w

. Automatica,

v

e

r

, K., 1996,

R

,

Prentice Hall

.

833-862.

A

n iterative

E

E Trans.

i

ng control

w

. Control

r

y for the

o

learning

t

r. Signal

v

e learning

t

al results.

T., 2006,

e

learning

f friction,

s

. Control

6.5 SDK

e

d Fixe

d

-

F

Shaping

q

ues. IEEE

a

n system

41, 1549–

R

obust and

ICINCO2012-9thInternationalConferenceonInformaticsinControl,AutomationandRobotics

152