An Integrated Approach for Efficient Mobile Robot Trajectory

Tracking and Obstacle Avoidance

Aleksandar Cosic, Marko Susic and Dusko Katic

Institute Mihajlo Pupin, Robotics Laboratory, University of Belgrade, Volgina 15, Belgrade, Serbia

Keywords: Mobile Robots, Trajectory Tracking, Obstacle Avoidance, Fuzzy Logic, Intelligent Control.

Abstract: An approach for nonholonomic two-wheeled mobile robot trajectory tracking and obstacle avoiding is

presented in this paper. If the desired trajectory is provided by high level planner, trajectory tracking

problem can be solved in various ways. In this paper, tracking is provided using proportional-integral (PI) or

fuzzy logic controller (FLC). Unfortunately, tracking is never perfect, due to uncertainties and obstacles can

change their positions in time. In order to overcome these difficulties, additional correction controller must

be used. Here is proposed fuzzy controller, which slightly changes control action of the tracking controller

in order to prevent collision with obstacles. This approach is proved to be efficient even in dynamic

environments. Simulation results are presented as illustration of the proposed approach.

1 INTRODUCTION

In recent years, due to growing popularity and

importance of wheeled mobile robots (WMRs) in

many applications, motion control problems

dedicated to WMRs attracted great attention.

Trajectory tracking problem can be considered as a

part of mobile robot navigation problem, which has

been intensively researched, e.g. (Laumond, 1998;

LaValle, 2006; Masehian and Sedighizadeh, 2007).

Considerable research efforts have been made on

trajectory tracking control of two-wheeled

differentially driven mobile robots. Despite the

apparent simplicity of the WMR kinematic model,

the design of stabilizing control law is challenging

due to the existence of nonholonomic constraints.

Varius control strategies have been presented

such as: sliding-mode control, e.g. (Bloch and

Drakunov, 1994), backstepping procedure, e.g.

(Taner and Kyriakopoulos, 2003), dynamic feedback

linearization, e.g. (Oriolo et al., 2002), Lyapunov-

type techniques, e.g. (Mastellone et al., 2008),

adaptive control, e.g. (Fukao et al., 2000), model

predictive control, e.g. (Kühne et al., 2005) and

intelligent techniques, based on neural networks and

fuzzy logic, e.g. (Jiang et al., 2005; Oh et al., 2005).

In general, closed-loop results obtained using

classic control approaches may present undisarable

oscillatory motions. From the other hand, fuzzy

logic may be good option for uncertain systems,

whose behaviour can be described linguistically. In

this paper, two tracking controllers will be designed,

nonlinear PI and fuzzy controller. Unfortunatelly,

due to uncertainties and obstacles movements,

collision with obstacles could happen even if the

high level planner provided collision free path. It is

the reason why additional fuzzy controller must be

introduced, which will correct the control action of

the tracking controller, when mobile robot comes

close enough to the obstacle.

The rest of the paper is organized as follows:

description of the WMR kinematic model is given in

Section 2, design of the control structure in Section

3, simulation results in Section 4, while the

conclusion is given in Section 5.

2 KINEMATIC MODEL OF THE

TWO-WHEELED MOBILE

ROBOT

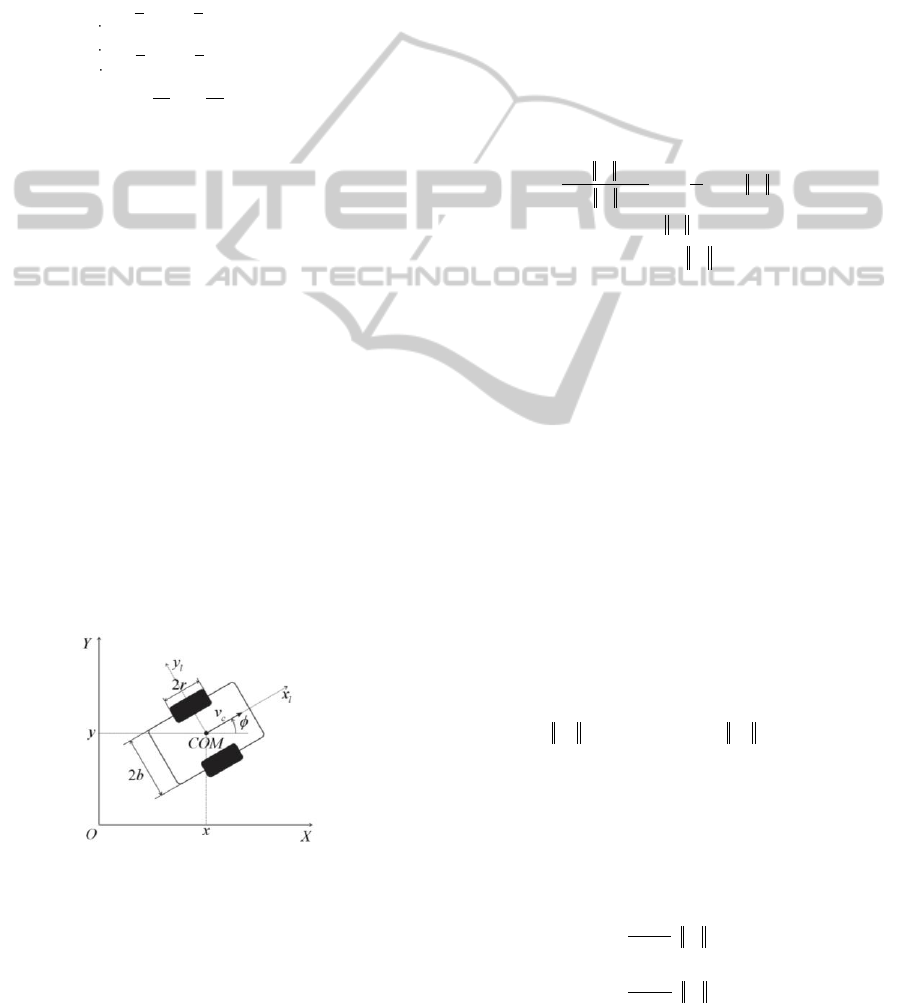

Schematic model of WMR is shown on Figure 1.

Derivation of the kinematic equations of the two-

wheeled mobile robot is given in (Susic et al., 2011).

World coordinate frame is denoted by {X,O,Y},

while {x

l

,COM,y

l

} denotes local coordinate frame,

attached to the robot, whose origin is placed at the

robot’s centre of mass (COM). State variables are

position and orientation of the robot, i.e. COM

211

Cosic A., Susic M. and Katic D..

An Integrated Approach for Efficient Mobile Robot Trajectory Tracking and Obstacle Avoidance.

DOI: 10.5220/0004010402110216

In Proceedings of the 9th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2012), pages 211-216

ISBN: 978-989-8565-22-8

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

position

and angle between x axes of the

world and local coordinate frame, while ω

L

and ω

D

denote angular velocities of the left and right side

wheels of the robot, respectively, and represent

control inputs, while

denotes COM linear velocity

and

denotes robot angular velocity around COM.

If and denote projections of velocity vector

onto coordinate axis of global coordinate system,

kinematic model of the mobile robot is given by:

cos cos

22

sin sin

22

22

L

D

rr

x

rr

y

rr

bb

(1)

3 DESIGN OF THE CONTROL

SYSTEM

Proposed controller consists of three parts: trajectory

tracking controller (TTC), obstacle avoiding

controller (OAC) and combined controller (CC). It is

assumed that the collision free trajectory is already

provided by high level planner, i.e. virtual vehicle

trajectory is known. TTC provides tracking of the

desired trajectory. For this purpose two controllers

will be presented, nonlinear PI and FLC. PI

controllers are simple and widely used in industrial

practice, while FLCs are intelligent control strategies

which are proved to be efficient in control of

complex systems. Main drawback of FLCs is large

number of parameters which has to be adjusted.

Tracking is never perfect, so, at this point, it is not

ensured that robot will pass from starting to

destination point safely. For this purpose fuzzy OAC

Figure 1: Kinematic model of mobile robot.

is proposed, which generates correction control

signal which moves robot away from the obstacle.

The last part of the control structure is combined

controller. Its role is to combine the control signals

obtained from TTC and OAC into control inputs of

the mobile robot, i.e. to make compromise between

“tracking” and “avoiding” action of the controller.

3.1 Design of the Trajectory Tracking

Controllers

3.1.1 Nonlinear Pi Controller

Tracking controller generates control action which

tries to direct robot to the desired trajectory. Let

denote robot position and orientation,

desired position and orientation at the

same time instant, and

desired velocity Velocity

generated by controller is denoted by

and can be

obtained as:

*

*

00

,

1

,

0,

min , /

v v v

e

e e e

v

e

e

v

zz

pz

z zi z

z

zi

z

Kd

d

T

d

d d d k

(2)

where

is velocity correction, k is positive gain

and d is the dead-zone size, dependent on

.

Tracking error and integral of tracking error are

denoted by

and

, respectively. Proportional gain is denoted by

K

p

, while T

i

stands for integral constant.

Velocity correction is nonlinear function of

errors sum, i.e. dead-zone around desired point is

introduced. Introducing nonlinearity is necessary,

because it does not allow oscillations of robot’s

position near the desired point. Dead-zone size

decreases when desired velocity increases.

Parameter

determines the maximal value of

tracking error near the destination point.

Angular velocities of the motors

are

weighted sums of the linear and angular velocities of

the robot

. So, control generated by controller

is given by:

,

Lt v z z Dt v z z

a a a a

vv

(3)

where

and

denote magnitude and angle of

the velocity vector

given by (2),

approximates derivative of the

, while weights

and

are control parameters. These parameters

weight straight-line and turning capabilities.

Derivative approximation

is given by:

*

,

,

z

z

s

z

z

s

d

T

d

T

e

e

(4)

ICINCO 2012 - 9th International Conference on Informatics in Control, Automation and Robotics

212

where

denotes the sampling time. It can be seen

from (4) that controller tries to align orientations of

the real and virtual robot when they are close

enough, i.e. if their distance is less or equal d.

3.1.2 Fuzzy Logic Controller

Controllers based on fuzzy logic are proved to be

efficient in control of complex systems, where other

control strategies do not provide satisfactory

performance. FLCs try to mimic action of

experienced operator.

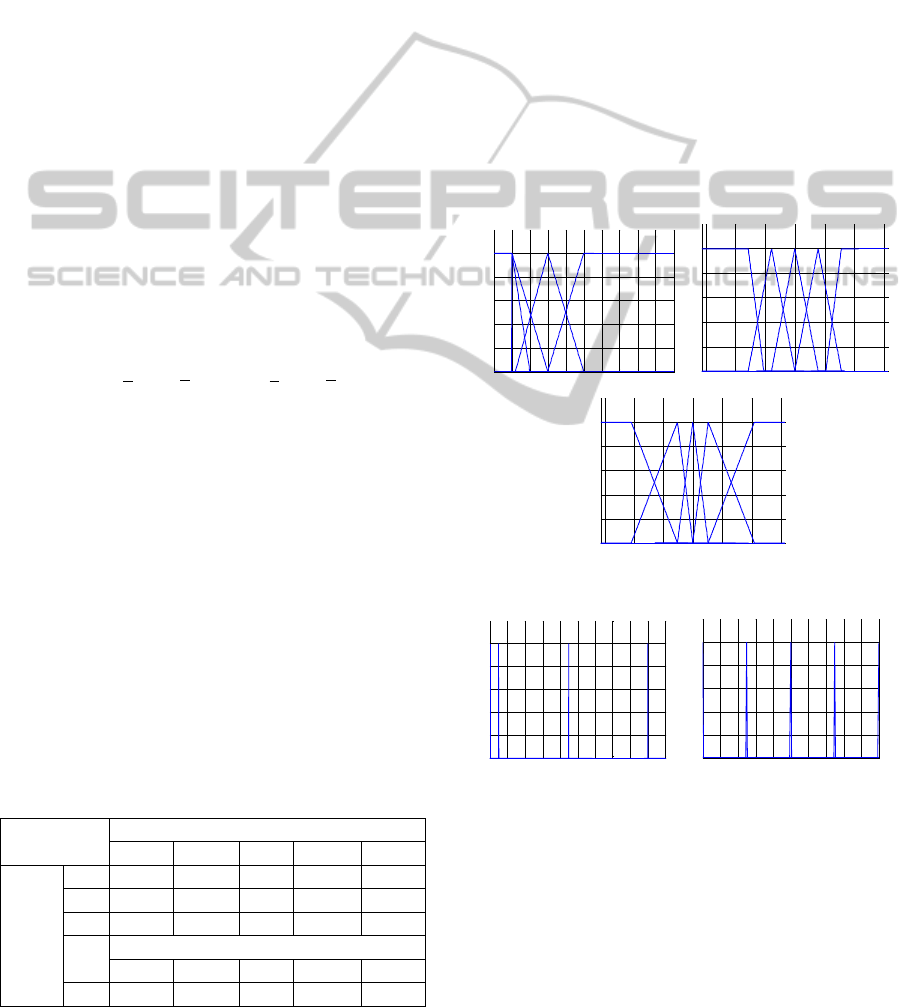

Proposed controller is Takagi-Sugeno-Kang

(TSK) type and has three inputs (“distance to virtual

vehicle” - Euclidian distance between real and

virtual COM position, “angle” - angle at which real

robot sees the virtual and “orientation difference” -

difference between virtual and real robot

orientations) and two outputs (“linear velocity” -

linear velocity of the WMR, normalized on [0,1] and

“angular velocity” - angular velocity of the WMR,

normalized on [-1,+1]). Membership functions of the

linguistic values of inputs and outputs are given on

the Figures 2 and 3.

According to (3), outputs of the whole FLC can

be obtained as:

,

Dt v t t Lt v t t

K v K K v K

(5)

where

and

are normalized linear and angular

velocities produced by the fuzzy inference

mechanism, while

and

are weights which

give the relative importance to straight forward and

turning capabilities.

Fuzzy rule base is given by Table 1. Membership

functions are represented by abbreviations, defined

on Figure 3. Also, every cell is represented by two

linguistic values. The first one corresponds to the

“linear velocity”, while the second one corresponds

to the “angular velocity”. As can be seen from Table

1, there are two sets of fuzzy rules. The first one

takes “distance to virtual vehicle” and “angle” as

inputs. This set of rules is active when robot is not

close enough to the desired point, and controller tries

Table 1: Fuzzy rule base of the TTC.

“angle”

BL

FL

F

FR

BR

“distance to virtual

vehicle”

N

Z/HP

S/Z

S/Z

S/Z

Z/HN

M

Z/FP

M/HP

M/Z

M/HN

Z/FN

F

Z/FP

L/HP

L/Z

L/HN

Z/FN

“orientation difference”

Z/HN

Z/HN

Z/Z

Z/HP

Z/HP

VC

LN

MN

S

MP

LP

to bring the robot close to this point. Second set of

rules takes “distance to virtual vehicle” and

“orientation difference” as inputs. This set of rules is

active when robot comes close enough to the desired

point, trying to align robot’s and desired orientation.

Thus, the idea is to introduce set of rules which

keeps orientation of the real and virtual robot

aligned when they are close enough.

3.2 Design of the Obstacle Avoiding

Controller

Path planning algorithm in complex scenarios with

large number of obstacles might generate path that

guides robot very close to the obstacles. Tracking is

not perfect, so obstacle avoidance is not ensured yet.

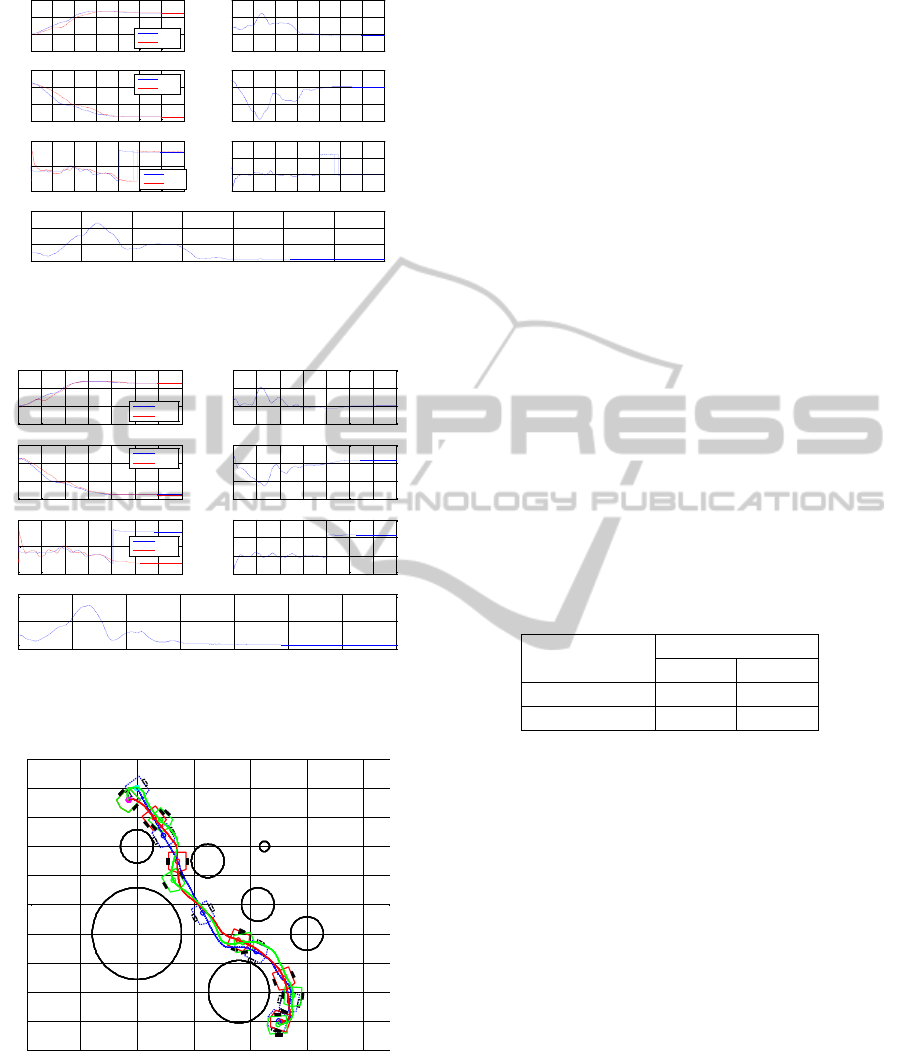

Obstacle avoiding fuzzy controller is two-input

(“distance to obstacle” and “obstacle viewing

angle”) and one-output (“angular velocity

Figure 2: Membership functions of the TTC’s inputs.

Figure 3: Membership functions of the TTC’s outputs.

correction”, normalized on [0,1]) system. Meaning

of the fuzzy inputs and output is similar as in TTC

design. Correction should be generated such that

mobile robot moves away from the obstacle, but

only when it comes close enough to it.

Membership functions of the fuzzy inputs and

output are given on Figures 4 and 5. Output of the

whole OAC is:

0 0.05 0.1 0.15 0.2 0.25 0.3 0.35 0.4 0.45 0.5

0

0.2

0.4

0.6

0.8

1

input variable : "distance to virtual vehicle" [m]

degree of membership

Very

Close(VC)

Near(N)

Medium(M) Far(F)

-3 -2 -1 0 1 2 3

0

0.2

0.4

0.6

0.8

1

input variable : "angle" [rad]

degree of membership

Back Left(BL)

Back Right(BR)

Front

Left(FL)

Front

Right(FR)

Front(F)

-3 -2 -1 0 1 2 3

0

0.2

0.4

0.6

0.8

1

input variable : "orientation difference" [rad]

degree of membership

Large

Negative(LN)

Medium

Negative(MN)

Small(S)

Medium

Positive(MP)

Large

Positive(LP)

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

0

0.2

0.4

0.6

0.8

1

output variable : "linear velocity" [rad/s]

degree of membership

Medium(M)

Large(L)

Zero(Z)

Small(S)

-1 -0.8 -0.6 -0.4 -0.2 0 0.2 0.4 0.6 0.8 1

0

0.2

0.4

0.6

0.8

1

output variable : "angular velocity" [rad/s]

degree of membership

Full

Negative(FN) Zero(Z)

Half

Negative(HN)

Full

Positive(FP)

Half

Positive(HP)

An Integrated Approach for Efficient Mobile Robot Trajectory Tracking and Obstacle Avoidance

213

K

(6)

where is output of the fuzzy inference system,

and

is output gain.

Fuzzy rules are given by Table 2. Abbreviations

are also used for membership function

representation. Avoiding action is the strongest

when the obstacle is straight ahead of the robot.

Table 2: Fuzzy rule base of the OAC.

“obstacle viewing angle”

BR

R

FR

FL

L

BL

“distance

to

obstacle”

N

SP

HP

FP

FN

HN

SN

3.3 Design of the Combined Controller

The task of the CC is to combine outputs from the

TTC and OAC in order to obtain control signals of

the mobile robot. It is basically a weighed sum of

TTC and OAC outputs, whose weights depend on

distance between robot and obstacle, i.e. it gives

relative importance to “tracking” and “avoiding”

action. If the robot is close enough to the obstacle,

OAC output becomes dominant, otherwise TTC

output is dominant. Тhe outputs of the CC are given

by:

1 2 1 2

,

L Lt D Dt

K K K K

(7)

where

and

denote the weights, given by (8),

and

are the outputs of the TTC and is

the output of the OAC.

min

min

1

11

max

max

2

22

1

min 1,

max 0,

c

c

K

K d K

d

K

K d K

d

(8)

where d denotes distance between robot and

obstacle,

denotes minimum distance to obstacle

when OAC becomes active,

is the minimum

contribution of the tracking signal in the overall

control, while

is the maximum contribution of

the avoiding in the overall control.

Figure 4: Membership functions of the OAC’s inputs.

Figure 5: Membership functions of the OAC’s output.

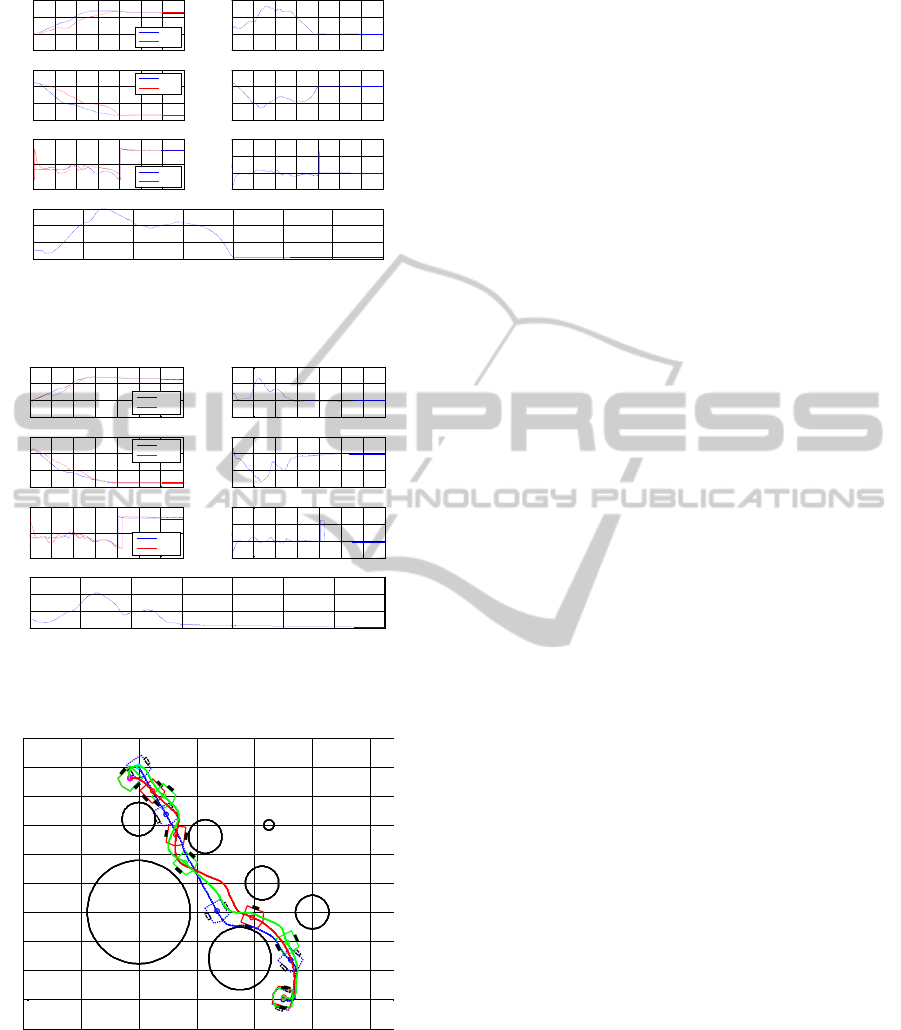

4 SIMULATION RESULTS

Proposed algorithm for mobile robot trajectory

tracking is implemented in MATLAB package.

Environment with seven circular obstacles is

adopted. Tracking performance will be presented in

two different scenarios. In the first scenario, planner

knows exact position of the obstacles, so generated

desired trajectory is guaranteed to be collision free.

In further text, this scenario will be denoted by

Scenario I. In the second scenario, some obstacles

slightly changed their positions, while desired

trajectory remained the same (in further text denoted

by Scenario II). Mean-square error (MSE) is adopted

as a measure of tracking quality, and MSE values

obtained in these scenarios are given by Table 3.

It is assumed that robot width is and

wheel radius is . Maximum angular

velocities of the wheels are

. It is assumed that the robot position and

orientation measurements are corrupted with white

Gaussian noise, which standard deviations are 1cm

and 1°, respectively. Starting point is

,

while the destination point is

for the

virtual robot. Starting point and orientation of the

real robot is

.

Results obtained in the Scenario I have been

presented on Figures 6, 7 and 8. Error on the

Figures 6, 7, 9 and 10 is defined as distance between

desired

and robot's position

at the

same time instant. Snapshots of the vehicles on

Figure 8 have been taken at the following time

instants: (0,3,6,10,15,35)s. Virtual robot is

presented by blue dotted line, real robot with PI TTC

controller with red solid line, while the one with

FLC TTC with green solid line. Parameters of all

controllers have been adjusted experimentally. PI

controller parameters are as follows:

.

PI outputs have been filtered with simple first-order

continuous filter whose transfer function is

. Choice of the controller parameters is critical.

0 0.5 1 1.5

0

0.2

0.4

0.6

0.8

1

input variable : "distance to obstacle" [m]

degree of membership

Near(N)

-3 -2 -1 0 1 2 3

0

0.2

0.4

0.6

0.8

1

input variable : "obstacle viewing angle" [rad]

degree of membership

Back

Right(BR) Right(R)

Front

Right(FR)

Front

Left(FL)

Left(L)

Back

Left(BL)

-1 -0.8 -0.6 -0.4 -0.2 0 0.2 0.4 0.6 0.8 1

0

0.2

0.4

0.6

0.8

1

output variable : "angular velocity correction" [rad/s]

degree of membership

Full

Positive(FP)

Half

Positive(HP)

Small

Positive(SP)

Small

Negative(SN)

Half

Negative(HN)

Full

Negative(FN)

ICINCO 2012 - 9th International Conference on Informatics in Control, Automation and Robotics

214

Figure 6: Tracking errors with PI TTC and OAC in

Scenario I.

Figure 7: Tracking errors with FLC TTC and OAC in

Scenario I

Figure 8: Comparative 2D view of robots motion in

Scenario I.

Increase of proportional gain

enhances the

tracking performance, but increases the presence of

noise in control signals. Decrease of

decreases the

tracking error, but may lead to instability.

Parameters

and

weight straight-line and

turning capabilities, so larger value of

is

recommended. Gains of the FLC are also chosen as:

. These parameters weight straight

motion and turning capabilities, respectively, so

larger values of

are advisable, in order to ensure

good tracking in sharp curves.

Output gain of the OAC is adopted as

, while

and

. This

means that the minimal “tracking” contribution is

40%, while maximal “avoiding” contribution is 60%

in overall control action. Critical distance to obstacle

on which CC modifies “tracking” control action with

“avoiding” contribution is

. Figure 8

shows that the “avoiding” contribution degrades the

quality of tracking near the obstacles, but robots

move away from the obstacles, decreasing the risk of

collision. In this case, FLC used as TTC is better

solution.

Results obtained in Scenario II, when obstacles

1, 2, 3 and 6 changed their positions slightly are

shown on Figures 9, 10 and 11. Snapshots of the

vehicles have been taken at the following time

instants: (0,3,7,13,35)s. FLC used as TTC provides

better result again.

Table 3: Mean-square error in different scenarios.

Scenario

MSE value [cm]

PI

FLC

Scenario I

26.9

17.6

Scenario II

51.9

22.7

5 CONCLUSIONS

The solution of trajectory tracking with obstacle

avoiding is presented in this paper. Although it is

assumed that planner which provides collision free

time-parameterized path is available, it is not

necessary. It is enough that only “sketch” of the

trajectory is provided, and OAC will correct control

action and push mobile robot away from the

obstacles. Proposed scheme can be used in different

scenarios with obstacles of arbitrary shape. This

approach can be applied even in dynamic

environments in which exist moving obstacles. The

proposed algorithms will be implemented in real

time control of 4WD mobile robot platform.

0 5 10 15 20 25 30 35

0

2

4

6

x[m]

virtual

real

0 5 10 15 20 25 30 35

-0.5

0

0.5

1

e

x

[m]

0 5 10 15 20 25 30 35

0

2

4

6

y[m]

virtual

real

0 5 10 15 20 25 30 35

-1

-0.5

0

0.5

e

y

[m]

0 5 10 15 20 25 30 35

-5

0

5

[m]

virtual

real

0 5 10 15 20 25 30 35

-5

0

5

10

e

[m]

0 5 10 15 20 25 30 35

0

0.5

1

1.5

tracking error[m]

time[sec]

0 5 10 15 20 25 30 35

0

2

4

6

x[m]

virtual

real

0 5 10 15 20 25 30 35

-0.5

0

0.5

1

e

x

[m]

0 5 10 15 20 25 30 35

0

2

4

6

y[m]

virtual

real

0 5 10 15 20 25 30 35

-1

-0.5

0

0.5

e

y

[m]

0 5 10 15 20 25 30 35

-5

0

5

[m]

virtual

real

0 5 10 15 20 25 30 35

-5

0

5

10

e

[m]

0 5 10 15 20 25 30 35

0

0.5

1

tracking error[m]

time[sec]

1 2 3 4 5 6

0

0.5

1

1.5

2

2.5

3

3.5

4

4.5

5

x[m]

y[m]

1

2

3

4

5

6

7

1

2

3

4

5

6

7

1

2

3

4

5

6

7

1

2

3

4

5

6

7

1

2

3

4

5

6

7

1

2

3

4

5

6

7

An Integrated Approach for Efficient Mobile Robot Trajectory Tracking and Obstacle Avoidance

215

Figure 9: Tracking errors with PI TTC and OAC in

Scenario II.

Figure 10: Tracking errors with FLC TTC and OAC in

Scenario II.

Figure 11: Comparative 2D view of robots motion in

Scenario II.

ACKNOWLEDGEMENTS

The results, presented in the paper, are obtained in

the research projects TR-35003 and III-44008

supported by Ministry of Science of Republic

Serbia.

REFERENCES

Laumond, J., 1998. Robot Motion Planning and Control,

Springer-Verlag, London.

LaValle, S., 2006. Planning Algorithms, Cambridge

University.

Masehian, E., Sedighizadeh, D., 2007. Classic and

Heuristic Approaches in Robot Motion Planning, A

Chronological Review, World Academy of Science,

Engineering and Technology, 29.

Bloch, A., Drakunov, S., 1994. Stabilization of a

Nonholonomic System via Sliding Modes, IEEE

Conference on Decision and Control

Taner, H. G., Kyriakopoulos, K. J., 2003. Backstepping

for Nonsmooth Systems, Automatica, Vol. 39, pp.

1259 – 1265.

Oriolo, G., De Luca, A., Vendittelli, M., 2002. WMR

Control via Dynamic Feedback Linearization:

Decision, Implementation and Experimental

Validation, IEEE Transactions on Control Systems

Technology, Vol. 10, No.6, pp. 835-851.

Mastellone, S., Stipanovic, D., Graunke, C., Intlekofer, K.,

Spong, M., 2008. Formation Control and Collision

Avoidance for Multi-agent Non-holonomic Systems:

Theory and Experiments, The International Journal of

Robotics Research, Vol. 27, No. 1, pp. 107-126.

Fukao, T., Nakagawa, H., Adachi, N., 2000. Adaptive

Tracking Control of a Nonholonomic Mobile Robot,

IEEE Transactions on Robotics and Automation, Vol.

16, pp. 609-615.

Kühne, F., Lages, W. F., Gomes da Silva Jr., J. M., 2005.

Mobile Robot Trajectory Tracking using Model

Predictive Control, 2

nd

IEEE Latin-American Robotics

Symposium

Jiang, X., Motai, Y., Zhu, X., 2005. Predictive Fuzzy

Logic Controller for Trajectory Tracking of a Mobile

Robot, IEEE Mid-Summer Workshop on Soft

Computing in Industrial Applications

Oh, J. S., Park, J. B., Choi, Y. H., 2005. Stable Path

Tracking Control of a Mobile Robot using a Wavelet

Based Fuzzy Neural Network, International Journal of

Control, Automation and Systems, Vol.3, No. 4, pp.

552-563.

Susic, M., Cosic, A., Ribic, A., Katic, D., 2011. An

Approach for Intelligent Mobile Robot Motion

Planning and Trajectory Tracking in Structured Static

Environments, Proceedings of the SISY 2011, pp. 17-

22.

0 5 10 15 20 25 30 35

0

2

4

6

x[m]

virtual

real

0 5 10 15 20 25 30 35

-0.5

0

0.5

1

e

x

[m]

0 5 10 15 20 25 30 35

0

2

4

6

y[m]

virtual

real

0 5 10 15 20 25 30 35

-2

-1

0

1

e

y

[m]

0 5 10 15 20 25 30 35

-5

0

5

[m]

virtual

real

0 5 10 15 20 25 30 35

-5

0

5

10

e

[m]

0 5 10 15 20 25 30 35

0

0.5

1

1.5

tracking error[m]

time[sec]

0 5 10 15 20 25 30 35

0

2

4

6

x[m]

virtual

real

0 5 10 15 20 25 30 35

-0.5

0

0.5

1

e

x

[m]

0 5 10 15 20 25 30 35

0

2

4

6

y[m]

virtual

real

0 5 10 15 20 25 30 35

-1

-0.5

0

0.5

e

y

[m]

0 5 10 15 20 25 30 35

-5

0

5

[m]

virtual

real

0 5 10 15 20 25 30 35

-5

0

5

10

e

[m]

0 5 10 15 20 25 30 35

0

0.5

1

1.5

tracking error[m]

time[sec]

1 2 3 4 5 6

0

0.5

1

1.5

2

2.5

3

3.5

4

4.5

5

x[m]

y[m]

1

2

3

4

5

6

7

1

2

3

4

5

6

7

1

2

3

4

5

6

7

1

2

3

4

5

6

7

1

2

3

4

5

6

7

ICINCO 2012 - 9th International Conference on Informatics in Control, Automation and Robotics

216