Mechatronic System Optimization based on Surrogate Models

Application to an Electric Vehicle

Moncef Hammadi, Jean-Yves Choley, Olivia Penas and Alain Riviere

LISMMA, SUPMECA-PARIS, 3 Rue Fernand Hainaut, 93400 Saint-Ouen, France

Keywords:

Mechatronic Design, Optimization, Surrogate Models, Modelica, Electric Vehicle.

Abstract:

Preliminary optimization of mechatronic systems is an extremely important step in the development process of

multi-disciplinary products. However, long computing time in optimization based on multi-domain modelling

tools need to be reduced. Surrogate model technique comes up as a solution for decreasing time computing in

multi-disciplinary optimization. In this paper, an electric vehicle has been optimized by combining Modelica

modelling language with surrogate model technique. Modelica has been used to model the electric vehicle

and surrogate model technique has been used to optimize the electric motor and the transmission gear ratio.

Results show that combining surrogate model technique with Modelica reduces significantly computing time

without much decrease in accuracy.

1 INTRODUCTION

Mechatronic Systems (MS) are interdisciplinary

products with a synergistic spatial and functional in-

tegration of mechanical, electronic and software sub-

systems (Craig, 2009).

The great challenge in mechatronic design lies in

optimizing a complete system with various physical

phenomena related to interacting heterogeneous sub-

systems.

Several multi-domain modelling tools such as

Bond-Graphs, VHDL-AMS, Matlab/Simulink and

Modelica are used for preliminary design of MS.

For instance, Modelica (Elmqvist et al., 1998)

combines object-oriented concepts with multi-port

methods for modelling and simulation of physical

systems. It includes a declarative mathematical de-

scription of models and provides a graphical mod-

elling approach. Multi-domain model library of

lumped parameter elements can be created and added

to the default Modelica library for future use. The

end results of Modelica modelling is a system of

differential-algebraic equations (DAE) that represents

the complete mechatronic system. So that, Modelica

is considered as an ideal tool for preliminary design

of MS. However, optimizing a mechatronic system

based on DAE is computationally expensive, due to

the considerable number of simulation evaluations.

For this reason, substituting DAE system with sur-

rogate models, using statistical methods, is one way

of alleviating this burden. The polynomial Response

Surface Method (RSM) (Box and Wilson, 1951) is

commonly considered as the first surrogate modelling

technique. It uses a polynomial formulation to ap-

proximate anexact function. Other techniques such as

Kriging (Krige, 1951) and Artificial Neural Networks

(ANNs) of Radial Basis Functions (RBF) (Hardy,

1971), (Hopfield, 1982) and (Powel, 1985) are also

used to model complex relationships between inputs

and outputs. Surrogate models are also known as

metamodels (Blanning, 1975).

In this paper, both RMS and ANNs of RBF sur-

rogate models have been generated from a Modelica

model of an Electric Vehicle (EV). After their val-

idation and comparison of their accuracy, the ANN

of RBF surrogate model has been chosen to optimize

the electric motor and the gear ratio of the EV. The

optimization based on the surrogate model has been

comparedwith an optimization based on the Modelica

model. Results found are compared with a real case of

an electric vehicle developed by general motors(GM

EV1). Results show an interesting reduction in com-

puting time of optimization without significantly af-

fecting the accuracy.

2 SURROGATE MODELLING

RSM and ANNs of RBF have been used in this study

due to their high accuracy and ease of use. The prin-

11

Hammadi M., Choley J., Penas O. and Riviere A..

Mechatronic System Optimization based on Surrogate Models - Application to an Electric Vehicle.

DOI: 10.5220/0004011900110016

In Proceedings of the 2nd International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH-2012),

pages 11-16

ISBN: 978-989-8565-20-4

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

cipal features of these two surrogate modelling tech-

niques are described in the following section.

2.1 Response Surface Method

As it has been mentioned, RSM uses a polynomial

formulation to approximate an exact function or a

simulation process F(X); where X is the input design

vector that can be represented by a matrix as:

X =

x

11

x

12

... x

1n

x

21

x

22

... x

2n

... ... ... ...

x

m1

x

m2

... x

mn

(1)

n and m are the number of design variables and the

number of sample points, respectively.

The approximation function F

a

(X) is therefore ex-

pressed as:

F

a

(X) = a+

n

∑

i=1

b

i

x

i

+

n

∑

i=1

c

i

x

2

i

+

n−1

∑

i=1

n

∑

j=i+1

d

ij

x

i

x

j

+ ...

(2)

Polynomial degree in RSM models is frequently less

than or equal to 2. Coefficients a, b

i

,c

i

,d

ij

,... are es-

timated by means of the least squares method.

2.2 Artificial Neural Network of Radial

Basis Functions Method

In an ANN of RBF, a response F(X) is approximated

with F

a

(X) as a linear combination of radial basis

functions Φ

j

.

F

a

(X) =

m

∑

j=1

ω

j

.Φ

j

(kX− µ

j

k) (3)

µ

j

are the centres of the radial functions and ω

j

are

the weighting coefficients that can be determined by

the least squares method.

2.3 Validating a Surrogate Model

The surrogate model F

a

(X) and the approximated

function F(X) are related as follows:

F

a

(X) = F(X) + E (4)

The validation of the surrogate model is performed

through the evaluation of the residual vector E. This

evaluation can be made by calculating several quanti-

ties such as the mean error (Em), the root mean square

error (Erms) and the maximum error (Emax), which

are respectively expressed as:

Em

i

=

|

m

∑

j=1

(F(x

ji

) − F

a

(x

ji

))|

m

; 1 ≤ i ≤ n (5)

Erms

i

=

s

m

∑

j=1

[F(x

ji

) − F

a

(x

ji

)]

2

m

; 1 ≤ i ≤ n (6)

Emax

i

= max

j

(|F(x

ji

)−F

a

(x

ji

)|); 1 ≤ i ≤ n;1 ≤ j ≤ m;

(7)

3 APPLICATION: ELECTRIC

VEHICLE OPTIMIZATION

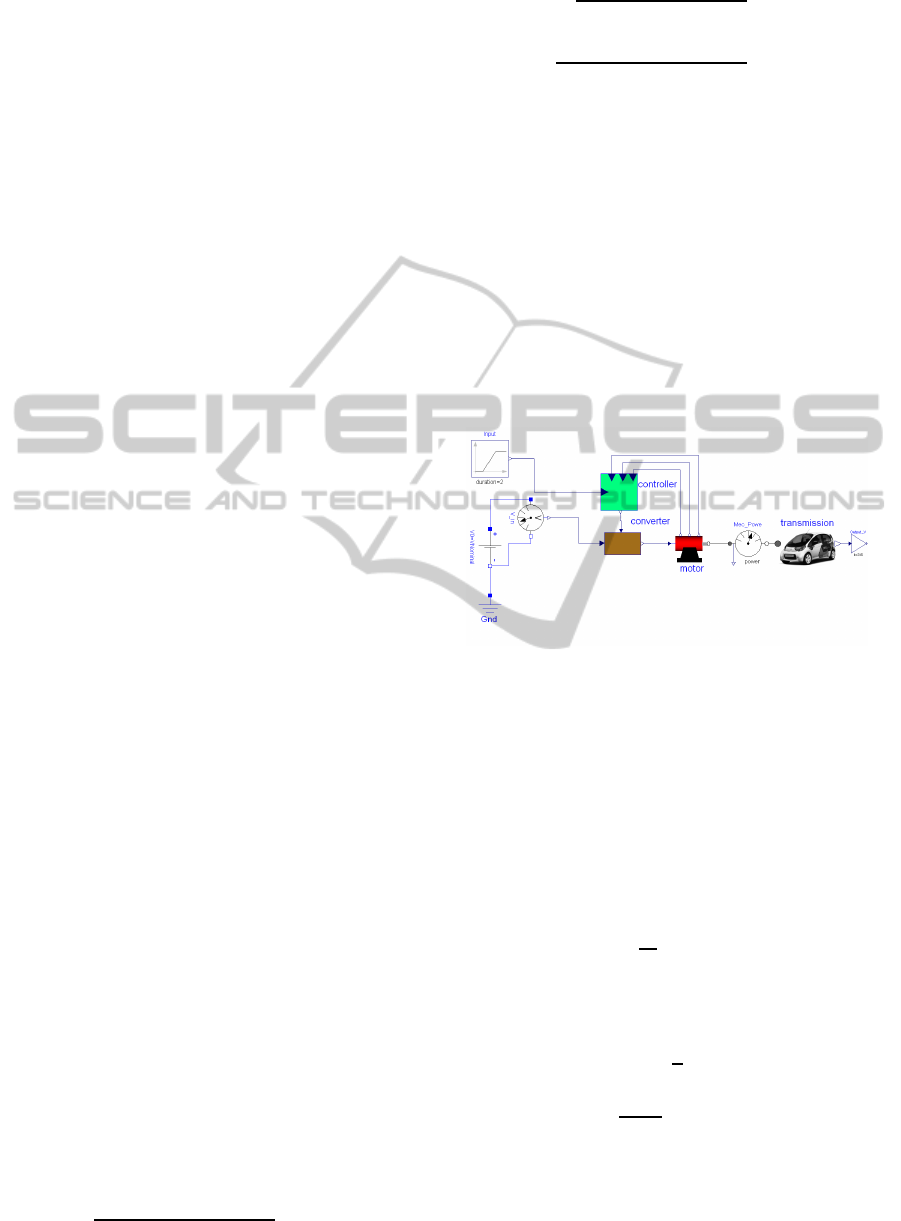

Figure 1 shows EV model which has been performed

using Modelica language. The EV is composed of a

battery (312 V), a power converter, a controller, an

electric motor and a transmission. The objective of

Battery

Accelerator pedal

Meca. Power sensor

Velocity output

w

i

v

Figure 1: Electric vehicle model (Modelica).

this study is to optimize the maximum electric power

Pe

Max

of the motor and the overall transmission gear

ratio G

r

. This optimization should respect a perfor-

mance constraint of acceleration to reach a velocity

V

10

= 100 km/h in 10 seconds. The electric motor is

modelled by the following equations (parameters and

variables are described in Tables 1 and 2).

k.ω

m

= V

emf

(8)

T

m

= k.i (9)

V

e

= L.

di

dt

+ R.i+V

emf

(10)

P

e

= V

e

.i (11)

The transmission model is defined by:

F

t

= M.g. f

r

+

1

2

.d

air

.C

D

.A

f

.v

2

+(M + I.

G

2

r

η

g

.r

2

).a+ M.g.sin(α)

(12)

P

m

= F

t

.v (13)

For the purpose of comparing the simulation results

with a real case, we chose values that match the elec-

tric vehicle EV1 of General Motors (GM), which are

SIMULTECH2012-2ndInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

12

Table 1: Electric vehicle parameters.

parameter value

Vehicle mass M(kg) 1540

Gravity acceleration g(m/s) 9.81

Coefficient of rolling resistance f

r

0.0048

Density of the air d

air

(kg/m

3

) 1.205

Drag coefficientC

D

0.19

Frontal area A

f

(m

2

) 1.8

Moment of inertia of the motor I(kg.m

2

) 0.03

Radius of the tyre r(m) 0.3

Slope angle α(rad) 0

Motor characteristics k(N.m/A) 0.2

Motor internal resistance R(Ω) 0.02

Motor inductance L(H) 0.01

Gear system efficiency η

g

0.95

Gear ratio G

r

opt.

Motor maximum power Pe

Max

(W) opt.

Motor maximum speed ω

M

(rad/s) const.

Motor critical speed ω

C

(rad/s) const.

published in (Larminie and Lowry, 2003). These pa-

rameters are given in Table 1. As indicated in Table 1,

the maximum electric power Pe

Max

and the gear ratio

of the system connecting the motor to the axle G

r

are

to be optimized. The maximum motor speed ω

M

and

the critical speed ω

C

are defined as constraints. ω

C

is the minimum speed above which the electric motor

powers the transmission efficiently. Table 2 gives the

variables which are dependant of time during simula-

tion. We introduce an optimizing objective variable

Table 2: Electric vehicle variables.

Motor rotational speed ω(rad/s)

Electromotive forces V

emf

(V)

Motor torque T

m

(N.m)

Electric current in motor i(A)

Voltage input V

e

(V)

Tractive effort F

t

(N)

Vehicle velocity v(m/s)

Vehicle acceleration a(m/s

2

)

Electric motor instant power P

e

(W)

Mechanical power P

m

(W)

Velocity at 10 seconds V

10

(km/h) ≈ 100km/h

V

10

(km/h) that represents the vehicle velocity at 10

seconds. The goal is to reach 100km/h. In the accel-

eration test, the controller and the power converter act

to power the electric motor with current in order to

provide a torque T

m

defined as:

T

m

= p

a

.Pe

max

/ω

C

(if ω ≤ ω

C

)

T

m

= p

a

.Pe

max

/ω

M

(if ω ≥ ω

M

)

T

m

= p

a

.Pe

max

/ω else

(14)

The percentage of acceleration (p

a

), during the accel-

eration test, reaches 100% in 2 seconds.

Based on the precedent mathematical formulation,

a Modelica model of the EV has been elaborated to be

simulated on an intervaltime of 30 seconds. The input

design vector X for the surrogate models is defined as:

X = [G

r

,Pe

Max

,ω

c

,ω

M

] (15)

The output variable is defined by V

10

which is deter-

mined by the Modelica simulations at every input de-

sign point.

The design space limits for X are defined by : 2 ≤

G

r

≤ 13; 90000 ≤ Pe

Max

≤ 110000; 600 ≤ ω

C

≤ 900;

1000 ≤ ω

C

≤ 1400.

The sample points of the design space domain

havebeen determined using the Design of Experiment

(DoE) technique with a Latin Hypercube method

(Mackay et al., 1979).

Automatic evaluation of the output variable has

been performed using iSIGHT software

1

, which has

been also used to elaborate both RSM and ANN of

RBF surrogate models.

The formulation of the optimization problem is de-

fined as follows:

min Pe

Max

, for 90000 ≤ Pe

Max

≤ 110000

min G

r

, for 2 ≤ G

r

≤ 13

max V

10

, for 98 ≤ V

10

≤ 101

1100 ≤ ω

M

≤ 1400

600 ≤ ω

C

≤ 900

(16)

To solve the non-linear multi-objective optimizing

problem, a sequential quadratic programming algo-

rithm called Non-Linear Programming by Quadratic

Lagrangian (NLPQL) (Schittkowski, 1985) has been

used. NLPQL is well suited for non-linear problems

with few objectives and continuous design space.

4 RESULTS AND DISCUSSION

In this paper, we have combined Modelica modelling

technique with surrogate model method for modelling

and optimization of an electric vehicle. Both RSM

and ANN of RBF surrogate models have been elabo-

rated.

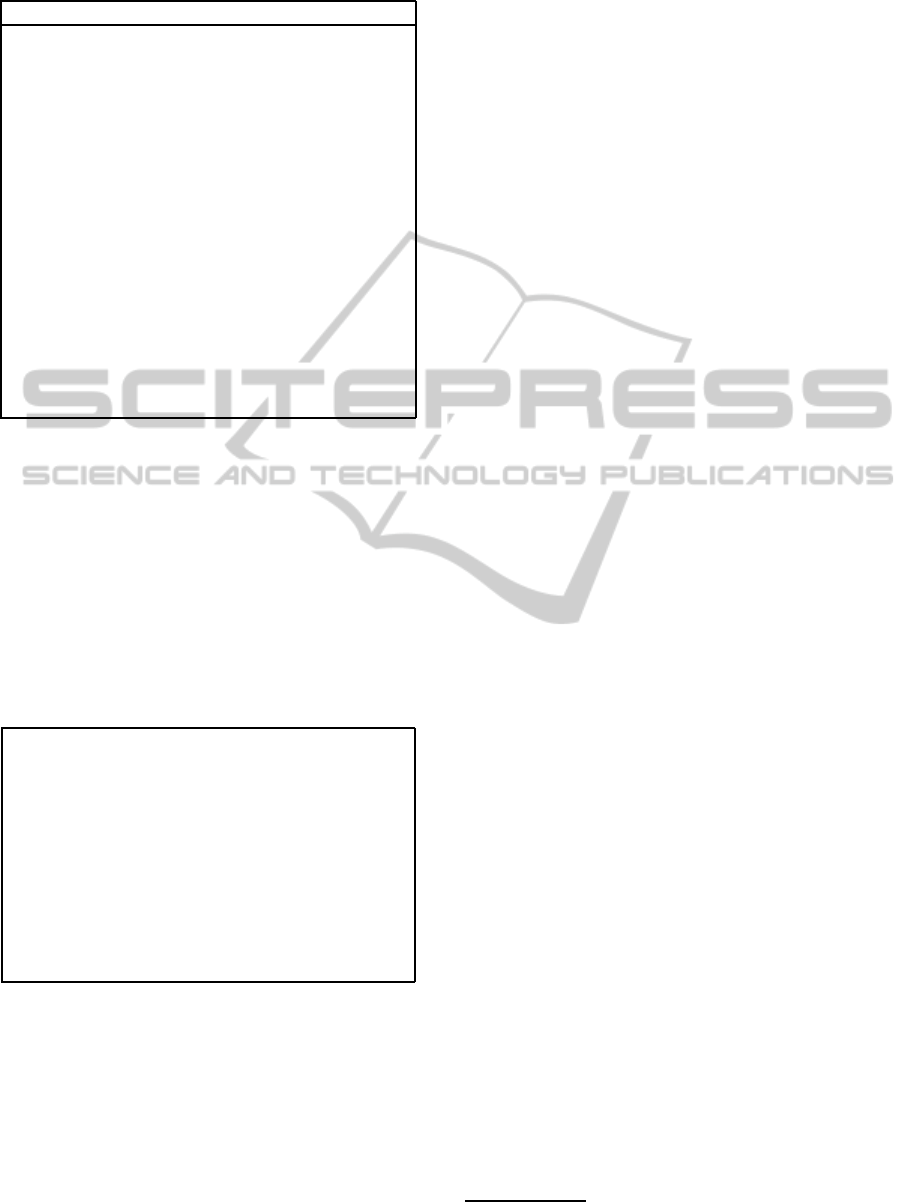

Table 3 gives the evaluation of residual vector E

for both RSM and ANN of RBF models.

Results show that ANN of RBF surrogate model

presents a better accuracy than RSM model. Figure

2 shows the distribution of residuals for the both sur-

rogate models. The results of validation prove the ca-

1

http://www.simulia.com/products/isight.html

MechatronicSystemOptimizationbasedonSurrogateModels

-ApplicationtoanElectricVehicle

13

Table 3: Residuals in RMS and RBF models.

Em (%) Erms (%) Emax (%)

RSM 4.1 5.4 11.9

RBF 2.1 2.8 7.1

actual

actual

residual

residual

RMS

RBF

Figure 2: Residual distribution of surrogate models (RSM

and RBF).

pacity of RBF models to approximate non linear re-

sponses. However, RSM model is simpler and eas-

ier to exchange between modelling platforms. In our

case, the algebraic model elaborated for the RSM sur-

rogate model is:

V

10

= − 81.29+ 19.G

r

+ 0.002.Pe

max

− 0.0847.ω

c

+ 0.0383.ω

M

− 1.1942.G

2

r

+ 0.007.G

r

.ω

c

+ 0.0003.G

r

.ω

M

(17)

Such simple mathematical model is useful for system

engineers at high abstraction level for system analysis

and decision making.

A response surface (V

10

= F(G

r

,Pe

Max

)) for the

RBF surrogate model is given by Figure 3. This re-

sponse surface shows that V

10

reaches a maximum,

which justifies the need to optimize V

10

.

Table 4 shows results of optimization based on

Figure 3: Response surface for ANN of RBF surrogate

model: V

10

= F(G

r

,Pe

Max

).

ANN of RBF surrogate model and a comparison

with an optimization based on the Modelica model.

Results show a good agreement between the two op-

Table 4: Optimization results.

RBF Modelica Err.(%)

Gr 9.15 10.1 9.4

Pe

Max

(kW) 102 98 5.2

V

10

(km/h) 99 100.7 1.7

ω

C

(rad/s) 828 780 6.1

ω

M

(rad/s) 1112 1154 3.6

Computing time(s) 4 332

timizations with an important gain of computing time

for the optimization based on the ANN of RBF surro-

gate model (4 seconds for RBF surrogate model and

332 seconds for Modelica model).

These results are close to those published for the

electric vehicle GM EV1. Indeed, for EV1 the electric

motor has a power Pe

Max

= 100kW, maximum speed

of 12000 rpm(ω

M

= 1256 rad/s), ω

C

= 600 rad/s

and a transmission gear ratio G

r

= 11 (Larminie and

Lowry, 2003). The choice of G

r

affects the perfor-

mance of acceleration but also has an influence on

other requirements such as the maximum vehicle ve-

locity, which has not been consideredin this optimiza-

tion. This explains the little difference between values

of G

r

found by optimization and the value chosen by

GM for EV1.

To verify the performance constraint of acceler-

ation test with the case of EV1 vehicle, we have

fixed the following values in the Modelica model:

Pe

Max

= 100kW; ω

C

= 600rad/s; ω

M

= 1256rad/s

and G

r

= 11.

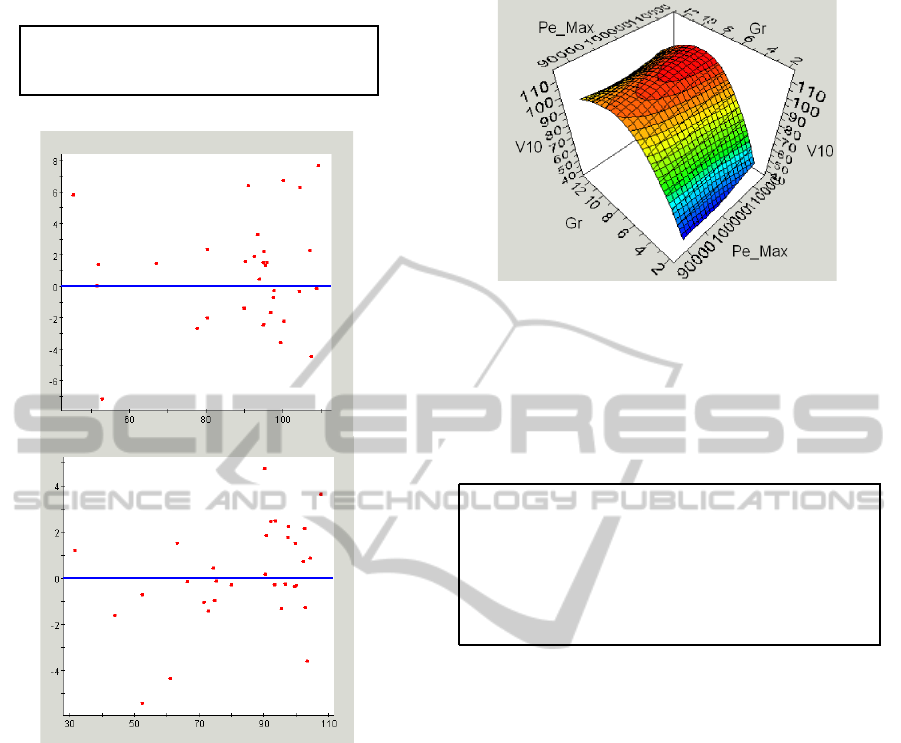

Figure 4 shows the input signal of pedal accelera-

tion and the output vehicle velocity. This figure con-

firms that the electric vehicle reaches a velocity of 100

km/h in 10 seconds.

SIMULTECH2012-2ndInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

14

0 5 10 15 20 25 30

-10

0

10

20

30

40

50

60

70

80

90

100

110

120

130

Time [s]

Input signal of acceleration (%)

V(km/h)

V(km/h)

Figure 4: Results of Modelica simulation during an acceler-

ation test of the EV (accelerator signal and vehicle velocity).

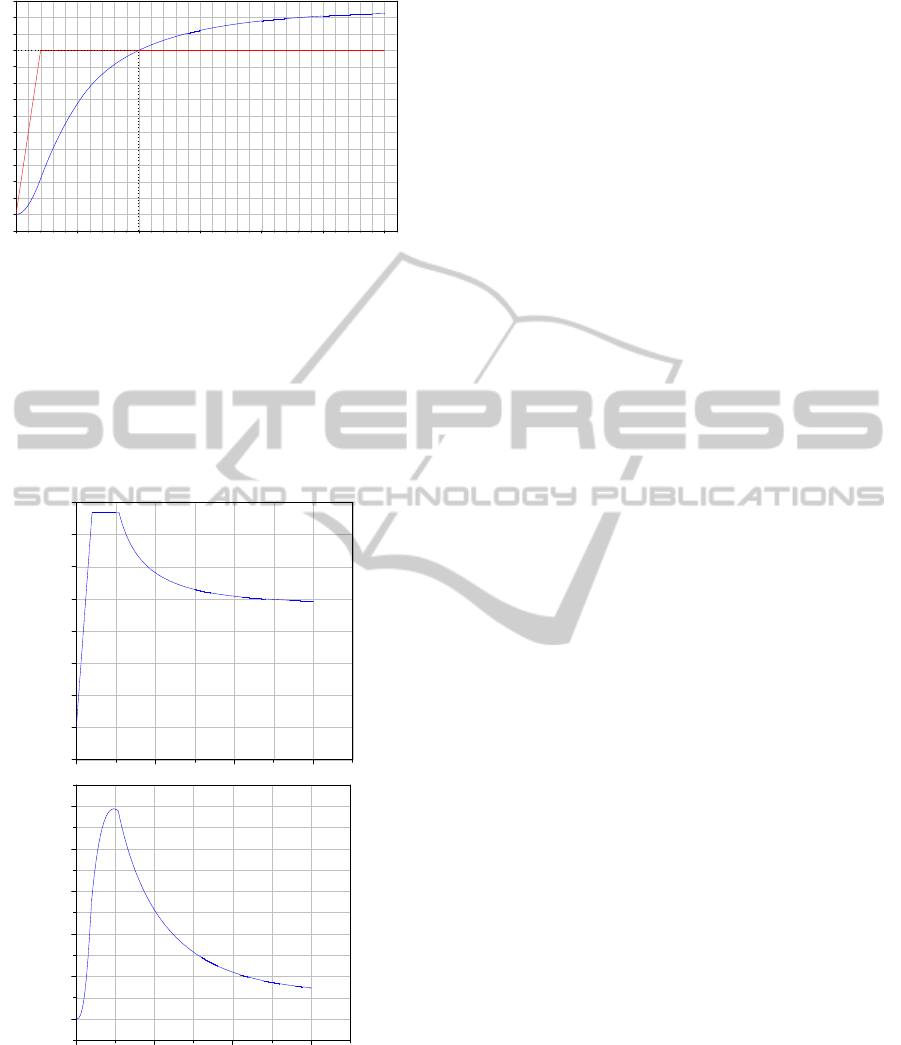

Figure 5 shows the variation of the electric current

and power during the performance test of accelera-

tion. The electric current reaches a maximum of 330

A and the electric power reaches a maximum of 98

kW. The value of the maximum current helps in the

choice of the battery. The simulation near the opti-

0 10 20 30

0E0

2E4

4E4

6E4

8E4

1E5

0 10 20 30

-50

0

50

100

150

200

250

300

350

Electric current i(A)

Electric power (W)

Time (s)

Time (s)

Figure 5: Electric current (top) and electric power (bottom)

during acceleration test of the EV.

mal solution is performed to verify the output design

variables. To improve the optimization accuracy, it

is possible to perform a second optimization on the

Modelica Model, but near the optimal solutions given

by the optimization based on the surrogate models. In

this case, surrogate models play a role of assistant in

optimization. This alternative has longer time of com-

puting but with a better precision, and in most cases

time will be shorter than direct optimization on Mod-

elica model without knowing the neighbourhoods of

the optimal solution.

5 CONCLUSIONS

An electric vehicle has been modelled using Model-

ica language. This model has been used as a support

to develop ANN of RBF and RSM surrogate mod-

els. A comparison of accuracy of the two surrogate

models has been made. It confirms that ANN of RBF

method is more accurate that RSM in the case of elec-

tric vehicle modelling. ANN of RBF surrogate model

has been used to optimize the electric motor and the

gear ratio of the EV. Results show the important gain

in computing time compared to direct optimization

based on the Modelica model, without affecting a lot

accuracy. Results of simulation in the case of acceler-

ation test have been compared to a real case of an EV

(GM EV1), and results show a good agreement with

those published.

Thus, combining Modelica and surrogate mod-

elling techniques is an effective method to reduce

design time and minimize complexity of optimizing

mechatronic systems.

REFERENCES

Blanning, R. (1975). The construction and implementation

of metamodels. Simulation, 24(6):177184.

Box, G. E. P. and Wilson, K. B. (1951). On the experi-

mental attainment of optimum conditions (with dis-

cussion). Journal of the Royal Statistical Society, Se-

ries B, 13:1–45.

Craig, K. (2009). Mechatronic system design. Technical

report, ASME Newsletter.

Elmqvist, H., Mattsson, S., and Otter, M. (1998). Modelica

: The new object-oriented modeling language. In The

12th European Simulation Multiconference, Manch-

ester, UK.

Hardy, R. L. (1971). Multiquadratic equations of topology

and other irregular surfaces. Journal of Geophysical

Research, 76:1905–1915.

Hopfield, J. (1982). Neural networks and physical sys-

tems with emergent collective computational abilities.

Proc. Natl. Acad. Sci., 79:2554–2558.

Krige, D. (1951). A statistical approach to some basic mine

valuation problems on the witwatersrand. Journal

of the Chemical, Metallurgical and Mining Society,

52:119–139.

MechatronicSystemOptimizationbasedonSurrogateModels

-ApplicationtoanElectricVehicle

15

Larminie, J. and Lowry, J. (2003). Electric Vehicle Technol-

ogy Explained. John Wiley & Sons.

Mackay, M. D., Beckman, R. J., and Conover, W. J. (1979).

A comparison of three methods for selecting values of

input variables in the analysis of output from a com-

puter code. Technometrics, 21:239–245.

Powel, M. (1985). Radial basis functions for multi-variable

interpolation: A review. In IMA Conference on Algo-

rithms for the Approximation of Functions and Data.

Schittkowski, K. (1985). Nlpql: a fortran subroutine solving

constrained nonlinear programming problems. Annals

of Operations Research, 5 (1-4):485–500.

SIMULTECH2012-2ndInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

16