From Farm to Fork: Traceability based on RFID

A Proposal for Complete Traceability in the Wine Sector

Iñigo Cuiñas, Isabel Expósito, José Antonio Gay-Fernández, Ana V. Alejos and Manuel G. Sánchez

Dept. Teoría do Sinal e Comunicacións, Universidade de Vigo, r. Maxwell, s/n 36310 Vigo, Spain

Keywords: RFID, Traceability, Tag, Wine.

Abstract: This paper highlights the objectives and activities of the European project “RFID from Farm to Fork”,

which is focused on the food industry traceability. The final goal is to extend the traceability information to

the final consumer, so these persons could feel the confidence on the food origin like our grandparents did

when they lived in a less globalised World. The activities of the project in a winery at Ribeiro denomination

of origin (Spain) at both vineyards (by means of wireless sensor networks) and the wine production process

(by RFID technology) are also presented along the paper, in order to show some of the project outcomes.

1 INTRODUCTION

European Regulation CE178 (Regulation EC

178/2002, 2002) stated that the capacity of tracing

and tracking a food along every stages of

production, transformation, and distribution is a key

question in the food sector. And it is important both

in terms of quality and safety, and in terms of

technology.

Thinking on quality and safety, the objective is

to recover the confidence of the consumers in the

products they purchase. That confidence on the food

products has evolved during last times, as the way

we acquire the food has changed a lot as our

societies advance and move their activity and

industrial sectors balance. Some years ago (and in

several countries not so many years ago), consumers

were very confidents on the origin of the food they

eat: people bought the food directly to the producer,

who belonged to a family known for generations; or

the number of intermediaries was very reduced, and

they were met by the buyers or neighbours, as well

as the distance covered by the product from its

origin (Cuiñas et al, 2011b). That time, people

bough wine bottles (or perhaps barrels) directly to

the winery, which was very confident. Perhaps the

buyers had previously sawn the farmers taking care

of the vineyards, or carrying the grapes, or washing

the barrels and bottles. Probably, the parents and

grandparents of these consumers had been clients of

the parents or grandparents of the winery holders!

Or, in the case they bought the wine in a shop, they

most likely met the seller for long ago, and also the

seller met the wine producer. And the same occurred

with meat, cheese, fish, and all the food they

consumed.

Besides, the transportation steps in the

production chain were short, or even there were no

transportation, as the local products dominated the

shops and markets. Possible problems related to

transport and delivery conditions (temperature,

conservation, etc.) had no space in the consumers

mind some years ago.

Currently, this situation has radically changed, as

our shopping habits are not the same of some years

ago. Nowadays, the small confident shop, or the

traditional market, is mainly reserved for special

days, for people looking for delicatessen groceries,

or for elderly that feel better maintaining their

traditional lifestyle. Most of the people generally

buy their food products in super or hypermarkets,

where the i.e. cheese is presented in clean and

aseptic plastic boxes, and labelled providing some

information. But we have lost the contact to the

farmer that took care of the cow or the sheep! So, we

receive a lot of information, but we do not have

confidence in the origin and in the process suffered

by the piece of cheese or meet, or the wine bottle,

we are buying. Something similar occurs with other

products.

Within this context of confidence loss, the price

of the product could be a determinant factor to

decide the acquisition of a product among the

265

Cuiñas I., Expósito I., Gay-Fernández J., V. Alejos A. and G. Sánchez M..

From Farm to Fork: Traceability based on RFID - A Proposal for Complete Traceability in the Wine Sector.

DOI: 10.5220/0004022302650270

In Proceedings of the International Conference on Signal Processing and Multimedia Applications and Wireless Information Networks and Systems

(WINSYS-2012), pages 265-270

ISBN: 978-989-8565-25-9

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

variety the supermarket offers us. This situation

gives an advantage to goods produced by large

companies, which could assure the quality along the

production chain, but also to those produced in

countries with lower salary costs or with less strict

sanitary laws, where they could manufacture at

lower costs.

Knowing the situation related to control the

quality and safety of the goods we buy for eating,

the high quality products developed by small

companies seem to be in disadvantages against these

products with less quality but also less price. And

this situation is becoming worse in an economic

crisis context. The chance for small and medium

enterprises (SME) in developed countries is the

incorporation of new technologies to focus their

activities to the production of added value products:

in terms of quality, in terms of origin guarantee, in

terms of deep information, or combining all of them.

An SME could not compete against non developed

country companies in price, but they could in quality

and origin control. Besides, these SME are in

disadvantage against large companies in terms of

assuring complete traceability.

The proposal of the European project “RFID

from Farm to Fork” (RFID-F2F) is focused on

SMEs and on a production sector: the food industry

in Europe. We have important salary costs, which

could be a problem to fight against producers from

other countries, but we also have strong experience

in origin guarantee systems as well as on sanitary

control of the food, which is assumed to be an

advantage in demonstrating the quality of the

product. The goal is to give this information to the

consumers… and, then, the consumers could select

this higher quality product! Large companies could

assure the traceability from the farm to the

consumer, as they control all the stages of the

business chain: farming, processing, transportation

and delivering. SME are only present in one or two

of these elements of the chain, so they need an

external umbrella to hold the traceability links

among the different agents.

2 THE “RFID-F2F” PROJECT

The project “RFID from Farm to Fork” is a CIP-

Pilot action involved within the 7th Frame Work of

the European Commission. The consortium is led by

the University of Wolverhampton (United

Kingdom), being the other members universities

from Spain (Vigo and Politécnica de Cartagena),

Slovenia (Ljubljana) and Italy (Salento), companies

(Treviso Tecnologia, Santer Reply, IDxS BVBA), or

institutions (EuroFIR, Institute of Food Research).

So, the represented European countries are five:

United Kingdom, Spain, Italy, Slovenia and

Belgium.

The action itself looks for the extension of radio

frequency identification (RFID) technologies

(Europe’s Information Society web page, 2011)

along the complete food supply chain: from the

farms where cows, fishes, sheep, grapes, etc. grow;

to the final consumer at supermarkets, including all

the intermediate stages: transport, manufacturing

processes, storage. The main objective is the use of

only one technology to perform a complete

traceability, recording data at each stage.

The final consumers could obtain different data

about the whole process experienced by the product

they are buying, just by moving the object (labelled

with a RFID tag) in the vicinity of a RFID reader,

which can be installed in the supermarket. An

alternative could be products provided by QR codes

or NFC tags that could be read from an application

at each personal smart phone.

The individual identification of a product allows

the software to obtain a complete traceability report

from a central database, and to bring the consumer

this information. Thus, the buyer could know what

happens with i.e. the wine at each instant of its

production, and also the conservation and

transportation conditions from the winery to the

shop, although each production stage would be

conducted by different agents.

Besides, each of the producers along the supply

chain could use the identification by radio frequency

to control its production and storage, and to know

some previous information of its ingredient matters.

The project involves both the design of the

complete system and its tests at different stages of

the chain: fishing companies, wine producers, food

transporters, and final users, in order to define the

actual interest of the system, its performance, and its

advantages and disadvantages (Swedberg, 2011).

After the tests or pilot experience, the consortium

will have valued information on the possibilities of

implementing RFID technologies for tracing and

tracking food products, as well as a deep evaluation

from the companies. This information would be

transferred to the European companies, and

indirectly to the whole society as a return of

investment of the project efforts.

The project will show the ability of RFID

technologies to make a return on investment for

SMEs in the food industry, as well as to provide

large information to the consumers (RFID-F2F web

WINSYS2012-InternationalConferenceonWirelessInformationNetworksandSystems

266

page, 2011). The opportunities for such a return on

investment arise from the increment of productivity

due to authentication, quality control, wastage

reduction, and energy optimization. Until now, these

advantages have been demonstrated in large

organizations, which have control over most or all of

the value chain and are in a position to make an end-

to-end investment. Vice versa, the “farm to fork”

traceability system has not yet been adopted by

independent SMEs, which only participate in one

stage of the value chain. By linking RFID and sensor

network technologies with an Europe wide database

as EuroFIR (EuroFIR web page), which can store

the exact history of any food product, SMEs will be

given the opportunity to optimize their own business

process to maximize return. In addition, a pan-union

resource will be created allowing producers to

demonstrate the quality and freshness of their

product, which will have the effect of increasing

consumer confidence as well as producer margins

(Cuiñas et al., 2011a)

It is known that the use of RFID in the food

chain has been previously tested, and it could

obviously provide a competitive advantage to the

involved companies (Gandino et al., 2007) (Pérez-

Aloe et al, 2007) (Fenu and Garau, 2009). However,

the radio propagation in presence of liquids presents

important differences compared to other more

friendly environments (Dobkin and Weigard, 2005).

Wine bottles, as an example, suffer from this

disadvantage, which needs to be evaluated

previously to incorporate this technology to the wine

industry.

3 THE RIBEIRO WINE PILOT

Denomination of origin is the name used in Spain to

define appellation regions: areas where a specific

product is controlled, taking care of the geographical

origin of the matters, the variety of the plants or

animals involved, the processes employed during the

elaboration of the food product, and also aspects as

bottling, labelling, storing and delivering. Among

various Spanish wine denominations of origin,

“Ribeiro” is a controlled wine producing region

located in Galicia, the North Western area of Spain.

In a pilot company, both WSN and RFID systems

have been deployed at the vineyards and winery,

respectively.

The selected environment to deploy the WSN is

a vineyard located in a mountain side from

Ribadavia. This vineyard is property of the winery

company.

The grapes involved in the production of Ribeiro

wines have to come from a strictly delimited area.

So, a requirement is to assure the location of the

vineyards by means of precise methods. The control

of different weather parameters is a must. The region

is very rainy in winter, but it is also very warm in

summer. The high humidity levels, in co-ordination

with the sunny time, could lead to problems with

plagues which are the main trouble during the

growing of the grapes. The installation of a wireless

sensor network (WSN) with adequate sensors help

the farmers to develop tailor made strategies to keep

the health of their plants.

During the wine manufacturing, at the winery, a

fast and comfortable way to control all the

movements of liquids among the different barrels,

across filters, cleaners, and other machines is one of

the claims of the winery managers. The proposal of

a RFID based traceability system, operated by a

handheld RFID reader appears to be a good solution

for this task. Water resistant RFID tags will be glued

to each machine and each barrel, and a three steps

standard event will be defined to describe the

movement of liquids from tank A (first step) to tank

B (second step) across the machine M (third step).

Some chemical data would be added manually to the

database at different stages along the manufacturing

of the wine.

The management of the bottle stock by

individually tagging the bottles appear to be more

complicated: there were some reading problems

around the bottles (Expósito and Cuiñas, 2011) and,

which is no less important, the cost of each

individual tag is still too large to be economical

assumable by the winery.

4 WIRELESS SENSOR

NETWORK AT THE

VINEYARDS

4.1 Network Description

A system following the ZigBee standard has been

installed during November 2010 last week, and it

has been working continuously since that date. A

coordinator node and six regular nodes compose the

communication facilities of the WSN. Different

sensors are connected to the regular nodes: soil

moisture and temperature, soil water content,

ambient temperature and humidity, leaf wetness,

solar radiation, and one weather station. The nodes

assure the communication of data among them and

FromFarmtoFork:TraceabilitybasedonRFID-AProposalforCompleteTraceabilityintheWineSector

267

towards the coordinator node. Each node collects

regularly the data from the sensors it has plugged in,

and it also transmits these data towards the

coordinator node. This coordinator connects to a

gateway to extract the information from the WSN to

a database installed at the winery or a management

place. The deployment and performance of such a

network has been widely described in (Gay-

Fernández and Cuiñas, 2011).

Prior to the deployment, large tests were

performed in controlled environments: both

propagation measurement campaigns and laboratory

experiments were carried out. The propagation

campaigns were focused in defining attenuation

models adapted for different environments (Gay-

Fernández and Cuiñas, 2011) (Gay-Fernández et al.,

2010). These studies allowed us to decide the

distances between nodes, which resulted to be up to

250 meters, depending on the environmental

conditions. The laboratory tests had the objective of

measuring the node energy consumption. We

observed that the nodes could work up to 4 months

without solar energy. As the individual solar panels

recharge the batteries during sunny (or even clear)

days, the node life would not be conditioned by the

energy supply.

4.2 Connectivity Aspects

The architecture of the global system is depicted at

Figure 1, involving the own WSN and the link to

systems placed out of the vineyards, where the data

has to be stored and then analyzed. The connectivity

at both stages has to be considered.

Figure 1: Global system architecture.

The connection among nodes is driven by the

ZigBee protocol, based on a mesh topology: if one

node fails, the network is automatically

reconfigured, looking for new paths to reach the

isolated nodes. During the operation of the WSN we

detected some connectivity fails due to the growing

foliage of the vineyard, but also due to the presence

of trees cutting the line of sight of the radio links.

The connection from the coordinator node to the

database could be more complicated, as external

power supply could be needed. The adopted solution

was the use of the GPRS network to extract the data

from the coordinator to the database via the Internet,

running tailor-made software on a local PC.

5 RFID DEPLOYMENT AT THE

WINERY

During the elaboration of the wine from the

harvested grapes, a lot of processes have to be

applied within the winery. The objective of the

RFID deployment at the winery is to register the

different traceability events suffered by the product,

in order to know what, where and when each event

occurs.

5.1 Hardware Definition

The hardware definition includes the selection of the

RFID tags and the RFID readers most adequate for

being employed along the wine production chain,

within the winery. The RFID activities begin at the

vineyard, where the use of a hand held reader to

read/write the tags at containers or trucks after the

harvesting appears to be better option than fixer

interrogator. Water resistant encapsulated tags

would be needed at this and other stages, in order to

survive the ambient conditions.

Figure 2: Tests on wine tanks.

At the winery, both hand held and fixed readers

will be needed: the hand held reader to read the tags

on grape containers, wine tanks and other

equipment/machines along the wine processing; and

the fixed readers will be mounted on conveyor belts,

forklifts and arcs at storage doors.

Previously to the selection of hardware and tags,

some tests have been performed, using tags glued on

WINSYS2012-InternationalConferenceonWirelessInformationNetworksandSystems

268

wine m

e

the test

o

tag ori

e

reading

differen

t

Figure

2

maximu

m

tag glue

d

in Tabl

e

suffered

Table 1:

R

the tag.

Orien

t

0º/90º

n

0º on

m

30º on

60º on

90º on

120º o

n

150º o

n

The

anechoi

c

readabil

i

b

ottles,

with up

measure

m

tailor-m

a

measure

m

read in (

E

Thes

p

ower a

f

wine is

l

empty b

o

b

ottle is

arc widt

h

5.2

S

The bu

s

definitio

RFID a

p

attack s

u

and the

n

catalog

u

p

roducti

o

consists

the tan

k

equipm

e

standar

d

Mos

t

supply

c

handhel

d

e

tallic tanks a

n

o

n metallic t

a

e

ntation, as

w

distances. W

e

t

encapsulat

e

2

depicts an

i

m

reading d

i

d

vertically o

n

e

1. This is

p

by the tag w

h

R

eading range

s

t

ation related to

t

n

on-metal surfac

m

etal surface

metal surface

metal surface

metal surface

n

metal surface

n

metal surface

second test

c

chamber. I

t

i

ty pattern ar

o

and two em

p

to seven R

F

m

ent system

a

de MATLA

B

m

ents aroun

d

E

xpósito and

e previous t

e

fter reading

a

l

ess than 25

%

o

ttle. Besides

,

modified in i

h

appears to

b

S

oftware

s

iness proces

s

n, which all

o

p

plication for

u

ch task was

t

n

to adapt a

l

u

e of standar

d

o

n chain fo

l

on moving a

k

/barrel A to

e

nt as filter

s

d

event could

b

t

of the dat

a

c

hain are goi

n

d

reade

r

, as it

n

d on bottles

.

a

nks was to

d

w

ell as to

d

e

used a han

d

e

d tags for

i

nstant of su

c

i

stance was

o

n

the tank, as

p

robably due

h

en it is horiz

o

s

as a function

o

t

he vertical

e

has been

m

t

consisted

o

o

und differen

t

p

ty used as

r

F

ID tag mod

e

was control

l

B

scripts. A

d

d

white wine

Cuiñas, 2011

e

sts indicates

a

RFID tag

o

%

of the same

,

the reading

p

ts shape, as

w

b

e reduced.

s

was the b

a

o

ws the pro

g

tracking sys

t

t

o define so

m

l

l the event

d

s. Many pro

c

l

low a sim

p

volume of wi

n

the B passi

n

s

, chutes, d

e

b

e easily defi

n

a

generated

a

n

g to be col

l

is more com

f

.

The objecti

v

d

etermine the

d

efine maxi

m

d

held reader

this experi

m

c

h campaign.

o

btained wit

h

could be che

c

to the curv

a

o

ntally locate

d

o

f the orientati

o

Reading range

162 cm / 160 cm

81 cm

78 cm

73 cm

53 cm

53 cm

73 cm

m

ade withi

n

o

n measuring

t

bottles (fou

r

r

eference) ta

g

e

ls. The com

p

l

ed by mean

d

escription o

f

bottles coul

d

)

.

that the rece

o

n a bottle fu

l

magnitude o

n

p

attern aroun

d

w

ell as the rea

d

a

sis for an e

g

ramming o

f

t

ems. The w

a

m

e standard e

v

d

efinition to

c

esses along

w

le scheme:

n

e (or must)

f

n

g through s

e

canters,... S

o

n

ed.

a

long wine

p

l

ected by usi

n

f

ortable to be

u

v

e of

best

m

um

and

m

ent.

The

h

the

c

ked

a

ture

d

.

o

n of

n

an

the

r

full

g

ged

p

lete

n

s of

f

the

d

be

e

ived

ll of

n

an

d

the

ding

e

vent

f

the

a

y to

v

ents

this

w

ine

they

f

rom

s

ome

o

, a

p

ilot

n

g a

u

sed

alo

n

ha

n

sep

p

ro

the

F

an

d

an

col

l

ma

n

ch

e

sel

e

cur

r

ob

s

htt

p

(th

e

Th

e

det

e

Th

e

p

h

o

thi

s

alo

n

inf

o

we

b

inf

o

of

t

n

g the winer

y

n

d held appli

c

arate forms

duction proc

e

initial displa

y

F

igure 3: Displ

a

After the rea

d

d

intermediat

e

EPCIS co

m

l

ected data.

n

agement op

e

mical analysi

Final consu

m

e

cting goods

r

ent grocerie

s

s

erved at th

e

p

://www.yout

u

Some produ

c

e

RFID versi

o

e

consumers

e

ct the NFC

s

e

informatio

n

o

ne to the RF

I

s

portal is us

e

n

g the bus

o

rmation, wh

i

b

page. Thu

s

o

rmation on t

h

t

he wine bottl

e

y

, at different

c

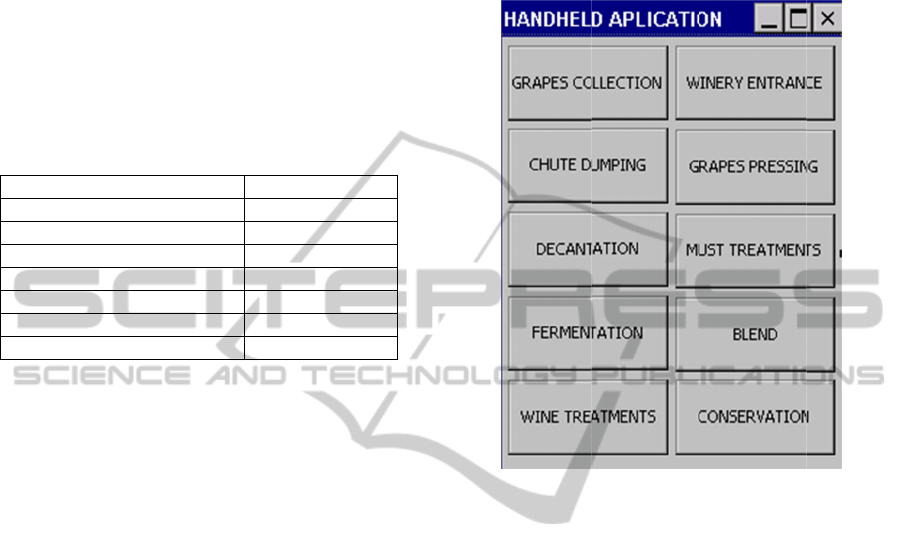

ation has b

e

depending

e

ss to be perf

o

y

of such appl

i

a

y of the hand

h

d

ing of origi

n

e

action, the

R

m

pliant XM

L

Extra info

r

e

ration coul

d

s

data).

m

ers would

h

among a la

r

shops or su

p

e

demonstrat

i

u

be.com/watc

c

ts could be l

a

o

n for low fre

q

would use

t

s

ignals or to

i

n

at such ta

g

I

D-F2F web s

e

e

d to ask the

d

i

ness chain

i

ch is elabora

t

, final cons

u

h

e different s

t

e

they have o

n

operation ar

e

e

en program

m

on the ste

p

o

rmed. Figur

e

ication.

h

eld reader app

l

n

and destinat

i

R

FID reader

L

file conta

i

rmation for

d

also be a

d

h

ave the pos

s

r

ge catalogu

e

p

ermarkets, a

s

i

ve project

v

c

h?v=lmvHo

h

a

belled with

N

q

uencies) or

Q

t

heir smart

p

interpret the

Q

g

s would co

n

erver. The co

d

database at e

a

for its tr

a

a

ted and pres

e

u

mers obtain

t

ages of the p

r

n

their hands.

e

as. So, a

m

ed with

p

of the

e

3 shows

l

ication.

i

on tanks,

generates

i

ning the

internal

d

ded (e.g.

s

ibility of

e

at their

s

could be

v

ideo a

t

:

m

3SYA.

N

FC tags

Q

R codes.

p

hones to

Q

R code.

n

nect the

d

e sent to

a

ch agent

a

ceability

e

nted as a

complete

r

oduction

FromFarmtoFork:TraceabilitybasedonRFID-AProposalforCompleteTraceabilityintheWineSector

269

6 CONCLUSIONS

The European project “RFID from Farm to Fork”

activities and objectives have been presented along

this paper, as an application of RFID technologies to

provide traceability along the complete food chain,

from producers to final consumers.

A pilot experience developed in a winery at

Ribeiro area, in Spain, has been also presented, in

order to show a specific installation. Previously to

this development, various tests have been carried out

in both WSN and RFID technologies, and their

results have been also commented.

Related to WSN deployment, propagation

models were defined from the results of large

measurement campaigns. They were useful to define

the distances between nodes in the network, and to

install the complete system.

The readability of RFID tags on metallic tanks

and on full wine bottles has also analyzed, and the

results were valid to determine the better allocation

of tags on such elements. The read distance when

the tag is glued on a metallic tank is reduced in more

than 50% compared to non metallic. And this

reduction also depends on the orientation the tag is

installed.

Related to the readability patterns around wine

bottles, the effect of the wine is very significant in

terms of received power and in terms of the shape of

the pattern. When the bottle is empty, the RFID tag

could be read all around, at enough power levels.

When the bottle is full of wine, the received power

from the tag is reduced significantly, whereas there

are various directions at which it is not possible to

read the tag: the shape of the readability patterns

change.

ACKNOWLEDGEMENTS

This work has been supported by the European

Commission (CIP-Pilot Actions), under the project

“RFID from Farm to Fork”, grant agreement number

250444. The authors would like to thank the winery

“Vitivinícola do Ribeiro” for their enthusiastic help

along the pilot project.

REFERENCES

Cuiñas, I., Catarinucci, L., Trebar, M., “RFID from Farm

to Fork: traceability along the complete food chain”,

Progress In Electromagnetic Research Symposium,

PIERS 2011, Marrakesh (Morocco), 2011.

Cuiñas, I., Expósito, I., Gay-Fernández, J. A., “The “RFID

from Farm to Fork” project proposal for food industry

traceability. A wine pilot example”, 5as Jornadas

Cientícias sobre RFID, Tarragona (Spain), 2011.

Dobkin, D. M., Weigand, S. M., “Environmental effects

on RFID tag antennas” IEEE MTT-S International

Microwave Symposium Digest, 2005.

EuroFIR (European Food Information Resource) web

page, http://www.eurofir.net

Europe’s Information Society web page, Thematic Portal,

http://ec.europa.eu/information_society/apps/projects/f

actsheet/index.cfm?project_ref=250444.

Expósito, I., Cuiñas, I., “RFID tag readability around

white wine bottles”, 19th International Conference on

Software Telecommunications and Computer

Networks, SoftCOM 2011, Split (Croatia), 2011.

Fenu, G., Garau, P., “RFID- based supply chain

traceability system”, 35th Annual Conference of IEEE

Industrial Electronics, IECON '09, pp. 2672-2677,

2009.

Gandino, F., Montrucchio, B., Rebaudengo, M., Sanchez,

E.R., “Analysis of an RFID-based Information System

for Tracking and Tracing in an Agri-Food chain”, 1st

Annual RFID Eurasia, 2007.

Gay-Fernandez, J. A., Garcia Sanchez, M., Cuiñas, I.,

Alejos, A. V., Sánchez, J. G. and Miranda-Sierra, J.

L., 2010, “Propagation Analysis and Deployment of a

Wireless Sensor Network in a Forest”, Progress In

Electromagnetics Research, PIER 106, pp. 121-145.

Gay-Fernández, J. A., Cuiñas, I., “Deployment of a

wireless sensor network in a vineyard”, International

Conference on Wireless Information Networks and

Systems, WINSYS 2011, Seville (Spain), 2011.

Perez-Aloe, R., Valverde, J. M., Lara, A., Carrillo, J. M.,

Roa, I., Gonzalez, J., “Application of RFID tags for

the overall traceability of products in cheese

industries”, 1st Annual RFID Eurasia 2007.

Regulation (EC) No 178/2002 of the European Parliament

and the Council of 28 January 2002, “laying down the

general principles and requirements of food law,

establishing the European Food Safety Authority and

laying down procedures in matters of food safety”,

Official Journal of the European Communities, 1

February 2002.

RFID-F2F (RFID From Farm to Fork) project web page,

http://www.rfid-f2f.eu/

Swedberg, C., “Ambitious European Project Traces Food

from Farm to Fork”, RFID Journal, article 8913,

October, 28

th

2011.

WINSYS2012-InternationalConferenceonWirelessInformationNetworksandSystems

270