Distributed Control System for Crystal Growth

A. E. Kokh, V. A. Vlezko and K. A. Kokh

Institute of Geology and Mineralogy, SB RAS, 3, Koptyuga Ave., 630090, Novosibirsk, Russia

Keywords: Crystal Growth Control System, LBO Crystal, Controller, Load-commutator, Thermal Field Symmetry.

Abstract: Distributed system for control over the crystal growth process is presented. The main advantages of the

system are its low cost, ability to recover after power failure, an application of standard ISaGRAF software

environment and available low-power PC-Controller. One of the option of the system is an ability to control

symmetry and dynamics of the heat filed. This option is the key factor for the progress in growth of

nonlinear optical LBO crystal.

1 INTRODUCTION

Crystal growth systems with various control loops

(rotating, pulling, weighting of the crystal etc.) have

been developed for industry since the middle of last

century. Now there are a lot of commercially

available growth stations with modern control

systems (CS). Our approach in elaboration of CS is

based on ability to nonuniformly heat the

crystallization domain and therefore to apply

nonsymmetric stationary or dynamic heat field. This

provides additional parameters to control over heat-

mass transfer processes which are always have been

considered as a key factor in the growth of high

quality crystal.

The base of our CS is a PC-controller I-7188

and remote input-output modules of I-7000 series

(produced by ICP DAS Company). The use of the

modules of I-7000 series provides quite cost-

effective reliability. They are not unique. A lot of

similar modules are produced by other companies,

for instance by Advantech. Also we have designed

home-made modules with controllers of crystal

rotation and pulling, as well as load-commutator for

control of the heat field.

2 HARDWARE

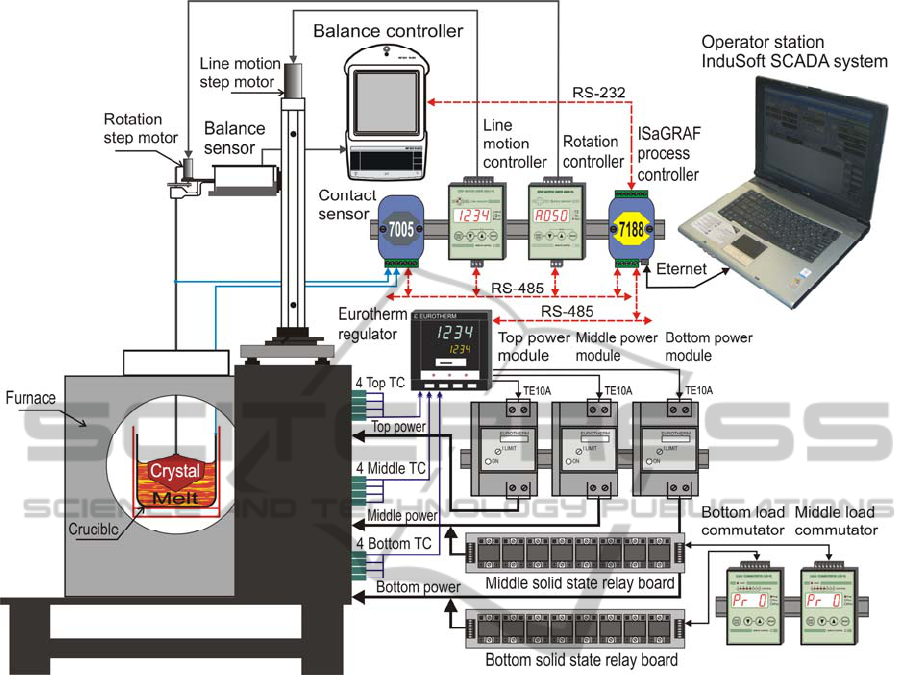

Here we consider one example of operating CS for

the growth of nonlinear crystal LBO (LiB

3

O

5

). Fig. 1

presents the scheme of the growth station which

consists of three-zone heating furnace, balance

sensor, pulling and rotation drives, contact-meter

and main controller I-7188EG. Temperature control

is realized by three-zone Eurotherm reglator through

the separated RS-485 bus. For that reason additional

serial ports for I-7188EG were added by introducing

mezzanine board X511. A main feature of the CS is

the presence of the load-commutators which may

switch segments of the heating zones through solid

state relays according to the program. The feedback

signal for thermoregulator is provided by four

parallely connected thermocouples placed around

heating zone. This was found to be enough for stable

regulation of temperature in the wide range of

periods of switching (1 sec - 20 min).

3 SOFTWARE

Each growth station with individual IP-address has

its own controller with onboard DOS-compatible

“Mini OS7”. In that way any standard programming

language may be used to realize a project. In our

case we were concentrated on the logic of crystal

growth process, so the I-7188EG controller with

built-in ISaGRAF 3.xx system was used. ISaGRAF

system implements the following functions: data

reading signal preprocessing, realization of control

algorithms, communication between modules and

HOST computer.

A program loaded in the controller is performed

with cycle 0.2 sec. Crystal growth parameters are

slow and have a very wide dynamic range. For

instance, the growth speed may vary from 0.001 to

hundreds of grams/hour.

While a parameter is low-rate changing, the

controller specifies some time interval and calculates

202

E. Kokh A., A. Vlezko V. and A. Kokh K..

Distributed Control System for Crystal Growth.

DOI: 10.5220/0004033902020205

In Proceedings of the 9th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2012), pages 202-205

ISBN: 978-989-8565-21-1

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

Figure 1: LBO growth station with ISaGRAF process controller and SCADA system.

the value. And on the contrary, if parameter changes

very fast, the controller defines how often it will

change the value.

Fig. 2 shows a fragment of FBD program of

process parameters calculation. Output value of

every parameter is the function of crystal length. So

the first part of the algorithm consists in calculation

of length increment as a function of growth speed.

After that other growth parameters are specified as a

function of the increment. In that way limitation of

input/output numbers (not more than 32) for each

block of FBD scheme is avoided.

Crystal growth process may take place up to

several months. During this time there may be some

imperfection in electrical supply while UPS blocks

do not totally protect the system. Or sometimes it is

necessary to reconfigure or even replace some

blocks of the CS. In that view survivability and

reliability of the system is very important. In other

words the controller should contain some algorithms

to restore values of all critical parameters and to

recover the CS after a power failure. It is done with

the current values saved in a nonvolatile RAM while

setpoints and other seldom changing parameters are

saved into EEPROM and are read from there in the

case of system reload with the symptom of

breakdown. The same concept of parameters restore

after breakdown or power off was realized for our

periphery modules like step motor drive MD1-VL

which may be used offline.

A SCADA program InduSoft Web Studio is used

as the program of upper level because of low price

and the presence of Modbus driver for direct

communication between ISaGRAF project and

SCADA. The last reason is also important since

many programs use various OPC-servers which slow

down the system.

A main purpose of SCADA-program is to

interface with operator and visualization of

parameters and trends. The program has 1500

variables which is quite enough for CS of one

growth station. On the other hand, all calculation

function, storage and initialization of variables, and

restore of data after breakdown are implemented in

the main controller.

DistributedControlSystemforCrystalGrowth

203

Figure 2: Block diagram of the piecewise-linear crystal

geometry master.

4 USE OF THE CONTROL

SYSTEM. EXAMPLE OF LBO

CRYSTALS GROWTH BY

KYROPOULOS METHOD

Kiropoulos method consists in the growth on seed

crystal slightly dipped in the melt (or the melt-

solution). The growth proceeds towards the melt by

a smooth decrease in temperature at small

temperature gradients, which makes it possible to

grow high quality crystals. This method is widely

used for production of large sapphire crystals of any

crystallographic orientation, with an extremely low

dislocation density of less than 1000 cm

-2

.

LBO single crystal is a well-known material used

in nonlinear optics (NLO) for the last 20 years. Due

to good operating performance and relatively high

nonlinear coefficients LBO crystals are widely used

for frequency conversion in the visible and near UV

regions. These crystals are of special interest now

since they may be used in the laser systems of

extremal intensity (http://www.extreme-light-

infrastructure.eu/). Growth from molybdenum oxide

fluxes has brought a considerable progress in LBO

growth technology but the crystals with large high

quality parts were still unavailable until recent time.

LBO growth furnace has 3 heating zones. The

bottom and middle zones are composed of 8 heating

elements. Their connection is realized through two

separate load commutators governed by the control

system. Each one allows to simultaneously switch

on any of the heating elements in any sequence and

for any time period (Kokh et al., 2009).

First advantage of such a system is the possibility

of intensive but noncontact mixing. It is very

important since homogeneity of badly-miscible LBO

and the flux seems to be a key factor to large size

and high-quality crystal growth. The melt

homogenization procedure is realized by prolonged

period between switchings (more than 15 minutes).

In this case, extremely high radial temperature

gradient produces intensified thermogravitational

convection. A convective pattern at the surface of

the melt (Fig. 3) clearly indicates a direction of the

prevalent flow which will be turned relative to the

crucible after next switching of the heaters.

Figure 3: Convective flows on the top of the melt-solution

during homogenization procedure.

In order to grow larger crystals the direct scale

up of the setup faces some serious problems. For

example, for large crucibles (>100 mm in diameter)

it is difficult to maintain axissymmetric heating and

hence to fix a coldest point on the melt surface at the

geometric center of the crucible. Otherwise distorted

heat field can lead to highly asymmetric crystal

growth which results in the formation of defects.

The CS allows to set the corrections to switching

time for any group of the heaters. Seeding process is

carried out in quazi – stable heat field when period

of switching is ~3 sec. In that case no temperature

oscillations are observed in the melt. Usually our

furnaces need delay corrections less than 0.5 sec for

some heaters to adjust surface temperature

distribution to axissymmetric one. This process is

controlled by observing the movement of small

pieces of LBO (~ 1-2 mm) thrown onto the melt

surface at a temperature of 10-15 degrees higher

than crystallization temperature (Kokh et al., 2010).

Step-by-step adjusting of time for each pair of

heaters is done until a crystal piece stops to move

and dissolves right in the crucible center.

ICINCO2012-9thInternationalConferenceonInformaticsinControl,AutomationandRobotics

204

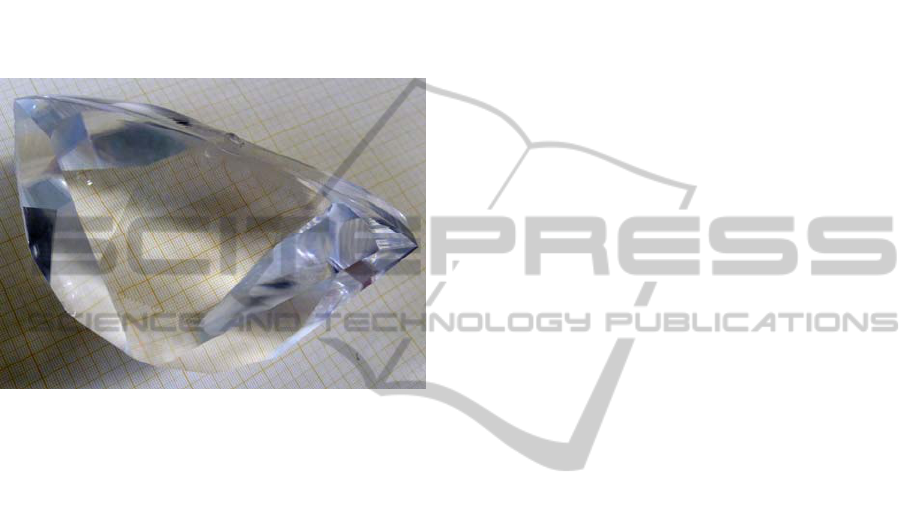

Large period of switching may result in the

considerable temperature oscillations (~10˚C) in

crystallization region. Until recently such conditions

were considered as unfavorable for crystallization

process. However our results have proved this

opinion to be incorrect (Kokh et al., 2012). The

progress of LBO growth under nonstable

temperature regime has resulted in the crystals (Fig.

4) suitable for fabrication of world largest 65 mm in

diameter optical elements for high energy laser

applications (Mennerat et al., 2011).

Figure 4: LBO crystal suitable for production of Ø65mm

nonlinear optical element; weight: 1290 g, dimensions:

149x131x83 mm.

5 CONCLUSIONS

Elaborated distributed control system provides

reliable growth process. One of the options of the

system is an ability to control symmetry and

dynamics of the heat field. By the example of LBO

crystals, this option was shown to contribute in the

progress of growth technology.

ACKNOWLEDGEMENTS

Financial support form grants RFBR 11-02-12156-

ofi_m and 11-02-12164-ofi_m is highly

acknowledged.

REFERENCES

Kokh A. E., Vlezko V. A., Kokh K. A. Control over the

symmetry of the heat field in the station for growing

LBO crystals by the Kyropoulos method. Instr. Exp.

Techn, 2009, v.52, 747-751

Kokh A., Kononova N., Mennerat G., Villeval Ph., Durst

S., Lupinski D., Vlezko V., Kokh K. Growth of high

quality large size LBO crystals for high energy second

harmonic generation // J. Crystal Growth. 2010,

Vol.312, N10, p. 1774-1778.

Kokh A., Vlezko V., Kokh K., Kononova N., Villeval Ph.,

Lupinski D. Dynamic control over the heat field

during LBO crystal growth by high temperature

solution method. J Crystal Growth. 2012,

10.1016/j.jcrysgro.2011.11.050

Mennerat G., Bonville O., Le Garrec B., Villeval Ph.,

Durst S., Lupinski D., Kokh A., Kononova N., Vlezko

V., Kokh K. Frequency doubling and tripling for

future fusion drivers. Abstracts of the OSA meeting of

50-year jubilee of Nonlinear Optics, Hawaii, July

2011.

http://www.extreme-light-infrastructure.eu/

DistributedControlSystemforCrystalGrowth

205