Development of Mobile Research Robot

A. Baums, A. Gordjusins and G. Kanonirs

Institute of Electronic and Computer Science, Dzerbenes street 14, Riga, Latvia

Keywords: Research Robot, Real Time System, Timelines, TUF, Physical Model.

Abstract: For new autonomous mobile robot design, the real time problem analysis at different periods of robot

activity phases is made. The robot sensor and actuator cluster structure is used. At first the robot is

determined as a hard real time system when all phases defined and executed sequentially are in hard

deadlines. At second for the robot activity with hard and soft deadline execution phases is proposed using of

the time/utility function (TUF). For time and energy consumption estimation, the flexible robot physical

model is developed and used. Wireless technology is proposed for new autonomous mobile robot design.

1 INTRODUCTION

New mobile research robot development for

education and training purpose is urgent, despite

now there are different ready-made research robots

(Adept mobilerobots, 2011a; b), (Segway Robotics,

2012) which were purchased primarily by

researchers. Before new commercial research of

autonomous robot for hard and unstructured

environment design began, there were different

significant problems necessary to solve: position

estimation, obstacle avoidance, motion trajectory

planning and map building, timely and energy

consumption estimation (Choset et al., 2005).

Historically the term “autonomous mobile

unmanned robot” implies a real time system (RTS).

Often systems are estimated and classified as hard,

firm or soft RTS. The required deadline is the

decisive subdivide factor. But it is the determined

parameter of application and environment. When the

deadline failure threatens human life, the hard

design system is obligatory. In other kinds of

applications the permissible complete task execution

time (ET) can be firm but at the same activity

(phase) the RTS can be soft. The hard system can be

considered as a special case of soft RTS.

Generalized timeliness calculation meter

time/utility function (TUF) was proposed by Jensen

in 1976. TUF is a generalization of the deadline

constraint, specifying the utility to the system

resulting from the completion of an activity as a

function of its completion time (Ravindran et al.,

2005). When activity time constraints are expressed

with TUFs, the scheduling optimality criteria are

based on accrued activity utility - e.g., maximizing

the sum of the activities’ attained utilities, assuring

satisfaction of lower bounds on activities’ maximal

utilities. Such criteria are called Utility Accrual

(UA) criteria. It can be especially useful for outdoor

robot control in environment with dynamically

uncertain properties (Balli et al., 2007). An energy-

efficient, utility accrual, realtime scheduling

algorithm called the Resource-constrained Accrual

Algorithm proposed by Wu, Ravindran and Jensen

(2007). Other optimization algorithm called Profit

and penalty aware scheduling algorithm proposed by

Li et al. (2012).

2 TIMELINESS ESTIMATION OF

AUTONOMOUS MOBILE

UNMANNED ROBOT

Autonomous mobile unmanned robots’ general

structure includes: one central unit CU (main

processor), clusters of sensors Sn and actuators Ac

with interface nodes. All nodes and information

lines can be characterized with some real time

properties (time delay, throughput, security).

Activity execution phases for an unmanned

outdoor Robot is represented by N+1 main finite

automata states and different kinds of execution time

intervals T

0

, T

1

,… T

k

, …T

N

. Phases k can include

particular phases or a number of N

k

states and

execution cycles or activities t

kw

. Execution cycles

329

Baums A., Gordjusins A. and Kanonirs G..

Development of Mobile Research Robot.

DOI: 10.5220/0004044303290332

In Proceedings of the 9th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2012), pages 329-332

ISBN: 978-989-8565-21-1

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

can be performed concurrently or sequentially.

Information from different sensors can be obtained

simultaneously. Concurrency of mechanical actuator

and electronic operation execution is especially

important for optimal real time robot design.

At phase zero (time interval T

0

) the registers of

nods are charged with data from the main program.

This program can be hold in ROM of central unit or

loaded using wireless connection from user data

base. This zero phase is not necessary to enclose in

the autonomous mobile outdoor robot real time

characteristic estimation.

Phase one (time interval T

1

) – the environment

estimation and building the route map:

- T

11

the robot start point estimation using GPS

(t

1gp

), data acquisition by video camera module at

start position (t

1vi

, data acquisition from digital

compass (t

1cm

) and data acquisition from infrared

optical short range distance meter (t

1sd

) and infrared

optical long range distance meter (t

1ld

), start point

coordinate estimation (t

1cu

) using CU.

Data acquisition from GPS, digital compass and

distance sensors can be executed simultaneously in

time t

1vi

required to complete data acquisition by

video camera module. Then start point coordinate

estimation in time T

11

is t

1vi

and t

1cu

determined

- T

12

is a sum of times required to turn camera in

horizontal (t

1th

) and vertical (t

1tv

) directions to search

for the first nearest object, using servomotors and

image acquisition time getting information about

recognized objects t

1vi.

This process repeats as much

times N

1tm

as needed to investigate view sector for

the object. T

12

is N

1tm

,t

1th

, t

1tv

and t

1vi

determined.

At the optimal conditions N

1tm

=1

- T

1

route map calculation (t

1cum

) by central unit

using main algorithm and data from GPS, digital

compass, video camera module and distance sensors.

T

1

= T

11

+T

12

+ t

1cum

(1)

Phase two (time interval T

2

) - robot turning to

the required direction actuating both left (t

2trl

) and

right (t

2trr

) motors. Motors are actuated

simultaneously, it can be accepted that their

operation time is equal T

2

= t

2trl

= t

2trr

Phase three (time interval T

3

) – robot movement

by calculated route map to the first, second, or N

st

objects, actuating motor drivers, distance encoders,

video camera module and compass:

- image acquisition by video camera module (t

3vi

)

- driving and steering (t

3ds

) to the object reading

data from distance l encoders

and required direction

α from compass. T

3

is N

st

,t

3ds

, t

3vi

determined.

Phase four (time interval T

4

) –investigation of

object parameters using video camera module (t

4vi

)

and central unit program (t

4cuo

). T

4

is t

4vi

and t

4cuo

determined.

Phase five (time interval T

5

) – obstacle

avoidance: obstacle determination using video

camera (t

5vi

), avoidance decision taking by CU

(t

5cuob

) (jump over or go around), obstacle avoidance

realization (t

5rob

). T

5

is t

5vi

, t

5cuob,

t

5rob

determined.

For the robot real time characteristics’

investigation, it is suitable to select some application

specific limited route map and time interval T

1

for

the calculation and select it as the deadline.

A deadline can be determined for each execution

phase. When sequence of all of the phases can be

determined in WCET

i

(worst-case execution time) -

the robot can be determined as hard RTS.

T

1

= T

1

+ T

2

+ T

4

+ T

5

=∑

i

5

WCET

i

= D

h

(2)

To compare and estimate different robot

realization structures using (1) it is necessary to

select the same numbers of N

1tm

and N

st

.

For sophisticated autonomous mobile robot

timelines with task completion slack time, start time

and soft deadlines utility accrual UA approach can

be used. The Utility (U) depends on the activity’s

completion time for phases T

i

and particular cycles

t

k

. These soft time constraints are subject to

optimality criteria such as completing all time-

constrained activities as close as possible to their

optimal completion time — so as to yield maximal

collective utility. Time/utility functions is a

generalization of the deadline constraint, specifies

the utility to the system resulting from the

completion of activity as a function of its completion

time.

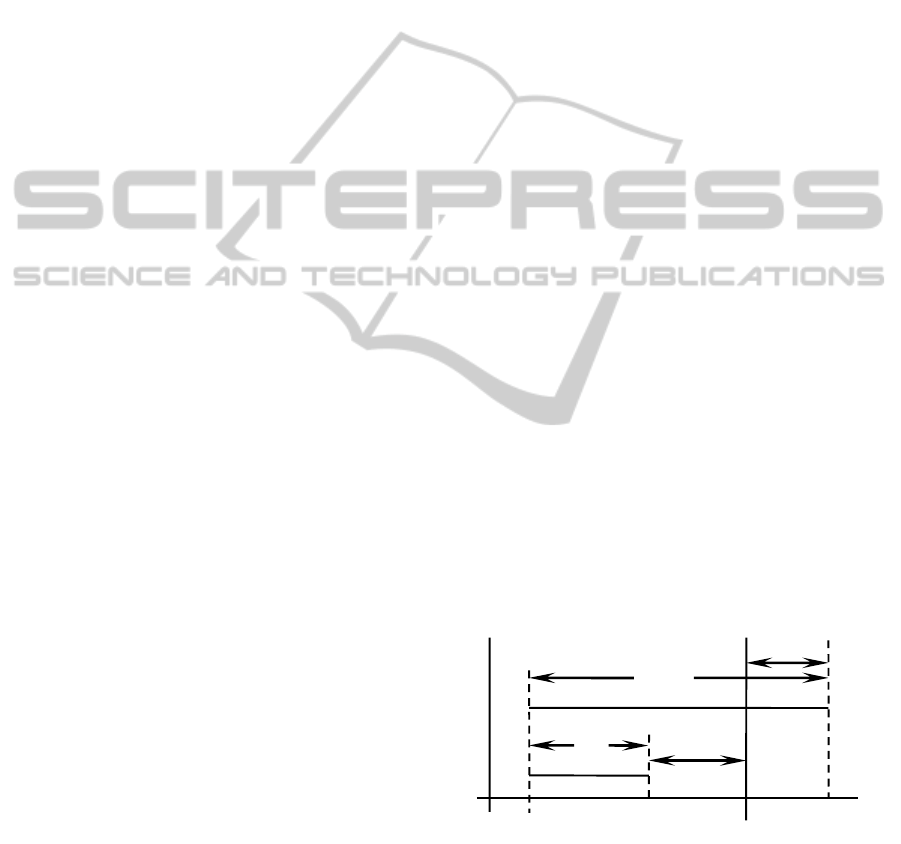

Activity ji utility (U) calculation is useful to

compare the realization time t

ji

and some soft

deadline d

s

(Figure 1.).

Figure 1: Activity j realization with deadline d

s.

This soft deadline depends on environment

where is acting the autonomous mobile robot. While

developing our research robot physical model the d

s

usually was equal to image processing delay (Baums

et al., 2011).

d

s

i

∆

ji(-)

∆

ji(+)

t

ji(-)

t

ji(+)

t

ICINCO 2012 - 9th International Conference on Informatics in Control, Automation and Robotics

330

Performing any tasks there is some probability

p

11(+)

of missing the deadline d

s

. For the activity ji

utility calculation, this time (t

ji(+)

=d

s

+∆

ji(+)

is

ij

τ

ij(+)

d

sij)

designated,

ij

- task starting time point.

For the first activity t

112

(phase one) camera turns

simultaneously in horizontal and vertical directions

(t

1th

t

1tv

):

U

112

=

112

=

12

τ

1ht(-)

d

s12

- p

12(+)

12

τ

1ht(+)

d

s12

(3)

The utility accrual UA of T

11

):

UA

11

=

112

+

1 vi

+

1cu

==

112

+

1vi

τ

vi(-)

d

s1vi

-

-p

1vi(+)

1lvi

τ

1vi(+)

d

s1vi

+

cu

τ

cu

d

scu

(4)

The utility accrual of T

12

:

UA

12

=

12

= N

1tm

(

112

+

1vi

)

(5)

TUF UA

1

= U

112

+ UA

12

+

cu

τ

cu

d

scu

=

=

112

+

12

+

cu

τ

cu

d

scu

=

1

1

d

s1

(6)

To compare this Time/utility function model

with the hard RTS model, it is necessary to estimate

the utility accrual for the same 5 phases (2).

TUF UA =

1

=

1

1

d

s1

+

2

2

d

s2

+

+

4

4

d

s4

+

5

5

d

s5

= D

s

D

h

;

(7)

The realization time τ

ji

, starting point

ji

and soft

end point d

sji

estimation can be made by using some

mathematical or physical models (Baums et al.,

2011).

For system energy and cost minimization,

decreasing of the node number is efficient. For

example, one node can be used to transfer data for

more than one different sensors or actuators.

3 DESIGN AND INVESTIGATION

OF AUTONOMOUS MOBILE

ROBOT

3.1 Robot’s Physical Model

Flexible physical model for autonomous robot time

and energy consumption investigation is developed

and published by the authors (Baums et al., 2011).

Aerial view of physical model it is proposed on

Figure. 2. There is only one node (system node) for

actuator (ac - motors) and video camera (se - vision)

connection. Other sensors (se - Compass CMPS03,

optical range meter Sharp GP2D15 and

GP2Y0A710YK) are directly connected to the

central unit.

The autonomous robot trip in real environment

with different objects was investigated and ant-

colony algorithm was used to build shortest round

trip route (Baums et al., 2011). Robot’s physical

model mainly is used for research and student

education.

Figure 2: Mobile robot’s physical model aerial view.

Physical model’s peak energy consumption was

experimentally estimated. The following results

were obtained: Control board (5V ∙50ma=0.250W);

2 SHARP range meters (2∙5V∙50ma=0.500W);

compass CMPS09 (5V∙25ma=0.250W); camera

CmuCam3 (10V∙450ma=4.5W); 2 servo motors

(2∙5V∙750ma=7.5W); motor driver (5V∙50ma=

0.250W), 2 motors (2∙10V∙3.50a=70W); maximal

energy consumption: ∑

ei

~ 83W.

3.2 Autonomous Mobile Robot’s

Design using Wireless Technology

As a central unit for the new generation autonomous

mobile robot design was used PDA HTC Flyer. The

structure of the robot is proposed on Figure 3.

Main differences between first and second

mobile robot physical models are:

- Video camera module. First robot used

CmuCam 3 built by Carnegie Mellon Univercity. It

had some disadvantages – such as low image

resolution, low data transfer rate, camera matrix low

sensitivity to the red color. New robot uses built in

High-Quality 8Mpix camera module. Because

Camera module and system processor are placed on

one module – HTC Flyer, image data transfer and

processing speed increased greatly.

- Navigation system. For the navigation purposes

first robot used electronic compass CMPS09,

encoder system, and range finders. New system uses

Sparkfun 9DOF AHRS module instead of CMPS09.

It includes 3 axis magnetic compass, 3 axis gyro, 3

axis accelerometer and ATmega328 for data

processing and transfer purposes. Using adaptive

filter (Kalman filter) AHRS module helps to make

much more precise robot position and direction

Development of Mobile Research Robot

331

Figure 3: Autonomous mobile robot built using wireless technology.

determination then just an electronic compass.

- CU. Main control unit of the first robot was

ATmega32. As a control unit for a new robot HTC

Flyer was chosen because of its powerful processor.

It is capable to perform calculations quickly.

- Communication abilities. The robot is capable

of communication using 3G or Wi-Fi networks. It

helps an operator to control robot and get telemetry

data from any place in the world where there are

available connection to the Internet.

Such a solution for the mobile robot is very flexible

giving ability to scale it for a task.

One of the first test tasks planned to realize on

built physical model is to detect colored markers in

the preset environment, estimate their position, build

shortest round trip route and move through it.

4 CONCLUSIONS

For the new autonomous mobile research robot

design, the real time problems are significant and it

is necessary to solve it in estimated time. For timely

analysis, an autonomous robot’s structure is based

on a single main processor, clusters of sensors and

actuators with its interface nodes. In different

robot’s activity phases the time/utility function TUF

and utility accrual UA criteria are selected.

For time and energy consumption experimental

estimation robot’s physical model is used. This

model is advisable for student education.

The new autonomous mobile robot is designed

using proposed wireless technology.

ACKNOWLEDGEMENTS

This work has been supported by European Social

Fund, grant Nr. 2009/0219/1DP/1.1.1.2.0/APIA/

VIAA /020 and Latvian Council of Science.

REFERENCES

Baums A., Gordjusins A., Kanonirs G., 2011.

Investigation of Time and Energy Consumption using

the Physical Model, Electronics and Electrical

Engineering, 5, pp.85-88.

Adept Technology, 2011a. Mobile robot Seekur. [online],

Avilable at: <http://www.mobilerobots.com/ research

robots/Seekur.aspx> [Accessed 1 May 2012]

Adept Technology, 2011b. Pioneer 3 DX. [online] <http://

www.mobilerobots.com/researchrobots/pioneerp3dx.a

spx> [Accessed 1 May 2012]

Ravindran B., Jensen E. D., Li P., 2005. On Recent

Advances in TUF Real-Time Scheduling and Resource

Management, In Proceedings of the 8 IEEE

International Symposium on Object-Oriented Real-

Time Distributed Computing, pp55-60.

Choset H., et al., 2005. Principles of Robot Motion:

Theory, Algorithms, and Implementations, MIT Press.

Wu H., Ravindran B., Jensen E.D., 2007, Utility Accrual

Real-Time Scheduling Under the Unimodal Arbitrary

Arrival Model with Energy Bounds. IEEE

Transactions on Computers, 56(10), pp.1358-1371.

Segway Robotics, 2012. RMP400. [online] Avilable at:

<http://rmp.segway.com/rmp-400-omni/> [Accessed 1

May 2012]

Li S., et al., 2012, Profit and Penalty Aware Scheduling

for Real-Time Online Services. IEEE Trans. Industrial

Informatics, 8(1), pp.78-89.

Balli U., Wu H., Ravindran B., Anderson J. S., Jensen E.

D., 2007. Utility Accrual Real-Time Scheduling under

Variable Cost Functions, IEEE Transactions on

Computers arch. 56(3), pp.358-401.

CU (HTC Flyer)

Bluetooth

System node (MSP430F1611)

AHRS

system

Sparkfun

9DOF

Sharp

range

meter

(1.5m)

Motor left

Motor right

Encoder left

Encoder right

System node (demultiplexer M74HC4053)

Motor driver

Sharp

range

meter

(5m)

Environment

Built in camera system

GPS

Servomotor

- H

Servomotor

- V

Wi-Fi, 3G

ICINCO 2012 - 9th International Conference on Informatics in Control, Automation and Robotics

332