Design and Experimentation of a Neural Network Controller

for a Spherical Parallel Robot

Donatello Tina, Luca Carbonari and Massimo Callegari

Department of Industrial Engineering & Mathematical Sciences, Polytechnic University of Marche, Ancona, Italy

Keywords: Neural Networks, Robot Control, Parallel Kinematics Machines.

Abstract: The paper deals with a neural network control for the gravity compensation of a parallel kinematics robot.

The network has been designed in a simulation environment then it has been implemented in robot’s

controller by using an FPGA device that is part of an embedded system. After the training phase, several

experiments have been performed on the prototype manipulator and the related datasets have been collected

and elaborated. In the end, a comparative analysis has shown the improved performance of the neural

network controller with respect to the inverse dynamics one, mainly due to the well-known difficulties in

deriving explicit models of friction and play in the joints.

1 INTRODUCTION

During the last two decades, research in the

Artificial Neural Network (ANN) field has increased

significantly in different branches of science. To the

best of our knowledge, King and Hwang (1989) first

theorized the application of ANN for robotics

applications; Narendra and Parthasarathy (1990)

demonstrated that Neural Networks can be also

usefully exploited for the modelling of dynamic

systems as well as for the control of automated

machinery. Other recent robotics applications for

neural networks are the solution of the kinematics of

a parallel manipulator (Zhang and Lei, 2011) and the

control of a planar robot (Serrano, 2011).

Field Programmable Gate Arrays (FPGA) can

perform a large number of parallel operations at very

high time rates and their architecture is very suitable

for the implementation of real time neural networks.

As a matter of fact remarkable realisations are

available already in scientific literature, e.g.

Orlowska-Kowalska et al. (2011) used an FPGA-

based ANN for the state estimation of a two mass

system with elastic couplings.

The main target of the present work is the

realisation of a gravity compensation module for the

control of a prototype parallel manipulator, named

Sphe.I.Ro. whose kinematics allows only motions of

pure rotation. The computation of the analytic model

of machine’s statics is quite burdensome due to the

presence of the closed kinematics chains. Therefore

an ANN has been created in order to obtain a

reliable and efficient static model of the robot, that is

able to provide the actuation forces needed to

maintain a certain configuration in the orientation

space.

Figure 1: Photograph of the Sphe.I.Ro. robot.

2 THE Sphe.I.Ro. ROBOT

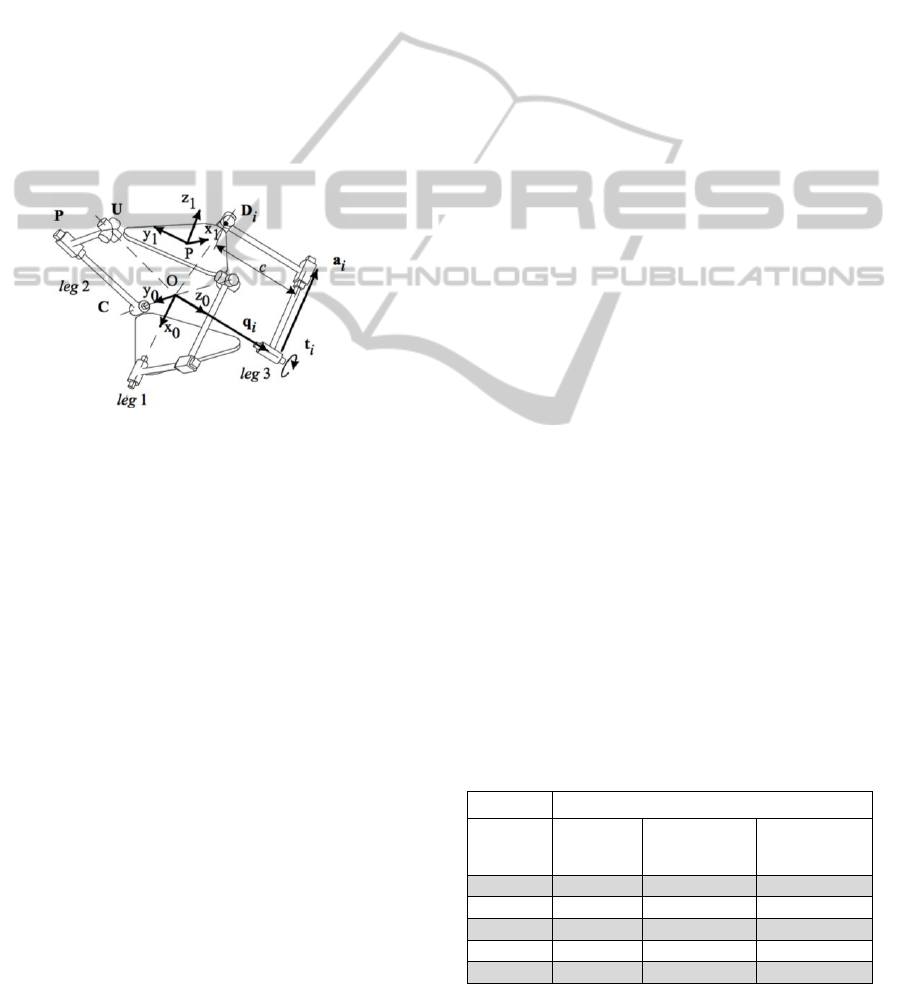

Sphe.I.Ro. (Spherical Innovative Robot) is a parallel

kinematic machine developed at the robotics

laboratory of the Polytechnic University of Marche.

It is made by three identical serial chains connecting

the moving platform to the fixed base, as shown in

Figure 1; each leg is composed of two links: the first

one is connected to the base by a cylindrical joint

(C) while the second link is connected to the first

250

Tina D., Carbonari L. and Callegari M..

Design and Experimentation of a Neural Network Controller for a Spherical Parallel Robot.

DOI: 10.5220/0004047602500255

In Proceedings of the 9th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2012), pages 250-255

ISBN: 978-989-8565-21-1

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

one by a prismatic joint (P) and to the end-effector

by a universal joint (U); for this reason its

mechanical architecture is commonly called 3-CPU.

Figure 2 shows a sketch of robot’s kinematics: when

the translations of the three cylindrical joints are

actuated, the end effector is only allowed to perform

pure rotations around a fixed point of the space

(Callegari et al., 2004). The large number of passive

prismatic pairs, typical of parallel kinematics, causes

high friction losses, which represent a relevant

disturbance for motion control and make quite

difficult the realisation of a good dynamic model of

the robot. Therefore the A.’s decided to turn to an

empirical model that could robustly take into

account these phenomena; in particular, the resort to

ANN’s systems proved able to fit the physical

behaviour of machine, obviously after a proper

training phase.

Figure 2: Schematic representation of robot’s kinematics.

3 DESIGN OF THE ANN SYSTEM

3.1 ANN Model

If the model of a single neuron is taken into

consideration, its output can be expressed as:

(1)

where x is the input vector, W is a weighting vector,

b is the bias number and σ is the activation function.

According to Cybenko’s theorem (Cybenko, 1989) a

static feedforward net with one hidden layer of

neurons has been chosen, with the number of

neurons n to be selected after some simulation trials,

as explained in the following section; the input of

the net are the 3 displacements q

i

of the actuators

while the output is represented by the 3 forces f

i

that

keep the robot at rest in the assigned configuration.

The resulting model of the whole net has the form:

(2)

where:

;

;

;

.

3.2 Simulation Network

A simulation model of the network was developed in

order to select the appropriate number of neurons for

the hidden layer and to tune the training procedures.

Both kinematic and dynamic models of the robot

were available already (Callegari et al., 2004, 2012):

it is remarked that the latter has been built according

to the virtual work principle, therefore resulting very

compact and efficient, potentially allowing a real-

time use.

Once set up the simulation environment, several

parameters of the ANN have been changed to look

for best gravity compensation performance. Every

net configuration has been tested after a proper

training, realized by using data sets of about 3 500

different orientations inside robot’s workspace. If

the latter is mapped into the joint space, it is

represented by a tetrahedron whose lateral faces are

singularity surfaces (Carbonari, 2012). For each test

configuration, the gravity force reflected to the

actuators was calculated by using the mathematical

model, therefore obtaining both input (joint

positions) and output (reflected gravity forces) data

set for the training of the net.

The ANN training has been performed by means

of the Levemberg-Marquard back-propagation

algorithm (Hagan and Menhai, 1994). The back-

propagation algorithm needs data to be pre-

processed in order to normalize the input of the net.

Nets with different numbers of neurons have

been investigated (see Table 1 for details); in each

case, the training has been interrupted when the

output error or the gradient became lower than a

given threshold. Simulation results showed that 20

neurons are a good compromise between net

complexity and net performance. It is noted that a

mean square error of about 26 mN has been achieved

throughout the workspace for the 20 neurons net:

this, for a mean actuation effort of about 48 N,

corresponds to a relative error lower than 1%.

Table 1: Training performance of different nets

(simulation).

Training stop criterion

No. of

neurons

Gradient

threshold

Actual

gradient

Performance

(mean square

error)

15

0.009

0.0090

0.0429

20

0.009

0.0080

0.0263

25

0.009

0.0500

0.0268

30

0.009

0.0072

0.0314

40

0.009

0.0088

0.0198

Design and Experimentation of a Neural Network Controller for a Spherical Parallel Robot

251

4 ANN IMPLEMENTATION ON

FPGA

The performance of the artificial neural network has

been experimented on the Sphe.I.Ro. robot, whose

control architecture is briefly described in the

following. The parallel robot is actuated by three

brushless linear motors, whose drivers are connected

to a PXI platform (by National Instruments) which

performs both control and supervision tasks. The

PXI device hosts an FPGA board, which deals with

several processes, such as managing encoders

signals, commanding the brakes of the 3 linear axes,

running the neural network and operating the pre-

and post-processing of network’s input and output.

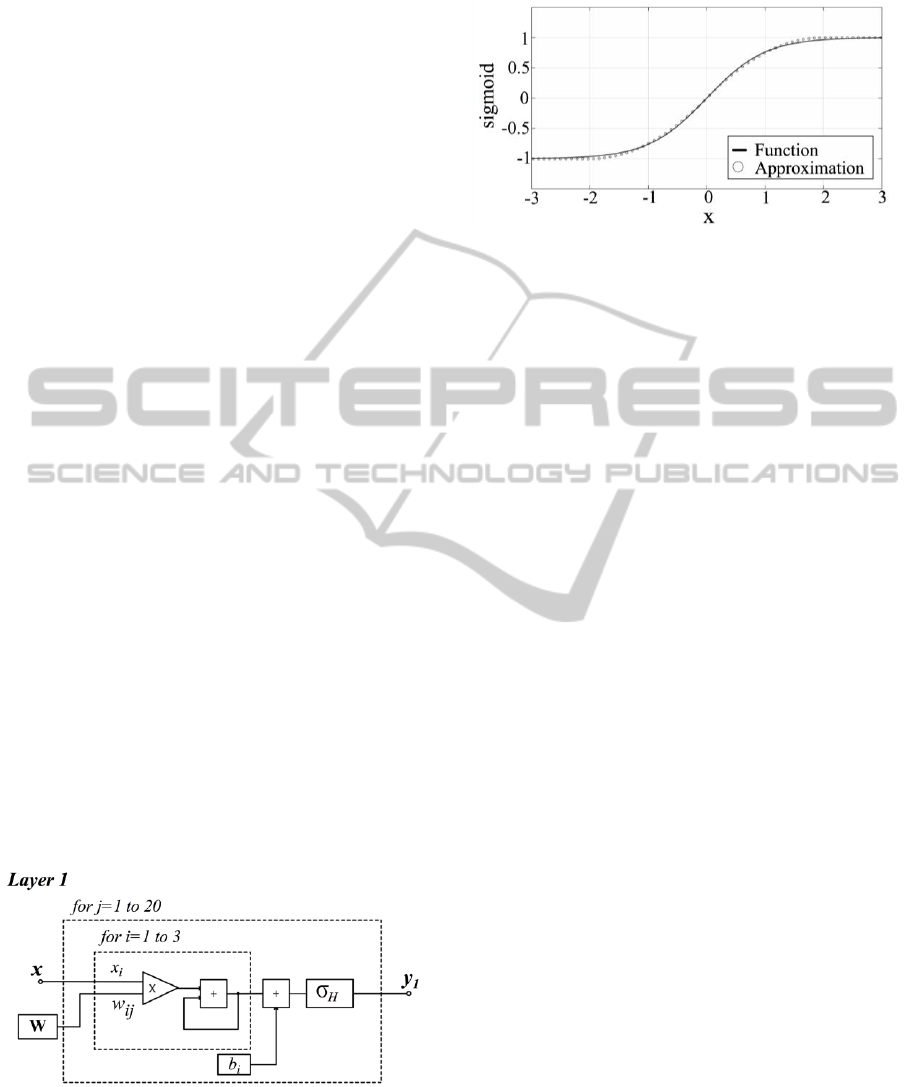

By grouping the elementary operations of the

ANN for layers, it is possible to implement the net in

LabView by means of two nested “for loops”, as

shown in Figure 3: the inner one for the

multiplication between the input and the

corresponding weight, and the outer one for the

implementation of neuron’s calculations. Figure 3

shows the hidden layer of the ANN, in case 20

neurons are used: x is the input vector of the net and

W is the weights matrix, where w

ij

represents the j

th

weight of i

th

neuron. It is noted that the activation

function σ

H

is the same for all the neurons. The

activation function has been realised by means of the

sigmoid tanh(x). According to Kwan (1992) an

approximation of a sigmoid function can be

implemented by using a sigmoid-like second-order

piecewise function

:

(3)

where and determine respectively the slope and

the gain of the nonlinear function (3) while L

represents the amplitude of the non-linear region.

Figure 3: Scheme of the neural network structure

implemented on the FPGA device.

In this work L=2 was used, see Figure 4. This

makes possible to evaluate the activation function by

means of two multiplications and one summation.

Figure 4: Sigmoid activation function σ_H (x) and its

approximation Γ(x).

5 CONTROL ALGORITHM

DESCRIPTION

The implementation of the software in the LabView

environment has been made through its typical

graphic language. Two types of code had to be

written: the ANN has been implemented on the

FPGA board while all other control software had to

run on the PXI controller, which supervises the user

interface and manages the manipulator’s control

system.

Furthermore an interrupt-based procedure

ensures the synchronization between the different

hardware components: in fact, the two devices run at

different clock rates, i.e. a maximum clock rate of

40 MHz for the FPGA board and 10 MHz for the

PXI controller. In order to optimize the FPGA

performance, the code has been partitioned into

different processes, able to perform in-parallel

different real-time tasks, i.e. encoder’s signals

processing, motor driving, ANN system computation

and safety procedures management.

In the PXI controller a Virtual Instrument was

implemented, by exploiting a series of routines that

guarantee the correct execution of the ANN on the

FPGA. In fact the net was designed and tuned in

Matlab and then adapted for real-time execution in

the LabView environment. Thus relevant data of the

net, such as weights matrix, bias vector, pre-process

and post process settings, were first set up in the

Matlab simulation environment and then exported to

the LabView one.

It is useful to assess and compare the

computation efforts needed by both gravitational

compensation models.

As for the ANN model, of course the

computation burden depends upon the number of

neurons that compose the net. For the net that has

ICINCO 2012 - 9th International Conference on Informatics in Control, Automation and Robotics

252

(a) (b)

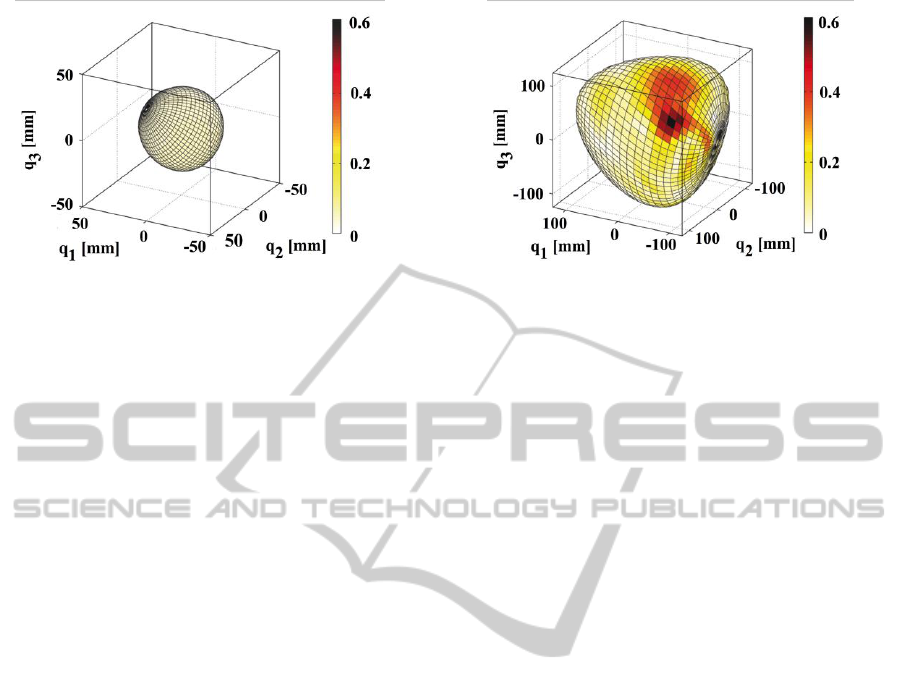

Figure 5: Norm of the error on different surfaces of joints space (different scales are used): (a) surface close to home

configuration, (b) surface close to workspace boundaries.

been actually implemented on robot’s controller

(one hidden layer with 20 neurons, 3 input and 3

output), the computation of gravity forces requires

166 multiplications and 43 summations.

If the analytical model is used, a huge number of

non linear operations must be used. In particular, an

algorithm based on this model involves 8305

operations, of which 532 are trigonometric

operation.

6 RESULTS

6.1 Simulation Tests

Several tests have been performed in order to

estimate the performances of the ANN gravity

compensation module. First, the entire workspace of

the Sphe.I.Ro. robot has been investigated through

computer simulation, by computing the gravity

compensation forces with the two available models,

i.e. the analytical model and the neural network

model. The deviation between the two models can

be evaluated as:

(4)

where

are the 3 motor thrusts compensating

the gravity force computed by the mathematical

model while

is the corresponding force

vector evaluated by the ANN in the simulation tests.

Each point of the surface visible in Figure 5a

represents a specific robot’s pose in the

neighbourhood of home configuration while the

surface of Figure 5b lays closer to workspace

boundaries. In both cases the norm of error vector

(4) is represented by different colour levels. Since

darker regions mean higher error values, it is

apparent that the error is relevant (

0.4 N) only

within a very limited region of the space. As a

matter of fact, the error becomes lower and lower as

the home configuration is approached: this is due

both to the choice of the training points and to the

increasing isotropy of robot kinematics. In fact,

during training, the points of the dataset have been

made denser in this part of the workspace, where

most operations are carried on.

The behaviour of both the neural network and the

analytical model can be better visualized in the task

space. To this aim, the orientation of the platform is

described by means of the elevation, azimuth and

torsion angles (

). By keeping the torsion angle

(

as a parameter, the error in the orientation space

can be represented as a function of elevation and

azimuth only: for instance, each point of the surface

in Figure 6a represents the norm of the error for a

configuration that is given by elevation

(the angle

around the base circle) and azimuth

(the polar

distance from the centre of the base circle). Figure 6

and Figure 7 represent the error evaluated in

simulation for a null torsion angle (

) and for a

torsion angle

respectively: this task space

representation clearly shows how the error increases

while workspace boundaries are approached, even if

it is pretty limited anyhow. It is noted that the peak

error values emerging in these figures are higher

than the errors that can be read in Figure 5 because

the corresponding points are external to those

surfaces and therefore they are not mapped there.

The prototypal machine is affected by significant

friction forces and bodies deformations, which can

be hardly evaluated in symbolic models, therefore it

was expected that the ANN based model would

perform better than the analytic model: the following

experimental tests aimed at assessing this point.

Design and Experimentation of a Neural Network Controller for a Spherical Parallel Robot

253

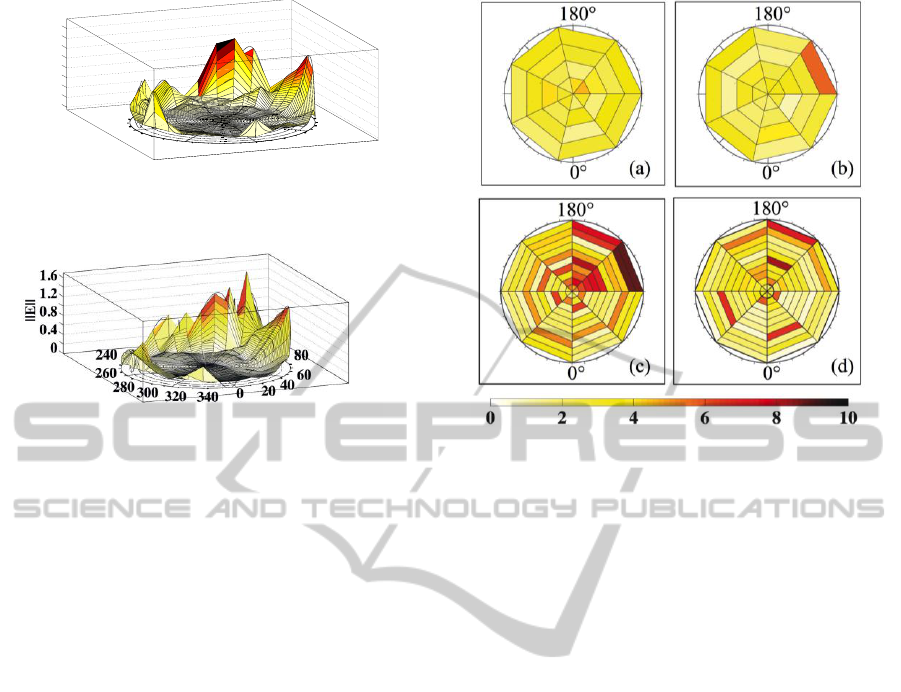

Figure 6: Error plot in the orientation space for

(simulation tests).

Figure 7: Error plot in the orientation space for

(simulation tests).

6.2 Experimental Tests

In order to collect the experimental dataset for the

training of the net, a PID controller has been used to

bring (and keep) the manipulator in all the selected

points of the workspace. Once Sphe.I.Ro. had been

driven to a new pose, the forces necessary to

maintain the robot in such configuration have been

recorded by measuring the current absorbed by

motors. The brushless linear motors used to drive the

rig have a proportional dependence between current

and force: the related constant is called “thrust

constant” (K

t

) and is provided by the manufacturer.

During the experimental tests, the robot has been

commanded to attain several orientations in the

workspace (different from the ones in the training

set) and the actual forces required by the actuators,

, have been compared with both the forces

estimated by the ANN,

, and the ones

provided by the analytical model,

. The arising

errors are:

(5)

(6)

Figure 8 allows a comparison between the

behaviours of the two models of gravity

compensation (analytical and ANN based): since the

two graphs have quite similar values, some critical

indicators are collected in Table 2.

In order to get more insight into this key issue,

Table 2 also presents the experimental performance

Figure 8: Actuation forces errors in different points of the

space:

(a) and

(b) for

=0;

(c)

and

(d) for

=15°.

of the ANN based controller, in case the training is

performed on the simulation data set (in place of the

on-field training); all the data are provided for both

torsion angles (

=0° and

=15°). It can be seen that

the performance of the ANN controller is better than

the analytical based one in all conditions tests, but

the difference is scarcely substantial. As could be

expected, such difference in performance becomes

smaller as the boundaries of the workspace are

approached and/or the values of the torsion angle

increases since less points have been taken in these

conditions for ANN training and, on the other hand,

the analytical model is able to capture, at least

partially, the rapidly changing manipulator’s

dynamics close to singular configurations.

In the end, it can be useful to investigate the

causes of the not completely satisfying behaviour of

the ANN based compensation: first of all, due to the

relevant time needed by on-line experiments, only

100 points have been considered to build the

experimental data set for net training (while 3000

points have been used in the simulations). Secondly,

due to the lag induced by static friction, for any

configuration of the manipulator there exist a whole

range of actuation forces that keep the machine in

equilibrium under the effect of gravitational force:

such effect surely affected the training phase and

thus the performance of the ANN compensation.

0

0.4

0.8

1.2

1.6

60

80

40

20

0

340320

300

280

260

||E||

240

ICINCO 2012 - 9th International Conference on Informatics in Control, Automation and Robotics

254

Table 2: Performance indexes of gravity compensation

models.

Max

error[%]

Ave

error[%]

ANN compensation

(on-field training)

=0°

7,0

2,8

=15°

11,5

4,6

ANN compensation

(simulation training)

=0°

9,0

3,8

=15°

13,6

4,9

Analytical model

compensation

=0°

8,5

3,8

=15°

12,6

5,4

7 CONCLUSIONS

The aim of this work was to investigate the

performance of ANN’s for the gravity compensation

of a spherical parallel manipulator. The availability

of an analytical model of robot’s dynamics allowed

to design the net through computer simulation and to

port the software to the real-time control hardware

after a first (preliminary) tuning.

After the on-field net training phase, more tests

have been performed to evaluate the compensation

effectiveness: the manipulator has been commanded

to reach several poses in the task space and the

output of the ANN has been compared with the

actuation forces actually needed; the same

comparison has been made with the actuation forces

provided by the analytical model of robot’s inverse

dynamics.

The results of the tests showed that the ANN

controller behaves better than the algorithmic one,

even if the improvements are not very relevant. It is

reckoned that better performances could be obtained

by a more extensive training on the field and in case

the mechanical structure were less influenced by

static friction, as is the present case: the influence of

this factor could be assessed by further

experimentation, by measuring the gravitational

actions with the manipulator in (slow) motion.

From the computational point of view, on the

other hand, the ANN based compensation

overperforms the analytical model, whose

computation is rather time consuming indeed.

REFERENCES

Callegari, M., Carbonari, L., Palmieri, G. and Palpacelli,

M.-C. (2012). Parallel Wrists for Enhancing Grasping

Performances. In: Grasping in Robotics, G. Carbone

ed., Springer, 2012. (In press)

Callegari, M., Marzetti, P., Olivieri, B. (2004). Kinematics

of a Parallel Mechanism for the Generation of

Spherical Motions, in J. Lenarcic and C. Galletti (eds),

On Advances in Robot Kinematics, Kluwer, pp.449-

458.

Carbonari, L. (2012). Extended analysis of the 3-CPU

reconfigurable class of parallel robotic manipulators.

Ph.D. Thesis, Polytechnic University of Marche,

Ancona, Italy

Cybenco, G. (1989). Approximation by Superpositions of

a Sigmoidal Function. Mathematics Control, Signals

and Systems, Vol. 4, no. 2, pp. 303-314.

Hagan, M.T. & Menhai, M. (1994). Training feed-forward

networks with the Marquardt algorithm, IEEE

Transactions on Neural Networks, Vol.5, No. 6,

pp.989-993

King, S.-Y., and Hwang, J. -N. (1989). Neural network

architectures for robotic applications. IEEE

Transactions on Robotics and Automation, Vol. 5, no.

5, pp. 641-657.

Kwan, H. K. (D. of E. E.). (1992). Simple sigmoid-like

activation function for digital hardware

implementation. Electronics Letters, Vol. 28, no. 15,

pp. 1379-1380.

Narendra, K. S. and Parthasarathy, K. (1990).

Identification and control of dynamical systems using

neural networks, IEEE Transaction on Neural

Networks, Vol. 1, no. 1, pp. 4-27.

Orlowska-Kowalska, K and Kaminski, M, (2011). FPGA

Implementation of the Multilayer Neural Network for

speed estimation of the Two-Mass Drive System.

IEEE Transaction on Industrial Informatics, Vol. 7,

no.3, pp. 436–445.

Serrano, F. E. (2011). Neural Networks Models for

Control and Identification of a Two Links Robotics

Manipulator. Proceedings CONCAPAN XXXI.

Zhang, D., & Lei, J. (2011). Kinematic analysis of a novel

3-DOF actuation redundant parallel manipulator using

artificial intelligence approach. Robotics and

Computer-Integrated Manufacturing, Vol. 27, no. 1,

pp. 157-163.

Design and Experimentation of a Neural Network Controller for a Spherical Parallel Robot

255