On the Temperature Control for a Test Case Short Pipe Network

Central Heating System

Nikolaos D. Kouvakas and Fotis N. Koumboulis

Halkis Institute of Technology, Department of Automation, 34400 Psahna Evoias, Greece

Keywords: Central Heating Systems, Temperature Control, Autonomous Heating, Dynamic Controllers.

Abstract: In the present paper the mathematical representation of a test case central heating system with a short pipng

network, three radiators and one boiler heating two apartments is developed in the form of a nonlinear

model. A linear dynamic controller achieving independent apartment temperature control and being

unaffected from the external temperature is proposed. The controller is developed on the basis of a linear

approximant. The closed loop performance is tested through simulations on the original nonlinear model.

1 INTRODUCTION

The problem of modelling and control of central

heating systems has attracted considerable attention

during the last years (see Cai, 2006; Hansen, 1997;

Koumboulis et al., 2007; Koumboulis et al., 2008a

and b; Koumboulis et al., 2009a,b and c;

Koumboulis and Kouvakas, 2010; Mendi et al.,

2002; Morel et al., 2001; Zaheer-Uddin et al., 1994;

Zanobini et al., 1998 and the references therein).

Significant attention has also been given to the

modelling of core components of central heating

systems as well as to the application of different

control techniques to regulate the performance

variables. These techniques range from classical and

metaheuristic controllers, fuzzy control schemes,

adaptive controllers, optimal controllers to multi

delay dynamic controllers satisfying transfer matrix

design requirements. In the present paper the

mathematical representation of a test case short pipe

network central heating system including two

apartments is presented in the form of a nonlinear

model. The first apartment has one room while the

second is considered to have two rooms. The system

consists of a short piping network, three radiators, a

boiler and three rooms. The main difference between

the present model and those in Koumboulis et al.,

(2007), Koumboulis et al., (2008a and b),

Koumboulis, Kouvakas and Paraskevopoulos

(2009a-c), and Koumboulis and Kouvakas (2010) is

the length of the pipes. The transport delays are

small and so they do not significantly to influence

the behavior of the plant. Thus, the present

mathematical representation does not incorporate

time delays. Furthermore, the first and the second

room of the second apartment are coupled via direct

heat exchange. A linear dynamic controller

achieving independent apartment temperature

control and being unaffected from the external

temperature is proposed. The controller is developed

on the basis of a linear approximant. The closed loop

performance is examined through simulations on the

original nonlinear model.

2 MODEL OF THE SYSTEM

In the present section the mathematical model of the

test case central heating system, will be presented. It

is similar to that proposed in Koumboulis et al.,

(2007), Koumboulis et al., (2008a and b),

Koumboulis et al., (2009a, b and c), and

Koumboulis and Kouvakas (2010). The system

consists of the piping network, three radiators, a

boiler and three rooms. In each room one of the

radiators is installed. The main difference between

the model developed here as compared to those

presented in Koumboulis et al., (2007), Koumboulis

et al., (2008a and b), Koumboulis et al., (2009a-c),

and Koumboulis and Kouvakas (2010) is that small

length pipes are used. Thus, the transport delays are

small and so they can be neglected. Furthermore, the

two rooms of the second apartment are considered to

be coupled via direct heat exchange. Let

1i

1

622

D. Kouvakas N. and N. Koumboulis F..

On the Temperature Control for a Test Case Short Pipe Network Central Heating System.

DOI: 10.5220/0004048506220627

In Proceedings of the 9th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2012), pages 622-627

ISBN: 978-989-8565-21-1

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

corresponds to the room of the first apartment, while

2i

2

and

3i 3

correspond to the two rooms of the

second apartment. Using the results presented in the

aforementioned papers, the nonlinear dynamic

model of the process can be computed to be in the

following general nonlinear form:

,,,Exuxt Fxu

,

,

xu

,

xt

F

(1a)

yt Cxt

C

xt

,

tLxt

t

xt

L

x

(1b,c)

where

123456789

x xxxxxxxxx

x

12

12

x

x

12

10 11 12 13 14 15 16

xxxxxxx

1 2 3 1,1 2,1 1,2 2,2 1,3 2,3

qqqT T T T T T

q

12

q

12

qq

12

,1 ,1 ,2 ,2 ,3 ,3

T

br fr f r f

TT TT T T T

T

12345

T

uuuuuu

T

T

12345

12345

uuuuu

1234234

123

,,,

T

burner fv fv fv

QPkkk

T

kk

QPkk

123

fv fv

22

2

2

2

fv f

fv

kk

fv ff

1

burner f v

1

,

1

Q

burner f v

QPkk

burner f vf

1234 ,1 ,2 ,3

TT

out out out e

TTTT

TT

T

TT

TT

T

T

,3

e

,3

e

3

TT

3

3

,,

,1 ,2,1

1234

121

TT

T

122

12

1

2

1234

T

and where

1

q

,

2

q

and

3

q

are the volumetric flow -

rates in the radiators of the first, second and third

rooms respectively,

,ji

T

is the

th

j

section temperature

of the radiator placed in the

th

i

room,

b

T

is the

boiler effluent temperature,

,ri

T

and

,fi

T

are the

ambient air and floor temperatures of the

th

i

room,

burner

Q

is the energy supply to the boiler,

P

P

is the

pressure applied to the pipe network by the pump,

,

i

fv

k

is the pressure drop coefficient of the

th

i

valve,

,out i

T

is the external temperature of the

th

i

room and

e

T

is the boiler room temperature. Note that

burner

Q

,

P

P

and

,

i

fv

k

are actuatable inputs while

,out i

T

and

e

T

are measurable disturbances. Note that

yt

and

t

t

are the performance and measurable output

vectors, respectively, while

L

and

316

C

3

3

1

6

. Their

nonzero elements are

1,15

1c

1

,

2,11

0.5c 0.

5

,

2,13

0.5c

0

.

5

,

3,11

1c

1

,

3,13

1c

1

,

1,11

1l

1

,

2,13

1l

1

and

3,15

1l

1

.

The nonzero elements of

E

and

F

are computed to

be:

2

1,1

1

8, Ldexu

1

8

L

Ld

2

,

2

1,2

1

16, Ldexu

2

1

16

L

Ld

2

2,1

1

8, Ldexu

1

8

L

Ld

2

,

2

2,3

1

16, Ldexu

2

1

16

L

Ld

2

3,2

1

8, Ldexu

1

8

L

Ld

2

,

2

3,3

1

8, Ldexu

1

8

L

Ld

2

5

1,

2

3

2

3

,

,

46

r

r

e

Lu

L

dd

xu

xdd

L

6

5

5

u

6

L

6

L

6

6

L

6

3

,

xd

d

3

,

xd

r

d

r

dd

d

dd

2

d

d

2

d

d

4

r

d

2

2

d

2

4

2,

2

2

2

2

,

,

44

r

r

e

Lu

L

dd

xu

xdd

4

L

4

4

4

u

4

4

4

L

4

4

4

L

4

4

4

L

4

2

,

xdd

2

,

xd

r

d

r

dd

d

dd

2

d

d

2

d

d

4

r

d

2

2

d

2

3

3,

2

1

2

1

,

,

42

r

r

e

Lu

L

dd

xu

xdd

L

2

3

3

u

2

L

2

L

2

2

L

2

1

,

xdd

1

,

xd

r

d

r

dd

d

dd

2

d

d

2

d

d

4

r

d

2

2

d

2

4,4

,1exu

1

,

5,5

,1exu

1

,

6,6

,1exu

1

7,7

,1exu 1

,

8,8

,1exu

1

,

9,9

,1exu

1

10,10

,1exu

1

,

11,11

,1exu

1

,

12,12

,1exu1

13,13

,1exu

1

,

14,14

,1exu1

,

15,15

,1exu1

16,16

,1exu

1

27 5 39 510,1

, xx x xx xexu x

5395

53

95

xx

xx

53

9

5

7

2

7

x

7

2

x

2

x

x

2

2

x

2

15 7 39 710,2

, xx x xx xexu x

7397

7397

xx

xx

73

9

73

5

1

5

x

5

1

x

1

x

x

1

1

x

1

15 9 27 910,3

, xx x xx xexu x

9279

92

79

xx

xx

92

7

92

5

1

5

x

5

1

x

1

x

x

1

1

x

1

11

112310,5

,1eaxauxxxx

123

1

xx

12

11

1

ax

a

1

11

212310,7

,1eaxaxxxxu

123

axxx

1212

11

2

1

ax

2

1

11

312310,9

,1eaxaxxxxu

123

axxx

1212

11

3

1

ax

3

1

31,1 3

2,,,,,,

pprr

fxLd fxLdfxu

3

xL

,

3

3

,

3

p

p

2

p

f

p

prr

3

fxLd

,

3

prr

3

,

3

23 123

2,,2 ,,

pp

f x xLd f x x xLd

123

p

3

xLd f x x xLd

123

,, 2 ,,,, 2 ,

3123312

3

3

2

35 3 2

,,

vt

fxud Kx u

2

3

2

Kx

u

2

3

22,1 2 3

,, , , 2 ,,

prr p

fxLd fx xfu dxL

23

,,

3

rr p

Ld f x x

2

,, 2,2

2

rr p

,,,

d

L

2

x

2

,

2

,

p

f

p

2

123 24 2 2

2,,,,

pvt

fx x xLd fxud Kx u

2

2

2

2

pvt

123

24

fx x xLd fxud Kx

u

2

2

2

2

,

,,

,

,

,

123 242423 2

p

123

24

123 242423 2

2

3,1 1 1 3 1

,,,, , ,

prrv t

fxLd fxudfu Kxx

2

1

13

13

Ld f xud

13

13

,,

,,

3

3

13

13

3

3

Kx

1

1

x

1

,

1

p

f

p

123 2

2,,

p

fx x xLd u

123

2

2

p

fx

xxLdu

123

2

,

,

12323

p

11

1144,

1

60 60 1,,

nn

q

fxu NHx x

C

C

60

1

60

1

0

1

6

0

C

1

n

1

1

4

4

x

1

1

510 411 0

n

xx xx

5

x

5

1

11 0

n

x

10

x

10

4

4

xx

4

4

15,1

1

45

,,

q

CNfxu Hxx x

5

x

C

1

1

H

H

N

H

N

1

4

q

1

4

q

Hx x

1

4

H

N

H

N

N

N

H

N

1

1

511 0

60

n

n

xx

1

511 0

60

n

xx

5

1

n

x

On the Temperature Control for a Test Case Short Pipe Network Central Heating System

623

11

2166,

1

60 6,1,0

nn

q

NH xf

C

xxu

C

6

1

0

6

1

0

0

1

60

C

1

n

1

1

6

6

1

x

1

710 613 0

n

xx xx

1

13 0

n

x

710

xx

710

6

6

xx

66

27,1 7

1

6

,,

q

Nfxu xCHxx

7

x

C

1

H

H

N

H

N

2

q

2

q

Hx x

2

H

N

H

NN

N

H

N

1

1

713 0

60

n

n

xx

1

713 0

6

0

n

xx

7

1

n

x

11

3188,

1

60 60 1,,

nn

q

fxu NHx x

C

C

60

1

60

1

0

1

60

C

1

n

1

1

8

8

x

1

1

910 815 0

n

xx xx

9

x

9

1

15 0

n

x

10

x

10

8

8

xx

8

8

39,1 9

1

8

,,

q

Nfxu xCHxx

9

x

C

1

H

H

N

H

N

3

q

3

q

Hx x

3

H

N

H

N

N

N

H

N

1

1

915 0

60

n

n

xx

1

915 0

60

n

xx

9

1

n

x

11 1 2 3 ,max10,1

,,

w

au x xxu xfT

1

x

1

1

u

1

1

a

1

23,max

x

x

T

15 10 4 27 10

11

j

axax ax xax ax

1

1

5

5

ax

5

1

1

10

42

10

10

10

42

42

42

1

1

7

7

7

7

0

1

1

ax

a

439 104,max

1

w

xax ax T

439 104,max

ax T

910410 4

a

x

1

39

39

xax

39

3

12310

xxxx

23

10

x

xx

2323

21 1 2 3 ,max

1

ww

aau C x x x T

1

1

1123,max

1

1

1

max

T

aa

u

1

1

1

C

x

1

2

2

aau

2

3

23

23

23

x

x

232

15 27 39

xx xx xx

15 27 39

xx xx xx

15 27 3

5273

21 1 2 3 ,maxww

aa u C x x x T

T

C

21

21

aa u

21

23,max

23

1

1

23ma

x

23

x

xT

23

23

1

1

C

x

1

123,max

/1

bw

aCxxxT

C T

1

123

,ma

x

b

123

max

bw

123

Cx x xT

1

b

123

23

11

11 12 1,121,1

60,, 60

nn

out

NR x x Rfxu

11 12 1,

2

out

Rx xR

11 12 112 1

t

60

1

n

1

1

n

60

NR

1

60

NR

1

11 1 1,2

60

n

f

RNxR

11

n

Nx

1

11

60

n

11

,2

R

11

1

1

11 13

60

n

out

RNxx

11 13

n

Nx x

1

11

60

n

11

411 511 01,2

1000

nn

xx xx R

11

nn

1

R

11

x

xxx

R

4

x

4

x

11 5 11 0 1

,2

xxx

R

11 5

11 0 1

11 5

1

x

xx

R

1,2

/( )

rfout

NC R R R

11

13 14 1,123,1

60,, 60

nn

out

NR x x Rfxu

13 14

1,

2

out

Rx xR

13 14 1

14 1

t

60

1

n

1

1

n

60

NR

1

60

NR

1

13 2 1,2

60

n

f

RNxR

13

n

N

x

1

13

60

n

21,2

R

21

1

1

11 13

60

n

out

RNxx

13

x

11

613 713 01,2

1000

nn

xx xx R

11

nn

1

R

11

x

x

xx

R

6

x

6

x

13 7 13 0 1,2

xxx

R

13 7

13 0 1

13 7

1

x

xx

R

1,2

/

rfout

NC R R R

11

1,1 3165

1

60 60,,

nn

rout

Nxf

NC R

xu

NC

1

n

1

1

1

6

60

n

60

Nx

3

1

R

1

NC

11

816 916 0

1000

nn

out

Rxx xx

x

x

8

x

8

x

1

n

1

x

1

x

16

x

16

x

9

x

9

x

1

6

1

n

1

x

x

0

2

12,1

11 1

,,

ff

x

xu

x

R

f

C

R

C

R

11

x

R

C

2

1

1

x

,

4

14,1

13 1

,,

ff

x

xu

x

R

f

C

R

C

R

13

x

R

C

4

1

1

x

6

16,1

15 1

,,

ff

x

xu

x

R

f

C

R

C

R

15

x

R

C

6

1

1

x

,

,qd

,

qd

,

12

, 1 Re , , Re ,f qd w qd f qd w qd

f

d

1

d

dfd

R

R

1

fq q fq q

1

,

d

e,

fq

1

,1

2

2

,

2

Re , , ReRe , ,

2

4

Re ,

q

qd

d

d

4

q

d

,

1

, =64/Re ,fqd qd

0.25

21

,/Re,fqd qd

,

,

1

/

1

/

/

Re

1

12

0.5 tanh 0.5wx x

0.

5t

an

h

0

.

5ta

n

h

12

0

.5

12

1

252

,, , 8

p

fqLd qd L dq

Ldq

252

d

q

25

5

qd

,8

422

,, 8

v

fqud d qu

qu

22

qu

22

d

8

4

4

2

2

,

12

123

1axxa xx

x

123

1

x

1

xx

22

12

a

a

1

1

where

,

,

ij

exu

and

,1

,,

i

fxu

are the

,ij

and

,1i

elements of

,Exu

and

,,Fxu

, while

d

and

r

d

are the pipe and radiators diameter respectively,

L

denotes the lengths of the pipes connecting the

pump to the first valve, the first valve to the second

valve, the second valve to the third valve,

r

L

denotes the equivalent length of the radiators

respectively;

1

1

,

1

1

and

2

2

are flow condition

parameters,

t

K

is the turbulent pressure drop factor

caused to the entrance of the radiators,

w

C

and are

the thermal capacity and density of the water

respectively,

C

and

0

0

are the heat capacity of the

water/radiator material and the nominal heat of the

radiator,

1

n

and are radiator model parameters,

N

is the number of sections of each radiation,

b

C

is

the thermal capacity of the boiler,

j

a

is the rate of

heat loss from the boiler jacket to the environment,

,maxw

T

is the maximum boiler effluent temperature,

1

a

and

2

a

are parameters connecting the boiler

lumped temperature to the boiler efficiency,

a

is

coefficient connecting the lumped water temperature

of the boiler to the inlet and outlet temperature,

f

C

ICINCO 2012 - 9th International Conference on Informatics in Control, Automation and Robotics

624

and

r

C

are the floor and room thermal capacities

respectively,

f

R

,

out

R

and

1,2

R

are the thermal

resistances between the room and the floor, the room

and the environment and the first and second room

respectively. From model (1) it is observed that the

performance variables are the temperature of the

room of the first apartment (1

st

output), the average

of the temperatures of the two rooms of the second

apartment (2

nd

output) and the difference between

the temperatures of the two rooms of the second

apartment (3

rd

output).

The linear approximant of the central heating

system (1) is computed to be of the form

xt Axt But D t

x

xt

B

ut

D

t

xt

A

(2a)

yt Cxt

yt

Cx

t

,

tLxt

t

L

xt

(2b,c)

After extensive computational experiments for a

wide range of inputs and disturbances, it has been

observed that the model (2) is an accurate

approximant of the original nonlinear model (1). In

the next section, the linear approximant will be used

to develop a linear controller performing satisfactory

to both the linear and the nonlinear model.

3 CONTROLLER DESIGN

Consider the dynamic controller

1

Us K s s

U

s

1

Ks s

1

2

Ks s GsWs

2

Ks

G

sW

s

2

sG

(3)

where

,,Us s s

,

Us

,

,

ss

,

and

Ws

denote the

Laplace transform of

,,ut t t

,,

ut t t

,,

and

wt

(external command). Clearly,

53

1

Ks s

5

53

5

5

3

5

5

3

5

5

s

,

54

2

Ks s

5

54

5

5

4

5

5

4

5

5

s

and

52

Gs s

5

52

5

5

2

5

5

2

5

5

s

. The

design goal will be that of independent control of the

main performance variables (i.e. the temperature of

the room of the 1

st

apartment and the average

temperature of the two rooms of the second

apartment) with simultaneous disturbance rejection.

Furthermore it is required to keep the difference

between the first and second room temperatures

enough small. If the controller (3) is applied to the

approximant (2), the design goal is formulated as a

block decoupling with simultaneous disturbance

rejection requirement, i.e.

1,1

2,2

3,2

0

0

0

C

Hs

Ps H s

Hs

0

Hs

1,1

11

0

Hs

11

1,1

Hs

0

2,2

22

Hs

22

0

0

0

0

H

,

3,2

0

Hs

32

0

Hs

,

34

0

D

Ps

3

0

34

(4a,b)

where

C

Ps

and

D

Ps

are the transfer matrices

mapping the external commands and the

disturbances to the performance outputs,

respectively, and where

1,1

Hs

,

2,2

Hs

and

3,2

Hs

are appropriate transfer functions.

A set of controller matrices satisfying the design

goal is:

†

16 1 C

Gs sI K sQs P sP s

†

†

PP

†

sI K s Q

C

C

sP sPs

†

C

16 1

Q

16 1

sI K s Q

16 1

(5a)

†

2161 d

Ks sI KsQsPsPs

†

†

sI K s Q s P s P s

†

16

1

d

Q

16 1

d

sI K s Q s P s P s

†

16 116

d

1

51 1d

Ps I K sQs K sQ s

1

Ps

KQ

K

IKsQ

1

d

Q

1

d

KsQ

s

1

d

K

51

51

IKsQ

s

511

(5b)

1

Ks

is arbitrary and proper

(5c)

where

1

16

Qs LsI A B

16

LsI A B

16

1

B

,

1

16d

Qs LsI A D

16

LsI A D

16

1

D

1

16

Ps CsI A B

16

CsI A B

16

1

B

,

1

16d

Ps CsI A D

16

CsI A

D

16

1

D

1

†

T

TT

Ps P s

Ps Ps

1

T

1

1

†

T

T

T

T

†

PP

†

T

T

T

T

Ps

Ps

†

s

P

T

T

P

P

P

P

P

Ps

P

P

P

Ps

Ps

T

T

T

P

P

P

P

Ps

P

P

P

Ps

Ps

P

P

and

Ps

Ps

is a

25

5

rational matrix preserving the

invertibility of

TT

Ps Ps

T

T

P

P

Ps P

Ps P

Ps P

T

T

P

Ps

Ps

Ps

. Choose

6

1

1,1 1,

1

() 1

j

j

Hs s

j

1

6

6

1

,

1

1

j

1

1

1,

j

,

6

1

2,2 2,

1

() 1

j

j

Hs s

1

j

1

6

6

2,

1

2

j

2

1

2,

j

6

1

3,2 3,

1

1

j

j

Hs s

1

j

1

6

6

3,

1

j

s

3

j

1

3,

j

Let

5mL

5

m

,

2m

r

L

2

m

,

0.015 md

0.

01

5

m

m

0.0096153 m

r

d

0.

00

96

1

m

,

3

971.81 Kgr m

81

9

71.

8

3

K

g

3

Kgr m

,

0.0003547 Pa s

0

354

7

0.00

0

Pa s

,

1

=0.00819

1

=0

.0

08

,

2

2300

2

0

23

00

2N

2

,

0

0.395 W

0

0.

39

5

W

,

0

0

,

0.00002

t

K

0

.

0000

2

,

36 KJ KC 36

K

KJ

K

KJ

,

1

1.25n

1

.2

5

,

29a

29

,

1

1a

1

,

2

0.12a

0

.

12

,

5.06 W K

j

a

5

.06

WK

W

WK

W

,

On the Temperature Control for a Test Case Short Pipe Network Central Heating System

625

2175525 J K

f

C 21

7

552

J

K

J

K

,

43268 J K

r

C 4

3

2

68

JK

J

J

K

J

,

0.01614 K W

out

R

0

.0161

4

KW

KW

,

0.0333 K W

f

R 0.0333

KW

KW

,

12

0.03 K WR

0

.

03

W

K

W

K

,

,max

100 °C

w

T 1

00

°C

°C

4170 J K Kgr

w

C

4170

JK Kgr

g

JK Kgr

J

,

42400 J K

b

C 42

40

0

JK

J

J

K

J

,

1

0.316

1

6

0.

31

6

1

2000 Wu 2000

W

W

,

2

2000 Pau

2

000

Pa

P

,

3

300u

300

,

4

300u

3

00

,

5

300u

300

,

1234

15 °C

1

23

4

15

°C

C

°C

1

lt hr57.58x

57

.58

t

h

l

t

hr

l

,

2

lt hr51.18x

5

1.1

8

t

h

l

t

hr

l

3

lt hr49.19x

49

.1

9

t

h

l

thr

l

,

4

92. 2 C1x

92

.2

1

C

5

88. 7 C6x

88

.7

C

,

6

91. 9 C6x

91. 9

C

,

7

87. 6 C8x

87

.6

C

8

91. 3 C5x

91

.3

C

,

9

87. 7 C5x

87

.7

C

,

10

95.79 Cx 95.

79

C

11

22.41 Cx

2

2.

4

1

C

,

12

22.41 Cx

2

2.

41

C

13

22.37 Cx 22.3

7

C

,

14

22.37 Cx 22.3

7

C

15

22.33 Cx

22

.3

3

C

,

16

22.33 Cx

22

.3

3

C

1,1

500

1,1

0

50

0

,

1,2

525

1,2

5

5

2

5

,

1,3

550

1,3

0

5

5

0

,

1,4

575

1

,4

5

5

75

1,5

600

1

,

5

0

600

,

1,6

625

1

,6

5

62

5

,

2,1

500

2

,

1

0

500

,

2,2

525

2

,

2

5

525

2,3

550

2

,

3

0

550

,

2,4

575

2,

4

5

5

7

5

,

2,5

600

2

,

5

0

6

0

0

,

2,6

625

2

,

6

5

625

3,1

500

3

,

1

0

500

,

3,2

525

3

,

2

5

52

5

,

3,3

550

3,3

0

550

,

3,4

575

3,4

5

57

5

3,5

600

3

,

5

0

6

0

0

,

3,6

625

3

,

6

5

625

,

0.009

09

0

.

0

Selecting

000

1.08

0.9

91.

28 0.7

062 0

06

00

Ps

1

062 0

0

000

09

28

.9

28

.9

28

1

.

08

9

108

9

0

0

0

0

0.

7

0

6

Ps

0

0.

0.

1

3954.21 7278.84 3148.84

8990.94 1246.73 6284.94

1435.48 3632.79 869.98

8654.17 9593.39 9528.82

7409.89 451.43 8273.09

Ks

7278.84 3148.84

7278.84 3148.84

8990 94 1246 73 6284 94

8990 94 1246 73 6284 94

8363279 86998

8363279 86998

8990.94 1246.73 6284.94

3954.2

1

3954.2

1

83

63

2.

79

86

9.

98

7 9593 39 9528 82

7 9593.39 9528.82

79

59

3.

39

95

28

.8

2

273

.

09

27

3

09

7278.84

7278.84

1246 73

1246 73

1246

.

73

8

8

48

48

14

35

14

35

8

.4

8

14

35

8654 17

8654.17

86

54

.1

7

9 451

.

43 82

74

09

8

94

51

4

38

2

7409

.

89

7409 89

the controller can be computed. It is pointed out that

the resulting closed loop system is asymptotically

stable.

To demonstrate the performance of the derived

controller, we apply the external commands

1

0.5 Cwt

0.5

C

,

2

1Cwt

1

C

. The

disturbances are considered to be all equal to

0.002 0.001 0.0005

18

15 2 1 e 2e e

33

tt t

t

t

8

1

2e e

8

0.0005

8

002 0 0

01

2e e

.002 0.001

000

002

t

0.0005

00

01

00

0.001

0.001

0.001

00

01

00

1

1

0

1

1

1

0

0

0

1e

1

e

0.

3

2e e

3

2

ee

3

3

3

1

e

3

1

5

2

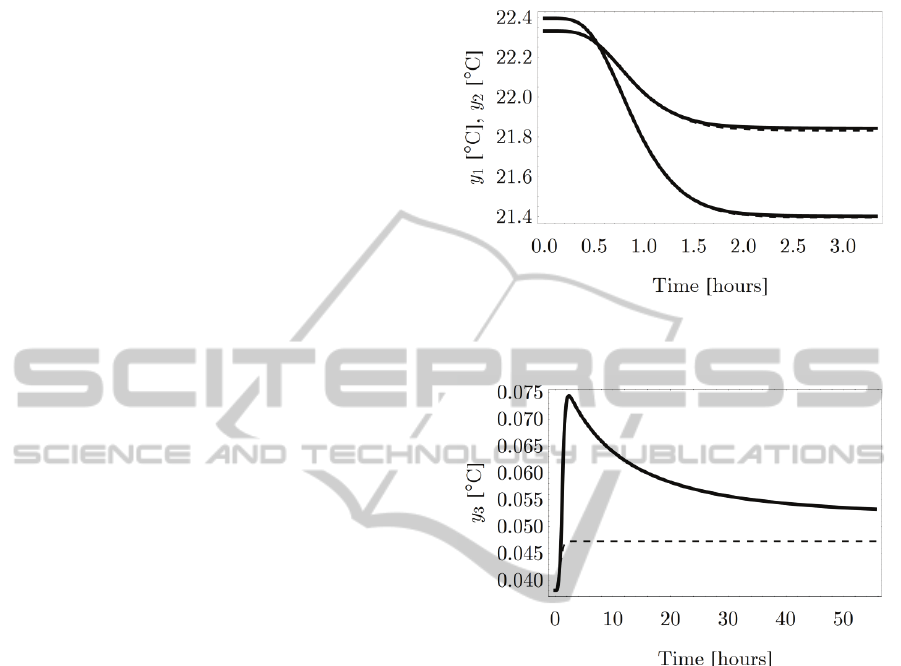

Using the above assumption, the closed loop

responses for the performance variables are

presented in Figures 1 and 2. From Figure 1 it can

readily be observed that the apartment temperatures

follow accurately the reference signals with the

respective curves being practically identical. The

maximum error throughout the simulation was for

the first performance variable about

0.012 C

C

while

for the second performance variable it was about

0.007 C

C

. Eventhough, in the third performance

variable (see Figure 2) the error is significantly

larger, it remains extremely small suggesting that the

variation cannot be sensed by the occupants of the

rooms. Before closing the section it mentioned that

state variables and the actuatable input variables

remain within acceptable limits.

4 CONCLUSIONS

The mathematical model of a test case central

heating system with a short piping network, three

radiators, a boiler and three rooms in two apartments

has been developed. Based upon the linear

approximant of the nonlinear model a dynamic

controller, achieving independent control between

the two apartment temperatures together with

rejection of the influence of the external

temperatures and small differences between the

temperatures of the rooms of the second apartment,

has been derived. The performance of the controller

has been examined through simulations on the

nonlinear model of the plant.

REFERENCES

Cai, W., 2006. Nonlinear Dynamics of Thermal-Hydraulic

Networks, PhD Dissertation, University of Notre

Dame.

Hansen, L. H., 1997. Stochastic Modeling of Central

Heating Systems, PhD Dissertation, Technical

University of Denmark.

Koumboulis, F. N., Kouvakas, N. D., Paraskevopoulos, P.

N., 2007. Modeling and Control of a Neutral Time

Delay Test Case Central Heating System, In

Proceedings of the 6th WSEAS International

Conference on Circuits, Systems, Electronics, Control

& Signal Processing (CSECS'07), pp.289-297,

December 29-31, Cairo, Egypt.

Koumboulis, F. N., Kouvakas, N. D., Paraskevopoulos,

P.N., 2008. Analytic Modeling and Metaheuristic PID

Control of a Neutral Time Delay Test Case Central

Heating System, In WSEAS Transactions on Systems

and Control, vol. 3, no. 11, pp. 967-981.

ICINCO 2012 - 9th International Conference on Informatics in Control, Automation and Robotics

626

Koumboulis, F. N., Kouvakas, N. D., Paraskevopoulos, P.

N., 2008. Dynamic Disturbance Rejection Controllers

for Neutral Time Delay Systems with application to a

Central Heating System, In Proceedings of the

International Conference on Modelling, Identification

and Control (ICMIC 2008), June 29 - July 2,

Shanghai, China.

Koumboulis, F. N., Kouvakas, N. D., Paraskevopoulos, P.

N., 2009. Dynamic disturbance rejection controllers

for neutral time delay systems with application to a

central heating system, In Science in China Series F:

Information Sciences, vol. 52, no. 7, pp. 1084 – 1094.

Koumboulis, F. N., Kouvakas, N. D., Paraskevopoulos, P.

N., 2009. Linear approximant-based metaheuristic

proportional-integral-derivative controller for a neutral

time delay central heating system, In Proceedings of

the IMechE Part I: Journal of Systems and Control

Engineering, vol. 223, pp. 605-618.

Koumboulis, F. N., Kouvakas, N. D., Paraskevopoulos, P.

N., 2009. On the Morgan's Problem for Neutral Time

Delay Systems via Dynamic Controllers with

application to a Test Case Central Heating System, In

Proceedings 3rd IEEE Multi-conference on Systems

and Control (MSC 2009), July 8-10, Saint Petersburg,

Russia.

Koumboulis, F. N., Kouvakas, N. D., 2010. Approximate

Temperature Control of a Neutral Time Delay Central

Heating System via a Two Term Disturbance

Compensator, In Proceedings of the 15th International

Conference on Emerging Technologies and Factory

Automation, September 13-16, Bilbao, Spain.

Mendi, F., Boran, K. and Kulekci, M. K., 2002. Fuzzy

Controlled Central Heating System, In International

Journal of Energy Research, vol. 26, no. 15, pp. 1313-

1322.

Morel, N., Bauer, M., El-Khoury, M. and Krauss, J., 2001.

NEUROBAT: A Predictive and Adaptive Heating

Control System Using Artificial Neural Networks, In

International Journal of Solar Energy, vol. 21, pp.

161-201.

Zaheer-Uddin, M., Zheny, G. R. and Cho, S.-H., 1994.

Optimal Operation of an Embedded-Piping Floor

Heating System with Control Input Constrains, In

Energy Conversion and Management, vol. 38, no. 7,

pp. 713-725.

Zanobini, A., Luculano, G. and Papini, A., 1998. Central

Heating Control: a New Technique to Gauge Room

Temperature, In Proceedings of the IEEE

Instrumentation and Measurement Technology

Conference, May 18-21, St. Paul, USA

APPENDIX

Figure 1: Closed loop responses for

1

y

and

2

y

(continuous -

1

y

and

2

y

, dashed – reference).

Figure 2: Closed loop response for

3

y

(continuous -

3

y

,

dashed – reference).

1

y

2

y

On the Temperature Control for a Test Case Short Pipe Network Central Heating System

627