Robust Arbitrary Reference Command Tracking

with Application to Hydraulic Actuators

M. G. Skarpetis, F. N. Koumboulis and A. S. Ntellis

Halkis Institute of Technology, Department of Automation, 34400, Psahna Evoias, Halkis, Greece

Keywords: Robust Control, Arbitrary Reference Command Tracking, Hydraulic Actuator.

Abstract: In this paper a robust tracking controller is proposed in order to track arbitrary reference signals in the

presence of same type disturbance signals. The robust tracking controller is based on the well known

Internal Model Principle appropriately modified with a Hurwitz invariability technique. The controller

parameters are computed using a finite step algorithm. Solvability conditions are derived. The proposed

controller is successfully applied to a hydraulic actuator uncertain model including uncertain parameters

arising from changes of the operating conditions and other physical reasons. Simulation results for all the

expected range of the actuator model uncertainties are presented indicating the satisfactory performance of

the robust controller in the presence of external disturbances.

1 INTRODUCTION

The problem of output tracking appears to be one of

the most popular control design problems (see (Chen,

1984), (Horowitz, 1963), (Dorf and Boshop, 2001),

(Goodwin et al., 2001), (Corless et al., 1984),

(Takaba, 1998); (Yaesh and Shaked, 1991) and the

reference therein). The problem of output tracking

for both non uncertain and uncertain systems (robust

tracking) is treated mainly using stabilizability

techniques, e.g. Dorf and Boshop, 2001; Corless et

al., 1984; Takaba, 1998. For robust tracking a variety

of approaches, to the most optimal or adaptive, has

been proposed in (Corless et al., 1984), (Takaba,

1998), (Yaesh and Shaked, 1991), (Skarpetis et al.,

2006a,b), and (Skarpetis et al., 2007).

The problem of robust tracking appears to be of

major interest in the design of controllers for

hydraulic actuators. This type of actuators is widely

used in many applications like manufacturing,

robotics, constructions and avionics. The dynamics

of fluid power are inherently uncertain. So, robust

control strategies are indispensible if one wishes to

guarantee safety and reliability of hydraulic actuators

(see Skarpetis et al., 2007; Karpenko and Shapehri,

2005; Koumboulis et al., 2006a and b; Koumboulis et

al., 1998; Kliffken, 1997; Kliffken and Heinrich,

2001; and the references therein). Robust asymptotic

tracking techniques like those in Skarpetis et al.,

2006a-b; Skarpetis et al., 2007 and robust PI-PID

design techniques like those in Koumboulis et al.,

2006a and b; Huang and Wang, 2000; Ho and

Huang, 2003; Musch and Steiner, 1995; Ge et al.,

2002; Toscano, 2005; Garcia et al., 2004;

Koumboulis, 2005; and Koumboulis, 1999; perform

satisfactory in many industrial hydraulic plants.

In this paper a robust tracking controller is

proposed in order to satisfy asymptotic command

following for arbitrary reference signals. The design

technique is based on the well known Internal Model

Principle (Goodwin et al., 2001), appropriately

extended using Hurwitz invariability for the

augmented system including the error dynamics. An

arbitrary reference model that produces desired

reference signals is used in the controller structure

and the overall closed loop robust stability is

guaranteed under sufficient conditions. The robust

tracking controller appears to guarantee satisfactory

performance under the influence of external

disturbance signals.

The present results are successfully applied to

control the position of a hydraulic actuator model

involving uncertain parameters arising from changes

of the operating conditions (temperature, pressure,

entrained air or water) as well as physical

uncertainties (loss in the effective area of the

actuator piston seal due to wear (Karpenko and

Shapehri, 2005)). Solvability conditions are

established. An analytic finite step algorithm for the

computation of the robust controller parameters is

94

G. Skarpetis M., N. Koumboulis F. and S. Ntellis A..

Robust Arbitrary Reference Command Tracking with Application to Hydraulic Actuators.

DOI: 10.5220/0004048600940102

In Proceedings of the 9th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2012), pages 94-102

ISBN: 978-989-8565-21-1

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

proposed. Following the algorithm, first, robust

stability regions are determined. Second, the

metaheuristic optimization algorithm proposed in

(Koumboulis and Tzamtzi, 2007) is applied, inside

these regions, to fulfil performance criteria. The

effectiveness of the controller is illustrated through

simulations for various values of the model

uncertain parameters. The present results appear to

be simple and easily applicable.

2 PRELIMINARY RESULTS

Consider the linear time-invariant SISO system with

non linear uncertain structure described by

() ()() ()() () ()

() () ()

xt Aqxt bqut dqwt

yt cqxt

=++

=

(1)

where

()

n

xt ∈ is the state vector, ()ut ∈ is the

input and

()yt ∈ is the output and ()wt ∈ is

external disturbance.

[

]

() ()

nn

Aq q

×

∈℘ ,

[

]

1

() ()

n

bq q

×

∈℘ ,

[

]

1

() ()

n

dq q

×

∈℘ and

[

]

1

() ()

n

cq q

×

∈℘ are function matrices depending

upon the uncertainty vector

1 l

qq q

⎡⎤

=∈

⎢⎥

⎣⎦

(

denotes the uncertain domain). The set ()q℘ is

the set of nonlinear functions of

q

. The uncertainties

1

,,

l

qq… do not depend upon the time. With regard

to the nonlinear structure of

(),Aq ()bq , ()dq and

()cq no limitation or specification is considered (i.e.

boundness, continuity).

Consider the case where the reference signal

()

r

yt is the output of a linear model described by

() () ; () ()

rrr rrr

xt Axt yt cxt==

(2)

where

()

r

yt∈ ,

1

()

r

r

xt

×

∈ and where

12 1

01 0 0

00 1 0

00 0 1

r

rr r

A

dd d d

−−

⎡⎤

⎢⎥

⎢⎥

⎢⎥

⎢⎥

⎢⎥

=

⎢⎥

⎢⎥

⎢⎥

⎢⎥

−− − −

⎢⎥

⎣⎦

,

10 0

r

c

⎡⎤

=

⎢⎥

⎣⎦

Consider the vector

,0r

x denoting arbitrary initial

conditions for system (2). Clearly, it holds that

() ( )

1

() () 0

r

rri

rir

i

yt dy t

−

=

+=

∑

(3)

The disturbance is assumed to be of the same type as

the reference signal, i.e.

() ( )

1

() () 0

r

rri

i

i

wt dw t

−

=

+=

∑

(4)

Define the tracking error

() () ()

r

tytytε =− (5)

Differentiating the error r-times, we get

() () ()

() ()

() () ()

() ( )

1

()

()

rrr

r

r

rri

ir

i

tcqxtyt

cqx t dy t

ε

−

=

=−=

=+

∑

(6)

or equivalently

()

() () ()

()

()

1

()

()

1

()

()

r

ri

r

i

i

r

ri

r

i

i

tdt

cqx t cq dx t

εε

−

=

−

=

+=

+

∑

∑

(7)

Define the variables

() ()

() ()

()

()

1

()

()

1

()

()

r

ri

r

i

i

r

ri

r

i

i

zt x t dx t

ut u t du t

−

=

−

=

=+

=+

∑

∑

(8)

According to (4), (7) and (8) the following

augmented system is defined:

()

() ()

()

d

xt Aqx bqut

dt

=+

(9)

() () () () ()

(1) ( 1)

T

r

xt t t t ztεε ε

−

⎡

⎤

=

⎢

⎥

⎣

⎦

() ()

()

1

()

0

,

0()

rr

r

nr

Aecq

Aq b q

Aq

bq

×

×

⎡

⎤

⎡⎤

⎢⎥

⎢⎥

==

⎢⎥

⎢⎥

⎢⎥

⎢

⎥

⎣⎦

⎣

⎦

,

(1)1

0

1

r

r

e

−×

⎡

⎤

⎢

⎥

=

⎢

⎥

⎢

⎥

⎣

⎦

.

Consider the static state feedback control law

() () () ()

12

ut fxt f t fztε==+

(10)

where

() () () ()

(1) ( 1)

T

r

ttt tεεε ε

−

⎡

⎤

=

⎢

⎥

⎣

⎦

.

The robust output command tracking is

formulated as follows (Chen, 1984; Goodwin,

Graebe and Salgado, 2001): the output of the

uncertain system (1) follows the output of the

reference system (2) while the tracking error (5)

RobustArbitraryReferenceCommandTrackingwithApplicationtoHydraulicActuators

95

decreases asymptotically to zero. This is satisfied

using a static state feedback control law of the form

(10) guaranteeing robust stability of the polynomial

() ()()

,, det

cl r n

psqf sI Aq bqf

+

⎡⎤

=−−

⎣⎦

(11)

The control law (10) can be expressed in terms of

the original systems using the differential equation:

()

()

() (1)

()

1,

11

()

()

2

1

() ()

()

rr

ri i

r

ii

ii

r

ri

r

i

i

ut du t f t

fx t dx t

ε

−−

==

−

=

+= +

⎛⎞

⎟

⎜

⎟

⎜

++

⎟

⎜

⎟

⎜

⎟

⎜

⎝⎠

∑∑

∑

(12)

where

1,

( 1,..., )

i

f

ir= are the elements of

1

f

. Eq.

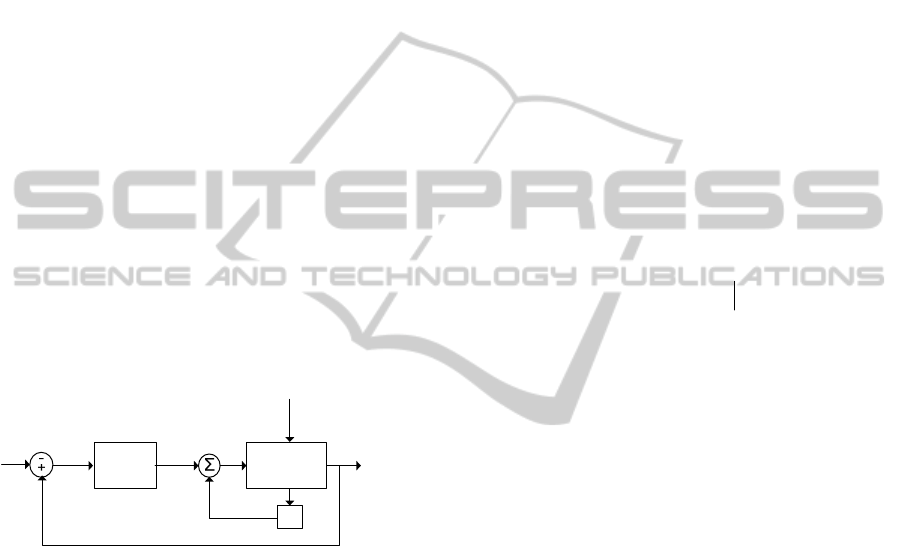

(12) is realized in state space form as (see Figure 1):

2

() () (), () ()

() () ()

cccc cc

xt Axt b t t cxt

ut t fxt

ευ

υ

=+ =

=+

(13)

11,

21,1

1,1

10 0

01 0

,,

00 0

10 0

r

r

cc

r

c

df

df

Ab

df

c

−

⎡⎤⎡⎤

−

⎢⎥⎢⎥

⎢⎥⎢⎥

−

⎢⎥⎢⎥

==

⎢⎥⎢⎥

⎢⎥⎢⎥

⎢⎥⎢⎥

−

⎢⎥⎢⎥

⎣⎦⎣⎦

⎡⎤

=

⎢⎥

⎣⎦

,,

ccc

Abc

()wt

()

r

yt

()tε

()tυ

(),(), ()

()

Aq bq d q

cq

()xt

2

f

()ut

()yt

Figure 1: Closed loop structure.

3 SOLVABILITY CONDITIONS

The polynomial (11) can be rewritten as

()

() ()

,, det det ()

adj

cl r r n

nr

psqf sI A sI Aq

f

sI A q b q

+

⎡⎤⎡ ⎤

=− −

⎣⎦⎣ ⎦

⎡⎤

−−

⎣

⎦

(14)

Define:

() () ()

1

1

rn

aq a q a q

+

⎡⎤

=

⎢⎥

⎣⎦

(15)

where

()

i

aq

( 1,...,irn=+) are the coefficients

of the polynomial

[

]

[

]

det det ( )

rr n

sI A sI A q−−.

Also define the polynomial matrix

() ()

(

)

() ()

μ

+

=Ω =

⎡⎤

−

⎣

⎦

0

,[ ]

adj

qT

nr

Psq q s s

sI A q b q

(16)

where

()qnrμ ≤+ is the maximum degree of the

polynomial matrix

() ()

adj

nr

sI A q b q

+

⎡

⎤

−

⎣

⎦

and

() () ()

() () ()

0()

,1 ,

;

q

T

iiinr

qq q

qq q

μ

ωω

ωωω

+

⎡

⎤

Ω=

⎢⎥

⎣⎦

⎡

⎤

=

⎣

⎦

(17)

According to definitions (15) and (17) the

augmented closed loop characteristic polynomial

(14) can equivalently be expressed as follows:

()

0**

1

,, [ ] ()

nr

cl

T

psqf s sAq

f

+

⎡⎤

⎢⎥

=

⎢⎥

⎢⎥

⎣⎦

(18)

where

**

()

T

T

Aq a

⎡

⎤

=−Ω

⎢

⎥

⎣

⎦

%

%

,

()

() ()

()

()

0

nr nr q

qq

μ

+×+−

⎡

⎤

Ω= Ω

⎢

⎥

⎣

⎦

%

(19)

Based on the above definitions and the results in

(Wei and Barmish, 1989), (Koumboulis and

Skarpetis, 1996) and (Koumboulis and Skarpetis,

2000) the following theorem is presented.

Theorem 1. The problem of robust output command

tracking for the uncertain system (1) and for arbitrary

signals produced by the reference model (2), is

solvable, via the controller (13), if the following

conditions are satisfied

(i) The elements of

()

**

Aqare continuous functions

of

q for every

q ∈

(ii) There exists

()

1nr++ −row submatrix of

()

**

Aq, let

()

*

Aq which is positive antisymetric.

Proof: According to the definition of the problem

presented in Section 2, the problem of robust output

command tracking for the uncertain system (1) via

the controller (13) is solvable if the polynomial (14)

is robustly stable. According to the results in (Wei

and Barmish, 1989), (Koumboulis and Skarpetis,

1996) and (Koumboulis and Skarpetis, 2000) the

uncertain polynomial is Hurwitz invariant if

conditions (i) and (ii) of Theorem 1 are satisfied.

In the following theorem necessity is studied.

Theorem 2. For the problem of robust output

command tracking for the uncertain system (1) and

for arbitrary signals produced by the reference model

(2), via the controller (13), it is necessary for the

roots of the polynomial

[

]

()adj () ()

n

cq sI Aq bq− not

ICINCO2012-9thInternationalConferenceonInformaticsinControl,AutomationandRobotics

96

to be unstable roots of

det

rr

sI A

⎡⎤

−

⎣⎦

for every

q ∈

.

Proof: The polynomial (14) can be rewritten as

follows

()

() ()

() ()

1

2

,, det det ()

adj ( )adj

adj ( )det

cl r r n

rr n

nrr

psqf sI A sI Aq

fsIAcqsIAqbq

fsIAqbqsIAbq

⎡⎤⎡ ⎤

=− −+

⎣⎦⎣ ⎦

⎡⎤⎡ ⎤

−− − +

⎣⎦⎣ ⎦

⎡⎤⎡⎤

−− −

⎣⎦⎣⎦

From the above relation it is clear that if

()qσ ∈ is

a root of

[

]

()adj () ()

n

cq sI Aq bq− , being unstable

for at least one

q ∈ . Then its value for this q

must not be eigenvalue of

det

rr

sI A

⎡⎤

−

⎣⎦

.

The condition of Theorem 2 is related to the

uncontrollable part of the augmented system

() ()

(,)Aq b q

. This condition is useful in choosing

the model of the reference signal.

Remark 1. The class of the systems that satisfy

condition (ii) of Theorem 1, can be widen, if, instead

of

()

**

Aq the matrix

()

**

AqT is considered

where

T is an appropriate invertible and independent

from

q matrix.

For the definition of positive antisymetric

matrices see Wei and Barmish, 1989; Koumboulis

and Skarpetis, 1996; and Koumboulis and Skarpetis,

2000). An analytic algorithm for the computation of

an

f

preserving Hurwitz invariability can be found

in the aforementioned papers.

4 ROBUST CONTROL FOR

POSITION TRACKING OF A

HYDRAULIC ACTUATOR

4.1 Actuator Model

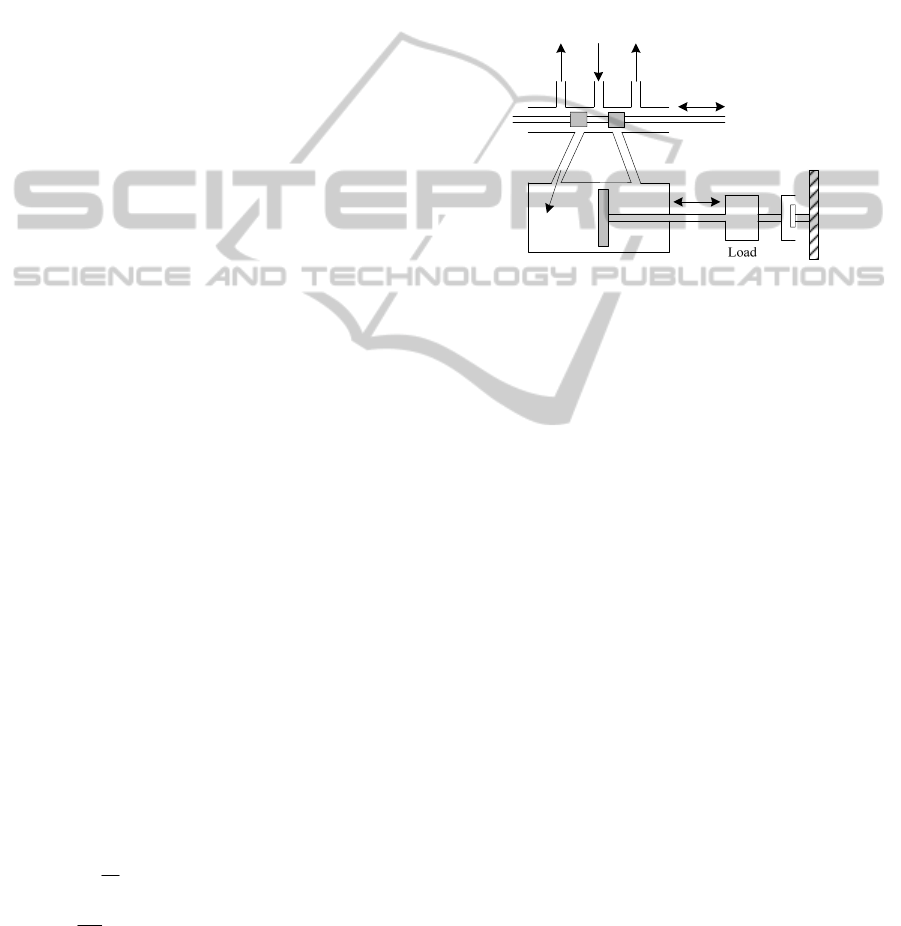

Consider a double acting servo valve and piston

actuator shown in Figure 2. The linearized

differential equations that describe the actuator –

valve dynamics can be formulated as follows

(Karpenko and Shapehri, 2005):

() ()

pp

xt tυ=

(20)

[]

1

() () () ()

pLpL

tAPtbtFt

m

υυ=−−

(21)

[]

4

() () () ()

LftpLp

Pt Kx t KPt A t

V

υ

β

υ

=−−

(22)

where

p

υ is the piston velocity,

p

x is the piston

position,

L

P is the hydraulic pressure across the

actuator piston,

L

F is the external load disturbance

and

x

υ

is the spool valve displacement. The

parameters

,,,Am bβ and V are: the piston surface

area, the mass of the load, the effective bulk modulus

of the hydraulic fluid, the viscous damping

coefficient and the total volume of hydraulic oil in

the piston chamber and the connecting lines,

respectively. The coefficients

f

K and

tp

K arise

from the linearization of the servo valve load flow

and the leakage flow.

v

x

p

x

b

q

A

L

P

m

p

υ

in

ν

Figure 2: Valve and piston schematic.

The valve displacement is usually produced by a

solenoid (electrohydraulic valve) actuated by the

input voltage

()

in

tν of the solenoid. The transfer

function of a solenoid can be approximated by the

servo valve spool position gain denoted by

v

k .

Using (20)-(22) the following linear system with

uncertain structure is derived in state space form:

00 0

() () () ( ) () ()

in L

xt A qxt B q t DF tν=+ +

(23)

0

() ()yt C xt= (24)

() () ()

()

T

ppL

xt t Pt

xt

υ

⎡

⎤

=

⎢

⎥

⎣

⎦

0

100C

⎡

⎤

=

⎢

⎥

⎣

⎦

0

112

01 0

() 0 / /

04/ 4/

Aq b m Am

qA V qq V

⎡

⎤

⎢

⎥

⎢

⎥

=−

⎢

⎥

⎢

⎥

⎢

⎥

−−

⎢

⎥

⎣

⎦

,

0

13

0

0

()

4/

Bq

qqk V

υ

⎡

⎤

⎢

⎥

⎢

⎥

=

⎢

⎥

⎢

⎥

⎢

⎥

⎣

⎦

,

0

0

1/

0

Dm

⎡⎤

⎢⎥

⎢⎥

=−

⎢⎥

⎢⎥

⎢⎥

⎣⎦

The parameter

1

q β= is an uncertain parameter

since the effective bulk modulus of the hydraulic

fluid changes due to temperature, pressure and

RobustArbitraryReferenceCommandTrackingwithApplicationtoHydraulicActuators

97

entrained air or water fluctuations. The parameter

2 tp

qK= changes due to migration of the system’s

operating point and the parameter

3

f

qK= changes

due to migration of the system operating point and to

loss in the effective area of the actuator piston seal,

due to wear (Karpenko and Shapehri, 2005). The

vector

123

qqqq

⎡⎤

=∈

⎢⎥

⎣⎦

is the uncertain

vector and

is the domain of uncertainty. The

nominal values of the system parameters are shown

in Table 1 and the expected range of variations of the

uncertain system parameters is shown in Table 2

(Karpenko and Shapehri, 2005).

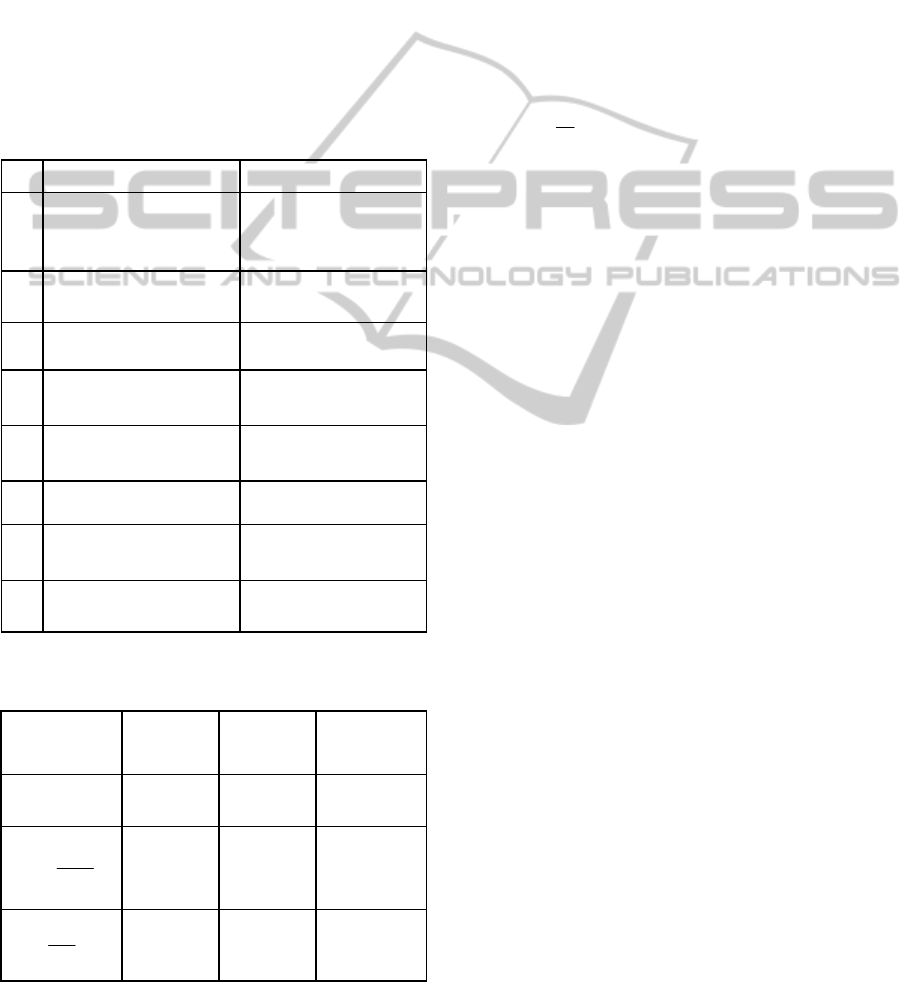

Table 1: Nominal Values for the Hydraulic Actuator’s

Parameters.

Definition Nominal Values

V

volume of hydraulic

oil in the piston

chamber

33

468 / 100 m

A

piston surface area

22

633 / 1000 m

β

effective bulk modulus

6

689 10 Pa×

tp

K

total flow pressure

coefficient

3

0/mPas−

b

viscous damping

coefficient

1

1000Nm s

−

m

load mass

12Kg

k

υ

servo valve spool

position gain

3

0.0406 10 /mV

−

×

f

K

servo valve gain

2

1.02 / secm

Table 2: Expected Range of Variations of the Uncertain

Parameters.

Symbol

Minimum

Values

Nominal

Values

Maximum

Values

()Paβ

6

550 10×

6

689 10×

6

895 10×

3

tp

m

K

Pa s

⎛⎞

⎟

⎜

⎟

⎜

⎟

⎜

⎟

⎜

⎟

⎜

⎝⎠

0

0

11

9.5 10

−

×

2

sec

f

m

K

⎛⎞

⎟

⎜

⎟

⎜

⎟

⎟

⎜

⎝⎠

1.02

1.02

1.76

4.2 Robust Tracking Controller

In this subsection a robust tracking arbitrary

controller for asymptotic tracking of the piston

position will be designed. According to (2) the

reference output model is derived for

2r = to be:

,01

,0

,02

() (), () (),

r

rrrrrrr

r

x

xt Axt yt cxt x

x

⎡⎤

⎢⎥

===

⎢⎥

⎢⎥

⎣⎦

where

21

01

r

A

dd

⎡

⎤

⎢

⎥

=

⎢

⎥

−−

⎢

⎥

⎣

⎦

and 10

r

c

⎡⎤

=

⎢⎥

⎣⎦

.

According to definitions of Section 2 the

following augmented system is introduced

()

() ()

()

d

xt Aqx bqut

dt

=+

where

() ()

()

() ()

1

T

xt t t ztεε

⎡

⎤

=

⎢

⎥

⎣

⎦

()

21

112

010 0 0

10 0

000 1 0

000 / /

0004/ 4/

dd

Aq

bm Am

qA V qq V

⎡

⎤

⎢

⎥

⎢

⎥

−−

⎢

⎥

⎢

⎥

⎢

⎥

=

⎢

⎥

⎢

⎥

−

⎢

⎥

⎢

⎥

−−

⎢

⎥

⎣

⎦

,

()

13

0

0

0

0

4/

bq

qqk V

υ

⎡

⎤

⎢

⎥

⎢

⎥

⎢

⎥

⎢

⎥

=

⎢

⎥

⎢

⎥

⎢

⎥

⎢

⎥

⎢

⎥

⎢

⎥

⎣

⎦

.

Apply the static state feedback law: ufx=

with

11 12 21 22 23

f

fffff

⎡

⎤

=

⎢

⎥

⎣

⎦

. The aforementioned

controller can be produced by the original input

signal

()ut using the following state space form:

() () (), () ()

cccc cc

xt Axt bet t cxtυ=+ =

where

11,2

21,1

0

,,10

0

cc

df

Ac b c

df

−

⎡

⎤⎡⎤

⎡⎤

⎢⎥⎢⎥

===

⎢⎥

⎢⎥⎢⎥

⎣⎦

−

⎢

⎥⎢⎥

⎣

⎦⎣⎦

and

2

() () ()ut t fxtυ=+ where

2212223

f

fff

⎡⎤

=

⎢⎥

⎣⎦

.

The augmented system closed loop characteristic

uncertain polynomial is:

()

() ()

() () ()

543

12 0 1

21

234

,,, , ,

,,,

cl

psqqf s qfs qfs

qf s qf s qf

γγ

γγγ

=+ + +

++

(25)

ICINCO2012-9thInternationalConferenceonInformaticsinControl,AutomationandRobotics

98

where

()

12 23 3

10

4

,

()

u

mq q f k q bV

dq

mV

f

γ

−+

+=

,

()

22 1 3

12 23 3 1 12 2

2

11

33

12

1

(4

4( )4 (

,4

)

)

u

uu

Af k q q

mV

bq q f k q d mq q f k q

qf A

bd V d mV

qγ −+

−+ −+

+

=

,

()

2

2112112213

212 23 3

11 2 23 3 2

1

,(44()

4( )

(4 ( ) ))

u

u

u

qf Adq Af df kqq

mV

dmq q f kq

bdqq fkq dV

γ =−+

+−

+−+

,

()

3122233

2

2121212223

1

,(4(( )

()))

u

u

qf q bd q f kq

mV

Ad Af df d f k q

γ =−+

+− + +

,

()

1

4

122113

4(

,

)

u

Af df kq

qf

q

mV

γ =

+

−

.

According to (15) and (17) define

()

0123

10aq a a a a

⎡⎤

=

⎢⎥

⎣⎦

(26)

12

01

4bqq

d

m

a

V

++=

,

2

11211212

1

444bq q d mq q bd V d mV

m

a

V

Aq ++ ++

=

2

11 112 2 1

2

22

44 4Adq bdqq dmqq bdV

m

a

V

=

++ +

,

22

3

2

1

4( )dq A bq

mV

a

+

=

()

25

34 35

43 44 45

52 53 54 55

61 63

00000

0000

000

00

0

000

T

q

ω

ωω

ωωω

ωωωω

ωω

⎡⎤

⎢⎥

⎢⎥

⎢⎥

⎢⎥

⎢⎥

⎡⎤

⎢⎥

−Ω =

⎣⎦

⎢⎥

⎢⎥

⎢⎥

⎢⎥

⎢⎥

⎢⎥

⎣⎦

(27)

where

61 52 43

13

34

4

u

Ak q q

mV

ωωωω−====

,

13

25

4

u

kqq

V

ω −=

,

4

3

53

11

4

4

u

Ad k q q

mV

ωω=−=

,

13

35

1

4( )

u

kb dmqq

mV

ω

+

=−

,

23

55

1

4

u

bd k q q

mV

ω −=

,

5

3

63

21

4

4

u

Ad k q q

mV

ωω=−=

,

12

45

13

4( )

u

kbd dmqq

mV

ω

+

−=

,

According aforementioned definitions the

augmented closed loop characteristic polynomial

(25) can equivalently be expressed as follows:

()

543210**

11 12 21 22 23

,, ()

1

cl

T

psqf s s s s s sAq

fffff

⎡

⎤

=

⎢⎥

⎣⎦

⎡⎤

⎢

⎥

⎣

⎦

(28)

where

**

()

TT

Aq a

⎡

⎤

=−Ω

⎢

⎥

⎣

⎦

(29)

Let

100000

00 0 0 0 1

00 0 0 10

00 0 10 0

00 10 0 0

010000

T

⎡

⎤

⎢

⎥

⎢

⎥

−

⎢

⎥

⎢

⎥

−

⎢

⎥

⎢

⎥

=

⎢

⎥

−

⎢

⎥

⎢

⎥

−

⎢

⎥

⎢

⎥

−

⎢

⎥

⎣

⎦

Choose the following

66×

row submatrix of

()

**

AqT,

()

21 22

31 32 33

*

41 42 43 44

51 52 53 54 55

64 66

100000

0000

000

00

0

000 0

Aq

φφ

φφφ

φφφφ

φφφφφ

φφ

⎡

⎤

⎢

⎥

⎢

⎥

⎢

⎥

⎢

⎥

⎢

⎥

⎢

⎥

=

⎢

⎥

⎢

⎥

⎢

⎥

⎢

⎥

⎢

⎥

⎢

⎥

⎣

⎦

(30)

where

21 0

aφ =

,

()

31 1

qaφ =

,

41 2

aφ =

,

51 3

aφ =

,

22 25

φω=−

,

32 35

φω=−

,

42 45

φω=−

,

52 55

φω=−

,

33 34

φω−=

,

43 44

φω=−

,

53 54

φω=−

44 43

φω=−

,

54 53

φω−=

,

64 63

φω−=

,

55 52

φω=−

,

66 61

φω=−

.

Theorem 3. The problem of robust output

command tracking for the uncertain system (1) via

the controller (13) is always solvable.

Proof: Condition (i) can easily be verified. The

matrix

()

Aq

∗

is positive antisymetric. It can be

constructed using the five positive up augmentations

(

66

φ ,

55

φ ,

44

φ ,

33

φ and

22

φ are positive numbers

for all the values of the uncertainties):

() () () ()

() ()

1234

*

5

qqqq

qAq

Φ→Φ→Φ→Φ→

→Φ →

where

()

166

q φΦ=,

()

56

2

66

0

0

q

φ

φ

⎡⎤

⎢⎥

Φ=

⎢⎥

⎢⎥

⎣⎦

,

RobustArbitraryReferenceCommandTrackingwithApplicationtoHydraulicActuators

99

()

44

35455

64 66

00

0

0

q

φ

φφ

φφ

⎡⎤

⎢⎥

⎢⎥

Φ=

⎢⎥

⎢⎥

⎢⎥

⎢⎥

⎣⎦

,

()

33

43 44

4

53 54 55

64 66

000

00

0

00

q

φ

φφ

φφφ

φφ

⎡⎤

⎢⎥

⎢⎥

⎢⎥

Φ=

⎢⎥

⎢⎥

⎢⎥

⎢⎥

⎣⎦

,

()

22

32 33

42 43 44

512

52 53 54 55

64 66

0000

000

00

,

0

00 0

qq

φ

φφ

φφφ

φφφφ

φφ

⎡⎤

⎢⎥

⎢⎥

⎢⎥

⎢⎥

⎢⎥

Φ=

⎢⎥

⎢⎥

⎢⎥

⎢⎥

⎢⎥

⎣⎦

.

The vector

() ()

1

cq q=Φ

is a Hurwitz invariant

core since the associate polynomial of

()

cq

(

()

[

]

T

cq ) is positive Hurwitz invariant. Hence,

condition (ii) of Theorem 1 is satisfied. For reference

and disturbance signals of sinusoidal form, condition

(iii) of Theorem 1 is also satisfied.

5 COMPUTATION OF THE

CONTROLLER PARAMETERS

Using a reference input of the form

( ) 0.02 [0.2 ]

r

yt Sin t= (

12

0, 0.04dd==,

,01 ,02

0, 0.004

rr

xx==) the tracking controller will

be computed using the following algorithm

Step 1 (Construction of the augmentation

matrices): The core of

()

Aq

∗

is

() ()

1

cq q=Φ .

From

()

1

qΦ using five up positive augmentations

the matrix

() ()

6

qAq

∗

Φ= is constructed.

Let

1

1τ = .

Step 2 (Determination of the region of

1

0ε >

for which

()

21

1

T

q ε

⎡⎤

Φ

⎢⎥

⎣⎦

is positive Hurwitz

invariant): According to the form of the associated

polynomial it is observed that robust stability is

guaranteed

1

0ε∀>

. Let

21

1τε

⎡⎤

=

⎢⎥

⎣⎦

and choose

the stability region of

1

ε

to be :

[

]

1

0.25,0.55

ε

∈ .

Step 3 The polynomial

()

322

T

q ετ

⎡⎤

Φ

⎢⎥

⎣⎦

is

robustly stable

2

0ε∀>

. Let

321

1τεε

⎡⎤

=

⎢⎥

⎣⎦

and

choose the stability region of

2

ε

to be:

[

]

2

0.2,0.3

ε

∈ .

Step 4: The polynomial

()

433

T

q ετ

⎡⎤

Φ

⎢⎥

⎣⎦

is

positive Hurwitz invariant inside the selected

region

[

]

3

0.01, 0.015

ε

∈ .Let

4321

1τεεε

⎡⎤

=

⎢⎥

⎣⎦

.

Step 5 : The polynomial

()

544

T

q ετ

⎡⎤

Φ

⎢⎥

⎣⎦

is

positive Hurwitz invariant inside the region

99

4

610,710

ε

−−

⎡

⎤

∈× ×

⎣

⎦

.Let

54321

1τεεεε

⎡⎤

=

⎢⎥

⎣⎦

.

Step 6: The polynomial

()

655

T

q ετ

⎡⎤

Φ

⎢⎥

⎣⎦

is

positive Hurwitz invariant inside the selected

region

[

]

5

0.0006,0.0008

ε

∈ .

Step 7: Using a search algorithm in the stability

regions specified in steps 2-6 and for all values of

the uncertain parameters, the following values for

12345

,,,,εεεεε are derived:

1

0.5ε = ,

2

0.25ε = ,

3

0.012ε = ,

9

4

610ε

−

=×

and

5

0.0007ε = .

Step 8 (Derivation of the gain vector): The gain

vector

f

that robustly stabilizes the associated

polynomial of

()

**

AqT (

()

** T

AqTf

) is

54321

1f εεεεε

⎡

⎤

=

⎢

⎥

⎣

⎦

and consequently the

gain vector that robustly stabilizes the associate

polynomial of

()

**

Aq is

5 1234

1

T

T

Tf εεεεε

⎡

⎤

=−−−−−

⎢

⎥

⎣

⎦

or equivalently the vector

1234

5

55555

1

/1

T

T

Tf

εεεε

ε

εεεεε

⎡

⎤

⎢

⎥

=−−−−−

⎢

⎥

⎣

⎦

Finally using the above relation the respective values

from Step 7 of the algorithm and relation (28) the

controller parameters are computed to be

11 12

21 22

23

6

1428.57 714.286

357.143 17.1429

8.5714

,,

,,

3*1

0

ff

ff

f

−

−−

=− −

−

==

=

=

6 SIMULATION RESULTS

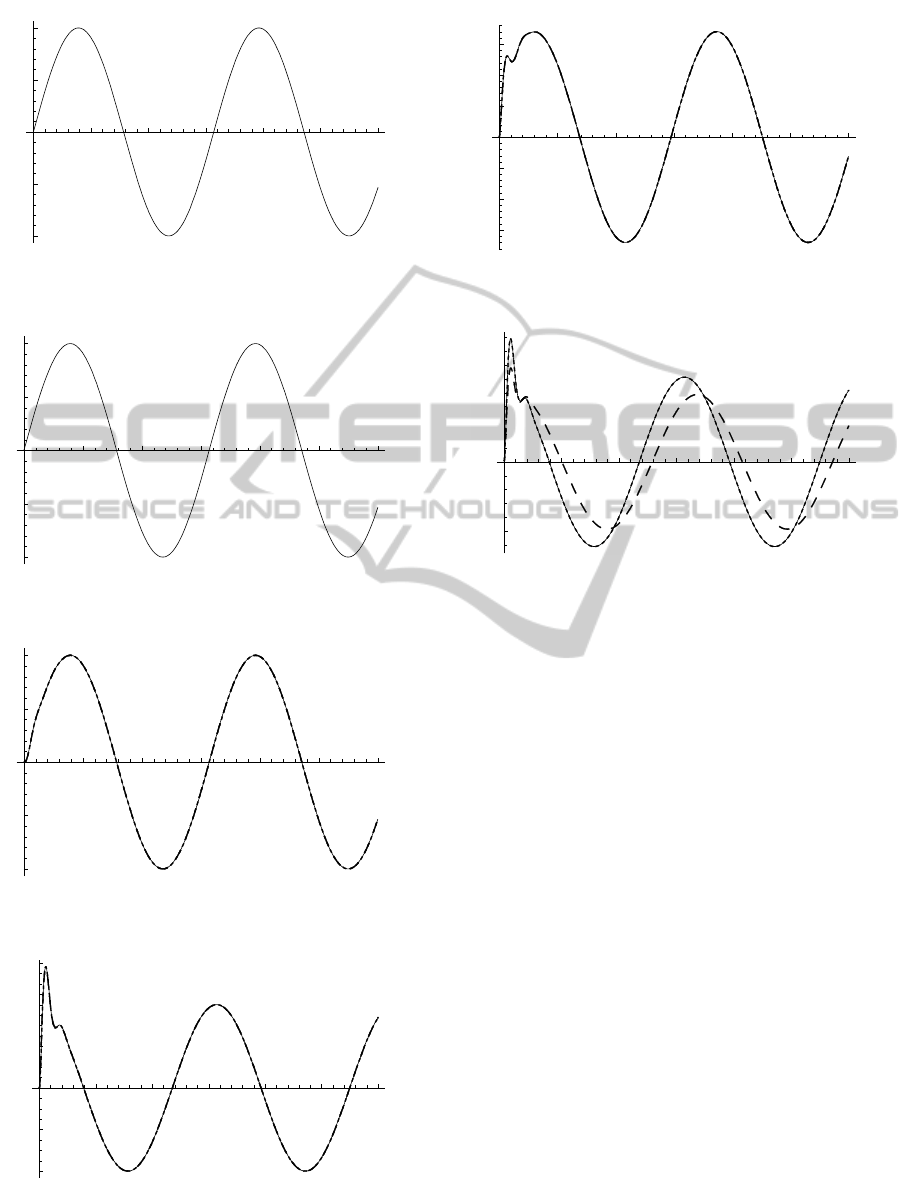

Using Table 1 and 2 and for a reference signal and

external disturbance as in Figures 3 and 4, the closed

loop performance is illustrated in Figures 5 – 7 and

the control signal is illustrated in Figure 8.

ICINCO2012-9thInternationalConferenceonInformaticsinControl,AutomationandRobotics

100

10 20 30 40 50 60

t

sec

0.02

0.01

0.01

0.02

Yr

t

Figure 3: Reference signal.

10 20 30 40 50 60

t

sec

10

5

5

10

F

L

t

N

Figure 4: External Disturbance.

10 20 30 40 50 60

t

sec

20

10

10

20

x

p

mm

Figure 5: The piston position.

10 20 30 40 50 60

t

sec

0.004

0.002

0.002

0.004

0.006

u

p

m

sec

Figure 6: The piston velocity.

10 20 30 40 50 60

t

sec

15

10

5

5

10

15

P

L

t

KPa

Figure 7: Hydraulic Pressure.

10 20 30 40 50 60

t

sec

0.05

0.05

V

in

t

V

Figure 8: Input voltage of the solenoid.

(Dotted line, Solid line, Dashed line is for the minimum, a

intermediary, and the maximum value of

q , respectively).

7 CONCLUSIONS

A Robust tracking controller has been designed for

arbitrary reference and disturbance signals.

Sufficient conditions have been derived and a finite

step algorithm has been proposed for fast and easy

computation of the controller parameters. The results

are successfully applied to a hydraulic actuator.

ACKNOWLEDGEMENΤS

The present work is supported by Archimedes III-

Strenghtening Research Groups In Technological

Education, NSRF 2007-2013.

REFERENCES

Chen, C. T., Linear System Theory and Design. Holt,

Rinehart and Winston, New York, 1984.

Corless, M. J., Leitmann, G., and Ryan, E. P., “Tracking

in the presence of bounded uncertainties,” presented at

RobustArbitraryReferenceCommandTrackingwithApplicationtoHydraulicActuators

101

the 4

th

Int. Conf. Control Theory, Cambridge, U.K.,

Sept, 1984.

Dorf, R. C., and Bishop, R. H., Modern Control Systems,

9

th

ed., prentice Hall, 2001.

Garcia, D., Karimi, A., Longchamp, R., “Robust PID

controller tuning with specification on modulus

margin”, Proceedings of the 2004 American Control

Conference, vol. 4, pp. 3297 – 3302.

Ge, M., Chiu, M.-S., Wang, Q.-G., “Robust PID controller

design via LMI approach”, Journal of Process

Control, vol.12, pp. 3-13, 2002.

Goodwin, G. C., Graebe, S. F., Salgado M.E., Control

System Design, Prentice Hall, 2001

Ho, F M.-T., Huang, S.-T. , “Robust PID controller design

for plants with structured and unstructured

uncertainty”, Proceedings of the 42nd IEEE

Conference on Decision and Control, 2003, vol. 1, pp.

780 – 785.

Horowitz, I. M., Synthesis Feedback Systems. New York

Academic, 1963.

Huang, Y. J., Wang, Y.-J. , “Robust PID tuning strategy

for uncertain plants based on the Kharitonov theorem”,

ISA Transactions, vol. 39, pp. 419-431, 2000.

Karpenko, M., Shapehri, N., “Fault – Tolerant control of a

servohydraulic positioning system with crossport

leakage”, IEEE Trans. on Contr. Syst. Technology,

Vol. 13, pp 155-161, 2005.

Kliffken, M. G., Heinrich, G. M., “A unified control

strategy for flight actuators”, Recent Advanced in

Aerospace Hydraulics, November 24-25, Toulouse,

France, 2001.

Kliffken, M. G., “Robust Sampled-Data Control of

Hydraulic Flight Control Actuators”, Proceedings of

the 5

th

Scandinavian International Conference on

Fluid Power, Linkoping, 1997.

Koumboulis, F. N., Industrial Control (in Greek), New

Technology Editions, 1999.

Koumboulis, F. N., “On the heuristic design of common

PI controllers for multi-model plants”, 10th IEEE

International Conference on Emerging Technologies

and Factory Automation, Catania, Italy, 2005, pp.

975-982.

Koumboulis, F. N., and Skarpetis, M. G., “Input -Output

decoupling for linear systems with non-linear

uncertain structure”, J. of the Franklin Institute, vol.

333(B), pp. 593-624, 1996.

Koumboulis, F. N., and Skarpetis, M. G., “Robust

Triangular Decoupling with Application to 4WS

Cars”, IEEE Transactions on Automatic Control, vol.

45, pp. 344-352, 2000.

Koumboulis, F. N., Skarpetis, M. G., Mertzios, B. G.,

“Robust Regional Stabilization of an Electropneumatic

Actuator”, IEEE Proceedings, Part D, Control Theory

and Applications, vol. 145, pp. 226-230, 1998.

Koumboulis, F. N., and Tzamtzi, M. P., A Metaheuristic

Approach for Controller Design of Multivariable

Processes, 12

th

IEEE Inter. Conf. on Emerging

Technologies and Factory Automation, Sept 25-28,

Patras, Greece, pp. 1429-1432, 2007.

Koumboulis, F. N., Skarpetis, M. G., Tzamtzi, M. P.,

“Robust PI Controllers for Command Following with

Application to an Electropneumatic Actuator”,

Proceedings of the 14th Mediterranean Conference on

Control Automation, Ancona, Italy, 2006.

Koumboulis, F. N., Skarpetis, M. G., Tzamtzi, M. P.,

“Robust PID Controller Design with Application to a

Flight Actuator”, Proceedings of the 32nd Annual

Conference of the IEEE Industrial Electronics Society

(IECON'06), pp. 4725-4730.

Musch, H. E., Steiner, M., “Robust PID control for an

industrial distillation column”, IEEE Control Systems

Magazine, vol. 15, pp. 46 – 55, 1995.

Skarpetis, M. G., F. N. Koumboulis and Ntellis, Α.,

“Robust Asymptotic Output Tracking for Four-Wheel-

Steering Vehicles”, IEEE International Conference on

Mechatronics, (ICM 2006), July 3-5, 2006, Budapest,

Hungary, pp. 488-492.

Skarpetis, M. G., Koumboulis, F. N., Ntellis, Α., “Robust

Tracking and Disturbance Attenuation Controllers for

Automatic Steering”, 14th IEEE Mediterranean

Conference on Control and Automation (MED’06),

June 28-30, 2006, Ancona, Italy.

Skarpetis, M. G., Koumboulis, Tzamtzi, M. P., “Robust

Control Techniques for Hydraulic Actuators ”, in

Proc. 15

th

MED Conf. on Control and Automation,

Athens, Greece 2007.

Takaba, K., “Robust preview tracking control for

polytopic uncertain systems”, in Proc. 37

th

IEEE Conf.

Decision Contr., Tampa, FL, 1998, pp. 1765-1770

Toscano, R., “A simple robust PI/PID controller design

via numerical optimization”, J. Process Control, vol.

15, pp. 81-88, 2005.

Yaesh , I. and Shaked, U., “Two degrees of freedom

H

∞

optimization of multivariale feedback systems”, IEEE

Transactions on Automatic Control, vol. 36, pp. 1272-

1276, 1991.

Wei, K, and Barmish, R., “Making a polynomial Hurwitz

invariant by choice of feedback gain”, Int. J. Contr.,

Vol 50, pp 1025-1038,1989.

ICINCO2012-9thInternationalConferenceonInformaticsinControl,AutomationandRobotics

102