SysML Parametric Models for Complex System Performance Analysis

A Case Study

Nga Nguyen and Hubert Kadima

Laris, EISTI, Avenue du Parc, 95011 Cergy, France

Keywords: Model-based System Engineering, SysML Parametric Diagram, Performance Analysis, Cruise Control.

Abstract: Parametric analysis is an essential tool in optimizing the performance of any system; it is, in particular, used

to fine-tune key parameters in a system design process. In this paper, using a vehicle cruise control system

as a non-trivial case study, we introduce a new approach for the performance parametric analysis of

complex systems using SysML models and a parametric constraint solver. System requirements are taken

into account to verify automatically whether the design solutions satisfy these requirements. This suggests

that in order to reduce time and resources, it is possible to perform initial performance analysis in a

modeling tool, just after the system functional and architectural analyses. Of course, once an approximate

operating point has been determined using this approach, experiments in specialized simulation tools can be

used to confirm and further refine the parameters of a system.

1 INTRODUCTION

SysML (SysML, 2010) is a visual modeling

language used to support the specification, analysis,

design, verification and validation of any engineered

system. Taking advantage of SysML concepts such

as requirements, blocks, flow ports, parametric

diagrams and allocations, it is easy to model

architectural and operational aspects of complex

systems at various levels of abstraction.

In this paper, we perform a sensitivity analysis,

which explores a parameter space, to find ideal

operational parameters allowing the validation of

alternative operational scenarios and system

configurations. The impact of constraints on system

properties and behaviours is analyzed in order to

optimize global system performance. We use

conjointly SysML parametric diagrams and a solver

in support of analyzing system alternatives

performances with respect to stakeholder

requirements, derived system requirements and

measures of effectiveness.

To illustrate our approach, we use a particular

case study: a Cruise Control Engine system. Since

many design parameters influence the operation of

such a system, it is difficult to quantify their impact

on the interactions within the system, and thus its

performance. The purpose of this study is thus to

investigate the consequences of varying some of

these operating parameters on the performance of

the system and to report the results using more

quantitative measures. The outcomes will be used to

improve the understanding of the system operation

and to optimize its performance by changing some

operating parameters or improving components. Due

to the large parameter space, and the complex,

highly coupled hybrid nature of the different internal

components of automatic systems, analysis is

complicated and sometime more specialized

simulation tools are necessary. The limits of our

approach are also discussed.

The structure of the paper is the following. In

Section 2, we describe briefly the functionalities of a

cruise control engine, the related SysML

requirement diagram and the dynamic model used in

our case study. Section 3 presents the parametric

analysis using the IBM Rhapsody SysML IDE,

SysML parametric models and IBM add-on

parametric constraint evaluator. Some preliminary

parametric analysis of dynamic constraints in trade-

off design activities and results of the case study are

discussed in Section 4. Conclusions are outlined in

Section 5.

2 CRUISE CONTROL SYSTEM

2.1 Functionalities

Cruise control is a system that automatically controls

321

Nguyen N. and Kadima H..

SysML Parametric Models for Complex System Performance Analysis - A Case Study.

DOI: 10.5220/0004058603210327

In Proceedings of the 2nd International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH-2012),

pages 321-327

ISBN: 978-989-8565-20-4

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

the speed of a vehicle by maintaining a constant

speed set by the driver. The implementation of a

cruise control system may vary but respects in

general the following principles. First, the cruise

control system may need to be turned on before use:

it passes from the disengaged state to the engaged

state. While engaged, cruise control becomes

activated when the driver sets the desired speed. A

driver instruction, such as braking or throttle pedal

depression, will put the cruise control on suspended

mode. Of course, we can easily go back to the

configuration before the suspension by using the

resume function supported by almost all systems.

Beside these operations, one can always increment

or decrement the desired speed when the system is

activated.

2.2 Requirements Model

Requirements analysis is the first step in the system

design process, where stakeholder requirements are

translated into system requirements that define what

the system must do and how well it must perform.

The result is a requirement diagram in which the

requirements are classified hierarchically. Complex

specifications are decomposed and categorized into

simpler ones, leading to a better interpretation that

will help with system verification and validation.

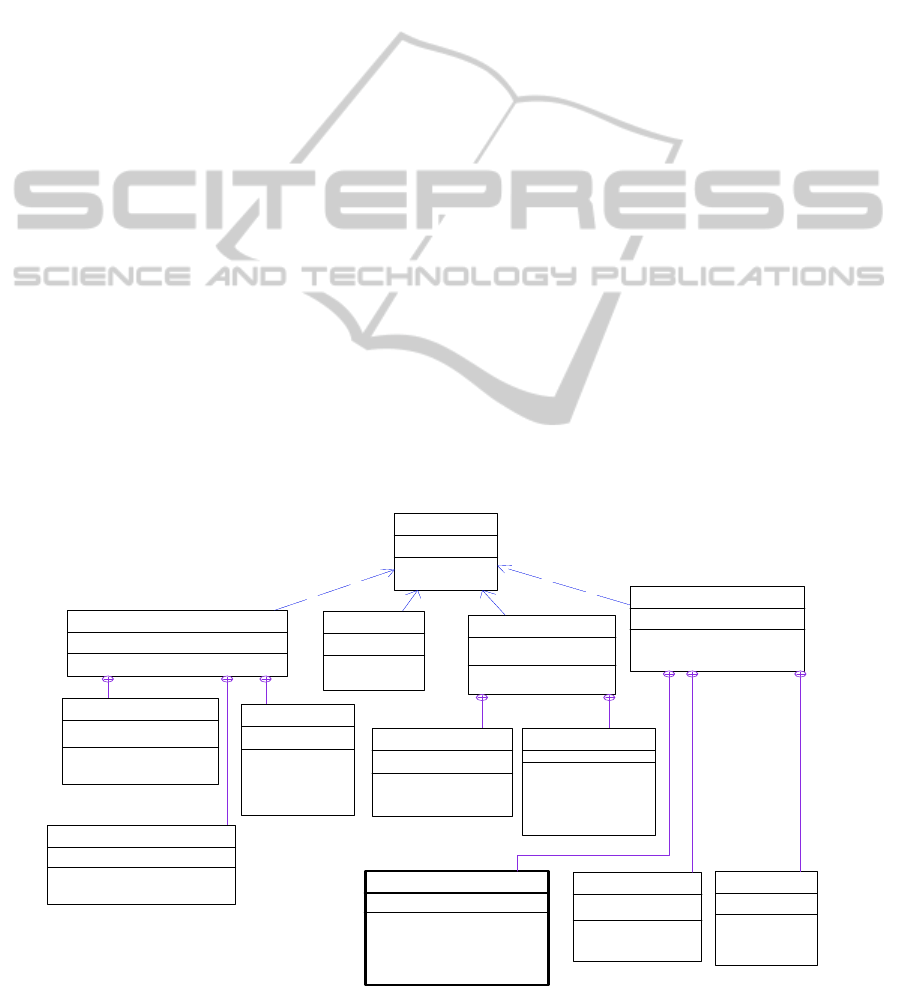

Figure 1 shows the requirement diagram for our

cruise control system. In the performance

requirement category, you can see some design

constraints for cruise control systems taken from

Control Tutorials for Matlab (Michigan, 1997), with

some of our own modifications. For example, when

the motor yields a 1500 Newton force, the car must

reach a maximum velocity of 30 m/s and be able to

accelerate up to that speed in less than 5 seconds.

Beside this, a 10% overshoot on the car speed and a

2% steady-state error are acceptable for the cruise

control system. The above criteria can be used later

to verify if the design solutions respect these

requirements. To complete the requirement analysis

phase, a model for system use cases must be built to

establish traceability links between requirements and

use cases provided, in order to ensure the coverage

of functional and performance requirements by the

use cases. These issues fall outside the scope of this

paper.

2.3 Dynamic Model

Almost all cruise control systems follow the closed-

loop control system principle. A sensor monitors the

car speed and feeds data to a controller that adjusts

the control as needed to maintain the reference

speed. When the car goes uphill or downhill, the

difference in speed is measured, and the throttle

position changed to increase or decrease engine

power, speeding or slowing respectively the vehicle.

Feedback from measuring the car velocity allows the

controller to dynamically compensate for changes to

the car speed.

Figure 1: Requirement Diagram of a Cruise Control.

Cruis e C ontrol

«R equireme nt»

ID = 001

Maintain a

constant

sp eed .

«derive»

Functional Managem ent

«R equire ment»

ID = 0 02

Ma nage the vario us operational

modes

«derive»

«derive»

Operational Safety

«R equire ment»

ID = 004

The system must be

sa fe and

comfortable

«derive»

Us er Interface

«Require me nt»

ID = 0 03

A generic

us er

interface is

id

«derive»«derive»

Enga ge-Disengage

«R equire ment»

ID = 007

The s ystem can be in the

engaged state or

disengaged state.

Spee d Settings

«R equire me nt»

ID = 0 08

The s peed

va lu e c a n be

chang ed by

incrementing

or

decrementing

b

y

a fi xed s te

p

.

Suspend-Resum e

«R equire ment»

ID = 0 06

The s ystem c an be

suspended or

resumed after

suspension

Displ ay

«R equireme nt»

ID = 0 09

Th e s yste m h a ve to

display the

information at any

tim e.

Errors

«R equireme nt»

ID = 010

Al l t h e e rr or s

encountered by the

system have to be

logged, except in

the di sen gag ed

mode.

«derive»

Performance Constrain ts

«R equireme nt»

ID = 005

The system must satisfy

so me behavioral

constraints

«derive»

Spee d and Time Lim it

«R equire ment»

ID = 0 12

When the en gine

generates about 1500

Newton force; the ca r m ust

reach its ma ximum speed

wh ich is 30 m s/s in les s

than 5 seconds

Exceedin g Speed

«R equireme nt»

ID = 0 123

Exceedin g 10 % of

desired s peed is

acceptable

Stabil ity Error

«R equire ment»

ID = 0 11

A stability

error of 2% is

acceptable

SIMULTECH2012-2ndInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

322

PID (proportional - integral - derivative)

controller is widely used in industrial control system

theory. The typical form of the PID algorithm is the

following:

(

)

=

(

)

+

(

)

+

(

)

where k

p

, k

i

and k

d

are tuning parameters that have to

be adjusted to optimum values to achieve the desired

response while maintaining the stability of the

system. The control signal u computed by the

controller is used to rectify the throttle position and

thus the torque delivered by the engine, generating a

force that accelerates the vehicle.

To illustrate our case study, we used the dynamic

model of a cruise control system found in Astrom

and Murray's book (Astrom and Murray, 2010).

Their proportional - integral (PI) controller has the

form:

(

)

=

(

)

+

(

)

=

−

where v

r

is the desired speed, v the current speed

and u the signal control. The torque T, controlled by

the throttle position, delivered by the engine and

transmitted through the gears and the wheels,

depends also on engine speed ω:

(

)

=

1−

−1

where the maximum torque T

m

is obtained at engine

speed ω

m

, and typical values are given for T

m

, ω

m

and β. The angular velocity is related to the speed

through the expression:

=

And the driving force generated by the torque T is

written as:

=

()

Typical values of α

n

(n is the gear ratio) for gears

1 through 5 are 40, 23, 16, 12 and 10. The car's

motion is given by the following equation:

=−

where m is the mass, F

d

the disturbance force which

has three major components : gravity force (F

g

),

rolling friction force (F

r

) and aerodynamic drag

force (F

a

). Different parameters such as the slope of

the road, total mass of the car, gravitational constant,

density of air, frontal area of the car as well as

coefficients of various forces are taken into account

in the model.

3 PARAMETRIC ANALYSIS

In this section, we provide information regarding the

main components of our tools environment. Good

tool integration is paramount here, since round-trip

interoperability between SysML parametric models

and an integrated solver is a key requirement of our

approach.

3.1 SysML Parametric Models

SysML provides mechanisms and constructs

necessary to successfully describe all the structural

and behavioural specifications and constraints of a

model of a system. In the design phase, it is

essential to annotate these models with qualitative

and quantitative requirements, known as non-

functional properties, aiming at verifying and

validating the temporal behaviour, power estimation

and other various constraints.

Block diagrams are the natural approach used by

SysML for expressing system-level models,

providing a standardized form of representation for

both the structure of a system and the equations that

characterize its dynamic and its functional and

behavioural constraints. Blocks are extended into

constraint blocks that can be used in parametric

diagrams, which enable users to model equations in

terms of constraints in SysML, establishing a

network of relations among the properties of a

system (Peak, et al., 2007). These mathematical

expressions can represent the physical properties of

a system (e.g., relevant physics laws) or non-

functional properties (e.g., cost, risk, performance,

reliability, etc).

Simulation and system parametric analysis then

can be realized to check that a system definition

meets a certain system requirement, which can be

modelled explicitly using the SysML “verify”

dependency stereotype. Furthermore, some non-

functional requirements can be written as constraints

so they can be automatically verified by an

integrated solver. Instead of using specific

simulation tools such as Simulink or Modelica, we

decided to exploit a lightweight solver already

integrated in a SysML supported toolset to carry out

parametric analyses.

3.2 IBM Rhapsody Toolset

IBM Rational Rhapsody(Hoffmann, 2010) is a

collaborative, model-based systems engineering

development platform providing simulation for early

requirement, architecture and behavioural validation.

SysMLParametricModelsforComplexSystemPerformanceAnalysis-ACaseStudy

323

We decided to use it in our research because it

provides tools to dynamically analyze and execute

SysML parametric diagrams to assist in trade study

analysis. The integrated Parametric Constraint

Evaluator is a Rhapsody add-on that allows the

evaluation of parametric diagrams via a Computer

Algebra System (CAS) that solves the corresponding

mathematical expressions. Matlab Toolbox and

Maxima are two CAS supported by IBM Rhapsody;

given its ready availability, we chose the open-

source Maxima for this work. Maxima manipulates

symbolic and numerical expressions, and includes

many operations such as differentiation, integration,

Taylor series expansion, Laplace transform, ordinary

differential equation solving, systems of linear

equations manipulation, etc. It yields high precision

numeric results, using exact fractions and variable

precision floating point numbers. Thanks to

Maxima, PCE is able to compute the values that

satisfy mathematical constraints or to solve

constraints to minimize or maximize a value of an

attribute for linear algebraic equations. Besides this,

it can also produce graphs showing how values

behave over time or over a range of values of other

parameters. These possibilities allow a system

engineer to analyze the behaviours of the system, to

validate the constraints and to perform trade studies.

However, some solver limitations that are discussed

later led us to an interesting debate about the choice

of lightweight simulation tools such as parametric

diagrams with respect to dedicated tools such as

Simulink or Modelica.

4 SENSIBILITY ANALYSIS

Instead of using specialized simulation tools, we

have tried to use the SysML parametric diagram

coupled with a solver to carry out 2 different

simulations: an open loop cruise control as in

(Michigan, 1997) and a closed loop with the

dynamic model in Section 2.3. Throughout our

experiments, the limits of the solver integrated in

Rhapsody were encountered and are discussed here.

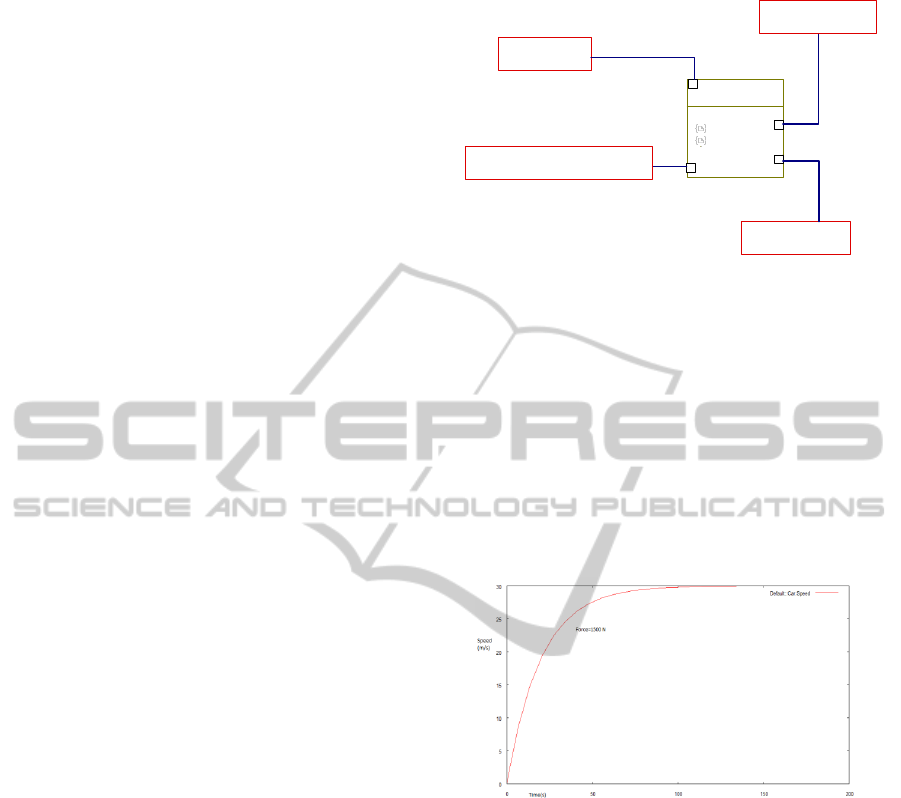

4.1 Open Loop Cruise Control

For an open loop experiment with linear differential

equations, our solver with Maxima succeeded at

producing desired results as with Matlab from the

parametric diagram in Figure 2.

Figure 2: Parametric Diagram of an Open Loop Cruise

Control.

We used here the same physical setup and system

equations as in (Michigan, 1997): friction opposing

the motion of the car is proportional to the car speed.

With an initial condition, a graph is generated from

the constraint view referencing the corresponding

parametric diagram, which is shown in Figure 3.

From the plot, we see that the car needs more than

100 seconds to reach the steady-state speed of

30m/s, which does not satisfy the performance

requirement about rise time (less than 5 seconds).

Figure 3: Speed vs. Time in Open Loop Cruise Control

(generated by PCE/Maxima).

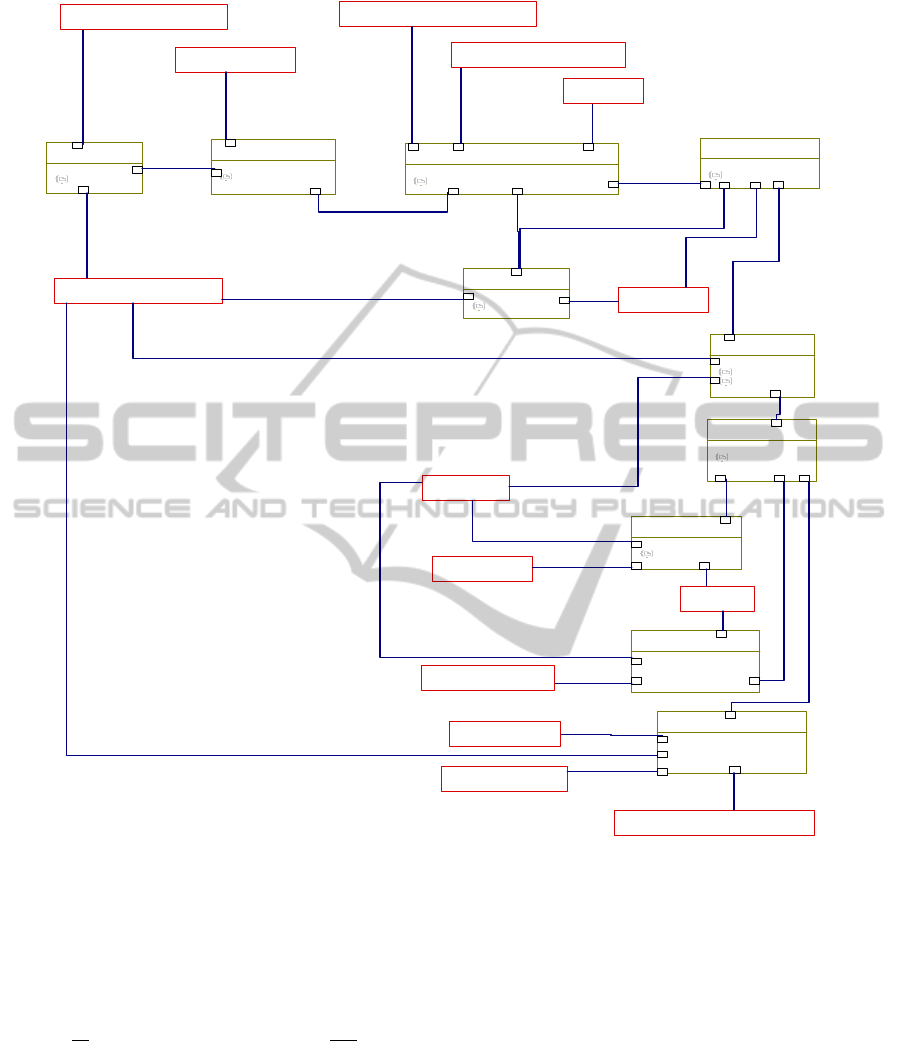

4.2 Closed Loop with Dynamic Model

Our second implementation is the dynamic model of

the cruise control system described in Section 2.3.

The corresponding SysML parametric diagram is

provided in Figure 4. Each parametric constraint

represents an equation dealing with the comparator,

the controller, the torque related to the throttle

position, the generated force, the car motion and the

different disturbance forces. Constants are given in

the value properties. Almost all physical units are

available in the Systems Engineering (SE) profile of

Rhapsody.

Some simplifications have been made due to

software limitations: not all the possibilities of

Maxima are fully implemented. As PCE does not

Car Motion

1 «Cons traint P roperty»

Co ns t r a i nts

m*der(v)+b*v=f

v( 0) =0

f:Real

b:Real

m:K ilo gr am

v: Mete r Per Se con d

Mass:Kilogram=1000

«Attribu t e»

Speed:MeterPerSecond

«Attribu t e»

For ce: Newton=1500

«Attribute»

Friction Coef:NewtonSecondperMeter=50

«Attribu t e»

SIMULTECH2012-2ndInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

324

Figure 4: Parametric Diagram of the Dynamic Model.

support the integral operation or the Laplace

transform, we had to give up the integral part of the

controller; only proportional gain is taken into

account in the controller. That gives us the following

nonlinear differential equation for the system:

=

(

−

)

1−

−

1

–

−0.5

−sin(1)

where the last three terms represent respectively the

three disturbance forces : rolling friction,

aerodynamic drag and gravity force. Every variable

of the equation, except speed (v) and time (t), is

either constant or of known values.

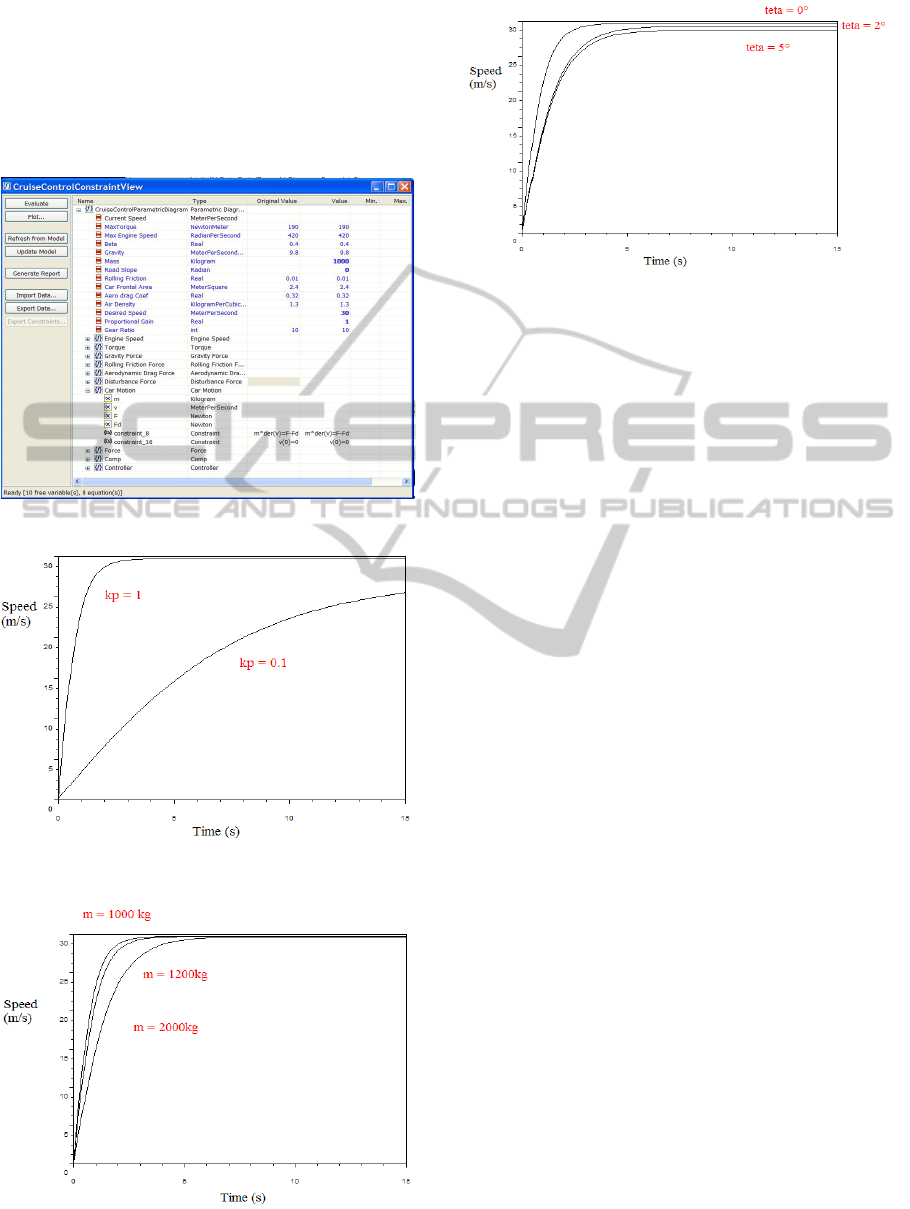

A constraint view referencing the above

parametric diagram can be generated, as shown in

Figure 5. Normally, through the fixing of some

values in the spreadsheet, such as the value for the

proportional gain, the road slope, the car mass, the

desired speed…, we can ask Rhapsody to evaluate

the system in order to detect inconsistent constraints

or to display graphs that show interesting

relationships, for instance between time and speed.

Unfortunately, since Maxima only gives us the

exact analytical solution for the nonlinear

differential equation (1), which is not exploitable,

PCE cannot be used here. So, we decided to fall

back to using Scilab, an open-source solver using

numerical solutions, which allowed us to plot graphs

that represent the relationship between speed and

time from Equation (1), when varying some system

Engine S pee d

1 «C onstr aintProperty»

Constr aints

w=alpha*v

alpha

w:RadianPerSecond

v:Real

Current Speed:MeterPerSecond

«Attri bute »

Torque

1 «C onst rai ntPr oper ty»

Constrai nts

T=u*Tm*(1-B*(w/wm-1)*(w/wm-1))

u:Real

T:NewtonMete

r

B:Real

w:RadianPerSecond

wm:RadianPerSecond

Tm:NewtonMeter

MaxTorque:NewtonMeter=190

«Attri bute »

Max Engine Speed:RadianPerSecond=42

0

«Attr ibute»

Beta:Real=0.4

«Attr ibute»

Gravity Force

1 «C onst rai ntPr oper ty»

Const r ai nt s

Fg=m*g*sin(t...

Fg:Newton

teta:Radian

g:MeterP

m:Kilogram

Grav ity :Meter

P

«At tr ibu te »

Mass:Kilogr am

«Attr ibute»

Road Slope:Radian

«Attr ibute»

Rolling Friction Force

1 «ConstraintProperty»

Constraints

Fr=m*g*C1

Fr:Newton

m:Kilogram

g:MeterPerSe

C1:R e a l

Rolling Friction:Real=0. 01

«At tr ibu te »

Aerodynamic D rag Force

1 «C o nst rai ntProperty»

Constraints

Fa=0.5*Rho*Cd*A*v*v

Fa:Newton

v:MeterPerSecond

Rho:KilogramPerCubicMete

r

Cd:R e a l

A:MeterSquare

Car F rontal Area:Mete

r

«Attr ibute»

Aero drag Coef :Real=0.3

2

«Attr ibute»

Air Density :KilogramPerCubicMeter=1.3

«Attri bute »

Distu rb ance Fo rce

1 «ConstraintProperty»

Con s t r ai nt s

Fd=Fr+Fg+Fa

Fd:Newton

Fa:Newton

Fr:Newton

Fg:Newton

Car M oti on

1 «ConstraintProperty»

Constr aints

m *d er(v)=F-Fd

v(0)=0

Fd:Newton

F:Newton

v:MeterPerSecond

m:Kilogram

Force

1 «C onst rai ntPr oper ty»

Cons t r ai nt s

F=alpha*T

alpha

F:Newto n

T:NewtonMete

r

w:RadianPerSecond

Comp

1 «Co nst rai ntPr oper ty

»

Constraints

error=v r-v

error:Re a l

v:MeterPerSecond

vr:MeterPerSecond

Des ired Speed:MeterPerSecond

«Attr ibute»

Controller

1 «C ons tr aint Pr oper ty»

Constr aints

u=Kp* e rro r

u:Real

Kp:Real

error:Real

Proportional Gain:Real

«At tr ibu te »

Gear Rat io:int=1

0

«At tr ibu te »

SysMLParametricModelsforComplexSystemPerformanceAnalysis-ACaseStudy

325

parameters. Some experimental results are given in

Figure 6, 7 and 8.

In Figure 6, we see that with k

p

= 1, the car

almost reaches the desired speed which is 30 m/s in

less than 5 seconds, so the performance

requirements about steady-state error and rise time

are verified.

Figure 5: Constraint View of the Dynamic Model.

Figure 6: Speed vs. Time with Different Proportional

Gains (generated by Scilab).

Figure 7: Speed vs. Time with Different Masses

(generated by Scilab).

Figure 8: Speed vs. Time with Different Road Slopes

(generated by Scilab).

With k

p

= 0.1, the system also arrives at the desired

target speed, but with a much longer rise time. In

Figure 7, by varying the total mass of the car and

keeping the value 1 for k

p

, we get different traces in

which only the trace for m = 1000 kg verifies the

condition of rise time less than 5 seconds. For the

other values of mass, further parameters must be

adjusted to achieve satisfying results. In Figure 8, by

varying the road slope while keeping the same value

for k

p

and m (1 and 1000kg respectively), we get

different outcomes. Since the vehicle has to provide

much more effort to go uphill (θ = 2° and 5°), with

the same value of k

p

, it cannot reach the desired

speed of 30 m/s.

The above results show that more experiments

must be run in order to find out optimum values for

the system parameters. All possible combinations of

the different value ranges for mass, road slope,

desired speed, etc must be taken into account. And,

of course, the integral and derivative gains are

necessary if we want to have more precision with

our cruise control system.

5 CONCLUSIONS

Due to the large parameter space and the highly

coupled hybrid nature of the different internal

components of automatic systems, their analysis is

usually complex and time consuming. In the case of

performance analysis, rather than performing

complete parametric analyses of complex systems in

the field, our paper suggests that initial parametric

performance analyses can be performed, in the lab,

using SysML parametric diagrams as main tool,

while at the same time leveraging conventional

modeling and simulation tools including

spreadsheets, math solvers, finite element analysis,

discrete event solvers and optimization tools. This

SIMULTECH2012-2ndInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

326

approach allows for greater repeatability and

requires less time and resources. Of course, once an

approximate operating point has been determined

using this approach, field experiments with more

specialized tools (Simulink, OpenModelica, ...) can

be used to confirm and further refine the parameters

of a system.

Some works have been done by an OMG group

for the integration of SysML and Modelica to profit

the strength of two complementary modeling

languages: the descriptive power from SysML and

the analytic and computational power from

Modelica (Johnson and Jobe and Paredis and

Burkhart, 2007), (Paredis, et al., 2010). In fact,

Modelica is well suited for representing differential

algebraic equations to model the flow of energy,

materials, signals ... in complex system.

Transformation specification has been proposed to

provide a bi-directional mapping between the two

languages. However, the requirement models of

SysML are not considered in this mapping. In our

approach, we can integrate requirement information

directly into parametric diagrams to validate the

design. By rewriting requirement constraints in a

formal language such as OCL or a temporal logic

language, we can put them in the parametric

diagrams and then formal methods can be used to

verify if there are errors in system design.

The preliminary results presented in this paper

are quite encouraging. With a lightweight system,

we achieved results similar to those provided using

specialized tools and the perspective to be able to

combine directly in the same tool structural and

behavioural specifications with requirement

constraints to validate the design process is

promising.

Nevertheless, this solution presents some

limitations: although parametric diagrams are non-

causal, they do not separate effort and flow

variables, which is a fundamental issue when

modeling physical systems. For example, Modelica

(using flow) and VHDL-AMS (using

across/through) contain such constructs. Beside this,

although the Rhapsody tool is well suited for

implementing the first steps of complex system

development process, i.e., requirement analysis,

system functional analysis and design synthesis, the

architecture mismatch in its Parametric Constraint

Evaluator integrated with Maxima should be

corrected to represent more complicated

mathematical relations. For instance, a solver

providing numerical solutions for nonlinear

differential equations and supporting Laplace or Z

transforms (Wescott, 2012) would be highly

appreciated.

The next step of our work is to make a complete

survey of different SysML parametric solving tools

such as ParaSolver for Artisan Studio, ParaMagic

for MagicDraw, etc. in order to compare how far

these tools are able to support complex system

models. Actually, the tutorial examples given by

these tools are rather not very complicated.

REFERENCES

University of Michigan, http://www.engin.umich.edu/

group/ctm/examples/cruise/cc.html, 1997.

OMG Systems Modeling Language, Version 1.2, Juin

2010.

H. Hoffmann. Systems Engineering Best Practices with

the Rational Workbench for Systems and Software

Engineering, Deskbook Release 3.1.1. Model-Based

Systems Engineering with Rational Rhapsody and

Rational Harmony for Systems Engineering, 2010.

T. Johnson, J. Jobe, C. Paredis, and R. Burkhart. Modeling

Continuous System Dynamics in SysML. In IMECE,

2007.

C. J. J Paredis, Y. Bernard, R. M. Burkhart, H. P.

de Koning, S. Friedenthal, P. Fritzson, N.F. Rouquette,

and W. Schamai. An Overview of the SysML-

Modelica Transformation Specification. In INCOSE

International Symposium, 2010.

R. S. Peak, R. M. Burkhart, S.A. Friedenthal, M.W.

Wilson, M. Bajaj, and I. Kim. Simulation-Based

Design using SysML–Part 1: A parametric primer. In

INCOSE International Symposium, 2007.

R. S. Peak, R. M. Burkhart, S. A. Friedenthal, M.W.

Wilson, M. Bajaj, and I. Kim. Simulation-Based

Design using SysML–Part 2: Celebrating diversity by

example. In INCOSE International Symposium, 2007.

K. J. Åström and R. M. Murray. Feedback Systems: An

Introduction for Scientists and Engineers. Princeton

University Press, 2010.

T. Wescott. Z Transforms for the Embedded System

Engineer. Wescott Design Services.

SysMLParametricModelsforComplexSystemPerformanceAnalysis-ACaseStudy

327