Modelling and Simulation of Human-like Movements

for Humanoid Robots

Parvin Abedi

1

and Ali Leylavi Shoushtari

1,2

1

Department of Computer Engineering, Shoushtar Branch, Islamic Azad University, Shoushtar, Iran

2

Department of Mechatronics, South Tehran Branch, Islamic Azad University, Tehran, Iran

Keywords: Human Body Dynamics, Humanoid Robots, Optimization-based Simulation.

Abstract: The humanoid robots are bio-inspired models of human body. The mechanical structure of humanoid robots

consists of several joints and segments. Numerous degrees of freedom are caused the redundancy problem.

There is an unanswered question concerning with strategies which central nervous system implements to

predict the human posture and gesture during different movements. A 7 degree of freedom model is used for

modelling humanoid robot and an optimization-based method is planned to simulation of human motion.

The joints angles and torques are subjected as optimization variables. The joints range of motion and limits

of actuator torques are used as optimization constraints. The weight lifting is the motion which is subjected

to simulation. Finally the results presented for two velocity lifting. The result shows the body posture varies

naturally and the weight maintain at the end position at final time correctly.

1 INTRODUCTION

Digital human modelling is used in an extensive field

of researches such as robotics, biomechatronics,

ergonomics etc (Blajer et al., 2007; Xiang et al.,

2010), because it can implement for calculating the

parameters that are not possible to measure like:

torques and internal forces of joints and stress

exerted to joint's soft tissues. An important usage of

modelling of human body is dynamic analysis of

humanoid robots (Arisumi et al., 2007).

For understanding how the human-like

movements planned for a humanoid robot, it is so

important to know how the redundancy problem

solved by central nervous system. In order to know

how the body postures varies during different

movements to construct motion animation of human

body, a model of whole human body dynamics

applied to movement simulation process. Simulation

and analysis of human movements commonly used

for athletics in order to improve performance of the

motion and so prevent injuries in cause of incorrect

movements (Demircan et al., 2009).

Biomechatronical model with large number of

degree of freedom needed to done the human motion

simulation more exactly and accurately. The

multiplicity of joint space variables (DOFs) causes

model manoeuvrable but creates redundancy

problem. We face with the redundancy problem

when the number of DOFs is more than needed to

perform a task. Both kinematic and dynamic

redundancy is problems with wide range of solutions

in some areas of researches as robotics biomechanics.

The robot manipulators with redundant degrees of

freedom are able to done different tasks skilfully

(Wang et al., 2010; Park et al., 2001). Human body

models usually contained large number of DOFs. For

applying these models to motion simulation,

optimization-based approaches are good methods to

overcome with the redundancy problem. Some of

these techniques are applied to robotic manipulator

models with redundant DOFs (Schafer et al., 2003;

Oh et al., 1997; Wang et al., 2010). Optimization-

based solutions are suitable ways to solve problem

with large number of variables, because this method

uses a few amount of data as inputs to result a large

number of variables as output set (Guran et al.,

2012). The input contains two set of constraints

impose to motion simulation process: 1. Constraints

obtained from motion dynamics and 2. Variety

limitation of optimized variables would be

optimized. The second type used as inequality

constraints and the first one contain some algebraic

and differential equations.

CNS arranges the task with the balanced

movements. Walking, sitting, running and lifting are

342

Abedi P. and Leylavi Shoushtari A..

Modelling and Simulation of Human-like Movements for Humanoid Robots.

DOI: 10.5220/0004094903420346

In Proceedings of the 9th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2012), pages 342-346

ISBN: 978-989-8565-21-1

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

good examples of tasks related to daily living

activities performed completely balanced

involuntarily. CNS uses an unknown algorithm to

manage tasks unconsciously. Optimization-based

simulation methods have performance analogous

with CNS function caused balanced movements.

These approaches used objective function description

subjected to minimizing which is duality of CNS

algorithm manner. On the other hand to simulate a

movement as like as shape that biological system

does, it assumed that optimization approach

minimized the objective function considered that

CNS try to minimize it too.

Ankle torque amplitude considered as criteria of

stability and the optimization algorithm tries to

minimize summation of ankle torque squares during

lifting time. A seven DOF biomechatronical model

of whole human body represented in part 2 obtained

from kinematical modeling based on D-H method

(Denavit and Hartenberg, 1995; Siciliano and Khatib,

2008; Khatib et al., 2009). Based on Lagrangian

method, the equations of motion are formulated in

inverse dynamics form. In section 3 simulation

process is described and in sections 4 and 5 presents

the simulation results and the conclusion

respectively.

2 MODELLING OF HUMAN

BODY

A planar model with 7DOF in sagittal plane

implemented in represents coordination system of

human body (Figure 1). All the limbs as shank, thigh,

lumbar, thoracic and cervical spine, arm and forearm

subjected to modelling and considered as rigid bars

with mass points at center of mass of each link which

named: l

,l

,l

,l

,l

,l

,l

respectively. For human

major joints as ankle, knee, hip, shoulder and elbow

had considered joint angles in modelling to figurate

human body posture and represented by the

names:

,

,

,

,

respectively. The box

assumed jointed to human body at the wrist with a

horizontal orientation. Biomechatronical models of

human body with coordination systems illustrated by

fig. 2. Human body dynamics commonly model as a

kinematics chain like robot manipulators, so the

method which is used to modeling the dynamics of

motion of human body, is like ones used for robotic

manipulators.

Figure 1: 7DOF model of human body with Denavit-

Hartenberg coordination systems which is attached to each

link.

The inverse dynamics form of equations of motion of

a kinematical chain is presented as bellow

(

)

̈ +(,̇)̇ +()=Γ

(1)

In (1)

(

)

is 7×7 matrix related to mass and

inertial properties of the model (Xiang et al., 2009)

and Γ is 7×1 generalized joints torque vector.

(,̇) is a term related to centrifugal and coriolis

forces and () is gravitational forces vector, this

term calculates as (2) and (3).

(

,̇

)

=

̇

(

)

−

1

2

̇

(

)

(2)

()=

(3)

Generalized joint torque represented in (1) divided in

two parts: 1. torques resulted in muscle forces and 2.

torques due to the box load exerted on wrist. These

kinds obtain as (4):

Γ =

−

!

;

!

="

#

$

!

%

&

(4)

In (4) "

is transpose of Jacobean matrix which

project box load to joints $

'*-

is box mass and %

is transpose of gravity force vector.

3 OPTIMIZATION-BASED

SIMULATION

In this paper lifting movement simulation considered

as optimization problem which CNS do either. In this

problem an objective function subjected to be

optimized with some constraints which limit the

motions boundary to a feasible range to construct

motion naturally. In other words it's being assumed

that CNS try to minimize a particular function value

to perform each task, and musculoskeletal system

impose some constraints to the motion too.

Modelling and Simulation of Human-like Movements for Humanoid Robots

343

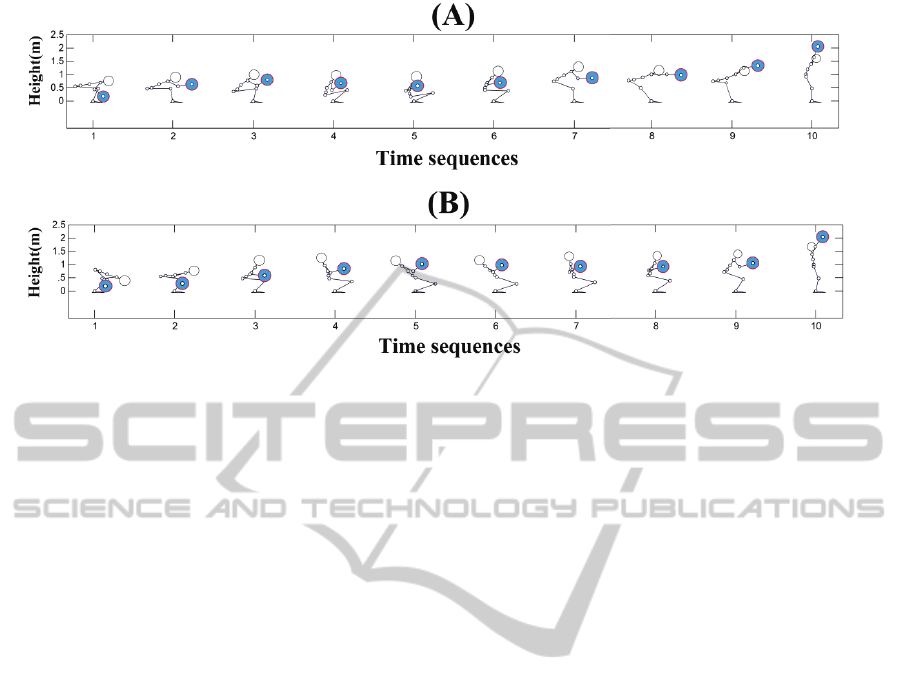

Figure 2: Body postures of humanoid robot, during lifting task for two lifting time: A) 3 second and B) 2.5 second. The

horizontal axis is time in term of second, by scaling 0.3 second for (A) and 0.25 second for (B).

Predictive dynamics is a novel approach used to

motion simulation (Xiang et al., 2010; Xiang et al.,

2009). It implements inverse dynamics as a major

constraint to modeling the dynamics of the motion in

the simulation process. The joints torques and angles

selected as the optimization variables, so by using

this method we can obtain joint angles and torques as

output according to task parameters used as inputs

(Guran et al., 2012). Simulation elements are

described in bellow sections.

3.1 Objective Function

By considering the lifting task as a simple inverted

pendulum motion, represents represent a simple

model to analysis the stability of motion. In other

hand If lifting motion models as a inverted pendulum

(Demircan et al., 2009) it can says that magnitude of

torque of pendulum joint, has direct relation to

amount of deviation from stability position (.=0

°

).

Therefore we can use of a particular function which

constructed in term of ankle torque as motion

stability index. It proposes this function as integral of

ankle torque squares in each time sequence (5).

/

(

,,3

)

=4

568

93

!:<

(5)

3.2 Constraints

The constraints used in this research are: joints

torques and angles limitations, initial and final

position of box, elevating constraint, inverse

dynamics, and body collision avoidance constraint

which is used for prevent of collision box with body

(Denavit, 1995).

−

6>?

=0 ;

6>?

=@

(

,3

)

(6)

In equation (6) is joints torque vector should be

predicted, and

6>?

is joints torque vector obtained

from inverse dynamics. Body collision avoidance

implemented in this simulation is a systematic

method to check the penetration value of the box into

the body in each iteration of optimization process. It

is used to determine horizontal position of the box to

collision avoidance adaptively.

The collision avoidance considered in

optimization process as a constraint to prevent

penetration of box with the body. It’s inequality

constraint and defined as a term of sufficient

horizontal distance 9A which wrist should move to

prevent collision box with the body.

4 RESULTS

The optimization process designed for 10 evenly

distributed time sequences. Inertial properties

considered as data used previously (Guran et al.,

2012). The optimization process ran for two lifting

times 2sec, 2.5 sec and 3 sec.

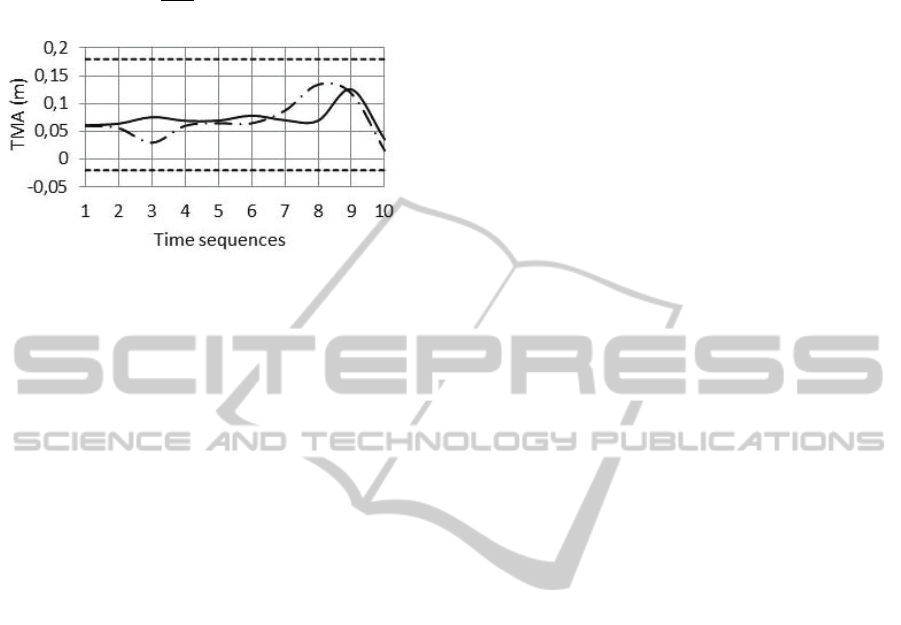

An index presented to evaluate the motion

stability during all the time sequences. Total moment

arm (TMA) of all the links are calculated as (7) it's

calculated from the moments respect to all of the

links weight for each configuration related to time

sequence. $

5

is total weight of body and A

(

3

)

is

horizontal position of B′3ℎ links at time 3, and D is

number of links. Optimized joint angles show that

how the body posture varies during lifting task, it

ICINCO 2012 - 9th International Conference on Informatics in Control, Automation and Robotics

344

illustrated in figure 2.

EFG

(

3

)

=

1

$

5

H$

A

(

3

)

I

:

(7)

Figure 3: TMA values for two lifting times (2.5 sec for

solid line and 3 sec for broken one) during lifting time. To

prevent falling forward or backward, TMA values should

be restricted between base of support (distance between

heel and toe). These two boundaries are shown as dashed

lines at TMA=-.02 (m) and TMA =0.18 (m).

5 CONCLUSIONS

Simulation process implements 7DOF

biomechatronical model of human body to simulate

weight lifting motion by using predictive dynamics

approach. The constraints which applied to this

process, limit motion space to a feasible region that

human limbs move through it. Major constraint

named inverse dynamic, implement the dynamics of

the motion in simulation process and finally the

optimized postures shaped by objective function

minimization. Figure 2 Shows that posture variation

does in a natural shape. The box motion is extremely

uprising, and it situates at initial and final position

exactly and also it hasn't collision to the body in all

of the postures. The motion of weight started at its

first position and ended at the final position correctly.

The wrist is mounted at centre of mass of weight in

sagittal plane. The results show that this position

never collided with the body. The motion of the

weight is uprising.

Figure 3 illustrate the TMA values during lifting

time and its boundaries. According to this figure,

Lifting movement performed completely balanced

because TMA have values between upper and lower

boundaries. In other words minimizing ankle torque

summation can guarantee motion balancing

.

REFERENCES

Blajer W., Dziewiecki K., Mazur Z., 2007. Multibody

modeling of human body for the inverse dynamics

analysis of sagittal plane movements. Multibody

systems Dynamics. 18(2). pp. 217-232.

Xiang Y., Arora J. S., Rahmatalla S., Marler T., Bhatt R.,

Abdel-Malek K., 2010. Human lifting simulation using

a multi-objective optimization approach. Multibody

Dynamics. 23(4). pp. 431-451.

Arisumi H., Chardonnet J. R., Kheddar A., Yokoi K. 2007.

Dynamic Lifting Motion of Humanoid Robots. IEEE

International Conference on Robotics and Automation.

Rome. Italy.

Demircan E., Khatib O., Wheeler J., Delp S., 2009.

Reconstruction and EMG-Informed Control,

Simulation and Analysis of Human Movement for

Athletics: Performance Improvement and Injury

Prevention. Proc. IEEE international conference on

Engineering in Medicine and Biology Society.

Minneapolis. MN. pp. 6534-6537.

Wang J., Li Y., Zhao Z., 2010. Inverse Kinematics and

Control of a 7-DOF Redundant Manipulator Based on

the Closed-Loop Algorithm. International journal of

Advanced Robotic System. 7(4). pp. 1-12.

Park K. C., Chang P. H., Lee S., 2001. Analysis and

control of redundant manipulator dynamics based on an

extended operational space. Robotica. 19(6). pp. 649-

662.

Schafer B., Krenn R., Rebele B., 2003. On inverse

kinematics and kinetics of redundant space manipulator

simulation. Journal of Computational and Applied

Mechanics. 4(1). pp. 53-70.

Peters J., Mistry M., Udwadia F., Nakanishi J., Schaal S.,

2007. A unifying framework for robot control with

redundant DOFs. Autonomous Robots. 24(1). pp. 1-12.

Oh Y., Chung W., Youm Y., Suh I. H., 1997. A Passive-

based motion control of redundant manipulators using

weighted decomposition of joint space. Proceeding

IEEE International Conference on Robotic and

Automation. Monterey. CA. pp. 125-131.

Zhang Y., Zhu H., Tan Z., Cai B., Yang Z., 2008. Self-

motion planning of redundant robot manipulators based

on quadratic program and shown via PA10 example.

Proceeding IEEE 2nd International Symposium on

Systems and Control in Aerospace and Astronautics,

Shenzhen. pp. 1-6.

Wang J., Li Y., Zhao X., 2010. Inverse Kinematics and

Control of a 7-DOF Redundant Manipulator Based on

the Closed-Loop Algorithm. International journal of

Advanced Robotic Systems. 7(4). pp. 1-10.

Guran A., Iqbal K., Shoushtari A., 2012. Biomechatronical

Motion Simulation of Human Lifting using a Novel

approach to Solve Kinematic Redundancy in Human

Movements. Euromech colloquium 538, Physics of

sports, Paris.

Denavit J., Hartenberg R. S., 1995. A kinematic notation

for lower-pair mechanisms based on matrices.

Transaction of ASME Journal of Applied Mechanics.

23. pp. 215–221.

Siciliano B., Khatib O., 2008. Springer handbook of

robotics. 1st edition. Springer publication.

Modelling and Simulation of Human-like Movements for Humanoid Robots

345

Khatib O., Demircan E., De Sapio V., Sentic L., Besier T.,

Delp S., 2009. Robotic-based Syntesis of human

motion. Journal of physiology-Paris. 103(3-5). pp.

211-219.

Spong M. W., Vidyasagar M., 1989. Robot Dynamics and

Control. John Wiley and Sons, Inc.

Xiang Y., Arora J. S., Rahmatalla S., Abdel-Malek K.,

2009. Optimization-based dynamic human walking

prediction: one step formulation. International Journal

for Numerical Methods in Engineering. 79(6). pp. 667–

695.

APPENDIX

The parameters of lifting task and lifter's body which

subjected to simulation are presented in table1 and

table 2 respectively.

Table 1: Parameters of lifter's body and related values.

Mass

(kg)

Inertia

(N.J

K

)

COM (m)

Length (m)

8

1

0.24

0.48

shank

20.8

1.7

0.22

0.44

hip

6

1.0

0.05

0.10

Lumbar

spine

7.9

1.3

0.09

0.18

Thoraci

c spine

11

1.4

0.105

0.21

Cervica

l spine

3.8

0.7

0.14

0.28

arm

3.2

1.34

0.15

0.30

forearm

Table 2: Parameters of lifting task and related values.

Parameters Values

Weight

40 kg

Initial horizontal position of

COM of weight

0.20 m

Initial vertical position of COM of weight

0.18 m

Final horizontal position of COM of

weight

0.1 m

Final vertical position of

COM of weight

1.95 m

Lifting time

2.5 and 3 (sec)

Number of time sequences 10

ICINCO 2012 - 9th International Conference on Informatics in Control, Automation and Robotics

346