Product Assortment Decisions for a Network of Retail Stores using

Data Mining with Optimization

Sudip Bhattacharjee, Fidan Boylu and Ram Gopal

Department of Operations and Information Management, University of Connecticut, Storrs, U.S.A.

Keywords: Product Assortment, Retail Operations, Optimization, Association Rule Mining.

Abstract: This paper presents a model for product assortment optimization for a network of retail stores operating in

various locations of a company. Driven by the local market information of each retail store, the model

determines the right products to include in a store’s assortment and which stores to ship from in the store

network. The model first learns the global patterns of the frequent itemsets based on association rule mining

to extract patterns of products with corresponding sales benefits. It then encodes the pattern information into

the development of a global optimization formulation, which maximizes the revenue of the company in

aggregate and identifies the optimal solution for each local store by taking into account the possibility of

shipments in the network. We use the transactional level data from an industry leading plastics manufacturer

and retailer in the United States to demonstrate the utility of the model.

1 INTRODUCTION

Retailers with multiple stores of commodity

products commonly face the problem of product

assortment selection, especially when these stores

are spread over several different geographic

locations. Given a network of stores, the problem

becomes how to incorporate varying market

conditions of store locations and at the same time

take into account the possible transportation of

products between stores, to decide on the right

product assortment for a given store location.

We approach the problem using data mining an

optimization tools. We use the conflict resolution

method (Bai et al., 2012) for itemsets extracted

using Association Rule Mining to extract global

patterns. We then use these patterns in a network

optimization problem to find the optimal product

assortment and shipment decisions for local stores.

We will make use of the measures developed in Bai

et al. (2012) to identify the concentration of clients

interested in certain patterns around a given location

and the retailer’s global sales performance on such

patterns.

For our analysis, we use the data of an industry

leading plastics manufacturer and distributor with

over seventy branch locations in the US, Canada and

Mexico. It offers a wide range of products such as

plastic sheet, rod, tube and film in various

shapes and sizes. These products are used to serve

various industries such as appliances, automotive,

electrical, manufacturing, medical, printing and

transportation. Companies such as these, with a large

number of branch locations, strive for solutions that

provide data-driven, quantitative decision support

tools that would help decide on the right product

assortment and shipment decisions for maximum

profitability of branch and company-wide

profitability.

This paper presents a model for product

assortment optimization for multiple stores of a

company where these stores, while holding a local

assortment of products, can also receive shipments

of products outside their portfolio from other stores

in the network. We contribute to the literature by

providing a network model of product assortment

decision using data mining and optimization tools.

We differentiate form earlier studies by providing a

more realistic framework where there is the

possibility of product shipments in a network of

stores which hasn’t been considered in the prior

studies.

2 LITERATURE REVIEW

Association Rule Mining (Agrawal et al., 1993,

Agrawal and Srikant, 1994, Brin et al., 1997) is the

319

Bhattacharjee S., Boylu F. and Gopal R..

Product Assortment Decisions for a Network of Retail Stores using Data Mining with Optimization.

DOI: 10.5220/0004106703190323

In Proceedings of the International Conference on Knowledge Discovery and Information Retrieval (KDIR-2012), pages 319-323

ISBN: 978-989-8565-29-7

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

extraction of patterns of interest among different

items in a collection of transactions. Association rule

mining techniques are based on the several measures

of interestingness such as support, confidence and

lift to gather possible association rules from the

databases. However, due to the increase in the size

and complexity of modern databases, the number of

the association rules mined can become

tremendously large. To narrow down and to

optimize the list of association rules, advanced

techniques have been proposed (Agarwal et al. 2000,

Han 2000, Malik 2006). We adopt the methodology

by Bai et al. (2012) which develops procedures for

eliminating conflicting patterns for the problem

under study, and differentiate between the frequent

patterns and beneficial patterns.

Product assortment decision has been the

attention of several studies. Caro and Gallien (2007)

study the problem of dynamically optimizing the

assortment of a store as more information becomes

available during the selling season. They focus on

one store and predict sales data to optimize the

assortment. Gaur and Honhon (2006) developed an

assortment planning model under the locational

choice demand model. In this model, products are

perceived as bundles of attributes, and each product

is defined by its location in an attribute space.

Individual preferences are defined by associating a

point in the attribute space with each consumer.

Problem of efficient shipment of products

between the stores in retail networks has also been

the center of research around inventory management

and distribution systems. In Caro and Gallien

(2010), authors address the problem of distributing a

limited amount of inventory across all the stores in a

fast-fashion retail network. They formulate a

stochastic model predicting the sales of a product in

a single store. They formulate a mixed-integer

program embedding a piecewise-linear

approximation of the first model applied to every

store in the network to compute store shipment

quantities maximizing overall predicted sales,

subject to inventory availability and other

constraints.

Although, closely related to these studies, we

focus on the product assortment decisions for

individual stores in the network when product

shipment is an option between the stores. We

maximize the revenue function of the company as a

whole taking into account the discount factors of

possible shipments. None of the above papers just

cited has brought together product assortment using

patterns of beneficial product combinations with the

availability of shipments in a network of stores.

3 MODEL

Let the firm offer a total of P products indexed as

pϵ1,…,P in B store locations indexed as

bϵ

1,…,B

to clients in S different industry

segments indexed as sϵ1,…,S. Let iϵ1,…,N

index the client companies in a given industry

segment across all stores. Note that each client i may

operate in one or more of the stores and N represents

the collection of all clients in all stores. Let π

denote the revenue of client i from its own sales. Let

r

,

denote the sales of product p from the firm we

model to client i. We define a transaction as the

vector t

r

,

,…,r

,

which indicates sales to the

client of various products.

Let Aa

,…,a

|

|

denote the set of all

frequent itemsets with lift values greater than 1. A

transaction is denoted as supporting a frequent

itemsetif r

,

0∀p ∈ a

. Let θ

,θ

⊆A, denote

the set of frequent itemsets that are supported by

transaction t

i

. Following the notation in Bai et al.

(2012), we introduce two key measures: Industry

coverage: Υp,a

∑

∀,

∑

∀

and Revenue

Capture Ratio: Φp,a

fπ

,r

,

∀i:a

ϵθ

.

Industry coverage denotes the ratio of revenues

of clients who purchased the frequent itemset a

without any conflicts with other frequent itemsets to

the revenue of all potential clients around the stores

of the firm. Revenue capture ratio describes the

ratio of the firm’s sales value of product p to the

revenue of clients that purchasea

. As a common

approach, we use

Φp,a

average

,

∀i:a

ϵθ

.

We first begin the analysis to remove conflicts in

the frequent itemsets and in the process prune the

number of itemsets for further analysis. Consider

two frequent itemsets

and

in

such that

,

∈

. They are said to conflict if

∩

∅ (where ∅ denotes null or empty set). In other

words, there exists at least one product that belongs

to both itemsets, which raises the question of which

itemset influences the sales of the products common

to both itemsets for a given transaction. Clearly, a

conflict removal strategy is needed to identify the

main itemset that influence the sales of a set of

products. Adopting the methodology by Bai et al.

(2012), we remove the conflicts in frequent itemsets.

We start with one frequent itemset and compare it

with every other frequent itemset for the transaction.

For each transaction, we terminate with a set of non-

conflicting itemsets, and prune the number of

itemsets for the whole set of transactions. At the end

KDIR2012-InternationalConferenceonKnowledgeDiscoveryandInformationRetrieval

320

of the process, for each product in each transaction,

at most one frequent itemset is utilized. This process

ensures that the frequent itemset that is identified

uniquely influences the products present in that

itemset.

For a given store, let Π denote the total revenues

of the client companies belonging to a given

industry segment in that store location. We focus on

deciding which products to offer (and as a result

which itemsets come into play) and the

corresponding branch sales figures. We define the

following variables:

1 if the product p is shipped from branch

to b, 0 otherwise, for p1,…,P , 1,…,B

and 1,…,B

1 if itemset a

applies for branch b, 0

otherwise, for j1,…,

|

A

|

and 1,…,B

1 if product ∈a

is shipped from branch

to b, 0 otherwise, for j1,…,

|

A

|

and

1,…,B, 1,…,B

Δ

1is the discount factor when product p is

shipped from branch to b, for p1,…,P ,

1,…,B and 1,…,B where Δ

Δ

.

Notice that when ,

1 if the product

p is kept in branch b and 0 otherwise. Similarly,

when , Δ

1 since no discount is

necessary. The total expected sales for a branch b

can be written as:

∑

Υ

p,∅

Φ

p,∅

Π

∑

Δ

∑∑

Υp,a

ΠΦ

p,∅

∑

Δ

|

|

Φp,a

∑

Δ

Next, we develop the optimization model using

the above sales formula for each branch to formulate

the objective function.

Problem

(no more than

products kept at

each store):

∑

∑

Υ

p,∅

Φ

p,∅

Π

∑

Δ

∑∑

Υp,a

ΠΦ

p,∅

∑

Δ

|

|

Φp,a

∑

Δ

s,t For 1B:

∑

1

(A product should be shipped

from at most 1 other store)

forp 1,…,P∀ ∈

1,…,B

b (If a store doesn’t hold a product, can’t ship

that product to other stores)

∑∑

∈

1

,∀

, (all

products of an itemset should be either received

or held for the itemset to be in effect)

∑

y

∀ ∈

,∀

(If any of the

products of an itemset are not received or kept

then the itemset is not in effect)

,∀∈

,∀

, ∀ ∈ 1,…,B

(When a product of an itemset is not received or

held,

0

1

,∀∈

,∀

,

∀ ∈

1,…,B

(When an itemset is in effect,

1 for

1

∑

y

,∀∈

,∀

(When an

itemset is not in effect,

0)

∑

(Maximum number of products

that can be kept at the store)

,

,

∈0,1

Note that the above formulation is for a single

industry segment. However, it can easily be

generalized for multiple industry segments by

summing the objective function over the industry

segments and populating the constraints accordingly.

4 COMPUTATIONAL ANALYSIS

AND RESULTS

In order to illustrate our model, we use a prototype

example for 10 products and 3 branches for a single

industry segment. After conflict removal, we extract

7 frequent non-conflicting itemsets. We randomly

select the shipment discount factor Δ

in the

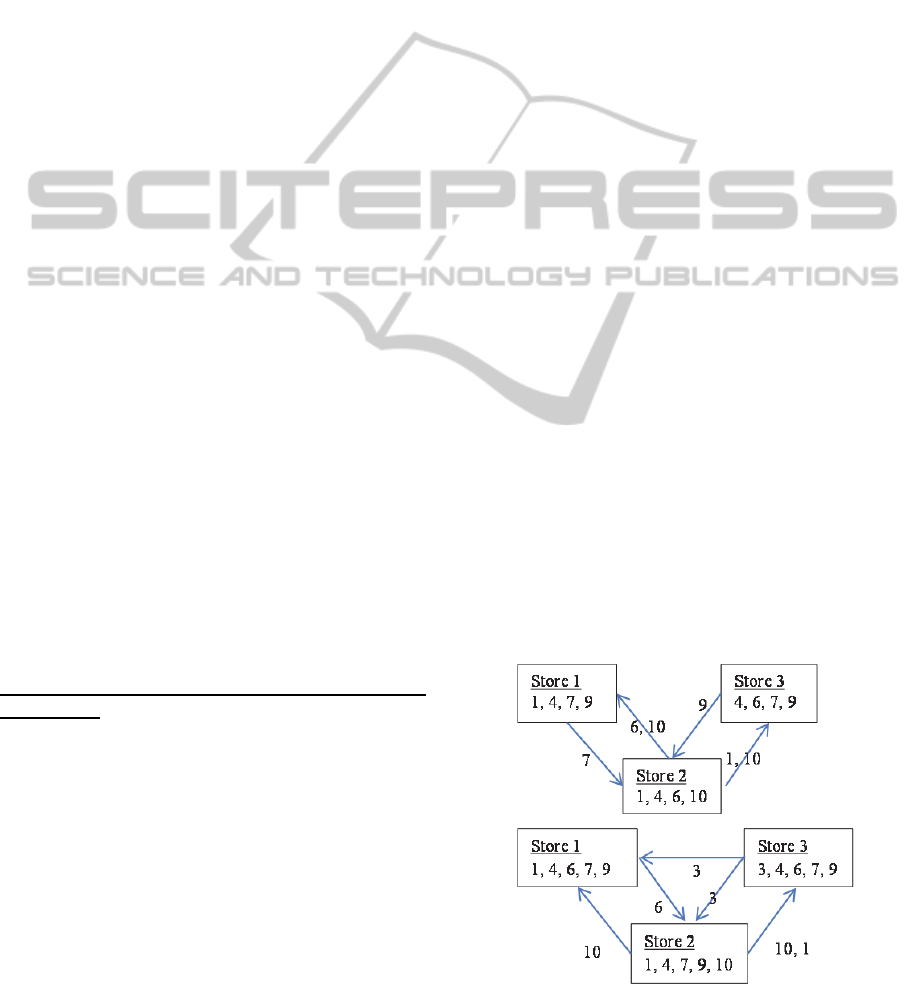

Figure 1:

=4 and

=5 shipment networks.

ProductAssortmentDecisionsforaNetworkofRetailStoresusingDataMiningwithOptimization

321

interval [0.5, 1] and use the same value of Π for all

stores. We solve the model for different values of

. In Figure 1, as an example, we display the

product shipment graphs for the two values of

=4

and 5. We observe that the shipments of products

dramatically change with an increase in

.

Table 1 reports the total revenue and individual

store revenues when maximum number of products

for all stores are set to increasing values of

starting from

7 for ease of presentation.

Notice that the product shipments are not

reported in Table 1 due to space limitations. When

the product assortments in Table1 for increasing

values of

are examined, we observe that the

assortments show much variability from one

to

another. This can be attributed to the random

shipment discount factor Δ

which does not have a

certain pattern. This results in variability in optimal

shipment of products as the number of products per

store is increased

Table 1: Revenues and product assortments.

Store Rev.(million)

# of

itemsets

Products in store

Total

Rev.

(million)

7

1 5.66 4 1,3,4,5,6,7,9

16.68 2 5.69 2 1,4,6,8,9,10

3 5.33 4 3,4,5,6,7,8,9

8

1 5.66 4 1,3,4,5,6,7,8, 9

16.69 2 5.70 2 1,3,4,6,7,8,9,10

3 5.33 4 3,4,5,6,7,8,9,10

9

1 5.61 7 1,2,3,4,5,6,7,8,9

16.57

2 5.65 5 1,2,3,4,6,7,8,9,10

3 5.30 7

2, 3, 4, 5, 6, 7, 8,

9, 10

We observe that the optimal revenue occurs at

=

8. To obtain values for

= 9, we force the

constraint in the model to an equality. We see that

the objective value for

= 9 is less than the optimal

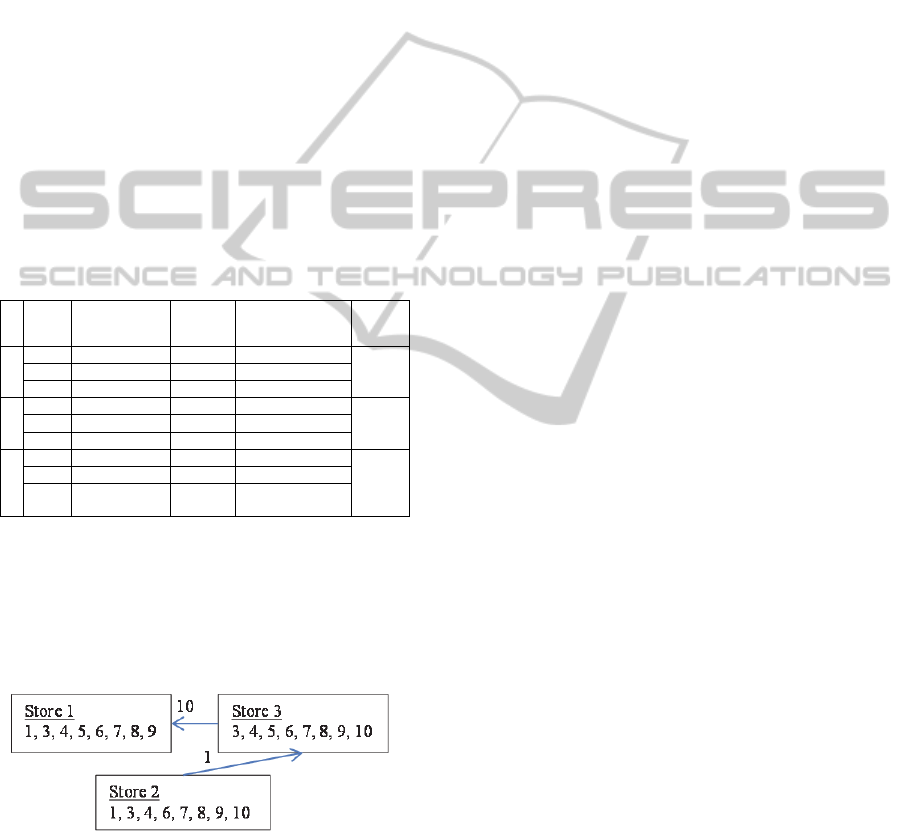

= 8. In Figure 2, we display the shipment graph

of this optimal network.

Figure 2: Optimal shipment network

.

In Table 1, when the numbers of itemsets are

compared, we see that they saturate around the

optimal value at 4, 2 and 4 for three stores of the

company. We note that for larger number of

products and higher number of stores, the optimal

graph will look more interesting as the shipment of

multiple products will be in effect and the related

revenues and assortments will show more variability

as multiple industry segments are considered. The

results of such a dataset from an industry leading

plastics manufacturer and retailer in the United

States will be demonstrated at the time of

presentation.

5 CONCLUSIONS

In this paper, we present a model for product

assortment optimization for a network of retail stores

operating in various locations of a company. We

combine local information captured from each retail

store and use a global frequent itemset analysis.

Later, for each retail store, our optimization model

determines the right products to include in a store’s

assortment and which stores to ship from in the store

network. The model first learns the global patterns

of the frequent itemsets based on association rule

mining to extract patterns of products with

corresponding sales benefits. It then uses a global

optimization formulation maximizing the revenue of

the company in aggregate and identifies the optimal

assortment for each local store by taking into

account the possibility of shipments in the network.

REFERENCES

Agarwal, R., Imielinski, T., Swami, A., 1993, Mining

association Rules Between Sets of Items in massive

databases, Proceedings of the ACM/SIGMOD

International Conference on Management of Data, pp.

207-216

Agrawal, R., Srikant. R. (1994) Fast algorithms for mining

association rules. Proceedings of the 20th

International Conference on Very Large Data Bases,

VLDB, pp. 487-499.

Agarwal, R., Aggarwal C. C., Prasad V. V. V. (2000). A

tree projection algorithm for generation of frequent

itemsets. Journal of Parallel and Distributed

Computing. 61. pp. 350-371

Bai, X., Bhattacharjee, S., Boylu, F., Gopal, R. (2012) A

Data Mining and Optimization Methodology for

Improving Branch Product Portfolio and Performance,

under review

Brin, S., Motwani, R., Ullman, Tsur. J. D., (1997).

Dynamic itemset counting and implication rules for

market basket data. In SIGMOD 1997, Proceedings

ACM SIGMOD International Conference on

Management of Data, pp. 255-264.

Caro, F., J. Gallien. (2007). Dynamic assortment with

demand learning for seasonal consumer goods.

Management Science. 53(2) 276–292.

KDIR2012-InternationalConferenceonKnowledgeDiscoveryandInformationRetrieval

322

Caro, F., J. Gallien. (2010). Inventory Management of a

Fast-fashion Retail Network. Operations Research.

58(2) 250–273.

Gaur, V., D. Honhon. (2006). Assortment planning and

inventory decisions under a locational choice model.

Management Science. 52(10) 1528-1543.

Han, J. A. (2000). Mining frequent patterns by pattern

growth: Methodology and Implications. ACM

SIGKDD Explorations Newsletter. 2(2) pp. 14-20.

Malik, H. H. (2006). Clustering web images using

association rules, interestingness measures, and

hypergraph partitions. Proceedings of the 6th

International Conference on Web Engineering (ICWE

'06). pp. 48-55.

ProductAssortmentDecisionsforaNetworkofRetailStoresusingDataMiningwithOptimization

323