Experience-based Fuzzy Control of an Anthropomimetic Robot

Veljko Potkonjak

1

, Nenad Bascarevic

1

, Predrag Milosavljevic

1

, Kosta Jovanovic

1

and Owen Holland

2

1

Faculty of Electrical Engineering, University of Belgrade, Bulevar ralja Aleksandra 73, 11000 Belgrade, Serbia

2

School of Informatics, University of Sussex, Brighton BN1 9 QJ, Falmer, U.K.

Keywords: Knowledge Base Control, Fuzzy Control, Machine Learning, Robot Arms, Bio-inspired Robot.

Abstract: This paper aims to present a novel experience-based solution for a black-box control problem, applied to an

anthropomimetic robot. The control method is tested on a point to point control problem of a multi-jointed

robot arm. The model characteristics – dynamics, kinematics, and control parameters – are considered as

unspecified, and therefore we deal with a machine learning approach that follows the cybernetic concept of

black-box. The only available data of the system are those obtained from measuring inputs and outputs. The

control algorithm involves two levels: feedforward and feedback. The main focus is, however, on feedback

level where the algorithm for experience-based estimation of kinematic coefficients is combined with fuzzy

logic control in order to relate the control inputs with the robot arm motion in the global frame.

1 INTRODUCTION

Contemporary humanoid robots are constructed in

order to replicate humans just by copying the outer

form, while keeping the internal classical machine

structure. If, however, one intended to replicate the

human internal mechanics, he would face a

situation: complex multi-degree-of-freedom joints,

muscles crossing over several rotation axes and

working in an antagonistic mode, presence of

mechanical compliance, etc. Such systems can no

more be modelled and controlled in a classical

analytical way – a biologically-inspired approach is

needed (Potkonjak et al., 2010).

Holland and Knight, 2006 have proposed a new

expression - anthropomimetics. It concerns a new

principle in robot construction (Fig. 1), mimicking

the human body, skeleton and muscle system. The

goal is to attain a high level of performances (e.g.

maneuverability) analogous to human paragon. The

idea of this paper is based on the work done within

the project ECCEROBOT (European 7th Framework

Program, project “Embodied Cognition in a

Compliantly Engineered Robot”).

By combining the experience-based approach

with fuzzy logic, this paper aims to solve the point-

to-point control problem in the absolute frame, i.e.

find a way to control the anthropomimetic robot in

reaching a prescribed hand tip position.

The outline of this paper is as follows. A short

overview of most similar projects and related topics

is presented in Section 2. Section 3 shows an

empirical approach to feedforward (FF) control. The

influence of each control input on the hand tip

motion in the global frame is evaluated in Section 4.

By implementing the fuzzy logic algorithm in

Section 5 we form the final control as FF+feedback

(FB) for the anthropomimetic robot arm. Efficiency

of our control algorithm is shown in Section 6.

(a) (b)

Figure 1: (a): ECCEROBOT test rig. (b): The latest

prototype of the ECCEROBOT.

2 RELATED WORKS

The posed problem can be considered from different

points of view, as black-box modeling or

identification of nonlinear systems.

389

Potkonjak V., Bascarevic N., Milosavljevic P., Jovanovic K. and Holland O..

Experience-based Fuzzy Control of an Anthropomimetic Robot.

DOI: 10.5220/0004117503890394

In Proceedings of the 4th International Joint Conference on Computational Intelligence (FCTA-2012), pages 389-394

ISBN: 978-989-8565-33-4

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

Rivals and Personnaz, 1995 showed that there

are advantages in using nonlinear state-space

models, including a larger class of nonlinear

dynamical models. Several examples of nonlinear

black-box model structures and approximation

issues are proposed by Ljung, 2001. Relationships

between fuzzy models, neural networks and classical

non-parametric models are discussed. Van Mulders

et al., 2009 introduced two nonlinear optimization

methods for the identification of nonlinear black box

systems. Each method relies on estimation of the

parameters of a polynomial nonlinear state-space

model by means of a nonlinear least-squares

optimization. Gonzalez-Olvera et al., 2009 presented

a black-box modelling of two degrees of freedom

manipulator. Recurrent neural networks with output

feedback are used to solve the visual servoing

problem.

Another possible solution for the black-box

control can be determined by applying machine

learning or predictive control algorithms.

Researchers in the field of robotics, Chhabra and

Jacobs, 2008 introduce a new learning model for

simulated two-joint arm motor control referred to as

the Greedy Additive Regression (GAR) model. The

model maintains a base of control sequences (i.e.,

motor synergies) and it is presented for learning the

coefficients of a linear combination of sequences.

Stulp et al., 2009 presented both, human data and

experience-based learning, in order to determine if

the end-effector can be brought into a position where

the object can be grasped, regardless of the path.

Haruno et al., 2001 proposed a new modular

architecture, the modular selection and identification

for control (MOSAIC) model, for motor learning

and control based on multiple pairs of forward

(predictor) and inverse models.

3 FEEDFORWARD LEVEL

3.1 Biologically Inspired Control

Potkonjak et al., 2012 presented the control of

antagonistic drives based on a biologically inspired

puller-and-follower concept for a single joint

system. The pattern of the EMG activity in elbow

flexors when a slow linear flexion movement is

produced against small constant load is analysed by

Tal’nov et al., 1999. After reaching the final value of

the joint angle, the burst in the agonist (AG) EMG

intensity slowly drops to a steady-state level. In

order to provide fine tuning of joint position, AG

activation is followed by burst in antagonist (ANT).

We apply the same logic to control the joints in the

robot. Namely, the input voltage fed into the

actuators must generate similar commands to

muscles, followed by the appropriate activation of

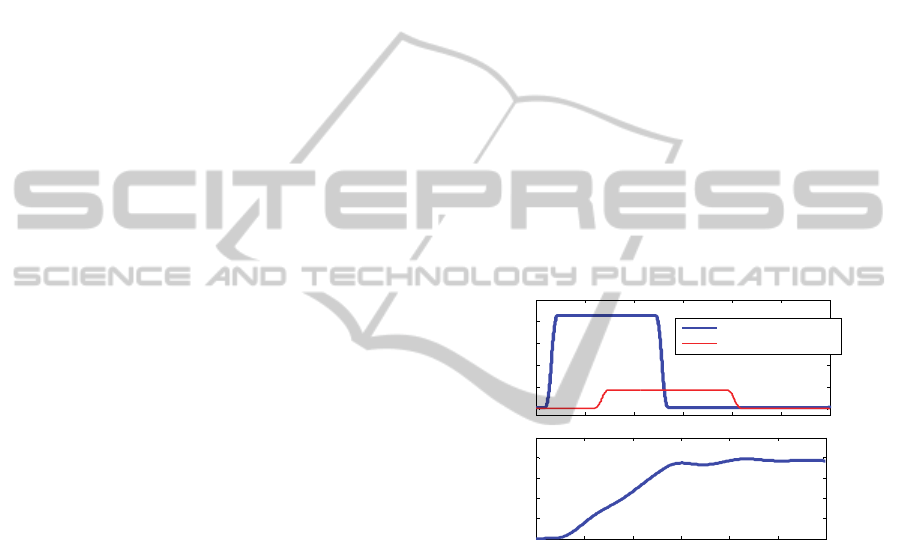

ANT. Fig. 2 demonstrates the input voltage of the

controlled joint and its position. It allows to

distinguish two input voltage components in both

AG and ANT: the control signal burst mainly

responsible for the joint motion; and the silent

period that keeps the reached steady state position.

The ratio between the maximum values of the AG

and ANT inputs as well as the ratio between their

burst time duration are constant for a particular joint.

Therefore, in order to move the joint to the required

position we should change appropriately the AG

maximum value and its burst time duration, while

the ANT value and its burst time duration are

proportionally modified. Namely, it is assumed that

antagonist activation would always make

proportional contribution to joint motion, compared

to agonist contribution. The joints are controlled by

voltage inputs presented in Fig. 2.

Figure 2: Top: Agonist and antagonist input voltage

control. Bottom: The obtained elbow angle during

appropriate control.

3.2 Experience Acquisition in

Multi-jointed System

The approach used in controlling a single-joint is

now generalized to the multi-jointed robot arm. In

examples, a fixed-base arm with seven single-

degree-of-freedom joints moved by antagonistically

coupled drives is considered. The experience

acquiring means the set of motion experiments

performed from a set of initial hand-tip positions

which define the initial region, and ending in a

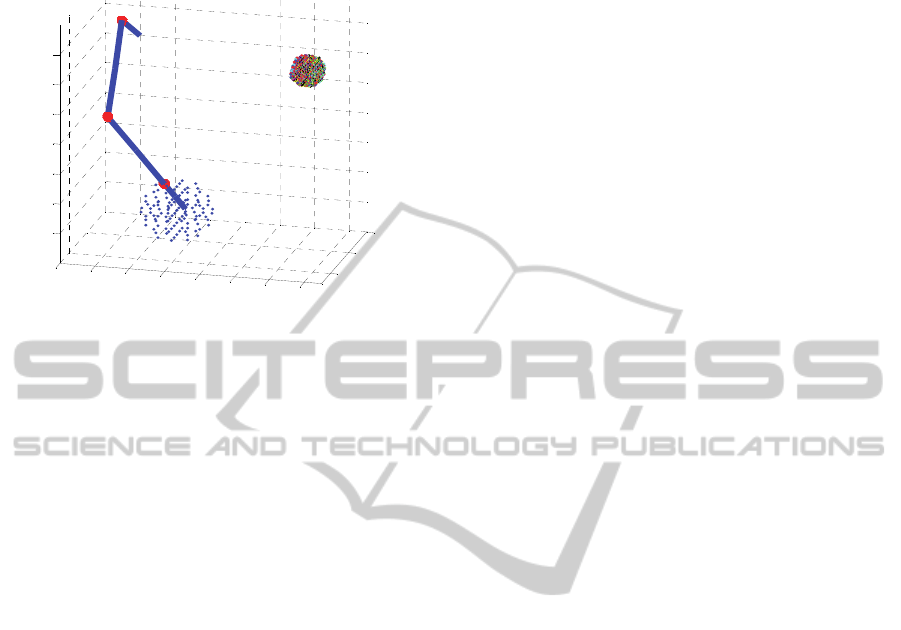

region of final positions. Figure 3 shows the initial

and the final region. When performing a motion

experiment, the joints are controlled by heuristically

determined control voltages which follow the pattern

0 0.5 1 1.5 2 2.5 3

0

1

2

3

4

5

Input voltage

0 0.5 1 1.5 2 2.5 3

5

10

15

20

25

30

time [s]

Elbow angle

Agonist voltage

Antagonist voltage

IJCCI2012-InternationalJointConferenceonComputationalIntelligence

390

presented in Fig. 2. The used pointing example does

not specify the path, only the end point.

Figure 3: Recorded initial and final positions of robot hand

tip.

The positions shown in Fig. 3, the initial and the

final sets, together with the controls applied in these

experiments are recorded and represent the system

experience, the experience base. The region of initial

positions is a sphere with the radius of 0.1, while

final region is in the sphere with the radius of

0.05. In case of a larger sphere, we have to spend

more time on experience acquisition if we intend to

keep the same distances within the grid, or we may

create a grid with larger distances which however

would require a more complex interpolation

procedure.

Created in the above described way, the

experience base relates the initial positions and the

input voltages, on one side, with the reached points

(output) on the other. Knowledge acquiring, the

training, means filling in the base. In our example,

for each initial position there are 90130 final

positions in the final sphere. The distances in the

initial grid are between 2.5 and3.5. The

relevant distance in the final set of positions

concerns the final points that resulted from the same

initial point: the distances are from 2 to2.5.

3.3 Feedforward Exploitation in

Multi-jointed System

In the exploitation stage the robot is required to

reach a target point (hand-tip position

) that has

not been previously reached in training, starting

from a position (

) that has not been previously

used. In this phase, the experience base is used to

derive the appropriate input control pattern. Here, a

linear interpolation scheme was applied to compute

the control from a set of closest neighbors found in

the base. The FF motor control represents as a linear

combination of these neighboring control sequences

(Chhabra and Jacobs, 2008).

The interpolation and the calculation of the FF

control are done before the robot moves, i.e. off-line.

Since any interpolation gives the approximate

solution, the obtained control would drive the robot

to a vicinity of the target point; the deviation being

dependant on the competency of the knowledge base

and the interpolation method; hence the closest

neighbours would be used for FF interpolation.

Therefore, the algorithm starts with the sequential

search for the closest four initial positions around

,

from the initial set. Also, the four final positions

around

, from the final set, as well as the control

inputs are chosen for the linear interpolation

algorithm. The positions

and

must be inside of

polyhedral defined by neighbours from the initial

and the final sphere, respectively. Namely, after

acquiring stage, the model shows generalization to

novel tasks whose dynamics lie within the

polyhedral of already learned dynamics (Haruno et

al., 2001). The total control input for each motor is

the summation of the sequences from experience

base using the coefficients, to weight the

contributions. Numerous experiments of FF

interpolation, in our case of the ECCEROBOT, have

shown that the distance between the position reached

by FF and the target position

in global frame does

not exceed 6. The required precision of the

robot hand tip is set to 1 in each axis. FF control

is not sufficient to drive the hand tip into satisfactory

final position. To achieve this requirement we need

to extend the control by adding feedback for fine

tuning. Therefore, at the moment when the tip is at

6 distance from the final point, the feedback

component is added.

4 FUZZY LOGIC FEEDBACK

CONTROL

We shortly remind of the goal – solving the point-to-

point control problem in the global frame, relying

only on experience. The fuzzy logic (Zadeh, 1965) is

chosen to cope with this complex problem. A fuzzy

controller is implemented.

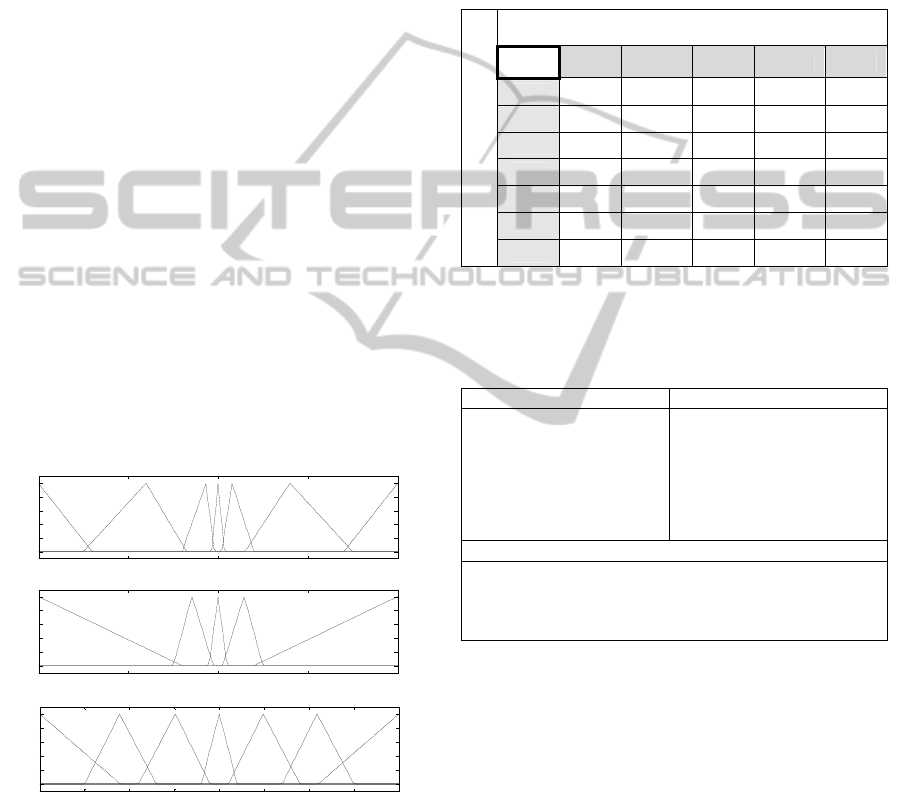

In the proposed fuzzy controller we use two

input variables (position error and derivative of

position error) and one output variable (voltage) for

each axis. The membership functions for inputs and

output are shown in Fig. 4.

As shown in Fig. 4, fuzzy membership functions

-0.1

0

0.1

0.2

0.3

0.4

0.5

0.6

-0.4

-0.2

0

-0.5

-0.4

-0.3

-0.2

-0.1

0

0.1

Z axis

INITIAL

POSITIONS

FINAL

POSITIONS

Experience-basedFuzzyControlofanAnthropomimeticRobot

391

comprise a range of values and can actually overlap.

Triangular shapes have been adopted for the fuzzy

subsets. Both input variable ranges (

,

) were

founded experimentally and the inputs do not exceed

defined values. The maximum feedforward position

error is extended to a 10mm in a case of the lower

base resolution. The “diff_error” input (and “error”

as well) is calculated every 0.001s (sampling time),

so derivative of the error has low values and

rescaling was required to obtain reasonable range of

inputs. The following five and seven fuzzy levels are

chosen for the control inputs of the fuzzy controller

in the fuzzification process. These numbers of sets

are established as optimal values for our system. The

final region of interests for “error” variable is

between [-1mm, 1mm], so the first fuzzy set (NOE)

has to be in that range, the second and the third set

(SNE and SPE) have to overlap with the first set and

have to be narrow if we want to control the error

near the zero value. The fourth and the fifth set (NE

and PE) cover a wider range around 5mm value and

the sixth and the seventh set (VNE and VPE) cover

more than 6mm values in a case of greater error.

These seven sets are also required for smooth error

change definition due to time. Numerous simulations

showed more satisfactory results if the sets do not

overlap at 0.5 degree. The number of sets depends

on the (input range)/(final region range) ratio and the

desired time response of the system. Analogues

procedure is applied to “diff_error” sets.

Figure 4: Membership functions for position error,

derivative of position error and voltage.

Seven sets of membership functions are defined

for the output variable “voltage”. We want to avoid

rough fluctuations of the voltage during changeable

position error and thus seven sets, including

overlapping between two consecutive sets, are

implemented.

If-then rule base is shown in Table 1. All

possible rule combinations of fuzzy inputs and their

results as outputs are presented in that table. The

used fuzzy operator is AND.

The derivation of the

fuzzy control rules is heuristic in nature and based

on the following theoretical criteria presented in

Table 1. Finally, for our purposes the centroid

defuzzification method is used.

Table 1: If-then rules.

ERROR

DERIVATIVE OF ERROR

AND

DNE SDNE DZE SDPE DPE

VNE VNV VNV VNV VNV VNV

NE NV NV SNV SNV NOV

SNE NV SNV SNV NOV SPV

NOE NV SNV NOV SPV PV

SPE SNV NOV SPV PV PV

PE NOV SPV SPV PV PV

VPE VPV VPV VPV VPV VPV

The meanings of the acronyms from Table 1 are

shown in Table 2.

Table 2: The meanings of the acronym from the Table 1.

ERROR DIFF_ERROR

VNE-very_negative_error

NE – negative_error

SNE – Snegative_error

NOE – no_error

SPE – Spositive_error

PE – positive_error

VPE – very_positive_error

DNE – diff_negative_error

SDNE–Sdiff_negative_error

DZE – diff_zero_error

SDPE– Sdiff_positive_error

DPE – diff_positive_error

VOLTAGE

VNV – very_negative_voltage NV – negative_voltage

SNV – Snegative_voltage NOV – no_voltage

SPV – Spositive_voltage PV – positive_voltage

VPV – very_positive_voltage

5 KINEMATIC COEFFICIENTS

The fuzzy logic was implemented and now we

dispose with the control signals of our process.

There are 2n (in our case n=7) control inputs and

only three outputs (x, y and z position), so that a

question is posed: How to determine the influence of

each control input on the hand tip motion in the

global frame?

Although this system has fourteen inputs, the

feedback phase uses only seven independent inputs,

the pullers, to control the hand tip positioning. The

other seven result from the puller-follower concept

(Potkonjak et al., 2012).

-0.01 -0.005 0 0.005 0.01

0

0.2

0.4

0.6

0.8

1

ERROR (INPUT)

VNE

VPE

NE

NOE

PE

SNE

SPE

Degree of member s hi p

-1 -0.5 0 0.5 1

0

0.2

0.4

0.6

0.8

1

DIFF__ERROR (INPUT)

Degree of member shi p

DNE

DZE DPE

SDNE

SDPE

-2 -1.5 -1 -0.5 0 0.5 1 1.5 2

0

0.2

0.4

0.6

0.8

1

VOLTAGE (OUTPUT)

VNV

NOV

VPV

NV

PV

SNV SPV

Degree of member s hi p

IJCCI2012-InternationalJointConferenceonComputationalIntelligence

392

Kinematic coefficients are defined as parameters

which describe the relation between control inputs

and the axes of the global frame. For each joint

(controlled by two inputs), three normalized

coefficients

,

,

are assigned, for x, y and

z axis, respectively.

Suppose that pure feedforward brings the hand

tip to point

(

,

,

). Coordinates of the

points from the narrow environment (neighbours of

) are denoted as (

,

,

), 1,2,…,(-

neighbour number). This chapter presents only the

algorithm for the x axis – the analogues procedure is

applied for y and z axes. The first calculated

parameter is

(1)

which defines normalized distance (between

feedforward and the neighbouring position) in

comparison to and distance for the current

neighbour

. Next calculated parameter is about

joint angle position in the local frame:

;

…

(2)

which determines normalized deviations between

joint positions (

;jointnumber) reached by

FF, and joint positions (

) of the neighbour.

Parameter

is used to normalize the joint

difference between all seven joints for the chosen

neighbour in the joint space. Now, the normalized

distance along axis between

and each

neighbour position

is evaluated. Equation (3)

estimates coefficients (

used to compare the

distances of each neighbour from

:

⋯

(3)

The required coefficients (

,

,

) have been

estimated. The influence of each coefficient should

be treated equally and therefore a product of these

parameters is formulated as a connection:

(4)

Equation (4) represents the influence of a particular

joint along x direction. The proper form which is

used as the final kinematic coefficient is

(5)

Finally, the influence of each joint on each axis

direction is calculated and can be used in final form.

The final equation for the control input during

feedback phase is

,

(6)

The variable

is a static voltage of i – joint

required to keep the joint in the prescribed position

during steady state. For the target position the static

voltage is estimated using feedforward algorithm

(see Section 3.3). The signs in (6) are chosen

experimentally using experience base. They

represent the situation when the control input is

increased, in which direction (positive “” or

negative “”) the hand tip moves to (for each axis).

6 SIMULATION RESULTS

Control was verified by simulation. The theory

developed above is applied to the simulator of the

robot arm driven by antagonistically coupled drives.

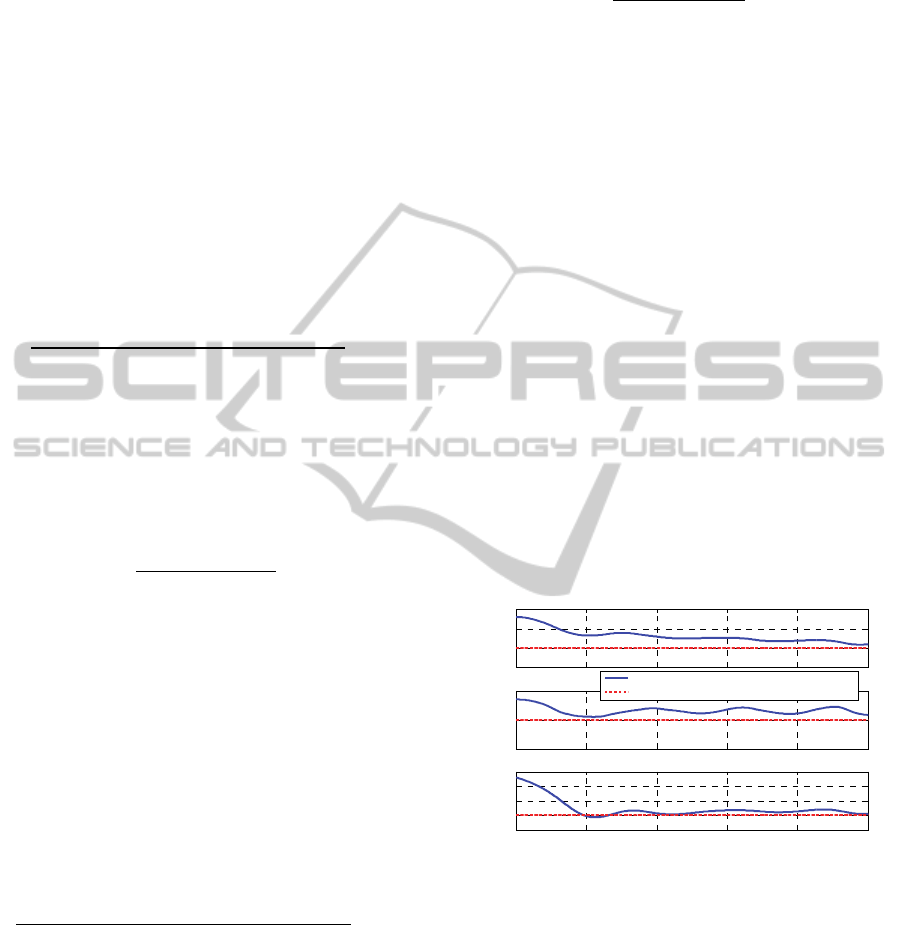

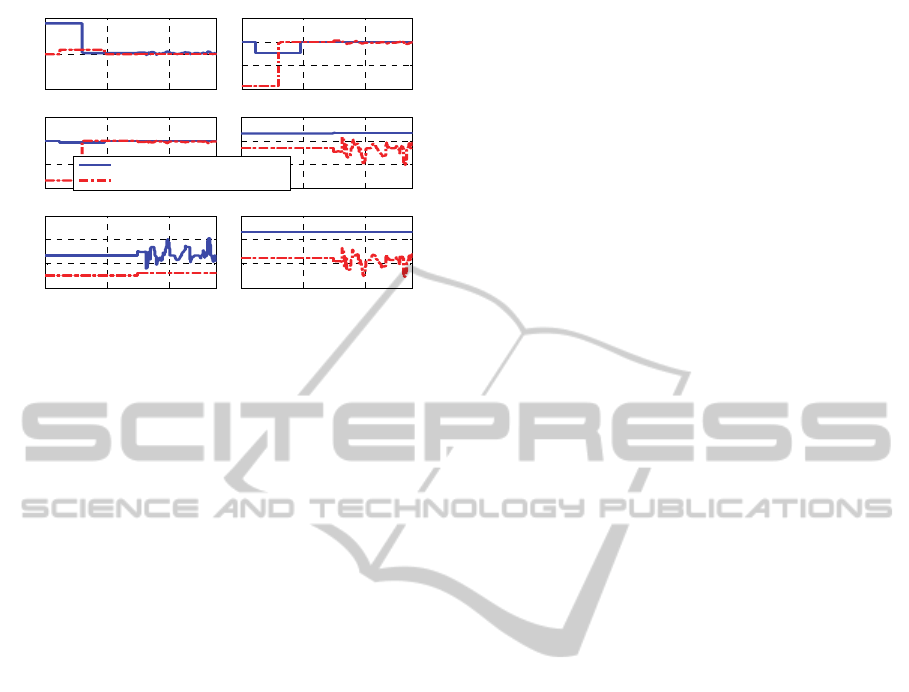

Figure 5: Hand tip position in global frame during

feedforward and feedback control.

Figs. 5 and 6 depict the example where the

feedforward makes the error of 5mm in z axis

direction. The whole motion of the robot arm

lasts5,5. During first 3 feedforward control is

applied in order to drive the robot arm tip from

initial position

to position

. In the next2,5 the

system is controlled by FF and FB. In spite of

oscillations caused by fuzzy controller the final hand

tip position finally comes into prescribed region,

1mm around the reference position

(Fig. 5).

Figure 6 shows FF and FB control signals.

3 3.5 4 4.5 5 5.5

0.529

0.53

0.531

0.532

X position [m]

3 3.5 4 4.5 5 5.5

-0.222

-0.22

-0.218

Y position [m

]

3 3.5 4 4.5 5 5.5

-2

0

2

4

6

x 10

-3

Time [s]

Z position [m]

Hand tip position along X,Y and Z axis

Reference position in global frame

Experience-basedFuzzyControlofanAnthropomimeticRobot

393

Figure 6: The feedforward and feedback control of the

most representative joints in the system.

7 CONCLUSIONS

The core of this paper was the implementation of

fuzzy controller along with estimation of kinematic

coefficients to formulate the feedback for a robotic

arm with antagonistically coupled compliant drives.

Since the suggested control algorithm relies on

the experience and fuzzy logic, it is expected to be

applicable to a wider class of robots. The only

modification would be different training data –

experience base should be customized for the

specific robot skills. Since the experience acquiring

stage in feedforward phase is time consuming,

further research can explore solution to speed up this

process. As our control depends on base resolution,

the future work would consider developing of more

sophisticated method to increase precision of the

control algorithm (e.g. to make more complex fuzzy

engine).

ACKNOWLEDGEMENTS

The research leading to these results has received

funding from the European Community's Seventh

Framework Programme FP7/2007-2013 - Challenge

2- Cognitive Systems, Interaction, Robotics - under

grant agreement no. 231864 - ECCEROBOT; and

partly by the Serbian Ministry of Science and

Technological Development under contracts 35003

and 44008.

REFERENCES

Chhabra, M., Jacobs, A., 2008. Learning to combine

motor primitives via greedy additive regression. The

Journal of Machine Learning Research. vol. 9. pp.

1535-1558.

Gonzalez-Olvera, M., Rodriguez-Morales, A., Tang, Y.,

2009. Black-box modeling of a 2-dof manipulator in

the image plane using recurrent neurofuzzy networks.

In Proc. of the IEEE Int. Conf. on Decision and

Control, pp. 8440-8445.

Haruno, M., Wolpert, D., Kawato, M., 2001. MOSAIC

model for sensorimotor learning and control. Neural

Computation. vol. 13. pp. 2201 – 2220.

Holland, O., Knight, R., 2006. The anthropomimetic

principle. In Proc. of The Symposium on Biologically

Inspired Robotics edited by J. Burn and M. Wilson.

Ljung, L., 2001. Black-box models from input-output

measurements. Proceedings of the 18th IEEE

Instrumentation and Measurement Technology

Conference. vol.1. pp. 138 - 146.

Potkonjak, V., Svetozarevic, B., Jovanovic, K., Holland,

O., 2010. Biologically inspired control of a compliant

anthropomimetic robot. In Proc. of the IASTED Int.

Conf. on Robotics and Applications. pp. 182 – 189.

Potkonjak, V., Svetozarevic, B., Jovanovic, K., Holland,

O., 2012. The puller-follower control of compliant and

noncompliant antagonistic tendon drives in robotic

system, International Journal of Advanced Robotic

Systems, vol. 8, pp 143-155.

Rivals, I., Personnaz, L., 1996. Black-box modeling with

state-space neural networks. Neural Adaptive Control

Technology. vol. 15. pp. 237-264.

Stulp, F., Fedrizzi, A., Zacharias, F., Tenorth, M.,

Bandouch, J., Beetz, M., 2009. Combining analysis,

imitation, and experience-based learning to acquire a

concept of reachability in robot mobile manipulation.

In Proc. of the IEEE Int. Conf. on Humanoid Robotics.

pp. 161-167.

Tal’nov, A., Serenko, S., Strafun, S., Kostyukov, A., 1999.

Analysis of the electromyographic activity of human

elbow joint muscles during slow linear flexion

movements in isotorque conditions. Neuroscience. vol.

90. pp. 1123-1136.

Van Mulders, A., Schoukens, J., Volckaert, M., Diehl, M.,

2010. Two nonlinear optimization methods for black

box identification compared. Automatica. vol. 46. pp.

1675–1681.

Zadeh, L., 1965. Fuzzy sets. Information and Control. vol.

8, pp. 338–353.

0 2 4

-5

0

5

right shoulder X joint

0 2 4

-10

-5

0

5

right shoulder Y joint

0 2 4

-10

-5

0

5

right elbow Y joint

Control inputs [V]

0 2 4

-1

-0.5

0

0.5

right elbow Z joint

0 2 4

-1

-0.5

0

0.5

right wrist Y joint

0 2 4

-0.5

0

0.5

1

right wrist X joint

Time [s]

Agonist control signal

Antagonist control signal

IJCCI2012-InternationalJointConferenceonComputationalIntelligence

394