Observability of Transportation Systems

A Methodology for Reliability Analysis in Logistics and Manufacturing

Jan Pinkowski

1

and Axel Hahn

2

1

OFFIS Institute for Information Technology, Escherweg 2, Oldenburg, Germany

2

Department of Computing Science, Carl von Ossietzky University,

Ammerlaender Heerstrasse 114-118, Oldenburg, Germany

Keywords: Reliability Analysis, Material Flow, Observability, Information Flow, Logistics.

Abstract: Real world events are observed by sensors since decades, for instance in the logistics where packages are

identified and tracked. This information result in an information flow. This information flow is used to

control the physical material flow. Hence, the information flow is a digital representation of the physical

material flow. However, to guarantee that the digital representation is in alignment to the physical world is a

challenging task. Especially for scenarios with manual operations, the representation is vulnerable for

errors. This paper proposes a generic approach to assure consistency between digital and physical world.

The paper presents a methodology to model the monitoring of physical entities and to analyse the model to

evaluate the risk of unreliable digital representation.

1 INTRODUCTION

Today, many parts of our all-day life are affected by

the use of sensors, devices and machines. Especially

at work, people are assisted by technique for

instance in a factory to produce, transport, register,

and analyse goods. Even human-free environments

where those processes are automated are more and

more common. However, humans as well as

Computer Integrated Manufacturing (CIM)

applications are working with their own

representation of the physical world. The digital

representation is generated by interpreting sensor

data. In any cyber physical system the consistency of

the digital representation and the physical world is

of crucial importance. Manufacturing Execution

Systems (MES) use this representation for steering

and controlling of manufacturing systems. When the

representation differs from the physical world, the

system is not reliable.

As an example we consider cross-docking

scenarios in warehouses. Each warehouse has

various incoming and outgoing packages daily.

Incoming trucks supply new packages to a

warehouse. Within the warehouse, conveyors such

as forklift trucks, belt and roll conveyors, transport

the packages to defined outgoing ports of the

warehouse. In order to control the transport,

packages must be identified. This identification is

done with sensors in the warehouse. The digital

representation holds and provides this information to

the conveyors. If a sensor identifies a package

wrongly, the digital representation differs from the

real world. Errors within the representation therefore

may lead to lost packages, inefficiencies etc. In

order to reduce such errors, stakeholders take

individual measures to ensure the correctness of the

digital representation.

However, this leads to the following questions:

How good is the monitoring of the system? How can

the correctness of the generation of the digital

representation be assessed? In general, the digital

representation abstracts from physical world systems

with its processes. For complex systems the

reliability of a system depends on the reliability of

each of the subsystems. Our focus is to develop a

generic methodology to evaluate the reliability of the

digital representation of material flow by evaluating

the subsystems to retrieve reliability for the overall

system. The paper is organised as follows: we start

with the related work in section 2, in which we

reference current research and define our approach

in contrast. This is followed by an overview of the

methodology where all phases with the

548

Pinkowski J. and Hahn A..

Observability of Transportation Systems - A Methodology for Reliability Analysis in Logistics and Manufacturing.

DOI: 10.5220/0004120605480551

In Proceedings of the 9th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2012), pages 548-551

ISBN: 978-989-8565-22-8

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

corresponding measures will be described. Each

phase of the methodology in section 3 is separated

into a subsection where we present goals, measures

and which techniques can be used. We conclude

then with a summary and outlook for future work.

2 RELATED WORK

When planning a warehouse with forklifts, storage

space and belt conveyors, simulation is most

commonly used. The major goal at this stage is the

efficiency and throughput of the warehouse. Those

values are determined with tools like Plant

Simulation (Bangsow, 2010). Our goal is to add the

perspective of reliability to the planning process of

transportation systems within warehouses.

Therefore, we use the risk analysis method Fault-

Tree-Analysis (FTA) (Lee, 1985). This method is

common in safety-relevant areas such as avionic

(ARP 4761) or automotive (ISO 26262). In the

logistics, safety and reliability analysis is not yet

prescribed. However, the application of such

methods can also decrease the financial risks of

errors in the transportation process. Essential for the

analysis is a model of the corresponding system.

Among various other model methods, there are some

basic technologies such as petri nets (Petri, 1962) or

Markov Chains (Spiegelhalter, 1995) that already

have been applied in the logistics. Current research

combines model and analysis approaches. In

(Buchacker, 1999) extended fault trees are used to

model the behaviour of a system and petri nets to

analyse the fault tree. In contrast, (Reza, 2009)

combine traditional petri nets and fault trees to

derive a forward and backward reachability analysis

method. Whereas our approach is a qualitative and

quantitative reliability analysis, by combining risk

analysis and process modelling.

3 METHODOLOGY

We introduce a generic method to detect risks of

misalignment of the physical world and its digital

representation for material handling operations. The

sequential phases and used methods are described in

the following subsections. This methodology with

modelling and risk analysis functions will be

implemented in a software tool. We propose the

application at design and planing time of a

transportation system.

3.1 Process Analysis Phase

The first phase in the methodology is the process

analysis. This means that the corresponding material

flow process is analysed to identify the interactions

between the following components:

• Actors: active roles that interact with the

environment

• Objects: passive objects that are used by an

actor

• Activities: actions that relate actors with

objects.

The major goal of this phase is to understand the

corresponding process. This knowledge is essential

for the following modelling phase and the later

evaluation.

3.2 Modelling Phase

Once, the Process Analysis phase is finished, and the

components are identified, we develop a model of

the system.

3.2.1 Model Structure

The model structure contains modelling constructs

which are the basis to build a model of the system. It

also contains the relation between these constructs.

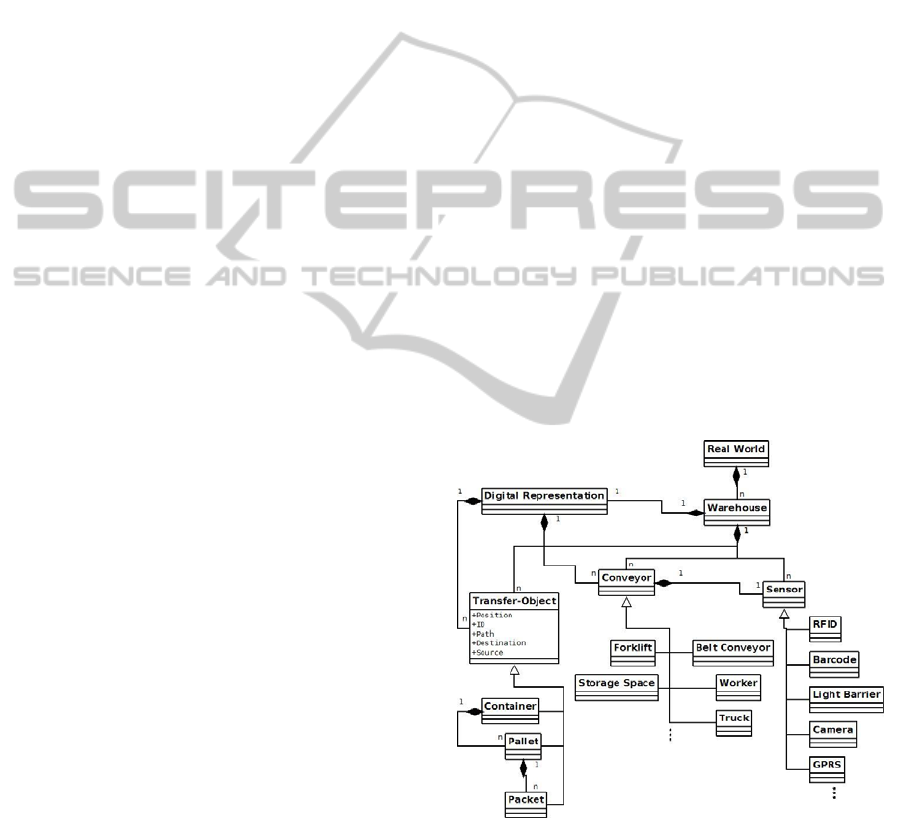

An excerpt of the structure is depicted in fig. 1.

Figure 1: Excerpt of the conceptual Model.

It illustrates the three major components: conveyors,

sensors and transfer-objects. These components are

involved in the transfer from real world to

representation. The digital representation contains

transfer-objects (TO) with attributes position, id and

path. The attribute id represents the unique identifier

ObservabilityofTransportationSystems-AMethodologyforReliabilityAnalysisinLogisticsandManufacturing

549

of each package. Path is an accumulation of the

positions where a TO was detected. To steer the

transport in the warehouse, there are also planned

paths in the digital representation. For controlling

purpose the planned and the actual path can be

compared. The real world consists of multiple

warehouses that interact with each other by

conveyors that transport goods. Each warehouse has

its own representation of the transportation process.

A warehouse has internal and external conveyors to

transport goods within, to, or from a warehouse.

The conveyors and sensors within a warehouse

provide information about the current status of the

transportation process. This information is used to

build a digital representation of the real world

transportation process.

3.2.2 System Model

The system model is an instance of the model

structure and contains detailed information about all

identified components involved in the analysed

process. An example of a system model is a special

warehouse layout, with conveyors and sensors at

defined positions with a defined behaviour. In

general, such models are used to abstract from the

complex real world using the outcome of the process

analysis. In our methodology the model instance is

the basis for the reliability evaluation, described in

section 3.3. The content of the model depends on a

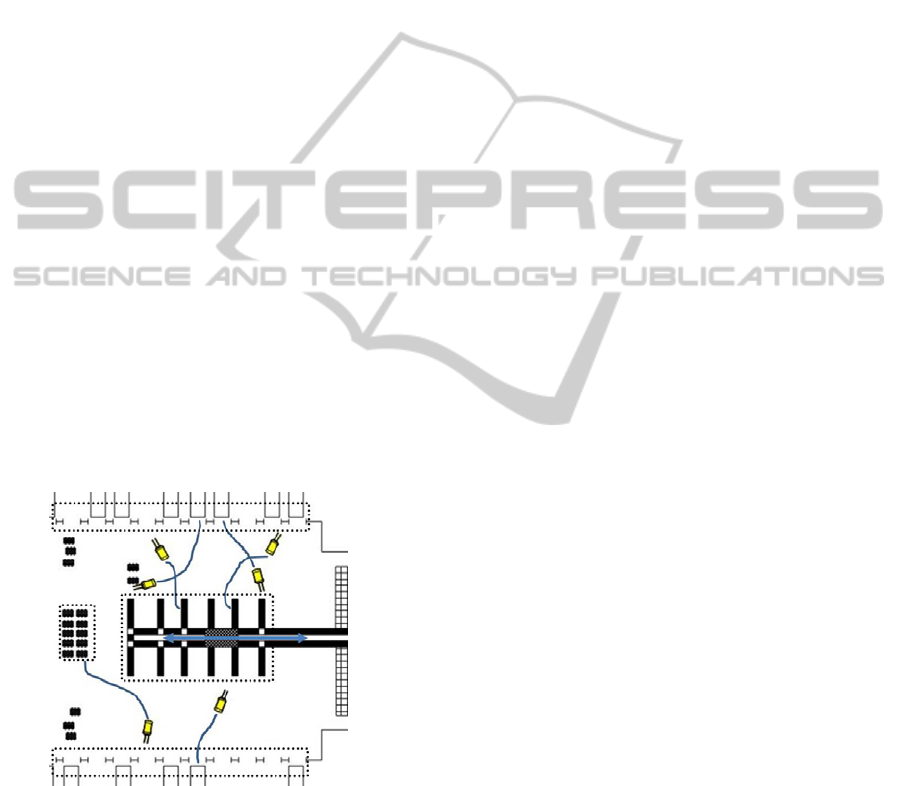

specific system, as illustrated in figure 2.

Figure 2: An Example Warehouse Layout.

The warehouse consists of forklifts, several belt

conveyor modules, packages, sensors and storage

space. Each conveyor has its own behaviour that

must be modelled to represent the material flow.

Also sensors have their own behaviour, because

different sensors detect different events with

different accurateness.

Sensors in the real world are not perfect. The use

of sensors is always related to failures and

restrictions. Typical restrictions are temperature,

humidity or light restrictions where the sensor

measurements contain errors. But also under ideal

conditions sensors are not perfect. In order to

evaluate the reliability and observability of the

material flow, the sensors play a major role.

3.3 Reliability Evaluation Phase

In (Laprie, 2001) the reliability is defined as the

”continuity of correct service”. Continuity means

that the reliability requirement applies to the whole

runtime. Correct service in our context stands for the

consistency between real world and representation.

”The validity of the reliability analysis of a system is

directly related to the validity of the model used to

represent the system” (Allan, 1992). In (Allan, 1992)

there are two main categories of reliability

evaluation techniques: analytical and simulation. A

popular analytical technique in research and

industrial practice is model checking (Clarke, 1999).

These complementary techniques are compared in

(Harris, 2006). It has been shown that simulation is

not complete in terms of error detection and model-

checking is vulnerable to state explosion problems in

complex systems. Therefore, simulation is the

common technology to analyse complex

transportation processes in the logistics. These can

be classified as dynamic, deterministic and discrete

(Law, 2000). After a model has been analysed by

simulation or model-checking, we evaluate the

actual reliability in the process. In (Allan, 1992) one

tool for reliability evaluation is probability theory

which helps to transform knowledge of the system

into a prediction of its likely future behaviour. In our

case we examine the components involved in the

transfer between real world and representation in

order to reveal errors and to distinguish the

probability for an error of a component. When all

components are described with probability theory,

the relation between components and the process is

known, then the reliability evaluation of the

components can be expanded to the whole system,

for instance by quantitative fault tree analysis.

We derive reliability from observability. This

means that the material flow is reliable when we

observe at any time any package within the material

flow. Also with a high degree of observability we

cannot exclude failures during the material flow, but

the system is able to recognise failures at the time

they appear. This recognition is done by sensors at

the spots where packages are transferred between

conveyors. At these spots the system compares the

digital representation with the real world. But as

ICINCO2012-9thInternationalConferenceonInformaticsinControl,AutomationandRobotics

550

introduced in section 3.2.2 sensors contain errors.

These errors are also part of the reliability evaluation

that helps to improve the design of a planned

warehouse.

3.4 Measures Phase

There are two main ways by which the reliability

can be affected. The first relates to quality and the

second to redundancy (Allan, 1992). Quality

concerns the components used in the system, in our

context the involved components on the transfer

between real world and representation. This includes

also personnel with their experience and training.

These human factors play an important role in the

reliability of systems (Allan, 1992). Redundancy

helps to improve reliability of a system, in case a

component fails that there is another component that

can do the function and does not fail.

The reliability evaluation reveals spots with a low

degree of observability. To improve observability at

this spots a measure is to use redundancy and

heterogeneity of sensors.

4 CONCLUSIONS

As introduced in the previous sections, we defined

the methodology with its phases. Which

technologies are applied exactly in the phases will

be evaluated in regard to their applicability, analysed

and compared in the next step. Afterwards we will

define a scenario to apply this methodology to a

specific transportation system. We will then analyse

and model the scenario with its transportation

process, and evaluate the reliability. The knowledge

obtained from the first iteration of the methodology

will be used to optimise the scenario system, for

example with new or redundant sensors. At the end

we will derive an optimised transportation system

with a reliable material flow, and a refined

methodology with applied specific modelling

technologies.

In order to support reliability analysis as an

additional aspect for planning of transportation

systems, we will develop a graphical tool. This tool

contains a graphical editor to create system models

as described in section 3.2.2. These models consist

of conveyors, sensors and packages. Defined state

transitions are used to represent the material and the

information flow. Based on this model we use Fault-

Tree-Analysis (FTA), as an automated risk analysis

method within the tool to evaluate reliability of the

planned warehouse at design and planning time. The

components within the model are annotated with

error probabilities to enable qualitative and

quantitative FTA. By combining the error

probability of the components with the FTA we

retrieve a calculation method with relation of the

components within the transportation system. The

modelling and risk analysis results are then

compared to evaluate vulnerable spots in the model.

REFERENCES

Allan, R. B. (1992). Reliability Evaluation Of Engineering

Systems: Concepts And Techniques. Springer.

Bangsow, S. (2010). Manufacturing Simulation with Plant

Simulation and Simtalk. Berlin: Springer.

Buchacker, K. (1999). Combining Fault Trees And Petri

Nets To Model Safety-Critical Systems. In Society for

Computer Simulation International (S. 439--444)

Harris, S. V. (2006). Error Detection Using Model

Checking vs. Simulation. In High-Level Design

Validation and Test Workshop.

Clarke, E. M., Grumberg, O., Peled, D. A. (1999). Model

Checking. The MIT Press.

Laprie, J. C. (2001). Fundamental Concepts of

Dependability. In Technical Report Seriesuniversity of

Newcastle Upon Tyne Computing Science (S. 7-12).

Law, A. M. (2000). Simulation Modeling and Analysis.

New York: McGraw-Hill.

Lee, W. S.; Grosh, D. L.; Tillman, F. A.; Lie, C. H.; , "Fault

Tree Analysis, Methods, and Applications A Review",

IEEE Transactions on Reliability, pp.194-203

Petri, C. A. (1962). Kommunikation mit Automaten. Bonn.

Reza, H. A. (2009). A Safety Analysis Method Using

Fault Tree Analysis and Petri Nets. In Proceedings of

the 2009 Sixth International Conference on

Information Technology: New Generations (S. 1089 -

1094). Washington DC: IEEE Computer Society.

Spiegelhalter, W. G. (1995). Markov Chain Monte Carlo

in Practice. Chapman & Hall.

ObservabilityofTransportationSystems-AMethodologyforReliabilityAnalysisinLogisticsandManufacturing

551