Towards the Integrated Simulation and Programming of Palletizing

Lines

Antonello Cal

`

o

1

, Davide Buratti

1

, Dario Lodi Rizzini

2

and Stefano Caselli

2

1

OCME S.r.l., Parma, Italy

2

University of Parma, Parma, Italy

Keywords:

Industrial Machine, Simulation, Visual Programming.

Abstract:

In this paper, we discuss the advantages and the issues of simulation and visual programming of palletizing

machines and, in general, palletizing lines, and we illustrate an integrated software tool suite that meets such

requirements. The increasing complexity of lines and the variability of product formats require a common

machine model for all the tools, together with the independence from visualization to allow software reuse

and extendibility. Furthermore, the model should also be able to include palletizing line components external

to the machine that are critical for performance and whose model is only partially known.

1 INTRODUCTION

Palletizing units have represented an important part

of manufacturing systems for decades. However, the

design of modern palletizing systems is facing new

challenges dictated by market demands, which in-

clude increasing production rates, the larger variabil-

ity in product packaging and formats, the thinner and

more fragile primary containers and products to be

palletized. The complexity of modern palletizing sys-

tems has increased: they have to ensure faster product

manipulation and to adapt online to different pallet

formats. This trend also challenges human operators,

whose skills often do not match the new generation of

machines.

Simulation and visual programming software

tools can help to meet the requirements for modern

palletizing units and assist both manufacturers and

end users. Several software packages have been pro-

posed for simulation of a machine component (Dong

et al., 2002), for integrated simulation and parame-

ters optimization of a manipulator (Kazi et al., 2002),

and for high-level simulation of manufacturing sys-

tems (Inukai et al., 2007). Few tools, however, inte-

grate simulation, programming and monitoring of a

complete palletizing line.

In our previous work (Argenti et al., 2010), we

proposed an integrated software tool suite for simula-

tion, programming and monitoring of palletizing ma-

chines. The tool suite had been designed for a line

of robot-based palletizing machines manufactured by

OCME S.r.l., but the underlying concepts are suitable

for a wide range of end-of-line machines. The pro-

posed application was able to handle several machine

configurations and some of these have been added

long time after the end of software design. How-

ever, new demands and requirements have come out

through the use and experience with the tool suite.

In particular, upstream or downstream components of

the palletizing line like transport conveyor belts or

end-line manipulators, which are not part of the pal-

letizing machine, are critical for the performance and,

thus, should be included in the simulation. Unfortu-

nately, the behavior of such components provided by

third-part manufacturers is often unknown. Further-

more, a customized version of the application is re-

quired with respect to both the machine model and the

user interface, when the tools are provided to a client.

A more modular and independent organization of the

software tools could simplify the customization.

In this paper, we discuss the advantages and the

issues of the integrated simulation, visual program-

ming and monitoring of palletizing machines with

their extensions and illustrate an improved software

tool suite to demonstrate our position. In particular,

we claim that an integrated simulator and programmer

that models machine logic and behavior avoiding un-

necessarily detailed physical description, can improve

and speed up the development and the programming

of a machine. The simulation and modeling should

also include components of the lines that can affect

the performance of the palletizing machine. When

377

Calò A., Buratti D., Lodi Rizzini D. and Caselli S..

Towards the Integrated Simulation and Programming of Palletizing Lines.

DOI: 10.5220/0004120903770382

In Proceedings of the 9th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2012), pages 377-382

ISBN: 978-989-8565-22-8

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

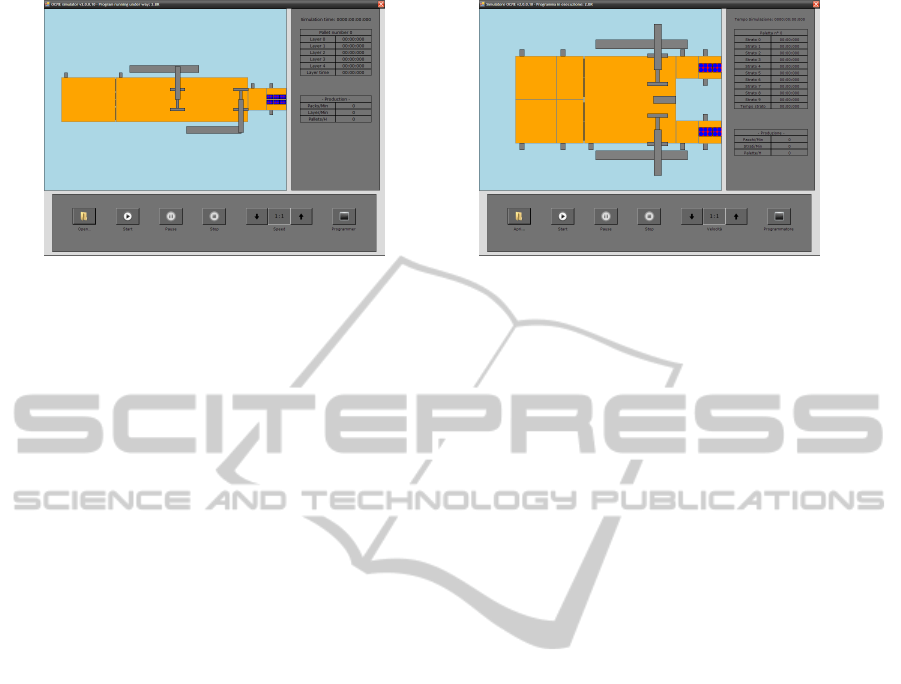

(a) (b)

Figure 1: Configuration of palletizers: single (a) or double (b) channel with arbitrary number and position of manipulators.

the behavior of such components cannot be fully de-

scribed, an approximate model can be used possibly

using a statistical model for some unknown variables

(e.g. the time required to perform a specific opera-

tion).

We also claim that the design of the tool

suite, while using a unique machine model for all

tools, should be inspired by the Model-View-Control

(MVC) software design paradigm, which allows code

reuse and ensures consistency among the behaviors

achieved by the applications. The new version of

the tool suite has been implemented using Microsoft

Expression Blend Framework (MEBF) to better meet

such requirements. Such framework allows a greater

independence of the machine model and control from

the visualization, since it manages interface as vector

graphics. Furthermore, the framework allows a more

modular organization of the suite: the application

consists of separate components, each described by

a XAML (eXtensible Application Markup Language)

file that specifies the graphic interface and the model

and control program.

The paper is organized as follows. Section 2 illus-

trates the common model of the palletizing machine

used by all tools. Section 3 describes the simulator.

Section 4 presents the visual programming tool for

the generation of control parameters. Finally, section

5 gives conclusion remarks.

2 MODEL OF THE PALLETIZING

MACHINE

The integrated tool suite for simulating, programming

and monitoring the palletizing lines is built on the

model of the system. Since the structure of a palletiz-

ing line as well as its core palletizing machine is sub-

ject to variability, the model consists of the composi-

tion of the elementary components of the system. The

accuracy level of each model depends on available in-

formation on the machine. A model should describe

the elementary components, the dimensional param-

eters, and the state of the machine. Since the aim of

the tool suite is to provide an user friendly interface

for palletizer management, the graphical representa-

tion of each component is as important as the list of

the attributes. However, the state of the machine is the

most critical part for machines that are provided by

third party manufacturers. Each tool uses the machine

model according to its own purposes. The simulator

modifies the state of the machine to emulate its be-

havior through state transitions. The monitoring tool

represents the current state of the palletizer according

to the messages received from the machine controller,

in the case there is a communication channel with the

controller. The programmer reads and writes the pa-

rameters that allow formation of pallet layers.

The model, the graphical representation and the

behavior of the machines palletizer should be inde-

pendent. The software design of the tool suite has

adopted the MVC paradigm that proposes such sep-

aration between the three aspects as a general design

criterion. Such approach has been applied to define

the palletizer components in (Argenti et al., 2010).

Figure 1 shows how the same components can be

reused to represent different machine configurations.

The same approach has been applied to model the

end-line manipulator that moves the already formed

pallet layers from the palletizing machine to the pal-

let layer stack. The end-line manipulator is not strictly

part of the machine, but it is manufactured by a third-

part producer. A complete model of the physical arm

and of its kinematics is either difficult to obtain be-

cause the information is unavailable or too complex

and detailed for our purposes. Thus, an approxi-

mate planar model of the manipulator has been ex-

ploited by partially reusing components designed for

the palletizer. The position of the manipulator com-

ICINCO2012-9thInternationalConferenceonInformaticsinControl,AutomationandRobotics

378

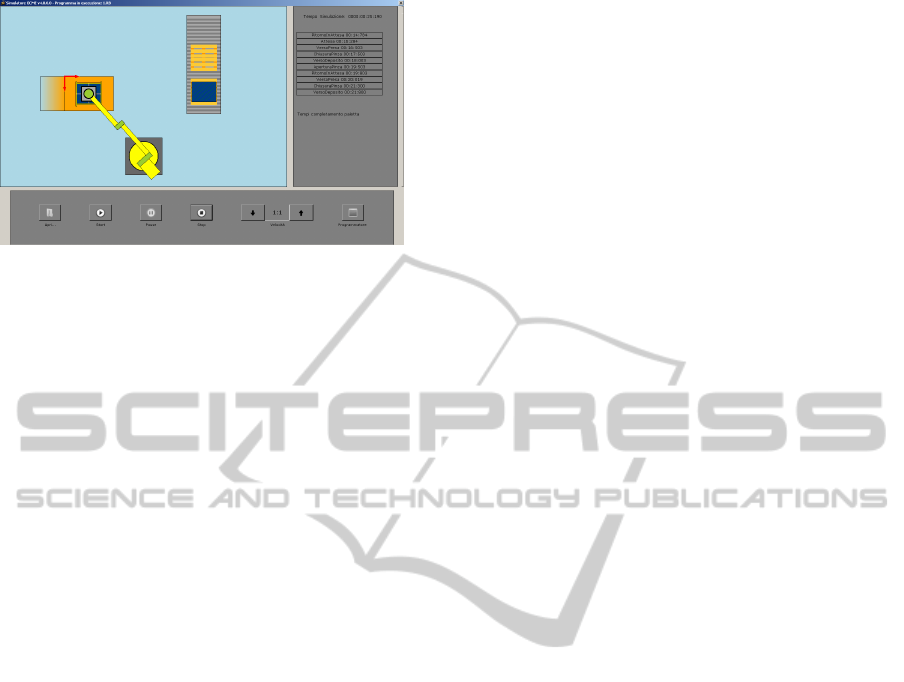

Figure 2: End-line manipulator to move and the formed

pallet layer from the palletizing machine (middle-left) to the

pallet layer stack (top-right).

ponents has been expressed with respect to a relative

frame. Figure 2 illustrates the graphical representa-

tion of the end-line manipulator. The design of the

machine model has proven sufficiently flexible and

robust to the introduction of this new palletizing line

element.

Although product units are not strictly part of the

machine, the concept of component has been conve-

niently extended also to units and group of units. A

component is defined as the basic part of the system

that contributes to the description of the system state.

Components also have a graphical representation and

their visualization is handled by proper routines. A

machine configuration is defined through a configura-

tion file in text format. During initialization, this file

is parsed and used to create the palletizer model with

the aggregation of the specified components. In the

future, we expect to convert the specifications con-

tained in the custom configuration file to the XAML

format to fully exploit the features of Microsoft Ex-

pression Blend Framework.

3 SIMULATOR

The proposed tool suite allows an accurate simula-

tion of the palletizing line to estimate its throughput

and the time required to complete specific production

steps. The simulating tool can also be used to dis-

play the final system to designers and customers. The

accuracy of simulation closely depends on the model

described in the previous session, since simulation is

essentially defined by the system state variables and

the transition function that modifies the value of state.

The simulation of the palletizing machine is fo-

cused on the product units. Indeed, the palletizing

machine operates on batches of product units in or-

der to arrange them into pallet layers. In this case,

the activity of each machine component is naturally

modeled as a queue or FIFO representing the sequen-

tial processing operated on product units as illustrated

in (Argenti et al., 2010).

The simulation of an external element like the

end-line manipulator illustrated in the previous sec-

tion has required a different approach. Indeed, the

end-line manipulator does not operate on single prod-

uct units or batches, but on pallet layers. Thus, the

FIFO interface, which is suitable to model the oper-

ations inside the palletizing machine, cannot be used

in this case. For this purpose, a hierarchy of simula-

tors and and a high level interface Simulator have

been defined. Simulator is a composite object that

allows the composition and joint management of mul-

tiple simulators. In this perspective, the palletizing

machine and the manipulator can share the same event

queue.

Each Simulator is responsible of the subsystem

state update. The state consists of both continuous

and logic variables. The transition events of logic

variables are handled at the beginning of a simulation

time interval as illustrated in (Argenti et al., 2010).

The coordination among the simulators is achieved

using the same simulation time step. In particular, the

global time step is adapted to the minimum update

time of the simulators (Zeigler et al., 2000).

3.1 The Queues of Palletizing Machine

The control and simulation of palletizing machine has

been decomposed in four queues or FIFOs: the in-

put conveyor belt queue, the manipulation queue, the

movable barriers queue and the conveyor belt queue.

As explained before a FIFO represent a specific oper-

ation or group of operations performed on the product

units that are stored in the FIFO.

The input conveyor belt queue controls the state of

the first group of two conveyor belts in each channel,

which separates product units in batches.

The manipulation queue controls the manipulators

that move product batches in the required position.

Since these manipulators are part of the machine, their

model and control is completely known (the finite

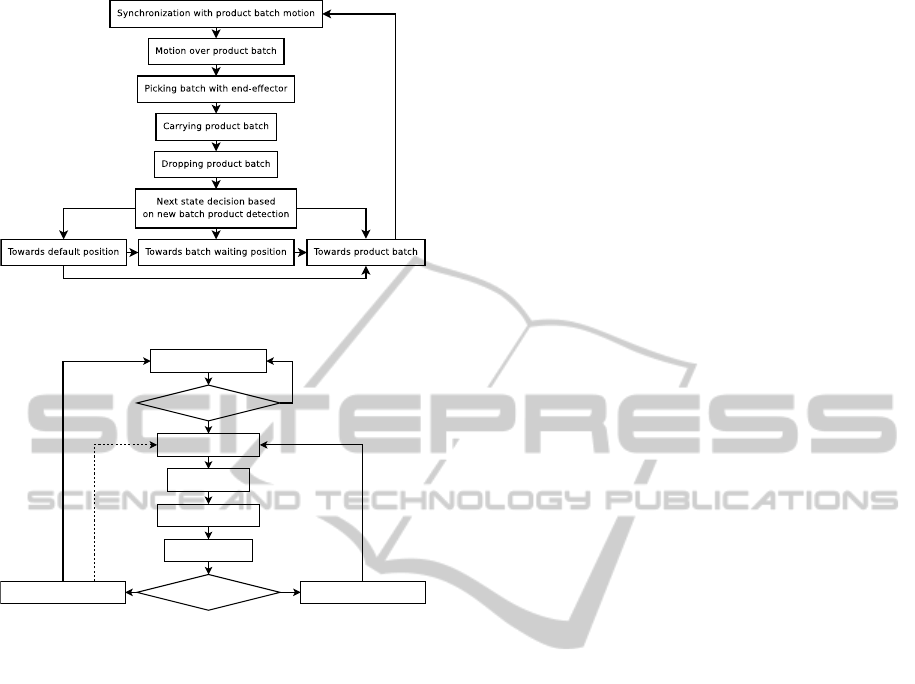

state machine is shown in Figure 3). The aim of these

manipulators is to place the batches that are not cor-

rectly aligned with respect to their final position in the

pallet layer. The manipulator can pick its target only

after a given position has been reached (third state di-

agram in Figure 3) and releases the product batch at a

given final position. Then, the arm moves toward the

new incoming batch, if there is one, or to a waiting

position (branching of state diagram).

The movable barriers queue controls the product

batches piling on the movable barriers located at the

TowardstheIntegratedSimulationandProgrammingofPalletizingLines

379

Figure 3: Finite state machine representing the manipulator

behavior.

Ready (Waiting Position)

Moving to Layer Area

Closing Arm Tool

Moving to Pallet Area

Opening Arm Tool

Moving to Waiting Position Moving to Layer Area

Layer Ready?

Layer Ready?

No

No

Yes

Yes

INTERRUPT:

Layer becomes

ready

Figure 4: Finite state machine approximating the behavior

of the end-line manipulator.

end of the manipulation conveyor belt. Barriers are

raised in order to form a section of the pallet and

are then lowered when the cumulated items are trans-

ferred to the merging conveyor belt. To avoid com-

penetration of product units, the simulator must han-

dle object collision. Management has be simplified

by assuming that all the incoming product units are

orthogonally oriented with respect to the barriers and

that the torques generated by contacts are negligible

independently from the contact surface. The accumu-

lation and contact has been handled using a segment

tree (De Berg et al., 2008).

The final conveyor belt queue controls the last

conveyor belt that transfers the formed pallet. The

number of configurations of the conveyor belt handled

by the simulator has been increased from the model

in (Argenti et al., 2010). In particular, pallet transfer

may be performed by a manipulator (discussed in the

next section), by a mechanical pusher, or by a lower-

ing platform.

3.2 End-line Manipulator

The manipulator is a component of the palletizing line

that is provided by a third party producer. In some

cases, the performance of a palletizing line depends

on the performance of the manipulator, e.g. when the

time required by the palletizer to form a pallet layer

is comparable with time required by the robot arm to

transport the layer. Thus, a simulation that aims at as-

sessing the throughput of the production line should

also consider the behavior of the robotic arm. Un-

fortunately, the knowledge of its physical and logical

model is usually incomplete and its exact behavior is

difficult to reproduce (i.e. the time required to execute

a motion).

Instead, the approximate finite state machine rep-

resented in Figure 4 has been used. The diagram is

similar to the finite state machine of the palletizer

manipulators. Since the transition time between two

states is only approximately known, the simulator re-

turns a time estimation proportional to the path length

or provided as an empirical constant. The user may

also choose to randomly generate the time according

to common statistical distributions (normal, negative

exponential, etc.).

The end-line manipulator does not operate on

product units or batches like the various parts of the

palletizing machine, but on already formed pallet lay-

ers. Hence, the simulation of its behavior cannot be

handled by a FIFO of product units. The control of

the end-line manipulator has been implemented as a

specific instance of Simulator interface. Such in-

terface may be integrated with other simulators like

the palletizer simulator to emulate the behavior of the

palletizing line.

4 PROGRAMMER

The aim of palletizing line programming is the gener-

ation of machine parameters consistent with the pallet

layer layouts specified by users. The human opera-

tor must only provide high level specification, choose

among the solutions proposed by the programming

tools according to convenient policies, and possibly

edit the solution. Finally, the tool generates the re-

quired parameters. These four steps are achieved by

the proposed tool that improves the previous version

illustrated in (Argenti et al., 2010).

4.1 Layout Generation

The computational counterpart of the physical layer

planning problem is the well-known bin packing

problem (Lodi et al., 2002), which is usually trans-

formed into an unidimensional knapsack problem.

ICINCO2012-9thInternationalConferenceonInformaticsinControl,AutomationandRobotics

380

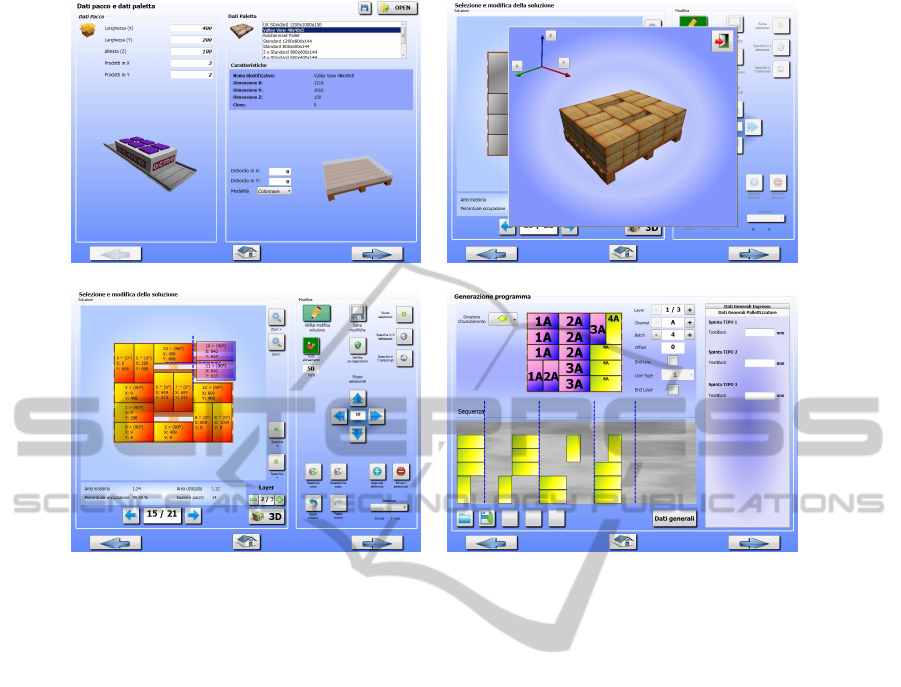

(a) (b)

(c) (d)

Figure 5: The four steps of the programming tool: the selection mask of pallet format and other requirements (a), layout

generation (b) and editing (c), and the batch decomposition and computation of machine parameters (d).

Unfortunately, bin packing algorithms assist in max-

imizing the number of product units per layer or pal-

let but do not consider other practical requirements

such as regularity in products arrangement, layer sta-

bility, and presence of symmetries. Alternative com-

putational approaches such as rectangular tessellation

and rectangle tiling suffer from similar drawbacks and

do not exploit special features of the problem such as

the uniform product size.

For these reasons, the proposed layout generation

system is based on a set of predefined patterns incor-

porating user expectations as well as typical indus-

trial requirements. The input data for layout compu-

tation consist of product size, allowed product over-

flow or required margin from pallet borders, and pal-

let style (plain or hierarchical). Figure 5(a) illustrates

the mask for inserting high level specifics like pal-

let format and product unit size. Then, the program-

mer generates possible pallet layer layouts according

to patterns like Binary Cut, Single Spiral, Column

and Double Spiral and maximizes the number of units

per layer (Figure 5(b)). The user can graphically edit

the found solutions through a drag-and-drop interface

and select the layouts to be used in each layer (Fig-

ure 5(c)). More details on layout patterns are avail-

able in (Argenti et al., 2010).

4.2 Batch Decomposition and

Parameters Computation

The second step of palletizer programming is the

computation of control parameters required to gener-

ate the given layout. The layout generated in the pre-

vious step consists of product units arranged inside

the planar shape of the pallet. Since the manipulation

of product units is oriented to batches, the decompo-

sition of the layouts in batches is crucial for parame-

ters computation. Batch formation must follow some

rules about maximum number and proximity of prod-

uct items. A batch corresponds to a group of units that

are manipulated together. Thus, its weight and size

are limited by the payload and the end-effector size

of the manipulators. Furthermore, the batch should

have single or double row rectangular shape depend-

ing on the machine configuration, since it is formed

through commands to the input conveyor belts. Batch

selection follows different rules. The sequence num-

ber of each batch must be consistent with the order

of accumulation. Batch feasibility is checked using

a graph-like data structure that represents proximity

relationships between units. The selection of batch

items can be performed manually, semi-automatically

or completely automatically.

TowardstheIntegratedSimulationandProgrammingofPalletizingLines

381

Given the batch decomposition of the pallet layer,

machine parameters are completely determined. The

parameters related to a batch include the number of

product items, the number of rows, the spacing from

the previous batch, the offset positions for manipu-

lation picking and release, the rotation flag, and the

offset positions for barrier raise and release. Barrier

offsets depend on the relative displacement of batches

in the pallet layer. Thus, the programmer divides the

batches in groups according to their alignment to a

common front line. Each group corresponds to prod-

uct batches simultaneously accumulated on the same

barrier. Figure 5(d) illustrates the final step of pro-

gramming tool with the batch numbering and the fi-

nal product unit sequence. The new version of the

programming tool allows parameter generation for a

larger number of machine configurations and supports

the addition of other machines.

5 CONCLUSIONS

In this paper, we have discussed the simulation and

programming of palletizing lines and have illustrated

the related issues through a tool suite developed for a

specific palletizer. A palletizing line consists of com-

ponents, whose behavior can be fully described or

only partially known. In the first case, the simulation

and the programming of the machine is better per-

formed on a common model. The simulation should

include the control logic and a kinematic model of

its parts sufficiently accurate to estimate the time, but

should also avoid unnecessary modelling of physical

interaction and dynamics of bodies. When the behav-

ior of some machine of the model is unknown, an ap-

proximate finite state diagram with empirical estima-

tion of transition times could be used. Such solution

is effective when such machine is not a bottle-neck of

the whole system.

The MVC design paradigm can effectively sup-

port software reuse and enforce consistency between

the different tools of the tool suite by separating the

management of data, graphical interface and logic

control. All the tools should be based on a common

model representing the structure of the machine, but

each tool should operate differently on the machine

data. Furthermore, a software organized in modu-

lar components allows customizable tools for the end

user.

All these design solutions have been derived from

a tool suite for the simulation, programming and mon-

itoring of a specific palletizing machine supporting

a high number of configurations. The simulator has

been extended to simulate an end-line manipulator us-

ing an approximate model. The programming tool as-

sists non-expert human operators in visual program-

ming of the palletizing task, and supports a variety

of configuration options automatically planning fea-

sible layers. The organization of the suite according

to Microsoft Expression Blend Framework has im-

proved the decoupling between model and interface.

The monitoring tool supports diagnostic activities and

allows efficient recovery when failure occurs. Fur-

thermore, it has enforced the modular subdivision of

the tools, e.g. the decomposition of the programming

steps, making possible a better customization of the

tool for a specific machine. The proposed tool suite

has been already successfully used by several opera-

tors on different palletizing lines in working plants.

ACKNOWLEDGEMENTS

This research has been supported by Regione Emilia-

Romagna, Italy, as part of the Integrapack project.

REFERENCES

Argenti, M., Buratti, D., Lodi Rizzini, D., and Caselli, S.

(2010). An integrated tool suite for simulation and

programming of palletizing units. In Proc. of the ISR

2010.

De Berg, M., Cheong, O., van Kreveld, M., and Overmars,

M. (2008). Computational Geometry, Algorithms and

Applications. Springer-Verlag, 3rd ed.

Dong, W., Palmquist, F., and Lidholm, S. (2002). A simple

and effective emulation tool interface development for

tricept application. In Proc. Int. Symp. on Robotics

(ISR).

Inukai, T., Hibino, H., and Fukuda, Y. (2007). Simulation

environment synchronizing real equipment for manu-

facturing cell. J. Advanced Mechanical Design, Sys-

tems, Manufacturing, 1(2):238–249.

Kazi, A., Merck, G., Otter, M., and Fan, H. (2002). Design

optimization of industrial robots using the modelica

multi-physics modelling language. In Proc. Int. Symp.

on Robotics (ISR).

Lodi, A., Martello, S., and Vigo, D. (2002). Recent

advances on two-dimensional bin packing problems.

Discrete Appl. Math., 123:379–396.

Zeigler, B. P., Praehofer, H., and Kim, T. G. (2000). Theory

of Modeling and Simulation. Academic Press, 2nd ed.

ICINCO2012-9thInternationalConferenceonInformaticsinControl,AutomationandRobotics

382