Towards Manufacturing Execution Systems for the Food and Beverage

Packaging Industry

Stefano Caselli

1

, Michele Pattera

1

and Massimo Ricci

2

1

Dipartimento di Ingegneria dell’Informazione, University of Parma, Viale delle Scienze 181/A, Parma, Italy

2

OCME s.r.l., Via del Popolo 20, Parma, Italy

Keywords:

Manufacturing Execution Systems, Packaging, SCADA.

Abstract:

In this paper, we describe the issues faced in bringing advanced supervisory and control concepts in the frag-

mented food and beverage packaging industry. Although packaging equipment manufacturers must cope with

tight cost constraints, heterogenous machines, and customers’ requests for specialized features, we take the

position that time is ready for bringing more advanced features such as automated production flow and full

production supervision even in this domain of consumer oriented and highly personalized products. Manu-

facturing Execution Systems, which have been introduced with success in other manufacturing areas, can be

applied in food and beverage packaging taking advantage from recently proposed standards. This effort re-

quires to supplement the software base of existing machines with an interface layer ensuring interoperability

according to the existing standards. By consolidating these standards and adopting good design practices,

flexible integration, supervision and control of packaging lines can be obtained.

1 INTRODUCTION

In food and beverage (F&B) packaging, most prod-

ucts are more than simple “black boxes”, i.e. items

that must be picked and placed into a larger box and

then wrapped together with thousands of identical

items. F&B products are consumer-oriented products,

and as such they often possess some special character-

istics (e.g., label, expiration date, or preferred side for

display) that must be taken into account in their pack-

aging. Increasingly often, multiple product fillers are

connected to the same packaging area where the dif-

ference in product type must be accounted for, or al-

ternative labels must be applied to the same product

for marketing purposes. Thus, for a variety of rea-

sons F&B products must be individually tracked and

treated during their packaging, taking into account the

differences among otherwise similar products shipped

from the same line, and sometimes even in the same

box or the same pallet.

Until recently, product variation was not too diffi-

cult to handle in the packaging area, mainly because

of the small number of customizable variables. In the

current scenario, however, the complexity brought by

product differentiation and marketing requirements

no longer can be coped with by manual intervention.

Equipment manufacturers must also face the com-

plexity associated with the strong customizations, in-

variably required in food production and packaging

lines, and the need to cope with special machines

from different manufacturers. Packaging equipment

manufacturers are indeed very attentive to satisfy

these increasing customers’ needs. Taking advan-

tage from technological evolution of control devices,

they are determined to evolve their systems to achieve

those characteristics of flexibility and interoperability

required by the market.

In this paper, we describe the issues faced in

bringing advanced supervisory and control concepts

in the fragmented F&B packaging industry. Although

equipment manufacturers must cope with tight cost

constraints as well as customers’ requests for spe-

cialized features, we take the position that time is

ready for bringing more advanced features such as

automated production flow and full production su-

pervision even in the F&B packaging domain. In

other domains, such as mechanical production, semi-

conductor manufacturing and packaging of pharma-

ceutical products, much higher levels of automation

have been obtained in the last 20 years, and the con-

cept of Manufacturing Execution System (MES) has

emerged (MESA, 1997). An MES is an information

system that drives the operation of shop-floor control

devices, provides complete real-time status and pro-

552

Caselli S., Pattera M. and Ricci M..

Towards Manufacturing Execution Systems for the Food and Beverage Packaging Industry.

DOI: 10.5220/0004121205520556

In Proceedings of the 9th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2012), pages 552-556

ISBN: 978-989-8565-22-8

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

duction data from the field to the ERP, and executes

ERP plans and commands. MESes bring obvious ad-

vantages in any domain. In this paper, we discuss

the obstacles that have hindered so far widespread in-

troduction of an information system like MES in the

F&B domain, and we outline a strategy to overcome

these obstacles thanks to technological development

and emerging standards.

Following a deeper discussion of the issues and

motivations leading towards MES-based automation,

the emerging standards that can be leveraged upon are

described. Next, we illustrate an architecture coping

with the heterogeneity of the underlying equipment

and enabling non-disruptive, progressive integration

of advanced features into existing automation design

paradigms.

2 MOTIVATIONS

In the last twenty years, production and packaging

industries have changed the design and organization

of their factories by introducing more accurate and

centralized planning mechanism. Major equipment

manufacturers are indeed supplying solutions to sup-

port production-related activities such as supervisory

control, production reports and traceability of finished

goods. In this new context, machines belonging to a

production line, in addition to the need to exchange

information with other machines in the same line for

smooth line operation, must communicate with enti-

ties outside the line itself. While the need for a new

layer of interaction appears everywhere, in several ar-

eas, including F&B packaging, a large gap remains

between the factory floor and the production planning

level. Currently, the goal is to bridge this gap tak-

ing advantage from a more efficient organization of

information already available and often not properly

utilized.

There are several reasons why the F&B area has

been lagging on the issues of integration and super-

visory control. Cost is one of these issues: the small

margins typical of this sector have been a deterrent

for investment in production technology. Moreover,

the need to cope with the many variations in produc-

tion previously discussed require more complex MES

configurations as well as development of a large num-

ber of custom modules. Finally, the need to integrate

specialized, heterogeneous and lagacy equipment fur-

ther increases the complexity and cost of developing

an appropriate production supervisory and control in-

frastructure.

A typical F&B production plant is made up by

the integration of many automatic machines such as

blowers, fillers, cappers, wrappers, palletizers, etc.,

as well as transport systems that handle product flows

from the beginning to the end of the line. Hetero-

geneity of suppliers allows cost and performance op-

timization of each machine, but often has disadvan-

tages in terms of overall industrial costs, set up times

and interfaces harmonization. The major problems,

however, are not due to different programming lan-

guages or physical connections in the various ma-

chine controllers. Rather, most problems stem from

the difficulty of handling conventions and naming not

homogeneous among the controllers. Since plant op-

eration involves different actors, it is important that

they can speak a common language: end users, equip-

ment manufacturers and systems integrators share the

interest in identifying terminology, control structures

and common organization methods for software pro-

grams, so that working together can be simpler and

more efficient.

Over the last decade, these issues have led the

stakeholders to establish working groups within in-

ternational organizations with the aim of reaching

a standardization of conventions that can meet cur-

rent needs. Two emerging standards relevant to F&B

packaging are PackML (ISA, 2008), developed by

the OMAC Packaging Workgroup, and the Weihen-

stephan standard (Kather and Voigt, 2010) developed

by the Technische Universit

¨

at M

˜

A

¨

unchen in conjunc-

tion with major German industrial players. Interoper-

ability, indeed, represents a new global challenge in

automation software.

2.1 PackML Standard

The PackML standard (ISA, 2008) has been proposed

by OMAC, the Organization for Machine Automa-

tion and Control (http://www.omac.org), and has been

adopted mainly in North America. PackML con-

siders many aspects of line automation and provides

guidelines for writing machine software and for com-

municating between different devices. Adopting the

full PackML proposed model requires a particular

software organization for each machine, according

to a functional decomposition and a predefined state

schema. Tables for receiving remote commands and

information exchange according to PackTags conven-

tions must be defined. The PackML standard in-

cludes also guidelines for Overall Equipment Effi-

ciency (OEE) computation. From a practical stand-

point, software refactoring is a process known to be

expensive and often cause of potential malfunctions.

For these reason PackML offers also a more conserva-

tive approach (PackTags-only approach) for standard-

ization of software already developed. This approach

TowardsManufacturingExecutionSystemsfortheFoodandBeveragePackagingIndustry

553

is implemented by simply inserting the data structure

in existing software, thereby obtaining a system that

at least complies to the standard for external inter-

facing purposes. This feature is very important for

the F&B domain, where legacy and third party hw/sw

components must be invariably accounted for.

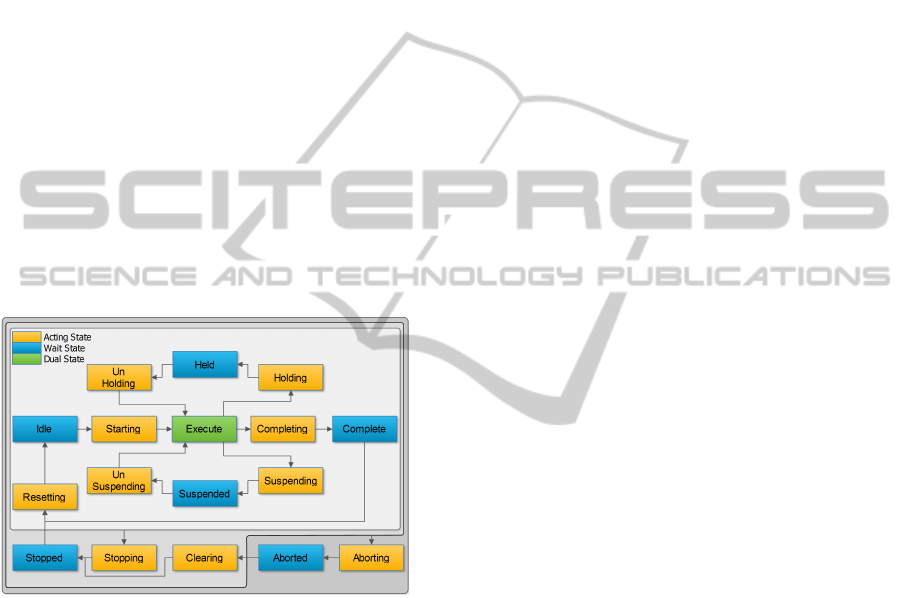

The full PackML state model is shown in Fig-

ure 1. This model represents all states and transi-

tions defined by the standard. The state model is suit-

able for representing operations of every type of auto-

mated machinery. Thanks to the naming convention

set called PackTags, each entity can expose all the

information inside a computation node (and receive

remote commands) in a structured and standardized

form. Adopting common naming conventions is pos-

sibly the most important issue in an integration sce-

nario: in this way all entities can exchange informa-

tion without the need to use a different protocol for

each different manufacturer. Exporting information

using this set of rules allows every other entity in the

plant, including supervisory systems, able to know in

a fine grained way the state of each machine and react

or interact appropriately.

Figure 1: PackMLstate model for automatic operation.

2.2 Weihenstephan Standard

The Weihenstephan standard (http://weihenstephan-

standards.com/), proposed by Technische Universit

¨

at

M

¨

unchen and developed in conjunction with ma-

jor German breweries, is gaining broad acceptance

mainly in Europe. The last major version of this stan-

dard is called WS2005 (Kather and Voigt, 2010). Its

focus is mainly on communication aspects, and for

this purpose it defines protocols to be used for each

ISO/OSI stack level.

The WS2005 part 2 document includes an exhaus-

tive list of tags for data exchange between machin-

ery and generic Product Data Acquisition (PDA) sys-

tems. Compared with PackTags, this set is less struc-

tured but more detailed. Tags defined by WS2005 are

specifically designed for packaging and beverage in-

dustries, so it would be difficult to apply this tag set

outside these sectors. Since the project motivating

this paper specifically adresses packaging of food and

beverage products, the WS tag set is very interesting,

especially in order to integrate the more flexible but

somehow generic PackTags set.

The WS2005 standard also provides harmoniza-

tion directives for interoperation with PackML, so the

two standards can share state models and the most im-

portant data describing general machine status. This

feature leaves designers free to integrate both proto-

cols and allows the design of equipment that can talk

with supervisory systems that adopt either standard.

3 MES IN PACKAGING

INDUSTRY

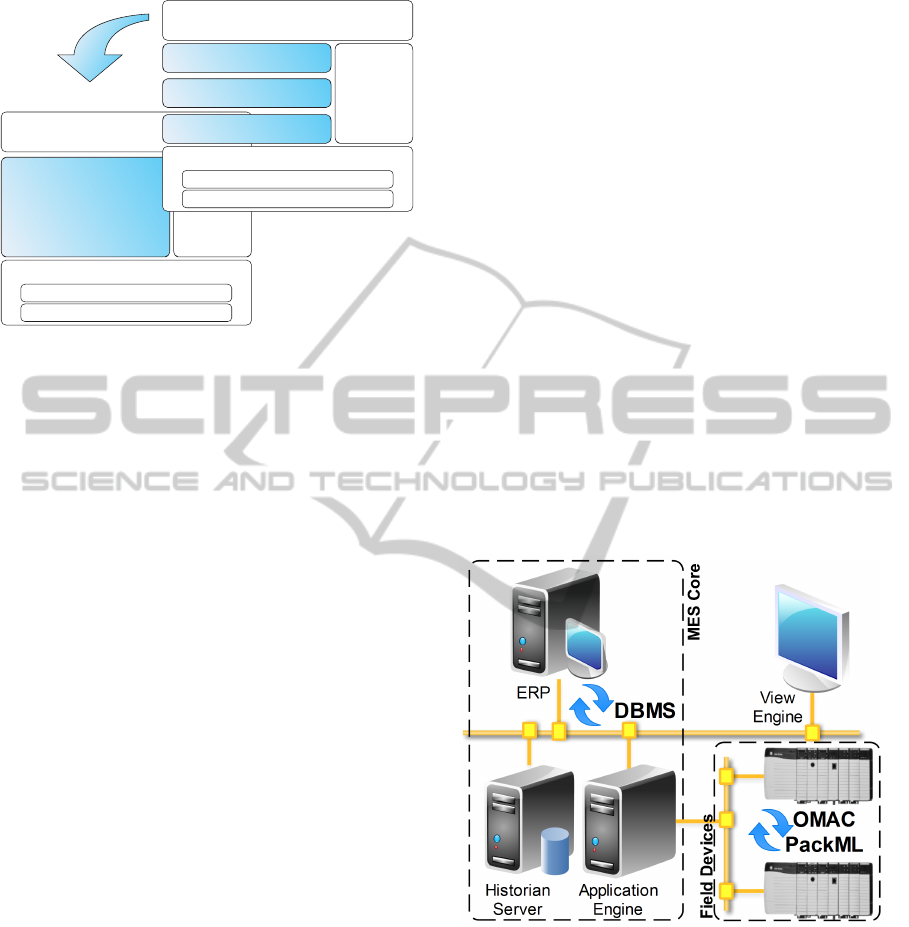

An MES is an information gateway integrated in the

enterprise network ensuring that all data are correctly

understood and operations executed in a consistent

way (Qiu and Zhou, 2004). MESes operate collect-

ing real-time data from the field and making them

available in an aggregate way throughout the whole

enterprise, eventually doing some minor computation

over the data collected (Figure 2). Their effective-

ness does not depend only on the features they offer or

the performance they can achieve, but requires a deep

involvement of all actors within the enterprise mov-

ing towards this new philosophy, that implies elimina-

tion of manual intervention on production processes

(MESA, 1997).

Automatic data collection performed by MES is

characterized by low latency and is transcription er-

ror free, so moving information in this way can re-

sult in a significant increase in effectiveness of plant

operation procedures. MES designs are oriented to

short term planning and performance optimization

of production lines, and perform coordination oper-

ations at a finer granularity compared to ERP sys-

tems. Whereas ERP functionalities are not standard-

ized, MESA has identified eleven functional requisite

types which can drive MES application in any shop

floor (Younus et al., 2010).

Packaging is a challenging domain for supervi-

sory systems. Packaging shop floors usually consist

of multiple lines with several specialized or similar

machines that can run different jobs with different

products and materials. In this scenario, an MES can

concur to many aspects of process production, such

as order dispatching, plant supervision, events track-

ing and OEE assessment.

Factors such as higher productivity, cost reduc-

ICINCO2012-9thInternationalConferenceonInformaticsinControl,AutomationandRobotics

554

MES

Integrated Production Data

Working with Operations

Management Systems

People and Practice

Products &

Process

Engineering

With MES

Business Intelligence

Business Intelligence

Products &

Process

Engineering

Operations Management System

People/Paper

Folklore/Practice

Before MES

Shop Floor

Control Devices

Automation Equipments

Shop Floor

Control Devices

Automation Equipments

Figure 2: Integrating the shop floor in the business intelli-

gence: Transition from a conventional information system

to a Manufacturing Execution System. Adapted from (Qiu

and Zhou, 2004).

tions and regulations compliance have always been

main motivations to support investments. Achieving

each of these goals has resulted in a more efficient

resource usage, regardless of the fact that they were

energy, materials, human resources or informations.

With introduction of MES, efficient resource usage

can become a goal, rather than a means (Soplop et al.,

2009). Materials management based on production

flow instead of intensive storing, real time monitoring

of plants, energy-as-a-resource management and dry

run prevention, elimination of paper based reporting,

. . . , are all activities that can be supervised and co-

ordinated by a MES in an optimized way, from order

dispatching to finished goods.

4 ARCHITECTURAL OVERVIEW

In this section we provide an overview of a system

architecture which achieves in the packaging context

the strategic goals associated with integration of a

MES. It is very important to remark the scalability

of the proposed solution, that allows a sharp separa-

tion among business level, factory floor and all other

components more closely linked to the core system.

The number of data points managed by a super-

visory system may change during its life, due to new

investments in equipment, or they may become more

important for enterprise planning. Indeed, there is no

general purpose hardware configuration that can han-

dle all instances and needs. What is needed is a dy-

namic entity that evolves based on amount of man-

aged data, required availability and performance con-

straints. The system should have the necessary com-

puting capacity according to the number of machine

controlled, and therefore to the amount of data pro-

cessed, in order to guarantee minimum latency.

Since the ultimate goal is to supply punctual in-

formation about shop floor equipment, allowing im-

mediate intervention when needed, the other issue

to be considered is system availability. In this sce-

nario, where a substantial amount of information

flows to and from production floor, it becomes im-

portant to eliminate, or at least to drastically re-

duce, system downtimes. As a matter of fact,

for information-driven production, system availability

close to 100% should be obtained. This goal is pur-

sued with load balancing techniques, increasing the

number of critical devices, and, further, implement-

ing store&forward algorithms in software to minimize

data losses when only some devices go down.

Figure 3 shows the system logic architecture that

can be used in most plants, regardless for their dimen-

sions. Each server role is not linked to a particular

physical machine, but it represents a software service

that can be run in various configurations like on a sin-

gle machine or spread across a cluster or in redundant

mode with a backup server, depending on plant in-

stance.

Figure 3: Architecture of a Line Information System for

Food and Beverage packaging.

Each node in figure 3 therefore represents a fea-

ture of the system:

View Engine. It represents the access point to infor-

mation for standard users. Usually is a worksta-

tion where operators can view the system’s cur-

rent status and get notifications if any device is

not working properly or requires attention.

Application Engine. It is the core engine of the ap-

plication. Each data change is notified from field

drivers and acquired from the application, which

TowardsManufacturingExecutionSystemsfortheFoodandBeveragePackagingIndustry

555

processes and dispatches information to all other

nodes over the network.

Historian Server. It has the responsibility to store

each data received from field devices through the

Application Engine. All events are recorded in its

optimized database in order to build a historical

base and retrieve them later for statistical and per-

formance computations.

ERP. It represents the contact point with business in-

telligence systems used at higher levels in the en-

terprise. The system downloads work orders from

the ERP and puts back results and statistics.

A key element to integrate new and legacy equip-

ment in the architecture is the introduction of a state

model according to one or both the standards previ-

ously discussed in the control software of each ma-

chine, so as to enable full interaction with the MES.

We have undertaken the effort to implement such

compatibility layer for a number of machines in-

volved in several packaging lines, thereby enabling

their integration into full Line Information Systems.

We claim that this effort is well worth given the po-

tential developments that it makes possible.

A system architecture like the one presented above

brings several advantages, due to the deep integration

among its components, floor plant and upper business

intelligence level. This integration makes possible a

bidirectional communication between involved actors

as well as the ”historicization” of all information re-

lated to the plant activities. Thus, the system permits

full supervision of process and machines, automat-

ing many procedures and doing computations over

data. From the enterprise management point of view,

this means to have a “plant dashboard” showing an

overview of the plant available 24Hx7D and popu-

lated with real time data. This dashboard enables pro-

duction planning and helps in justifying, or more pre-

cisely understanding, factory performance (e.g. from

OEE factors). Likewise, at a lower logical level, line

managers can monitor their lines from a single con-

trol point as well as be assisted in identifying trouble

sources and get reminded of planned maintenance op-

erations.

5 CONCLUSIONS

The issues discussed in this paper provide evidence of

the revolution that is currently in progress in the F&B

packaging domain, regarding line control and ma-

chine coordination. Although this revolution started

several years ago, only now an overall view of the

most innovative market players shows a new model of

plant organization, that is also affecting those who are

less caring at these issues. One can’t help but notice

that the evolution in packaging lines, from electrome-

chanical, to software-based controls, to mechatronic

systems, has several similarities with the techology

evolution in the ICT domain. In the same way in-

formation systems use middleware services for coor-

dinating actions in distributed environments, packag-

ing industries are now ready to move to fully super-

vised factories that exploit MES as core components

to bridge the gap between shop-floor and business lev-

els. In F&B packaging, adopting sound representa-

tional and communication standards at the machine

level has proven to be a key enabling step for MES-

based production and supervision.

ACKNOWLEDGEMENTS

The research and development described in this pa-

per has been carried out in the framework of the col-

laborative effort IntegraPack (www.integrapack.it),

partially funded and supported by Regione Emilia-

Romagna, Italy. We thank the many people who have

contributed to the issues and developments outlined

in the paper.

REFERENCES

Bratukhin, A. and Sauter, T. (2010). Bridging the gap be-

tween centralized and distributed manufacturing exe-

cution planning. In ETFA, 2010, pages 1–8.

ISA (2008). Machine and unit states: An implementation

example of ISA-88. Technical report, ISA.

Kather, A. and Voigt, T. (2010). Weihenstephan standards

for production data acquisition in bottling and packag-

ing plants, general part. Technical report, Technische

Universit

¨

at M

¨

unchen. Version 2005.03.

MESA (1997). MES explained: A high level vision. In

MESA White Paper 6. MESA International.

Qiu, R. and Zhou, M. (2004). Mighty mess; state-of-the-art

and future manufacturing execution systems. Robotics

Automation Magazine, 11(1):19–25, 40.

Ricken, M. and Vogel-Heuser, B. (2010). Modeling of man-

ufacturing execution systems: An interdisciplinary

challenge. In ETFA, 2010, pages 1–8.

Soplop, J., Wright, J., Kammer, K., and Rivera, R. (2009).

Manufacturing execution systems for sustainability:

Extending the scope of MES to achieve energy effi-

ciency and sustainability goals. In ICIEA 2009, pages

3555–3559.

Younus, M., Peiyong, C., Hu, L., and Yuqing, F. (2010).

MES development and significant applications in

manufacturing -a review. In ICETC, 2010, volume 5,

pages 97–101.

ICINCO2012-9thInternationalConferenceonInformaticsinControl,AutomationandRobotics

556