On the Development of a Theoretical Framework for New Product

Development

Lixin Wang and Athanassios Kourouklis

Business School, University of the West of Scotland, Paisley Campus, PA1 2BE, Paisley, U.K.

Keywords: Knowledge Management, Supply Chain Management, Product Lifecycle Management, New Product

Development, Open Innovation.

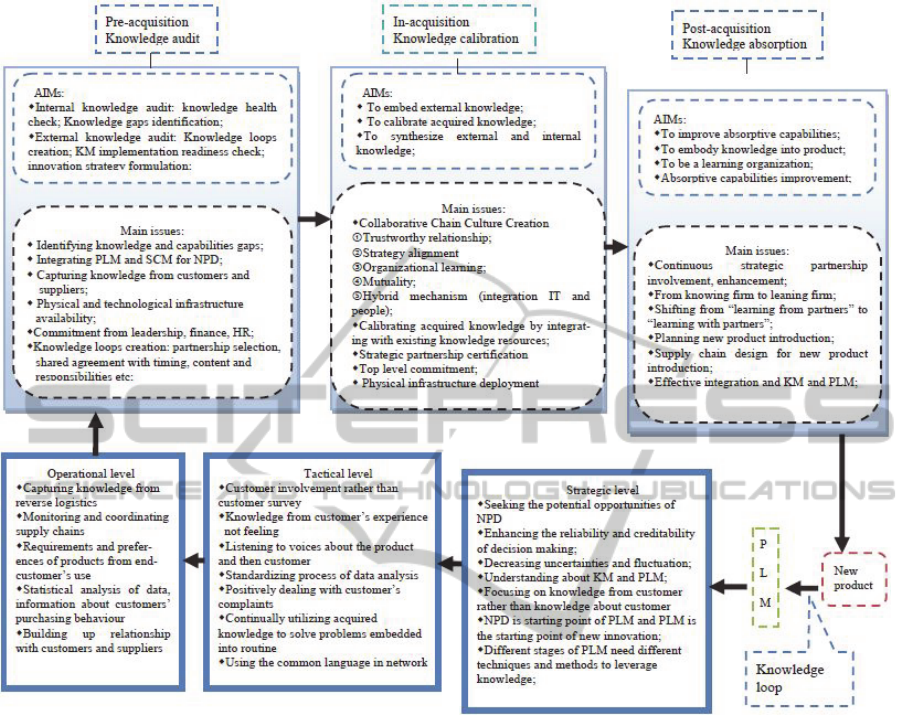

Abstract New Product Development (NPD) is critical for a firm’s survival and development. As firms are increasing-

ly challenged by internal deficiencies and paucities of knowledge resources, they need to embrace open in-

novation strategies. Subsequently, involving suppliers and customers into the process of NPD has been

viewed as the most effective means by which internal and external knowledge resources can be optimally

leveraged. However, there is a lack of available and reliable mechanisms to facilitate this process. This pa-

per presents a comprehensive theoretical framework developed by harmoniously combining the relevant

theoretical fields of Knowledge Management (KM), Open Innovation (OI), Supply Chain Management

(SCM) and Product Lifecycle Management (PLM). Additionally, within this framework, Knowledge Audit,

Knowledge Calibration and Knowledge Absorption have been employed as valuable tools to manage

knowledge loops across the three innovation stages: pre-acquisition, in-acquisition and post-acquisition.

1 INTRODUCTION

1.1 Background

In today’s business environment, companies are con-

tinually challenged by shorter product lifecycles,

faster technological changes, demanding and sophis-

ticated customers and the abiding trends of interna-

tionalisation, globalisation and convergence of indus-

tries. In response to these changes, increasingly, in-

novation and NPD has been viewed as critical to a

company’s success (D’Alene, 1994); (Veliyath et al.,

2000). Moreover as competition is shifting from be-

tween firms to between supply chains (Christopher,

1992), external actors, such as customers and suppli-

ers are increasingly influencing the process of inno-

vation (Thomke et al., 2002).

As a result, during the last decade, research inter-

ests on innovation have been shifted from closed

innovation to open innovation where the purposive

inflows and outflows of knowledge, as the impetus of

accelerating innovation process, can be effectively

managed (Chesbrough et al., 2003). Most important-

ly, due to the paucity or deficiency of internal

knowledge assets, firms have to rely on external

knowledge to foster innovation and to enhance their

performance (Ireland et al., 2002). In this line of rea-

soning, speeding up creative operations will rely on

the ability of the firms to co-ordinate, formulate a

competitive strategy and compensate for intrinsic

deficiencies by optimally leveraging external

knowledge resources (Ireland et al., 2002).

According to Drucker (1992), knowledge has be-

come the primary resource for the new economy,

where the tangible resources have become secondary.

This has been advocated by some researchers who

argue that knowledge will become not just as a source

of competitive advantage, but as the only source of

competitive advantage. (Drucker, 1993); (Nonaka,

1994); (Nonaka and Takeuchi, 1995). It is therefore

becoming strategic importance that firms constantly

improve their ability to effectively managing

knowledge flows, ensure success of NPD and in-

crease competitiveness (Bell, 1999); (Tidd and Hull,

2003); (Karmarkar, 2004); (Schulttze and Stabell,

2004); (Chesbrough et al., 2006).

It has been suggested that valuable knowledge

could be obtained and exploited through collaboration

and cooperation across SC networks and optimally

add value for the end customers. Therefore, it be-

comes imperative for firms to identify valuable

knowledge sources within both internal and external

environment and foster innovation quicker than the

competitors (Darroch, 2005). Recent research has

49

Wang L. and Kourouklis A..

On the Development of a Theoretical Framework for New Product Development.

DOI: 10.5220/0004136400490059

In Proceedings of the International Conference on Knowledge Management and Information Sharing (KMIS-2012), pages 49-59

ISBN: 978-989-8565-31-0

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

indicated that the supply chain is becoming the major

source of external knowledge, skills, ideas and added

value through collaborative efforts across the chain

members (CBI, 2005); (Sainsbury, 2007). More spe-

cifically, supply chain networks simultaneously influ-

ence the present and future (IfM, IBM, 2007). Supply

Chain Management (SCM) proponents have argued

that the change in the nature of competition is becom-

ing the momentum which shifts the competition from

individual firms to supply chains. Furthermore this

shift has urged the management practice to re-audit

and re-build the value-adding system and forced

firms to re-evaluate and re-structure their value chains

by adopting a holistic view of the supply chain. In

this setup, customers as the “prosumer” (Toffler

1980) together with suppliers have been increasingly

considered as the key drivers, co-innovators, co-

developers and primary resources to NPD (Thomke

and von Hippel; 2002).

Unfortunately, these issues have never been sim-

ultaneously discussed, particularly for NPD, and un-

surprisingly there are no comprehensive and reliable

frameworks to reference. Accordingly, there are a

number of gaps that hinder the endeavours of inte-

grating these relevant theoretical fields into a credita-

ble and reliable framework. The main gaps are the

following:

─ Intra-firm KM effort is increasingly becoming an

emerging research field wherein the potential value of

KM might be optimally explored and exploited.

However, tacitness of knowledge together with the

intricate technical requirements associated with KM,

even in an inter-firm context, is a barrier to the suc-

cess of intra-firm KM implementation. So the ques-

tion is how to compensate for intrinsic deficiencies of

Knowledge Management Systems and employ the

proper KM techniques to facilitate efforts on an intra-

firm and open innovation context.

─ Open innovation is subject to tremendous pressure

emerging from the competitive business environment

and complexity of synthesizing external and internal

knowledge assets. The shift from closed innovation to

open innovation requires firms to do more than just

“open the book”. Therefore, the difficulty is how to

develop a multidimensional method by which a firm

can systematically identify, embed and embody

knowledge scattered in the external environment.

─ Firms have to network with strategic partners that

possess sharable knowledge. Therefore, effective

combination of SCM and PLM is vital to achieve the

goal of creating knowledge loops in a network con-

text. However, the difficulties might be the feasibility

and reliability of embedding knowledge from the

process of managing product lifecycle and effective

SCM. Additionally to what extent a firm’s innova-

tion will rely on the knowledge from suppliers and

customers and how can evaluate the value of

knowledge?

This paper is presented in six sections. The first sec-

tion introduces the background and states the aims

and objectives of the research based on a comprehen-

sive evaluation of identified theoretical gaps. Section

two gives a brief explanation of the adopted research

approach followed by a literature review. The fourth

section presents and discusses the foundations of the

theoretical framework that is presented in more detail

in section five. Finally the sixth section briefly dis-

cusses the preliminary theoretical framework fol-

lowed by concluding remarks.

1.2 Aims of Research

A prerequisite to this state of affairs is to design a

comprehensive and creditable system by harmonious-

ly combining relevant theoretical fields to bridge the

gaps. In doing so, this paper aims to present a prelim-

inary theory-based framework which can facilitate the

process of managing knowledge loops for NPD and

outline a novel approach for innovation within in-

creasingly competitive environment. It mainly em-

ploys Knowledge Audit, Knowledge Calibration and

Knowledge Absorption techniques to control

knowledge loop across three collaborative innovation

phases, pre-acquisition, in-acquisition and post-

acquisition.

2 METHODOLOGY

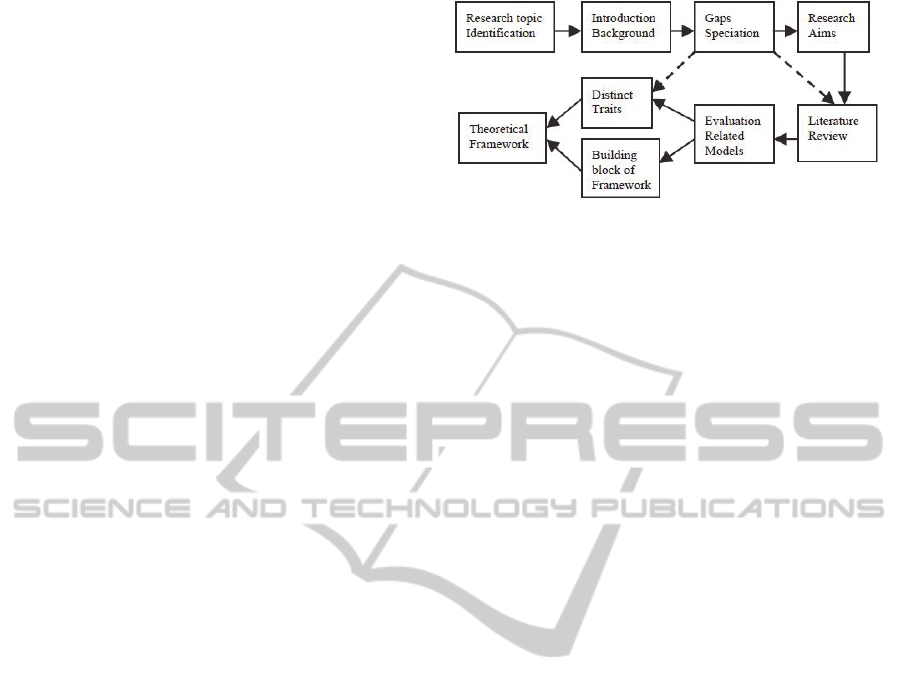

Adoption of the methodology (See Figure 1) is

shaped by the research aims. In order to design a

theory-based framework, gaps specification has been

positioned as the prerequisite of formulating the basic

research aims. It is followed by a relevant literature

review that highlights not only the main building

blocks of the framework but also uncovers distinct

characteristics. These characteristics, if explored and

developed effectively, provide one approach to bridg-

ing the theoretical gaps.

3 LITERATURE REVIEW

3.1 Knowledge Management

Increasingly, innovating firms have to improve their

KMIS2012-InternationalConferenceonKnowledgeManagementandInformationSharing

50

abilities to meet the never-ending requirements, from

demanding customers and fierce competition, by

effectively managing internal and/or external valuable

knowledge resources.

KM is a kind of strategy which delivers the right

knowledge to the right persons at the right time

(APQC). And KM efforts can be understood, no

longer merely as an option but rather as a core issue

that has to be thoroughly dealt with for firms to sur-

pass the global competition (Singh, 2007). Effective

KM implementation for innovation can be solely

realized by aligning with the overall business strategy

not only within internal environment, but also across

the external supply chain (Mudge, 1999); (Okunoye

and Kartsen, 2002); (Dan Holtshouse, 2011).

As a process (OECD, 2003), KM can improve the

learning abilities and increase effectiveness and effi-

ciency of organizational performance by systemati-

cally coordinating processes of knowledge internali-

zation, externalization, socialization and combination

(Mockler et al., 1992); (Nonaka, 1994). This view-

point about KM has been advocated by Davenport et

al., (2003) who place the attention on the process of

“knowledge import” and “knowledge export”. The

underlying principle is to “export” imported

knowledge to the rest of firm for the purpose of solv-

ing problems or encouraging innovation. Meanwhile,

the resource-based view of firms has shown that rela-

tionships between buyers and sellers are the most

important intangible resources than technical and

organizational capital (Penrose 1959); (Darroch,

2005).

KM can be seen as an effective coordinating

mechanism which ultimately enables the resource to

be converted into capabilities (Nelson and Winter,

1982); (Darroch, 2005). Earl (2001) suggests that KM

can be regarded as central to product and process

innovation or improvement, executive decision-

making and organizational adaptation and renewal. In

term of innovation, the KM perspective of NPD is

about how to seek optimal ways of controlling the

valuable knowledge assets. In essence, this process is

an effort of utilizing these mechanisms to coordinate

the conversion process, namely from the embedded

knowledge to embodied knowledge (Madhavan et al.,

1998). Most importantly, in order to innovate, firms

need to create an inventory of knowledge assets and

make it more visible, accessible, sharable and meas-

urable (Jarrar 2002); (Skyme and Amidon, 1997).

Furthermore, the firms can benefit from successful

KM implementation by enhancing their competitive

advantage, customer focus, employee relations and

development, innovation, and lower costs (Skyrme

and Arnindon, 1997); (Dykeman, 1998).

Figure 1: Research methodology.

3.2 Innovation

Today’s business environment is fiercely competitive.

Globalization, ever fast changing technologies and

increasingly demanding customers are constantly

pushing the performance bar upward. Becoming an

innovator is the only way to be a winner. Unsurpris-

ingly, successful firms have to innovate at the global

frontier and shift the technology frontier better than

their rivals (Porter and Stern, 2001). A survey con-

ducted by Product Development and Management

Association (PDMA) has shown that successful new

products contributed 50% to 60% of sales in most

companies (Hustad, 1996). Additionally, success of

NPD will help the firms to siege new opportunities

and actually propel the firms into new business fields

wherein they can gain first-mover advantages or sur-

pass the competitors in term of responsiveness or

innovativeness.

According to CBI (Confederation of British In-

dustry) (2005), innovation is considered as being ‘the

successful exploitation of new ideas’ across industrial

networks that collaborate in a SC context to stimulate

the creation of these ideas. Meanwhile this process

will rely on the decision to exploit and develop the

power of effective KM implementation which can

support innovation and creativity (IFM and IBM,

2007). Consequently, firms become much more pre-

pared to innovate and perform successfully to meet

the requirements from the customer and market faster

and better than the competitors.

DTI (2007) also concluded that there is a need to

take a broader view of the innovatory process and to

tap into a network environment, because that individ-

ual actor is seldom capable to innovate independent-

ly. Networks through establishment of “weak and

strong ties” (Granovette, 1973) and bridging of

“structural holes” (Burt, 1992) can greatly enhance

the processes of knowledge creation. This viewpoint

has been advocated by Antoni who states that the

knowledge needed for innovation is often a product

of the confrontation and combination of different

fields of knowledge from heterogeneous resources

OntheDevelopmentofaTheoreticalFrameworkforNewProductDevelopment

51

(Antonio, 2009). Therefore, it has become a strategic

attractive option to acquire knowledge from external

sources to compensate for scarcity of internal re-

sources (Freeman, 1987). In a similar vein, open

innovation (Chesbrough, 2003), as an emerging inno-

vation strategy, has been regarded as the essential

element to revitalize in-house innovation or closed

innovation and to accelerate the innovation process

(Schebrough, 2003); (Tether, 2002); (Coombs et al.,

2003); (Howells et al., 2003). Gassmann et al., (2004)

present three archetypes of the open innovation pro-

cess:

Outside-in: integrating external knowledge, cus-

tomers and suppliers;

Inside- out: bring ideas to market;

Coupled processes: couple outside-in and inside-

out process and work in alliances in a complementary

manner;

3.3 Supply Chain Management

Basically, SCM covers all business processes be-

tween vertically linked entities within three dimen-

sions, action, relationship and process (Bowerox et

al., 1999); (Cooper et al., 1997); (Lambert et al.,

1998); (Bask and Juga, 2001); (Persson, 2002).

The Council of Supply Chain Management Pro-

fessionals (2006) concluded that SCM “encompasses

the planning and management of all activities in-

volved in sourcing and procurement, conversion and

all logistics management activities. In essence, supply

chain management integrates supply and demand

management within and across companies.” SC as a

value chain can offer the opportunities to simultane-

ously improve the individual firm’s performance and

increase the possibilities to achieve common goals or

“growing the pie” (Harwick, 1997). Meanwhile, it

provides firms with a way to optimally leverage its

core competences and unique skills and strategically

outsourcing non-core activities to external networks

(Cox, 1999); (Laseter, 1998); (Quinn, 2000).

The relation-oriented definition (Aitken, 1998) of

SCM suggests that relationships; cooperation and

mutuality are vital in improving effectiveness and

efficiency and overall performance. Consequently,

appropriate relationships with channel members are

not only the antecedent of successful “outsourced

activities” but also the consequence of fruitful collab-

oration. Therefore, it is core to improve the abilities

and create a mechanism by which the intricate rela-

tionship can be enforced (Drucker, 1998); (Bowersox,

1999).

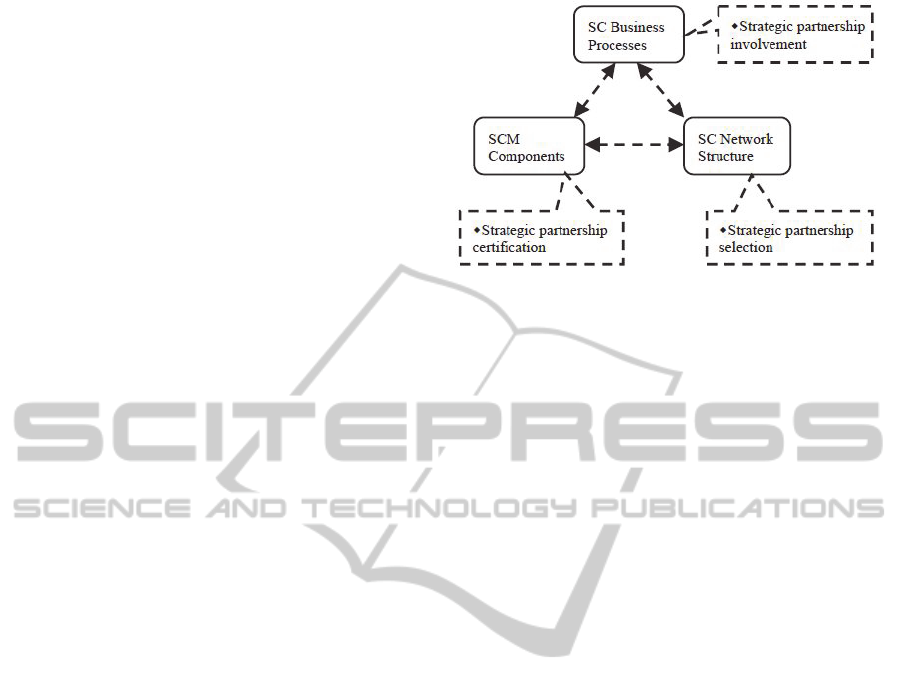

Figure 2: SCM Framework (adapted from (Lambert et al,

2000); (Cooper et al, 1997)).

SCM presents the effective integration of key

business processes that add value to end-customer,

from upstream suppliers, manufacturers, distributors

and retailers (Richard and Wisner, 2005). So it can be

seen as an approach to coordinating functions and

processes and responding the requirements of cus-

tomers through effective management of information

and knowledge across the network (Nancy et al.

2003). Cooper et al. (1997) state that the SCM en-

compasses three closely inter-related elements: the

SC network structure, the SC business processes, and

the SCM components (see Figure2). This framework

provides the basic principles of creating strategic

supply chain configuration considering all exogenous

and endogenous variables related to NPD and strate-

gically, operationally and technologically create long-

term stable relationships (Hult et al., 2004). Basically

strategic supply chain relies on three aspects: strate-

gic partnership selection, strategic partnership certifi-

cation and strategic partnership involvement (Burt

and Soukup, 1985); (Swink, 1999); (Shin et al.,

2000).

Based on the extant literature, it is widely accept-

ed that the suppliers’ innovative capabilities are the

major determinants for collaboration. Meanwhile,

Burton (1988) argues that suppliers accounted for

approximately 30% of the quality problems and 80%

of product lead-time problems. Recently, most of

research focuses on the timing of supplier’s involve-

ment. Petersen et al., (2005) state that early supplier

integration is an important coordinating mechanism

for decision making that links product design, process

design and supply chain design together. The main

derived benefits have been classified as the following

by a number of researchers (Handfield et al., 1999);

(Ragatz et al., 2002):

Early identification of technical problems;

Fewer engineering change orders or prototypes;

Better utilization of internal resources;

KMIS2012-InternationalConferenceonKnowledgeManagementandInformationSharing

52

Access to new or supplementary product and pro-

cess technologies;

Reduced technical and financial risk;

Improved product features

Shorter time to market

3.4 Customer Knowledge Management

It is worth noting that the failure rate of NPD is high,

with some researchers estimating it to be between 40-

75% (Stevens and Burley, 2003). According to Mans-

field (1981) and Zirger (1990), the lack of a fit be-

tween new product attributes and customer require-

ments is a major cause of the failures. Essentially,

tacit nature of knowledge (Polanyi, 1966), stickiness

of knowledge (Von Hippel and Tyre 1996) and

“knowledge that is located, embedded and invested in

practice” (Bourdieu, 1977), (Lave, 1988) have been

viewed as the main barriers which hinder processes of

knowledge creation. Ironically, if companies fail to

continually innovate, they die (Chesbrough,

2003).Within such background, Customer Knowledge

Management (CKM) has been regarded as the key

perquisite for NPD (Chesbrough, 2003). Paquette

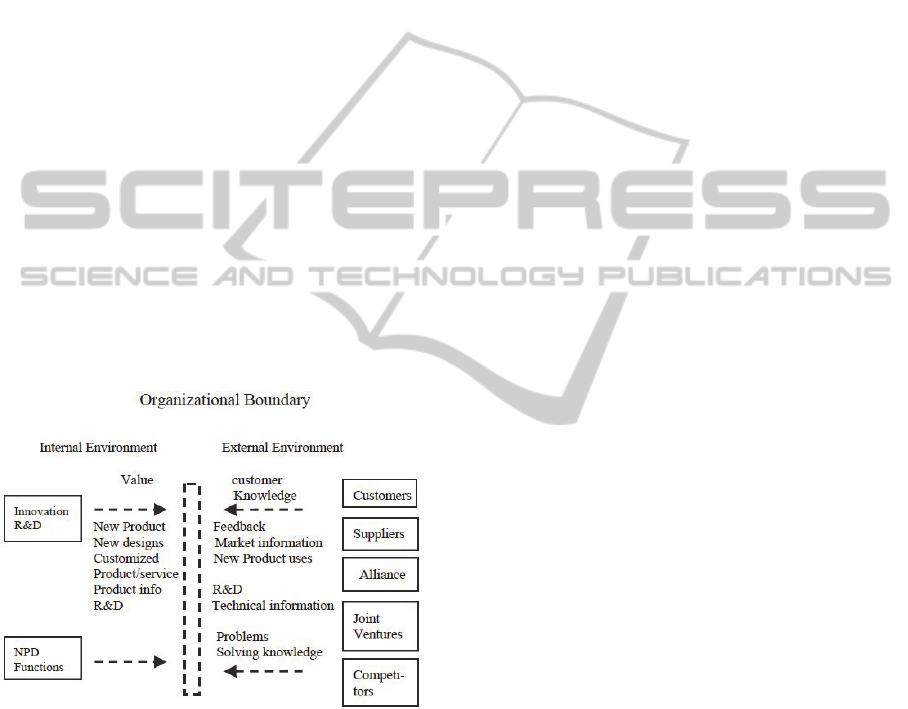

(2006) presents a depiction of customer knowledge

flows shown in Figure 3.

Figure 3: summary of Customer Knowledge (Paquette,

2006).

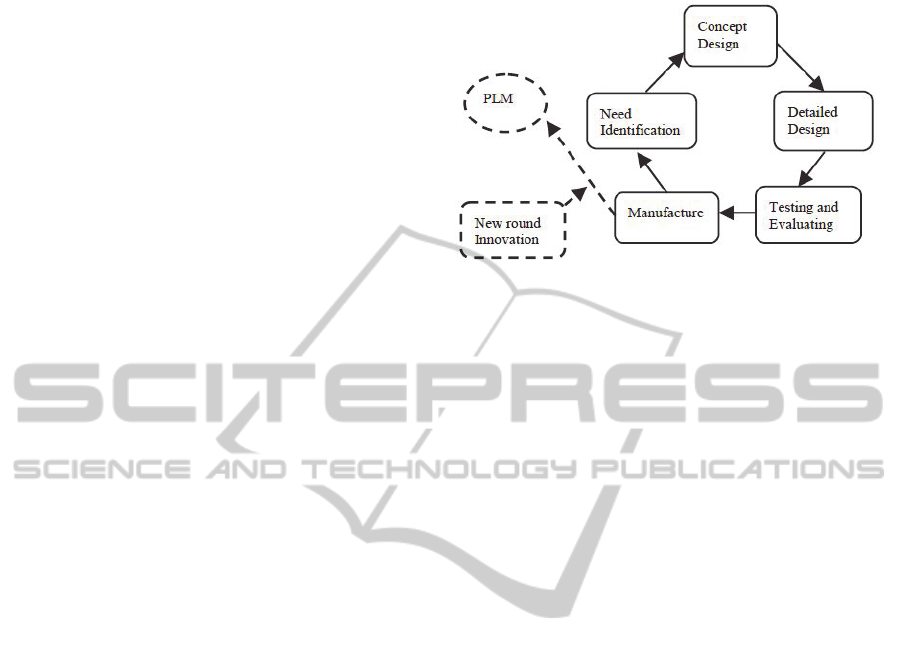

Traditionally, a NPD project (see Figure 4) needs

to effectively coordinate R&D and marketing to iden-

tify potential opportunities and formulate sound

means to make it happen. In essence, the combination

can be regarded as the process to leverage comple-

mentary knowledge resources. Increasingly, success

of NPD projects requires companies to develop com-

petence by creating an external knowledge sharing

ecosystem which can not only ensure the success of

NPD, but also it is hard to simulate (Charlie and Re-

bentisch, 2003). In doing so, many companies have

shifted their attention from customer relationship

management (CRM) and data mining strategies to

CKM and recently from exploration of knowledge

about customer to knowledge from customer (Berson

et al., 2003); (Davenport et al., 2001). This is because

that customer has moved from passive recipients of

NPD in 1970s and early 80s towards demanding to

play a more active role in the 21st century (Prahalad

and Ramaswamy, 2000). In one word, customer has

moved out from audience onto the stage. Customer

knowledge, as one of the most important knowledge

bases for an organization, can be broadly defined as a

combination of external consumer knowledge and

supply chain knowledge etc (Bennet and Gabriel,

1999); (Paquette, 2006). Accordingly, CKM refers to

processes of involving customer into innovative ac-

tivities or improvement of performance by sharing

valuable knowledge within the network environment.

This process actually increases the firms’ competitive

advantage by encouraging learning process or cus-

tomer learning wherein two-way exchange of

knowledge can benefit the both parties (Stewart,

1997). However this process is considered to be rela-

tively passive and even tacit for most of researchers

and practitioners. Probably, the challenge here is to

create mechanism to manage the relationships (Dav-

enport et al, 2001). Among the numerous researchers,

Leonard and Rayport (1997) developed an “empathic

design”, which is an observation-oriented research

method, to involve the customer into the process of

innovation by exploring the tacit knowledge through

observation of their daily routine. Similarly, Von

Hippel (1986) argues that “lead user” is a source of

novel product concept which plays vital roles to com-

pensate for the deficiencies of potential user experi-

ence in the real world. According to Gibbert et al.,

(2002), there are five styles of CKM:

prosumerism stems from the expression “prosum-

ber” (Toffler, 1980) and indicates that customers can

play the key roles as co-innovators, as in Bosch and

Mercedes-Benz, Quicken, IKEA practice (Gibbert et

al, 2002).

Team-Based Co-Learning focuses on embedding

customer knowledge into a platform which can facili-

tate the process of embodying the shared knowledge

into new product or service. In this setup, Ama-

zon.com and Toyota have been regarded as the most

typical examples.

Mutual Innovation was, initially, identified by

Von Hippel (1988) who found out that end-users play

decisive role of innovation. According to Gibbert et

al, (2002), Rider Logistics have been developed from

a trucking company to logistic solution providers

OntheDevelopmentofaTheoreticalFrameworkforNewProductDevelopment

53

through mutual innovation with its customers.

Communities of Creation are different from tradi-

tional communities of practice and reflected in the

mutual interaction of groups of customer knowledge

in order to achieve the common goal of knowledge

creation (Sawnhney and Prandelli, 2000). Examples

are “beta” created by Microsoft and Netscape; “An-

tenna shops” from Sony and Panasonic.

Joint Intellectual Property is the most intense form

of cooperation between companies and their custom-

ers by sharing ownership of NPD (Gibbert et. al,

2002). For example, Skandia Insurance and Koopera-

tiva Forbundet.

3.5 Product Lifecycle Management

Recently, the interest about CKM has been positioned

as an effective Product Lifecycle Management (PLM)

approach (Ameri et al, 2005). According to Stark

(2005), PLM is “the activity of managing a compa-

ny’s products all the way across their lifecycle (from

cradle to grave) in the most effective way”. In es-

sence, PLM is the starting point of the innovative

process which consists of continual knowledge identi-

fication and knowledge acquisition from customers or

market. Therefore, effectiveness of PLM will dramat-

ically influence further processes of knowledge crea-

tion and ultimate success of NPD projects. In this line

of reasoning, gathering information and knowledge

from the customer and market will be the key start of

efforts to synthesize knowledge loops for successful

NPD. Particularly In term of managing knowledge

across the product lifecycle, it might require different

approaches within the different stages from product

introduction, growth, maturity (saturation), and de-

cline to retirement (Ameri et al., 2005). Basically,

there are a number of issues which need to be ad-

dressed:

Vital shift: from customer survey to customer

involvement;

Listening to voices about the product and then to

the customer;

Gaining as much as invaluable (information)

knowledge from reverse logistics;

Managing the firm (or supply chain) as a whole

rather than separate functions;

Standardizing the process of management and

information analysis;

Accurate evaluation of possibilities of potential

risks and advanced planning activities;

Increasing the reliable and feasible decision-

making;

Calibrating strategy based on valuable feedback

and seizing new opportunities;

Figure 4: Product introduction process (adapted from Mar-

shall, 2000).

4 FOUNDATIONS OF

THEORETICAL FRAMEWORK

Just as discussed above, this paper aims to expand

NPD into SC context. Accordingly, it is vital to struc-

ture the framework based on effective combination of

SCM and KM. Inspired by the strategic supply chain

model (Lambert et al., 2000); (Cooper et al., 1997),

this theoretical framework is constructed into three

phases, pre-acquisition, in-acquisition and post-

acquisition. Moreover, in order to embrace open in-

novation strategy (Gassmann et al., 2004);

(Schebrough, 2003), the framework especially focus-

es on two aspects: firstly analyzing internal and ex-

ternal knowledge assets regarding to internal availa-

bility and external complementary credibility (and

sharability). This process is extraordinarily linked

with Knowledge (Management) Audit Approach

(Leibowitz, 1999) and has to be conducted within the

pre-acquisition phase. Secondly, as a process of trans-

ferring embedded knowledge to embodied knowledge

(Madhavan et al., 1998), innovation is subject to co-

ordination of the two actions. In its essence,

Knowledge embedding can be matched with

Knowledge Calibration (Pillai and Goldsmith, 2006)

and ultimate knowledge embodying will be closely

linked with Knowledge Absorption and absorptive

capability (Cohen and Levinthal, 1990). Subsequent-

ly, as key drivers of innovation, these two KM tech-

niques can be utilized to facilitate the process of

knowledge embedding and knowledge embodying

across two phases: in-acquisition and post-

acquisition. In fact, this framework might compensate

for the deficiencies of existing Open Innovation stud-

ies and expand the related research into broader con-

text.

KMIS2012-InternationalConferenceonKnowledgeManagementandInformationSharing

54

5 PRELIMINARY THEORETICAL

FRAMEWORK

Based on the literature review, a preliminary theory-

based ACA (Audit, Calibration and Absorption)

framework (See Figure 5) is formalized as following:

5.1 Pre-acquisition and Knowledge

Audit

Audit Approach is a critical part of a KM framework

and an effective first step of internal KM efforts

(Leibowitz, 1999). Effectiveness of Knowledge Audit

is a determinant which directly affects the decision

making about “can I do it” (Knowledge Management

Audit) and further activities related to managing

knowledge resources. Essentially, it can provide an

outline by systematically investigating and evaluating

the “health” of a firm’s knowledge and ability and

readiness of further KM implementation. Most im-

portantly, it encourages two fundamental and philo-

sophical conversions; from we do not know what we

know to know what we don’t know and from know

what we don’t know to know how to know. The main

objectives of Knowledge Audit or knowledge man-

agement audit in the pre-acquisition phase are:

What we know and what we don’t know

(knowledge and abilities gaps identification)

Who knows and can we cooperate (partnership

selection)

How to make it happen (knowledge loop creation)

Are we ready to embrace activities of KM? (abil-

ity audit)

To formulate an innovative strategy (outside-in,

inside-out or coupled model);

To analyze data or information from customers

and market;

To locate and evaluate the valuable external

knowledge assets and select strategic partnerships

(for example: suppliers, customers);

To create and disseminate strategic goals through

mutual collaboration and cooperation;

5.2 In-acquisition and Knowledge

Calibration

According to Pillai and Goldsmith (2006), knowledge

calibration is a measure of the degree of agreement

between knowledge accuracy and confidence within

the knowledge acquiring and embedding processes.

Meanwhile, capability to calibrate knowledge acts as

a facilitator or valuable catalyst which can support

firms to make judgement about strategic partners in

term of abilities, characteristics, potential develop-

ment and criteria of meaningful interaction. The

main objectives in this phase constitute the require-

ment for the following actions:

Building up trustworthy relationships;

Enhancing mutuality;

Addressing shared goals and consistently improv-

ing routine activities;

Harmoniously integrate and optimally utilize IT-

based hard infrastructure and people-based soft

mechanisms;

Improving leaning awareness and abilities;

Cooperative Chain Culture Creation (C4);

5.3 Post-acquisition and Knowledge

Absorption

Employing KM techniques will aim to facilitate not

only sharing of knowledge between providers and

receivers but also embodiment or absorption the ac-

quired knowledge into the new products or services.

Accordingly, there are numerous factors that will

affect the success of knowledge absorption, but

amongst them, absorptive capability and the learning

processes are the decisive determinants (Cohen and

Levinthal, 1990); (Helfat et al., 2007). Absorptive

capability is the ability to use prior knowledge to

recognize the value of new knowledge and to assimi-

late and apply it to create new knowledge and capa-

bilities (Cohen and Levinthal, 1990). The learning

processes are the mechanisms and key impetus that

effectively compensate for the firms’ ability deficien-

cies (Helfat et al., 2007). The key issues of this phase

should be addressed as following:

Continuously improve the strategic partnership;

Evolve from knowing firm to learning firm( en-

couraging individual creative activities; indirectly or

directly customer involvement etc);

Migrate from learning from partners to learning

with partners (acting with suppliers as a whole by

joint activities and optimally uses knowledge to re-

duce uncertainties);

Embody technology knowledge and market

knowledge into NPD and plan product introduction

(integrating related factors, such as distributors, re-

tailers, inventory and marketing etc);

6 CLUCLUDING REMARKS

This framework focuses on systematically synthesi-

OntheDevelopmentofaTheoreticalFrameworkforNewProductDevelopment

55

Figure: 5 Preliminary ACA framework.

zing relevant theoretical fields and expanding NPD

into supply chain context by adopting OI strategy.

More specifically, it has accurately captured the na-

ture of existing knowledge management system and

the core of NPD to design a three-phase knowledge

creation framework. It logically integrates three KM

techniques into the process of innovation and syn-

chronizes with SCM. In essence, by referencing this

framework, researchers and practitioners can easily

manage NPD projects in terms of optimally leverag-

ing knowledge resources, accurately self-positioning,

detecting and employing solutions to solve the poten-

tial problems. And as a result, the firm can achieve

the goals of shortening “time to the market”, obtain-

ing first mover advantages and satisfying the end

customer requirements.

As part of a wider research project, this paper

mainly focuses on presenting a theoretical framework

which can be considered as a reference model for

further research. This framework integrates a number

of theoretical concepts and utilizes existing approach-

es to facilitate effective use of knowledge manage-

ment techniques in the NPD process. At this stage,

the proposed framework needs to be evaluated from a

practical point of view. In this sense, a process of

validation will be undertaken to verify and improve

the creditability and feasibility of this framework.

REFERENCES

Aitken, M. J., 1998. An Introduction to Optical Dating.

Oxford University Press, Oxford.

Antonio Messeni Petruzzelli. 2009. External knowledge

sources and proximity. Journal of Knowledge Mana-

gement, VOL. 13 NO. 5 2009, pp. 301-318,

Ameri F, Dutta D., 2005. Product Lifecycle Management:

Closing the Knowledge Loops. Computer-Aided Des.

Appl., 2(5): 577-590.

Burt, R. S. 1992. Structural holes: The social structure of

competition. Cambridge, MA: Harvard University

KMIS2012-InternationalConferenceonKnowledgeManagementandInformationSharing

56

Press.

Bask, A. H. and Juga, J., 2001, “Semi-integrated supply

chain: towards the new era of supply chain manage-

ment”, International Journal of Logistics: Research

and Applications, Vol. 4 No. 2, pp. 137-52.

Berson, A., Smith, S. & Thearling, K., 2003. Customer

acquisition. Building Data Mining Applications for

CRM (p. 7). New York.

Bennett, R. and Gabriel, H. I., 1999, Organizational factors

and knowledge management within large marketing de-

partments: an empirical study. Journal of Knowledge

Management, 3 (3) 212-225.

Bowersox, D. J., Closs, D. J. and Stank, T. P., 1999, 21st

Century Logistics: Making Supply Chain Integration a

Reality, Council of Logistics Management, Oakwood,

IL.

Bourdieu, P. 1977. Outline of a Theory of Practice. Cam-

bridge University Press, Cambridge, UK.

Bell, D., 1999, the coming of post-industrial society: A

venture in social forecasting, Basic Books, New York.

Burt, D. N. and Soukup, W. R., 1985, Purchasing role in

new product development. Harvard Business Review,

63, 90–97.

Cooper, M. C., Lambert, D. M., and Pagh, J. D., 1997,

Supply Chain Management: More Than a New Name

for Logistics. The International Journal of Logistics

Management 8(1), 1–13.

Cox, A., 1999, "Power, value and supply chain manage-

ment", Supply Chain Management: An International

Journal, Vol. 4 No.4, pp.167-75.

Christopher, M., 1992, Logistics & Supply Chain Manage-

ment, Pitmans, London.

Cohen, W., Levinthal, D., 1990, «Absorptive capacity: A

new perspective on learning and innovation.

Chesbrough, H., 2003. Open Innovation. The New Impera-

tive for Creating and Profiting from Technology. Har-

vard Business School Press, Boston, MA.

Coombs, R., Harvey, M., Tether, B., 2003. Analysing dis-

tributed processes of provision and innovation. Indus-

trial and Corporate Change 12, 1125–1155.

Confederation of British Industry (CBI), 2005, Innovation

Survey, CBI, November.

Carlile, P., & Rebentisch, E. S., 2003. Into the black-

box:The knowledge transformation cycle. Management

Science, 49(9), 1180-1195.

Drucker, P. F.: “Management’s New Paradigms.” Forbes

Magazine, October 5, 1998, pp 152–177.

D’Aveni, R., 1994, Hyper competition: Managing the Dy-

namics of Strategic Manoeuvring. The Free Press, New

York .

Druker P. F., 1992 Managing for the Future, Butterworth-

Heinemann, Oxford.

Department of Trade and Industry, 2007. Innovation in

Services, DTI Occasional Paper no. 9, June, HMSO.

Dykeman J. B., 1998. Knowledge management moves from

theory toward practice. Managing Office Technology

43(4): 12–13.

Davenport, T. H., Prusak, L. and Wilson, J. H., (2003),

‘‘who’s bringing you hot ideas and how are you re-

sponding?’’, Harvard Business Review, Vol. 81 No. 2,

pp. 59-64.

Dan Holtshouse: available: Http: www.information

week.com/762/know.htm (6/ 2011).

Davenport, T. H., Harris, J. G., & Kohli, A. K., 2001. How

do they know their customers so well? MIT Sloan Man-

agement Review, (winter), 63-73.

Darroch Jenny: Knowledge management, innovation and

firm performance, Journal of Knowledge Management,

Vol.93 2005, pp 101-115.

Earl, M., 2001, “Knowledge management strategies: toward

a taxonomy”, Journal of Management Information Sys-

tems 18 (1), pp. 215–233.

Freeman, L., Romney, K. & Freeman, S., 1987. Cognitive

structure and informant accuracy, American Anthropol-

ogist, 89: 310-325.

Gibbert, Michael, Leibold, Marius, Probst, Gilbert, Five

styles of Customer Knowledge Management, and how

smart companies put them into action. Available at:

http://archive-ouerte.unige.ch/downloader/vital/pdf/tmp

/b4cghni2pnfv1gs980ius7a9p2/out.pdf. 17th April

2012.

Granovetter, M., 1973, the strength of weak ties. American

Journal of Sociology, 78(6), 1360–1380.

Gassmann, Oliver; Enkel, Ellen: Towards a Theory of Open

Innovation: Three Core Process Archetypes. 2004. -

R&D Management Conference (RADMA) - Lisabon,

Portugal

Hustad, T. P., 1996. Reviewing current practices in innova-

tion management and a summary of selected best prac-

tices. In: The PDMA. Handbook of New Product Devel-

opment. Wiley and Sons, New York, pp. 489–51

Harwick, T. 1997, "Optimal Decision-Making for the Sup-

ply Chain," APICS - The Performance Advantage,

(7:1), pp. 42-44.

Helfat C, Finkelstein S, Mitchell W, Peteraf MA, Singh H,

Teece DJ, Winter SG (eds). Blackwell: Oxford, U.K.;

19–29 2007.

Howells, J., James, A., Malik, K., 2003. The sourcing of

technological knowledge: distributed innovation pro-

cesses and dynamic change. R&D Management, 33,

395–409.

Hult, G., Thomas, M., Ketchen, D. J. Jr and Slater, S. F. ,

2004, “Information processing, knowledge develop-

ment and strategic supply chain performance”, Acade-

my of Management Journal, Vol. 47 No. 2, pp. 241-54.

Handfield, R, B and E., L. Nichols, 1999, Introduction to

Supply Chain Management, New York, Prentice Hall

Inc.

IfM and IBM. 2007. succeeding through Services Innova-

tion: a discussion paper, Cambridge, United Kingdom:

University of Cambridge Institute for Manufacturing.

Jarrar Y F., 2002, Knowledge management: learning for

organizational experience, Managerial Auditing Jour-

nal, Vol. 17 No. 6, pp. 322-328.

Kogout, B. & Zander, U. 1992. Knowledge of the Firm,

Combinative Capabilities, and the Replication of the

Technology. Organization Science, 3. 383-397.

Karmarkar, U., 2004, Will you survive the services revolu-

tion? Harvard Business Review, Vol. 82, No. 6, pp 100-

107.

OntheDevelopmentofaTheoreticalFrameworkforNewProductDevelopment

57

Lambert, D.J., Cooper, M.C. and Pagh, J.D. (1998), “Sup-

ply chain management, implementation issues and re-

search opportunities”, International Journal of Logis-

tics Management, Vol. 9 No. 2, pp. 1-19.

Laseter T. Balanced Sourcing: Cooperation and Competi-

tion in Supplier Relationships, Jossey-Bass Publishers,

San Francisco, CA, 1998.

Liebowitz, J. (ED.), 1999, The knowledge Management

Handbook, CRC Press, Boca Raton, FL.

Lave, J. 1988. Cognition in Practice: Mind, Mathematics,

and Culture in Everyday Life. Cambridge University

Press, Cambridge, U.K.

Leonard, Dorothy and Rayport, F Jeffery, 2002, Spark

innovation through emphatic design. http://iic.wiki.fgv.

br/file/view/LEONARDO%3BSpark+Innovation...Desi

gnHBRv75i6nov-dec_97.pdf/221834616/LEONARDO

%3BSpark+Innovation...DesignHBRv75i6nov-dec_97.

pdf.

Lambert D. M. and Cooper, M. C, 2000, issues in Supply

Chain Management, industrial Marketing Management

29, 65-83.

Madhavan Ravindranath and Grover Rajiv, 1998, From

Embedded Knowledge to Embodied Knowledge: New

Product Development as Knowledge Management,

Journal of Marketing Vol. 62, No. 4. pp. 1-12

Mudge, A., 1999, ‘‘Knowledge management: do we know

what we know?’’, Communication World, Vol. 16 No.

5, pp. 24-9.

Mansfield, E. Schwartz, M., & Wagner, S. 1981. Imitation

Costs and Patents: An Empirical Study. Economic

Journal, 91 (364): 907-18.

Mockler, R. J., & Dologite, D. G. 1992. Expert systems to

support strategic management decision-making. In D.

E. Hussey (Ed.), (vol. 3) (pp. 133–148). International

review of strategic management.

Nelson, R. R. and Winter, S. G. 1982, An Evolutionary

Theory of Economic Change, Harvard University

Press.

Nonaka, I. and Takeuchi, H. 1995, The Knowledge Creat-

ing Company, How Japanese Companies Create the

Dynamics of Innovation, Oxford University Press, and

Oxford.

Nonaka, I. 1994, “the dynamic theory of organizational

knowledge creation”', Organization Science, Vol. 5 No.

1, February, pp. 14-37.

Okunoye, A. & Karsten, H. 2002. Where the global needs

the local: variation in enablers in the knowledge man-

agement process. Journal of Global Information Tech-

nology Management, 5(3), 12–31.

OECD, 2003 “Conclusions from the Results of the Survey

of Knowledge Management Practices for Minis-

tries/Departments/Agencies of Central Government in

OECD Member Countries”, February 3-4, 2003,

GOV/PUMA/HRM.

Persson, G., 2002, “Supply chain management, a multidis-

ciplinary study of integrated supply chains”, in Persson,

G. and Grønland, S.E. (Eds), Research Report No.

9/2002,

Norwegian School of Management BI, Oslo.

Prahalad, C. K and Hamel, G. 1990, “The core compenten-

cy of a corporation”, Harward business review, 68 (3),

79-91.

Porter, M. E. and. Stern, S., 2001, Innovation: location

matters. MIT Sloan Management Review 42 4 pp. 28–

36

Paquette, S. April 2012, Customer knowledge management

available at: ftp://ftp.eng.umd.edu/:/home/glue/s/p/spa

quett/pub/docs/Paquette%20-%20Customer%20Know

ledge%20Management.pdf.

Polanyi, M. 1966. The Tacit Dimension. Anchor Day

Books, New York.

Petersen, K. J., Handfield, R. B., Ragatz, G. L., 2005. Sup-

plier integration into new product development: coordi-

nating product, process and supply chain design. Jour-

nal of operations management 23 (3/4), 371–388.

Pillai K G, Goldsmith R E., 2006. Calibrating managerial

knowledge of customer feedback measures: a conceptu-

al model. Marketing Theory. Volume: 6 Issue: 2 pp.

223-243.

Penrose, E. T., 1959. The theory of the growth of the firm.

Basil Blackwell. Oxford

Prahalad, C. K. and Ramaswamy, V. K., 2000. Co-opting

customer competence. Harvard Business School 78 (1).

Quinn, F. J., 2000, "The clockspeed chronicles", Supply

Chain Management Review, Vol. 3 No.4, pp.60-4.

Ragatz, G., Handfield, R., Petersen, K., 2002. Benefits

associated with supplier integration into new product

development under conditions of technology uncertain-

ty. Journal of Business Research 55 (5), 389–400

Sainsbury, Lord, 2007, Race to the top: A review of the

Government’s science and innovation policies, Inde-

pendent HM-Treasury Report, HMSO, October.

Stevens, G, A., & Burley, J. 2003, piloting the rocket of

radical innovation. Research Technology Management,

46 (2) 16-25.

Skyme, D. and Amidon, D. 1997, “the knowledge agenda”,

Journal of knowledge management, Vol.1 No. 1, pp.27-

37

Swink, M., 1999, Threats to new product manufacturability

and the effects of development team integration pro-

cesses. Journal of Operations Management, 17, 691–

709Stewart, Thomas A. 1991, 'Brainpower', Fortune,

pp.44-56 (3 June).

Schulttze, U. and Stabell, C. 2004, “Knowing what you

don’t know? Discourses and contradictions in

knowledge management research”, Journal of Man-

agement Studies, Vol. 41 No. 4, pp. 549-73.

Stark, John, 2005. Global Product: Strategy, Product

lifecycle Management and Billion Customer Questions.

Springer.com.

Shin, H., D. A. Collier and D. D. Wilson, 2000. Supply

management orientation and supplier/buyer perfor-

mance. J. Oper. Manage, 18: 317-333.

Singh, M., Kant, R. 2007. Knowledge management as

competitive edge for Indian engineering industries in:

Proc. of the International Conference on Quality and

Reliability, Chiang Mai, Thailand, 398–403. 5-7 No-

vember, pp.398-403, 2007a.

Sawhney, M. & Prandelli, E., 2000. Communities of crea-

tion: managing distributed knowledge in turbulent mar-

kets. California Management Review, 42(4), 24-54.

KMIS2012-InternationalConferenceonKnowledgeManagementandInformationSharing

58

Tapp L., 1997. Emerging triumphant, Business Quarterly

61(3): 27.

Tidd, J. and Hull, F. M., 2003. Services Innovation: Organ-

isational responses to technological opportunities and

market imperatives, Imperial College Press, London.

Thomke, S. and von Hippel, E., 2002, Customers as Inno-

vators, Harvard Business Review April, 5–11.

Toffler, A., 1980. The Third Wave. Morrow, New York.

Tether, B., 2002. Who co-operates for innovation, and why.

An empirical analysis. Research Policy 31, 947–967.

Veliyath R. and Fitzgerald E., 2000. Firm capabilities,

business strategies, customer preferences, and hyper-

competitive arenas: the sustainability of competitive

advantages with implications for firm competitiveness.

Competitiveness Review, 10 1 pp. 56–82.

Von Hippel and Tyre. 1996. The mechanics of learning by

doing: Problem discovery during process machine use.

Tech. and Culture 37 312–329.

Zirger, B. J. & Maidique, M. A., 1990. A Model of New

Product Development: An Empirical Test: Management

Science, 36(7), 876-883.

OntheDevelopmentofaTheoreticalFrameworkforNewProductDevelopment

59