X-FEM based Topological Optimization Method

Meisam Abdi, Ian Ashcroft and Ricky Wildman

Wolfson School of Mechanical and Manufacturing Engineering, Loughborough University, Loughborough, U.K.

Keywords: Topology Optimization, Isoline, X-FEM, Eso.

Abstract: This study presents a new algorithm for structural topological optimization by combining the Extended

Finite Element Method (X-FEM) with an evolutionary optimization algorithm. Taking advantage of an

isoline design approach for boundary representation in a fixed grid domain, X-FEM can be implemented to

obtain more accurate results on the boundary during the optimization process. This approach can produce

topologies with clear and smooth boundaries without using a remeshing or a moving mesh algorithm. Also,

reanalysing the converged solutions in NASTRAN confirms the high accuracy of the proposed method.

1 INTRODUCTION

In recent years, structural optimization has become a

rapidly growing field of research with application in

many areas such as mechanical, civil and automotive

engineering. Topology optimization is one of the

most challenging aspects of structural optimization,

in which one needs to find the best topology as well

as shape of a design domain. The approaches which

have been proposed for the topology optimization of

continuous structures fall into two categories: first,

mathematical based methods such as

homogenization (Bendsøe and Kikuchi, 1988), Solid

Isotropic Material with Penalization (SIMP)

(Bendsøe, 1989); (Zhou and Rozvany, 1991) and

level set method (Wang et al., 2003); (Allaire et al.,

2004); second, heuristic methods which are more

intuitive and less mathematical, such as evolutionary

structural optimization ESO/BESO methods (Xie

and Steven 1993); (Querin et al., 1998); (Yang et al.,

1999).

ESO is based on the assumption that the optimal

layout of the design domain can be obtained by

gradually removing inefficient material from the

design domain (Huang and Xie, 2009). In the

original ESO method, the elements of the design

space are ranked in terms of their sensitivity, and

those with lower sensitivity are removed from the

design domain until a desired optimum is obtained.

Bi-directional evolutionary structural optimization

(BESO) is an extension of ESO in which the

elements are allowed to be added and removed

simultaneously. These heuristic methods are easy to

program and provide a clear topology (no grey

regions of intermediate densities as in SIMP) in the

resulting optimal designs. Conventional ESO/BESO

algorithms have been successful since they can be

easily combined with the finite element model of a

structure. However they suffer from a week

capability of boundary representation. In these

methods the geometrical information of the

boundaries is not clear during the optimization

process and the boundaries of the optimal solution

are represented by the jagged edges of the finite

elements. This limitation causes difficulties in

combining these methods with CAD and the

obtained solutions require post processing to

manufacture a smooth design.

The fixed grid finite element method (FG-FEM)

allows the boundaries of the design to cross over

finite elements. This capability has been used in

boundary based optimization methods such as the

level set method, and element based optimization

methods such as fixed grid evolutionary structural

optimization (FG-ESO) method. FG-ESO or Isoline/

Isosurface approach (Victoria et al, 2009; Victoria et

al, 2010) is an alternative to ESO in which the

inefficient material is allowed to be removed/added

within the elements of the design domain during an

evolutionary process. The boundaries are defined by

the intersection of Iso-line plane with the criteria

distribution of the design domain. Since in this

approach the boundary of the design is no longer

consistent with the fixed finite elements as in ESO, a

classical finite element analysis may result in poor

FE approximation on the boundary. Conventionally

466

Abdi M., Ashcroft I. and Wildman R..

X-FEM based Topological Optimization Method.

DOI: 10.5220/0004148404660471

In Proceedings of the 2nd International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SDDOM-2012), pages

466-471

ISBN: 978-989-8565-20-4

Copyright

c

2012 SCITEPRESS (Science and Technology Publications, Lda.)

in the fi

x

stiffness

of the s

o

the den

widely

a

(Allaire

have sh

o

for the

b

(Wei e

t

method

which c

a

FEM e

x

b

y add

i

represen

this app

r

often de

of the l

e

fixed m

e

recent l

e

(Wei et

a

This

evolutio

n

domain.

to the

p

ropose

d

framew

o

and the

represen

p

erform

a

topolog

y

solution

s

the accu

r

2 M

E

2.1

S

The to

p

objectiv

e

written

a

where c

the gl

o

matrices

finite el

e

of the

s

domain

fraction.

p

resenc

e

x

ed grid finit

e

is assumed

p

o

lid material

w

sity scheme)

a

ccepted and

et al., 2004);

o

wn that it c

b

oundary ele

m

t

al., 2010).

T

(X-FEM) is

a

n be used to

x

tends the cl

a

i

ng special

n

t a discontin

u

r

oach, the g

e

scribed by a

l

e

vel set descr

i

e

sh framewo

r

e

vel set base

d

a

l., 2010); (

M

study pres

e

n

ary optimiz

a

The novelty

o

evolutionary

d

method

d

o

rk for geom

e

boundaries

n

ted by isol

i

a

nce. The al

g

y

optimizatio

n

s

are reanalys

e

r

acy of the pr

o

E

THOD

O

S

tructural

O

p

ology opti

m

e

is to mini

m

a

s:

Minimize

:

Subject to:

is the total s

o

bal displac

e

, respectivel

y

e

ments in the

d

s

olid part o

f

volume an

d

While in

e

/absence of

e

element app

r

p

roportional t

o

w

ithin the el

e

. Although

implemente

d

(Victoria et

a

annot provid

e

m

ents (Dunn

i

T

he Extende

another fix

e

model void/s

o

a

ssical finite

e

shape funct

u

ity inside f

i

e

ometry of th

e

l

evel set met

h

i

ption of the

r

k of X-FEM

d

topology

o

M

iegroet et al.,

e

nts a simp

l

a

tion approac

o

f this work i

s

optimisatio

n

d

oesn't requ

i

e

try descripti

o

of the desig

n

i

nes of a

d

g

orithm is i

m

n

of two test

c

e

d with NAS

T

o

posed meth

o

O

LOGY

O

ptimizati

o

m

isation pro

b

m

ize the stra

i

:

=

∑

,

=

∗

train energy,

e

ment and

y

. N denote

s

d

esign domai

n

f

the elemen

d

∗

the p

r

ESO/BES

O

each eleme

n

r

oach, the ele

m

o

the area fra

c

e

ment (also c

a

this approac

h

d

in many

w

a

l., 2009), st

u

e

accurate re

s

i

ng et al., 2

0

d

finite ele

m

e

d grid appr

o

o

lid interface

s

e

lement appr

o

i

ons which

i

nite element

s

e

discontinui

t

h

od. Combin

a

g

eometry an

d

has been us

e

ptimization

w

2007).

l

e and effe

c

h

in a fixed

s

to apply X-

F

n

algorithm.

i

re a level

o

n in the X-

F

n

can be si

m

d

esired struc

t

m

plemented i

n

c

ases and the

f

T

RAN to eva

l

o

d.

o

n Proble

m

b

lem where

i

n energy ca

n

∗

and U and

K

global stif

f

s

the numbe

r

n

,

,

the vol

t

,

the d

e

r

escribed vol

O

methods,

n

t in the d

e

m

ent

c

tion

a

lled

h

is

w

orks

u

dies

s

ults

0

08);

m

ent

o

ach

s

. X-

o

ach

can

s

. In

t

y is

a

tion

d

the

e

d in

w

ork

c

tive

gri

d

F

EM

The

set

F

EM

m

ply

t

ural

n

the

f

inal

l

uate

m

the

n

be

(1)

(2)

K

are

f

ness

r

of

l

ume

e

sign

l

ume

the

e

sign

do

m

p

ro

p

eac

ou

r

as

dis

t

sol

i

lo

w

du

r

re

m

we

a

me

t

ca

n

wit

h

ele

m

XF

E

2.

2

(b)

(c)

Fig

u

con

d

inte

Fin

a

m

ain is consi

p

osed metho

d

h

element is

study, we ha

v

the criterion

t

ribution with

i

i

d material

w

w

SED region

s

ing the evo

l

m

oval of mate

a

k material p

r

t

hod). The st

r

n

be calculate

d

h

the ele

m

m

ent stiffnes

s

E

M scheme.

2

Isoline

T

(a)

u

re 1: a- I

n

d

itions. b-

S

rsection of cr

i

a

l solution sho

w

d

ered as a

d

d

the distribu

t

considered a

s

v

e used strai

n

for finding

i

n the design

d

w

ill be gradu

a

s

and added t

o

utiona

r

y pro

c

r

ial can be a

c

operty to low

r

ain energy d

d

fro

m

=

1

2

m

ent displace

m

matrix whic

h

T

opolo

gy

O

n

itial design

d

S

tructural bo

u

i

teria (SED) d

i

w

n in a fixed g

r

d

esign variab

l

u

tion of mate

r

s

a design v

a

n

energy dens

i

the efficient

domain. The

r

a

lly removed

o

the high SE

D

cedure. The

c

hieved by a

s

w

SED region

s

d

ensity of the

/

m

ent vector a

n

h

is calculate

d

O

ptimizati

o

d

omain with

u

ndary repre

s

d

istribution an

d

r

id domain.

l

e, in our

r

ial inside

a

riable. In

i

ty (SED)

material

r

efore, the

from the

D

regions

effective

s

signing a

(sof

t

-kill

elements

(3)

n

d

the

d

using an

o

n

boundary

s

ented by

d

MSL. c-

X-FEMbasedTopologicalOptimizationMethod

467

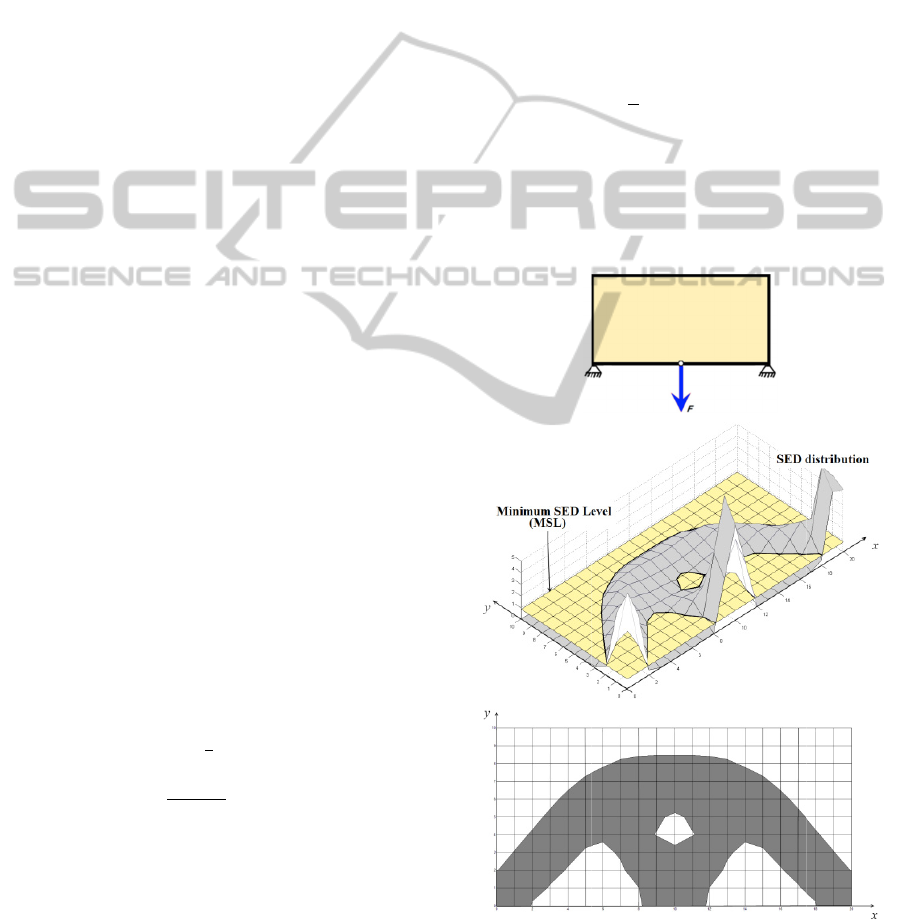

The basic idea of isoline design is to represent the

shape and topology of the structure using the

contours of desired structural behaviour. This idea

has been suggested in several studies (Maute and

Ramm, 1995); (Lee et al., 2007). The isoline

optimization algorithm that we use in this paper is

originated from the isoline topology design (ITD)

algorithm proposed by Victoria et al., 2009.

The ITD approach can be summarized into the

following steps:

1- An extended finite element analysis is performed

to find the distribution of strain energy density

within the design domain.

2- A minimum SED level (MSL) is determined and

the new structural boundary is obtained from

intersection of SED distribution and MSL.

3- The regions of the domain having the criteria

level less than MSL are not included in the design

domain. Therefore their material property is set to

the weak material. The regions where the criteria

level is more than MSL are inside the design domain

and their material property is set to the solid

material.

4- Steps 1-3 are repeated by gradually increasing

the MSL until a desired optimum is obtained.

2.2.1 Integration Scheme

In a conventional fixed grid approach, the stiffness

matrices of the boundary elements are approximated

by a density scheme in which the stiffness of an

element is proportional to the area ratio of the solid

part of the element. The material is considered to be

uniformly distributed through the whole element and

the variations in material distribution in an element

are not taken into account in calculating the element

stiffness matrix. For example, figure 2 shows three

different shapes for a boundary element where the

area fraction of solid material within the element is

0.50. Using density method the same stiffness is

calculated for all three elements. This issue may

cause errors near the boundary of the design during

the optimization process.

(a)

(b)

Figure 2: a- Typical boundary elements for area

ratio=0.50. b- Their density scheme equivalent solid

element with 50% density.

The extended finite element method (X-FEM) is

an alternative fixed grid approach proposed by Moës

et al in 1999. It was originally developed to

represent crack growth in a fixed grid domain

without meshing the internal boundaries. X-FEM

has also been implemented for other kinds of

discontinuities such as fluid structure interaction

(Gerstenberger and Wall 2008) and modelling holes

and inclusions (Sukumar et al 2001). In our case, the

X-FEM scheme for modelling holes and inclusions

can be implemented for modelling the boundary of

the design (weak/solid material interfaces) during

the optimization process. In this approach, the

displacement field is approximated by the following

equation:

=

(4)

where

are the classical shape functions associated

to degree of freedom

, and the Heaviside function

H(x) has the following properties:

=

1∈Ω

0∉Ω

(5)

where Ω

is the solid sub-domain. Since there is no

enrichment in the displacement approximation

equation of X-FEM in modelling holes and

inclusions, there will be no augmented degrees of

freedom during optimization. Equation 5 defines a

zero displacement field for the void part of the

element, which means that only the solid part of the

element contributes to the element stiffness matrix.

Thus we can use the same displacement function as

FEM and simply remove the integral in the void sub-

domain of the element.

=

Ω

Ω

(6)

with the displacement differentiation matrix,

the elasticity matrix for the solid material and t the

thickness of the element. When an element is cut by

the boundary, the remaining solid sub-domain is no

longer the reference rectangular element. So we

partition the solid part of the boundary element into

several sub-triangles (figure 3) and use Gauss

quadrature to calculate the integral given by

equation 6.

2.2.2 Combining X-FEM and the

Optimization Algorithm

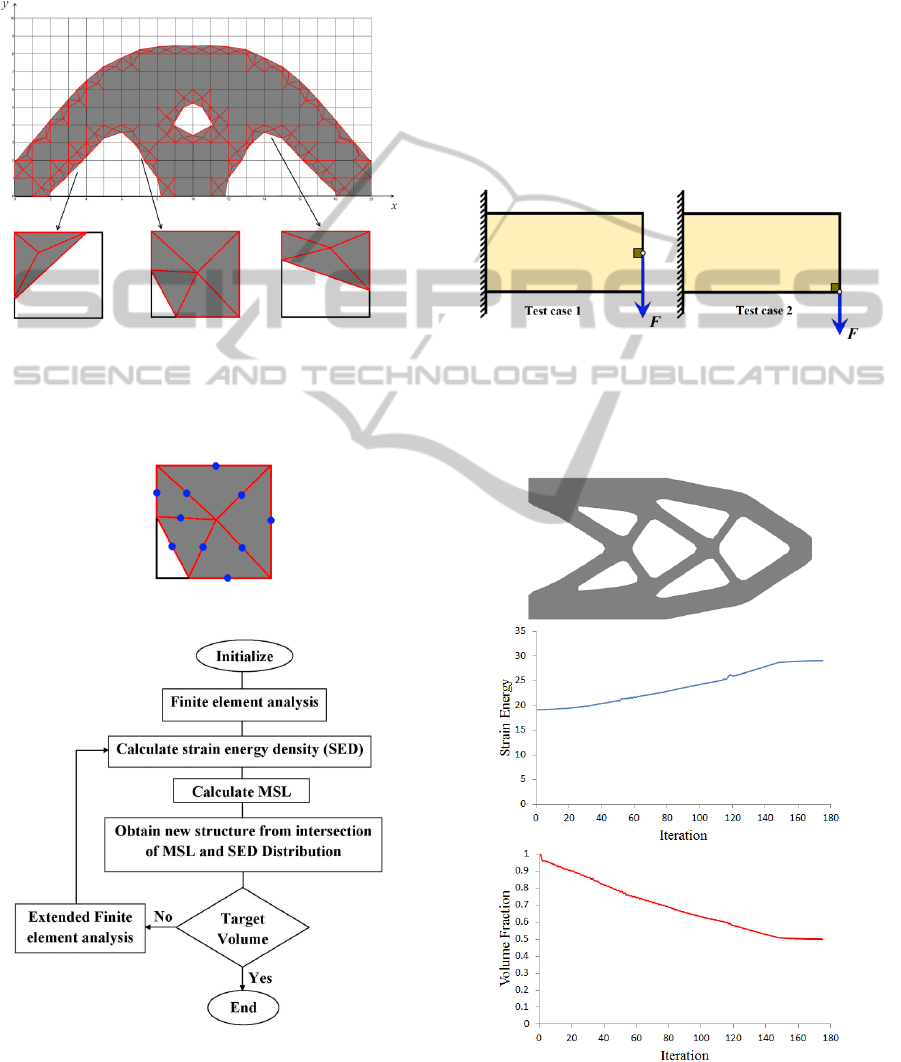

Figure 5 illustrates the topology optimization

procedure used which in general consists of

initialization, X-FEM structural analysis, and isoline

SIMULTECH2012-2ndInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

468

update scheme. In initialization, the initial material

distribution within the design domain and the

descretization of the design domain, as well as the

necessary parameters for the isoline topology design

are defined.

Figure 3: The solid sub-domain of the boundary elements

are partitioned into several sub-triangles.

In our study, the second order Gauss rule with 3

midline Gauss points was implemented (figure 4).

Figure 4: X-FEM integration scheme.

Figure 5: Flowchart of optimization algorithm.

In the X-FEM structural analysis, by using nodal

criteria numbers, the elements are categorized into

three groups: solid, void and boundary elements.

Solid and void elements are treated using classical

finite element approximation. The stiffness matrix of

the boundary elements are calculated by partitioning

the solid sob-domain into several sub-triangles and

applying the Gauss quadrature integration scheme

described in the previous section.

The minimum SED level (MSL) is calculated by

increasing the value from the last iteration. The new

structure is obtained from the intersection of the

MSL and current criteria distribution. The process is

continued until the target volume is achieved.

Figure 6: The two test cases.

3 TEST CASES

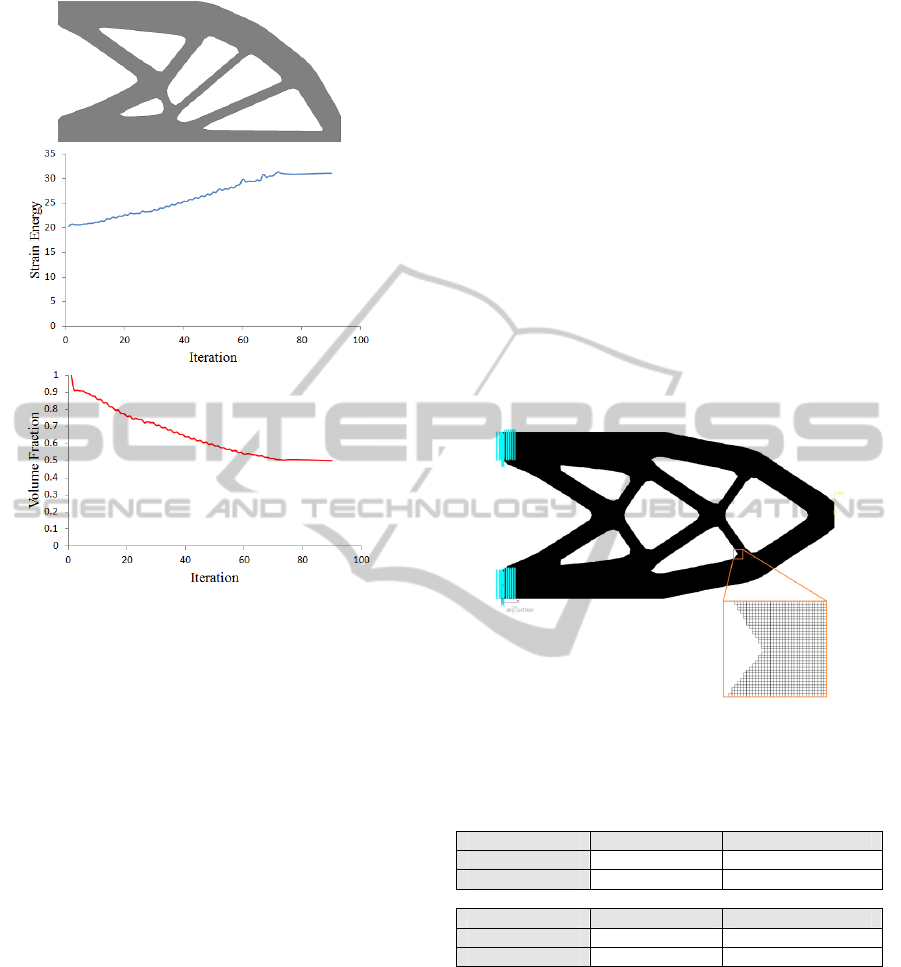

Figure 7: Optimized final design and iteration histories of

objective function and volume fraction for test case 1.

X-FEMbasedTopologicalOptimizationMethod

469

Figure 8: Optimized final design and iteration histories of

objective function and volume fraction for test case 2.

The proposed method of combining X-FEM and

evolutionary optimization algorithm was

implemented in a MATLAB code to present the

topology optimization of 2D rectangular domains.

Two test cases are used in this study (figure 6). First

a short cantilever beam having length 60, height 30

and thickness 1 where a unit concentrated load is

applied in the middle of the free end. The second test

case was a cantilever beam having the same

dimensions as test case 1 but with the load applied at

the bottom of the free end. A 60x30 mesh was used

for both cases to discretize the design domain. To

avoid singularity issues with the concentrated

loading, the loading region was treated as a non-

design domain.

The optimized final design, as well as the

iteration histories of the objective function and

volume fraction for the test cases 1and 2, are shown

in figures 7 and 8, respectively. It can be seen that

the strain energy increases, as material is gradually

removed from the design domain, then reaches a

constant value at convergence.

3.1 A Methodology for Evaluating

X-FEM Solutions

To evaluate the performance of the final solutions

and the accuracy of the proposed method, the

obtained solutions were discretized by a very fine

structured mesh and imported to NASTRAN to

perform a classical finite element analysis (figure 9).

Table 1 compares the X-FEM solutions and the

regenerated NASTRAN structures in terms of their

strain energies and tip displacements. It can be seen

that the X-FEM solutions are very close to the

regenerated NASTRAN solutions. The slight

difference in the X-FEM and NASTRAN results

may be attributed to the different mesh size used in

the two approaches.

Figure 9: XFEM solution discritized by a very fine mesh

and imported to NASTRAN.

Table 1: Comparison of X-FEM solutions and regenerated

NASTRAN structures.

Test case 1 Strain Energy Tip Displacement

X-FEM 29.04 54.00

NASTRAN 29.21 54.39

Test case 2 Strain Energy Tip Displacement

X-FEM 31.08 57.54

NASTRAN 31.24 57.85

4 CONCLUSIONS

In this study, X-FEM and Isoline design are

implemented for the topology optimization of 2D

continuum structures. By applying the proposed X-

FEM scheme there is no need to use the time

consuming remeshing and moving mesh approaches

to improve the FE solution. The generated structures

have smooth boundaries which need no further

interpretation and post-processing. The numerical

SIMULTECH2012-2ndInternationalConferenceonSimulationandModelingMethodologies,Technologiesand

Applications

470

examples presented in this paper show the accuracy

and efficiency of the proposed algorithm.

ACKNOWLEDGEMENTS

The authors are grateful for the funding provided by

Loughborough University.

REFERENCES

Allaire, G., Jouve, F., Toader, A. M., 2004. Structural

optimisation using sensitivity analysis and a level set

method, J. Comp. Phys., 194, pp. 363–393.

Bendsøe, M. P. 1989. Optimal shape design as a material

distribution problem. Struct. Optim. 1, pp. 193–202.

Bendsøe, M. P. and Kikuchi, N., 1988. Generating optimal

topologies in structural design using a homogenization

method. Computer Methods in Applied Mechanics and

Engineering, 71, pp. 197-224

Dunning, P., Kim, H. A. and Mullineux, G., 2008. Error

analysis of fixed grid formulation for boundary based

structural optimisation. In: 7th ASMO UK / ISSMO

conference on Engineering Design Optimisation, 7-8

July 2008, Bath, UK.

Gerstenberger, A., Wall. W. A., 2008. An eXtended finite

element method/Lagrange multiplier based approach

for fluid-structure interaction. Computer Methods in

Applied Mechanics and Engineering, 197, pp.1699-

714.

Huang, X., Xie, Y. M., 2009. Evolutionary Topology

Optimisation of Continuum Structures, Wiley.

Lee, D., Park, S., Shin, S., 2007. Node-wise topological

shape optimum design for structural reinforced

modeling of Michell-type concrete deep beams. J

Solid Mech Mater Eng, 1(9), pp. 1085–96.

Maute, K., Ramm, E., 1995. Adaptive topology

optimisation. Struct Optim, 10, pp. 100–12.

Miegroet, L. V., Duysinx, P., 2007. Stress concentration

minimization of 2D filets using X-FEM and level set

description. Structural and Multidisciplinary

Optimisation, 33, pp. 425-38.

Querin, O. M., Steven, G. P. and Xie, Y. M., 1988.

Evolutionary structural optimisation (ESO) using a

bidirectional algorithm. Engineering Computations, 15

( 8), pp. 1031-1048.

Moës, N., Dolbow, J. and Belytschko, T., 1999. A finite

element method for crack growth without remeshing,

International Journal for Numerical Methods in

Engineering. 46, pp. 131–150.

Sigmund, O., 2001. A 99 line topology optimisation code

written in Matlab. Struct Multidiscipl Optim, 21, pp.

120–127.

Sukumar, N., Chopp, D. L., Moës, N. and Belytschko, T.,

2001. Modeling Holes and Inclusions by Level Sets in

the Extended Finite Element Method. Computer

Methods in Applied Mechanics and Engineering, 190,

pp. 6183–6200.

Victoria, M., Martı´, P., Querin, O. M., 2009. Topology

design of two-dimensional continuum structures using

isolines. Computer and Structures, 87, pp.101–109.

Victoria, M., Querin, O. M., Mart

ı´, P., 2010. Topology

design for multiple loading conditions of continuum

structures using isolines and isosurfaces. Finite

Elements in Analysis and Design, 46 , pp. 229–237.

Wang, M. Y., Wang, X., Guo, D., 2003. A level set

method for structural topology optimisation. Comput.

Meth .Appl. Eng., 192, pp.227-46.

Wei, P., Wang, M.Y., Xing, X., 2010. A study on X-FEM

in continuum structural optimization using level set

method. Computer-Aided Design, 42, pp. 708-719.

Xie, Y. M. and Steven, G. P., 1993. A simple evolutionary

procedure for structural optimization. Computers &

Structures, 49, pp. 885-896.

Yang, X. Y., Xie, Y. M., Steven, G. P., and Querin, O. M.,

1999. Bidirectional evolutionary method for stiffness

optimisation. AIAA J., 37(11), pp.1483–1488.

Zhou, M., Rozvany, G. I. N., 1991. The COG algorithm,

Part II: Topological, geometrical and general shape

optimisation. Comp. Meth. Appl. Mech. Eng., 89, pp.

309-336.

X-FEMbasedTopologicalOptimizationMethod

471