A Roadmap to Implement a Quality Management System

Derek Flood, Fergal Mc Caffery and Valentine Casey

Dundalk Institute of Technology, Dublin Rd, Dundalk, Ireland

Keywords: Medical Devices, Software Process Improvement, Roadmaps, Quality Management System.

Abstract: In recent years the proportion and complexity of software in medical devices has increased considerably.

This has presented an opportunity for software development organisations to expand into the medical device

domain. Due to the high level of risk associated with medical devices, strict regulations must be adhered to

in order to market such products. One key aspect of these regulations is the necessity to have in place a

Quality Management System to help ensure an organisations’ ability to consistently meet customer and

regulatory requirements. This paper presents a roadmap which can be used to assist organisations, wishing

to develop medical device software to implement a Quality Management System.

1 INTRODUCTION

Advancements in technology have allowed medical

practitioners to provide a higher level of care to

patients and offer a wider range of treatment options.

However, when technology is used there is a risk to

the patient if that device should fail. To offset these

risks organisations must comply with the regulatory

requirements of the country where the device is to be

sold (Burton et al., 2006).

Software is becoming a more pivotal component

of medical devices due to its flexibility and its

ability to allow complex changes to be made,

without the need for hardware changes (Lee et al.,

2006), resulting in increased medical device

software complexity (Rakitin, 2006). In addition

software can now in its own right also be considered

a medical device (Mc Hugh et al., 2011). Therefore

software development organisations are subjected to

the same regulatory requirements as other medical

device organisations.

Software organisations now have an opportunity

to expand into the medical domain. These

organisations however must develop more stringent

processes in order to meet regulatory compliance. A

significant difficulty for such organisations is that

there is no prescribed method for performing

regulatory compliant software development

activities (McCaffery et al., 2010). Regulatory

bodies instead provide guidance documents

outlining what activities should be performed

(McCaffery et al., 2010).

To help address this shortfall this paper details a

software development process roadmap which can

be used to guide organisations through the

implementation of a Quality Management System

(QMS) which is compliant with the ISO 13485 (ISO,

2003) standard. The roadmap presented here has

been developed using the specific practices defined

in the Medi SPICE process assessment model, which

is designed to assess an organisations ability to

develop medical device software.

This paper is structured as follows. Section 2

introduces the Medi SPICE (McCaffery et al., 2010)

framework. Section 3 Introduces ISO 13485 and

details a roadmap for implementing a QMS, while

Section 4 outlines how the roadmap will be

validated. Section 5 details some of the limitations

of the roadmap and how these will be addressed in

the future. Conclusions are provided in Section 6.

2 MEDI SPICE

As regulatory bodies only detail what activities must

be performed, medical device organizations have

been compliance centric in their approach to

software development. As a result there has been

very limited adoption of software process

improvement within the medical device domain

(Denger et al., 2007).

Existing generic Software Process Improvement

(SPI) models, such as the Capability Maturity Model

Integration (CMMI

®

) (CMMI Product Team, 2006)

133

Flood D., Mc Caffery F. and Casey V..

A Roadmap to Implement a Quality Management System.

DOI: 10.5220/0004183601330138

In Proceedings of the International Conference on Health Informatics (HEALTHINF-2013), pages 133-138

ISBN: 978-989-8565-37-2

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

and ISO 15504-5:2012 (ISO/IEC 15504-5:2012,

2012) (SPICE), do not provide sufficient coverage to

achieve medical device regulatory compliance

(McCaffery and Dorling, 2010). To address this

issue a medical device specific SPI framework, titled

Medi SPICE, has been developed.

The objective of undertaking a Medi SPICE

assessment is to determine the state of a medical

device organisation’s software processes and

practices. This is in relation to the regulatory

requirements of the industry and best practice with

the goal of identifying areas for undertaking process

improvement (McCaffery and Dorling, 2010). It can

also be used as part of the supplier selection process

when an organisation wishes to outsource or

offshore part or all of their medical device software

development to a third party or remote division

(Casey, 2010).

Medi SPICE is based upon the latest version of

ISO/IEC 15504-5:2012 and ISO/IEC 12207:2008

(ISO/IEC, 2008). It is being developed in line with

the requirements of ISO/IEC 15504-2:2003

(ISO/IEC, 2003) and contains a Process Reference

Model (PRM) and Process Assessment Model

(PAM). It also incorporates the requirements of the

relevant medical device regulations, standards,

technical reports and guidance documents.

The Medi SPICE PRM consists of 44 processes

and 15 subprocesses which are fundamental to the

development of regulatory compliant medical device

software. Each process has a clearly defined purpose

and outcomes that must be accomplished to achieve

that purpose.

Medi SPICE also contains a PAM which is

related to the PRM and forms the basis for collecting

evidence that may be used to provide a rating of

process capability. This is achieved by the provision

of a two-dimensional view of process capability. In

one dimension, it describes a set of process specific

practices that allow the achievement of the process

outcomes and purpose defined in the PRM; this is

termed the process dimension. In the second

dimension, the PAM describes capabilities that

relate to the process capability levels and process

attributes, this is termed the capability dimension.

3 QMS ROADMAP

The ISO 13485 – Medical devices - Quality

management systems – Requirements for regulatory

purposes, is an international standard defining the

requirements for the implementation of a QMS to be

used for the development of medical devices. The

standard not only covers software but also

incorporates hardware and related activities such as

production and servicing.

The main focus of the QMS is to help insure that

high quality processes are implemented and

monitored. The standard places a strong emphasis on

ensuring the organisation is committed to the quality

of their products, through effective process

management and a commitment to quality from all

levels of the organisation from top management

down.

To assist organisations to implement a QMS, a

roadmap has been developed. The roadmap is

divided into three phases. The first phase is project

planning and should occur at the start of a medical

device software development project.

The second phase is the system development

phase. During this phase the product is built using

the system development lifecycle.

The final phase is on-going and irregular

activities. The phase contains a number of practices

that should be performed during the development of

the product however; they do not fall under

individual stages of the software development

lifecycle. As these do not follow a strict sequence

they are not included as numbered steps.

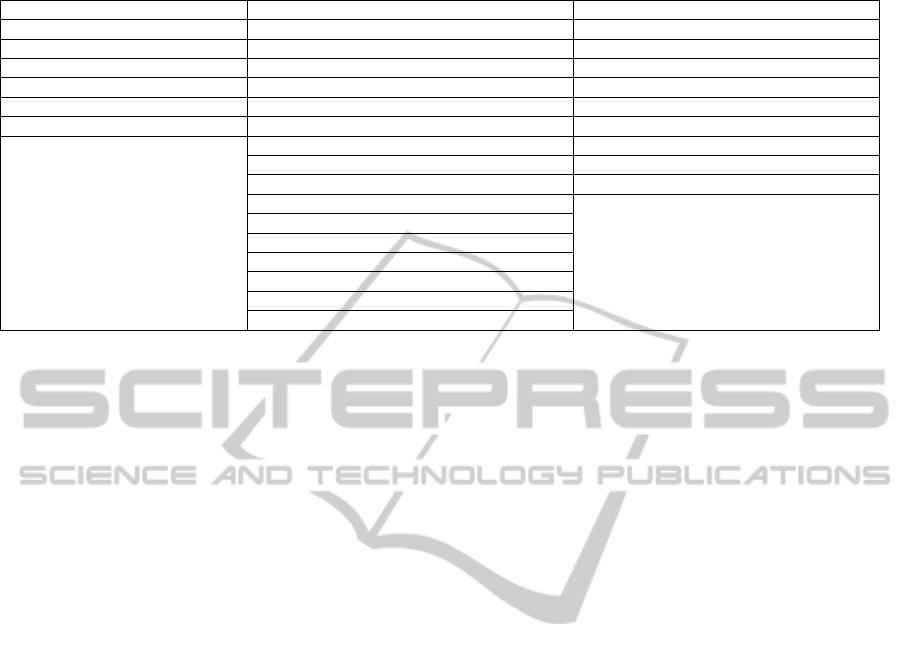

Table 1 outlines the steps included within each

phase of the roadmap. The planning phase contains 6

steps, the systems development phase contains 16

steps and the on-going and event driven phase

contains 9 steps.

3.1 Project Planning Phase

The first section of the roadmap should be

performed prior to the development of the medical

device. During this phase the organisation will

establish the product scope and the procedures to be

used during the development of the medical device.

Step 1: Appoint a Quality Manager. The first step

in implementing a QMS is to assign a member of the

management team responsibility for overseeing and

reporting on the QMS, and promoting the awareness

of regulatory and customer requirements throughout

the organisation.

Step 2: Define Quality Objectives and Policy. The

quality objectives and policy outline the

organisations commitment to quality and guide the

processes used to ensure product quality. At this

stage the organisation’s quality manual

incorporating the scope of the QMS, and details and

justification for any exclusion and/or non-

application, is established.

HEALTHINF2013-InternationalConferenceonHealthInformatics

134

Table 1: Steps in the QMS roadmap.

Planning Phase Systems Development Phase On-going and Irregular Activities Phase

Appoint a quality manager Gather customer requirements Risk analysis

Define quality objectives Assign resources Document management

Establish product scope Analyse system requirements Software configuration management

Establish SDLC Design the system architecture Quality assurance

High level planning Software development Validation and verification

Low level planning Software requirements analysis Software review and audit

Software architectural design Problem resolution

Detail the software design Change request management

Software construction Acquisition

Software integration

Software qualification testing

Software installation

System integration

System qualification testing

Delivery

Customer support

Step 3: Establish the Product Scope. This step

involves the definition of the customer requirements

and an internal analysis of the organisations ability

to meet these. In addition to this a communications

interface should be established to ensure effective

communication between the customer and the

organisation.

Step 4: Establish the Software Development

Lifecycle (SDLC) for the Project. During this step

the organisation should define the software

development lifecycle that should be used during the

development of the product. This should include all

processes necessary for the QMS and the sequence

and interaction between these processes.

Step 5: High Level Planning. The next step is to

define the high level processes necessary for the

development of the product. For example,

development of a document management strategy.

Step 6: Low-level Planning. While high-level

processes define the overall strategy to be employed,

the low-level processes are focused on particular

areas or provide more detailed instructions to meet

the overall strategy.

3.2 System Development Phase

After the planning phase has been completed, the

organisation will begin to develop the medical

device. These steps follow the order of the software

development lifecycle and can be implemented in

the presented order.

Step 7: Gather Customer Requirements. The first

step of this phase is to determine the customer

requirements for the project. As part of this stage,

risk analysis should be performed and documented.

Step 8: Assign Resources. When the customer

requirements have been defined and understood top

management should ensure that adequate resources,

in terms of personnel and infrastructure, are in place

and documented.

Step 9: Analyse System Requirements. In this

step, non-functional requirements, potential risks

and performance expectations are identified. The

process, and consistency with customer

requirements, should be documented and

maintained.

Step 10: Design the System Architecture. If

external software components are to be used an

appropriate acquisition strategy should be in place.

The system architecture design should be consistent

with the system requirements and the process used

should be adequately documented.

Step 11: Software Development. The software

implementation process to be used during the project

should be documented and maintained. If any

deviation from this process is encountered the

relevant documentation should be updated.

Step 12: Software Requirements Analysis. The

requirements of the software component of a

medical device are analysed in the context of the

complete system and its operating environment.

Traceability and adequate testing should be ensured.

Risk control measures should be implemented and

any modifications to the system requirements should

be documented.

Step 13: Software Architectural Design. As part of

the QMS, it is necessary to ensure that the

architectural design is consistent with the system and

software requirements.

Step 14: Detail the Software Design. A detailed

software design document should be produced. This

shall be consistent with the system architecture. The

ARoadmaptoImplementaQualityManagementSystem

135

process used should be adequately documented.

Step 15: Software Construction. The software

units defined in the software design document

should be constructed. Detailed documentation,

including traceability, should be maintained as

required by the configuration management strategy.

Step 16: Software Integration. The software units

should be integrated into the complete software

system. The integrated system should be tested

independently from the testing of individual

components. The results from this testing, as well as

the strategy for integration and testing should be

documented and maintained.

Step 17: Software Qualification Testing. In this

step the integrated software system is tested. User

documentation should be updated as necessary. A

fundamental component of this stage is to ensure

that a regression test strategy is developed and

carried out. All processes used and results obtained

should be documented and maintained.

Step 18: Software Installation. Documented

procedures, including verification and acceptance

criteria, should be established as part of the QMS.

This documentation should be made available to

other agents who have been authorised by the

customer to perform installation activities.

Step 19: System Integration. The next step is to

integrate the software with the overall system. Each

component of the system should be independently

verified to ensure that they meet the system

requirements. The results of such verification and

the process used should be documented. Traceability

should be ensured.

Step 20: System Qualification Testing. As part of

the system qualification testing phase, a QMS

should ensure that the system tests can be traced

back to system requirements. The process used

should be documented and maintained.

Step 21: Delivery. The QMS requires that the

organisation should ensure that delivery conditions,

in accordance with the supply agreement, are met.

Step 22: Customer Support. The QMS should

ensure that the organisation monitors the operational

use and ensure that adequate support is available to

the customer. The organisation should also collect

and retain customer satisfaction data relating to both

the product and the customer service.

3.3 On-going and Irregular Activities

Phase

During the development process a number of

activities are performed at regular intervals or when

specific events occur. The schedule for these

activities should be defined during the planning

phase; however, the execution of these activities can

occur at any time.

Risk Analysis. At all stages of the product

development, the organisation should ensure that

adequate risk management activities are performed.

The level of risk analysis is dependent upon the class

of device that is being developed.

Document Management. Throughout the entire

development process a consistent document

management process should be in place. Each

document should be checked before distribution,

ensuring they are available where needed.

Software Configuration Management. During the

lifetime of the project, configuration items should be

maintained and accessible at the point of use. The

QMS should ensure that each configuration item is

uniquely identified and that a description of each

item is maintained.

Quality Assurance. The QMS dictates that regular

assessments should be performed in terms of both

the processes used during the development of the

product and the product itself. Through processes

assessment activities the organisation should

perform process improvement activities when

possible.

The organisation should also periodically assess the

achievement of the quality objectives and monitor

the performance of the QMS. When a deviation from

the quality objective is found, the organisation

should strive to take action as quickly as possible to

ensure that the quality of the product is not

negatively affected.

Part of the assessment and improvement

initiatives should be commitment from all relevant

departments within the organisation. This will

ensure assessment activities will not interfere with

the main functions of the organisational units under

assessment. The results of the assessment and any

process improvement activities that will take place

should be communicated to all stakeholders.

Validation and Verification. At regular intervals

the organisation should perform validation and

verification activities to ensure that the product is

correct and meets project requirements and quality

standards. The results of these activities should be

recorded and any problems identified should be

entered into a software problem resolution process.

The results of such activities should be

communicated to all relevant stakeholders.

Software Review and Audit. At regular intervals

the organisation shall prepare and conduct a

HEALTHINF2013-InternationalConferenceonHealthInformatics

136

software review and audit. If a product is found to be

non-conforming then the organisation should take

appropriate action either by removing the non-

conformities or by authorising its release under

concession. If the product is released under

concession, the organisation should ensure that it

still meets all regulatory requirements. The nature of

the non-conformity and the identity of the person(s)

authorising the concession should be documented.

Problem Resolution. The organisation should

ensure that any problem identified is recorded and

the root cause of the problem is diagnosed. The

organisation should have procedures in place to alert

users of the problem pending a fix or a change. A

solution for the problem should then be found and

implemented while tracking the status of the issue

until it is resolved. If no action is taken as a result of

a problem being identified, the organisation should

justify and record why no action has been taken. The

organisation shall maintain records of all customer

complaints.

Change Request Management. A documented

procedure should be in place to address change

requests. This procedure should ensure that an audit

trail is in place enabling traceability. Prior to the

implementation the organisation should assess the

impact of the change request on both the existing

system and other change requests. Additionally the

risks associated with the change request should be

analysed.

Upon implementation of the change request, the

organisation should perform all necessary

verification and validation activities. All

configuration items should be updated if impacted

by the change.

Acquisition. In the event the organisation shall

incorporate external software units in the product,

the organisation should ensure that an appropriate

acquisition process is followed. This process should

encompass a process for supplier tendering and

selection, acquisition of the product, acceptance

criteria and testing and a means for managing

changes and resolving issues with the supplier.

4 VA L I D AT I O N

Two aspects, order and completeness, of the

roadmap presented above will be validated. Order

refers to the placement of the practices in each step.

It will be necessary to ensure that all practices that

are depended upon are in place before an

organisation tries to implement any new practices.

The completeness of the roadmap refers to its ability

to cover the requirements of the ISO 13485 standard.

The order of the implementation steps will be

validated using the Medi SPICE dependency graphs

(Flood et al., 2012). The practices in each step will

be validated to ensure that all dependant practices of

each step are performed in the same or preceding

steps. If a practice is found to be performed in the

same step of the roadmap the organisation will be

alerted and instructed to perform this practice before

any dependant ones.

In order to validate the completeness of the

roadmap a number of qualified ISO 13485 assessors

will be asked to review it. A semi-structured

interview will then be conducted with the assessor.

5 LIMITATIONS AND FUTURE

WORK

The roadmap presented here is based on ISO 13485.

In the US the FDA produce a similar regulation,

FDA Regulation 21 CFR 820 (FDA, 2007), for

organisations wishing to distribute medical devices

within the US. Although both documents provide

similar guidance additional practices may be

required for medical device organisations wishing to

operate within the US. However, it should be noted

that the FDA are currently implementing a pilot

programme to accept a QMS that is compliant with

ISO 13485.

The next step of this work will be to perform a

similar analysis of the FDA Regulation 21 CFR 820.

The relevant best practices will be identified and any

additional requirements identified will be

incorporated into the existing roadmap to produce a

roadmap for organisations wishing to distribute

medical devices in Europe and the US.

The roadmap presented above allows an

organisation to create a QMS, assuming they have

no existing processes in place. In the case of

software development organisations wishing to enter

the medical device domain, some existing processes

may be in place and the roadmap will need to be

tailored for these organisations.

In addition to this there are some steps that may

not need to be performed, depending on the

circumstances of the organisation or product.

To address these issues an assessment method

that can be used to determine the organisations

existing processes and their specific requirements

will be developed.

ARoadmaptoImplementaQualityManagementSystem

137

6 CONCLUSIONS

This paper presents a software process roadmap for

the implementation of a QMS for organisations

operating within the medical device domain. In

order for medical device products to be sold, they

must be approved by the relevant regulatory body

within the region the device is to be sold, such as the

FDA in the US. The regulations set forth by these

organisations require that a QMS is in place during

the development and distribution of medical devices.

To assist organisations wishing to develop

medical devices, this paper details a software

process roadmap for implementing a QMS. This

roadmap is based on the ISO 13485, an International

standard detailing the requirements of a QMS for

organisations in the medical device domain, and the

base practices defined in the Medi-SPICE PAM.

ACKNOWLEDGEMENTS

This research is supported by the Science

Foundation Ireland (SFI) Stokes Lectureship

Programme, grant number 07/SK/I1299, the SFI

Principal Investigator Programme, grant number

08/IN.1/I2030 (the funding of this project was

awarded by Science Foundation Ireland under a co-

funding initiative by the Irish Government and

European Regional Development Fund), and

supported in part by Lero - the Irish Software

Engineering Research Centre (http://www.lero.ie)

grant 10/CE/I1855

REFERENCES

Burton, J., McCaffery, F., and Richardson, I., A risk

management capability model for use in medical

device companies. in International Workshop on

Software quality (WoSQ '06). 2006. Shanghai, China:

ACM.

Casey, V. (2010) Virtual Software Team Project

Management. Journal of the Brazilian Computer

Society, 16, 83 – 96.

CMMI Product Team (2006) Capability Maturity Model®

Integration for Development Version 1.2. Software

Engineering Institute, Pittsburch PA.

Denger, C., Feldmann, R., Host, M., Lindholm, C. &

Shull, F. (2007) A Snapshot of the State of Practice in

Software Development for Medical Devices. First

International Symposium on Empirical Software

Engineering and Measurement. Madrid, Spain.

FDA 2007. Title 21-Food and Drugs Chapter I --Food and

Drug Administration Department of Health and

Human Services subchapter h--Medical Devices part

820 Quality System Regulation. U.S. Department of

Health and Human Services.

Flood D., Mc Caffery, F., Casey, V., (2012)

“Understanding the Relationships Within the Medi

SPICE Framework”, The Seventh International

Conference on Software Engineering Advances

(ICSEA 2012).

ISO 13485:2003 (2003) Medical devices — Quality

management systems — Requirements for regulatory

purposes. Second ed. Geneva, Switzerland, ISO.

ISO/IEC 12207:2008 (2008) Systems and software

engineering - Software life cycle processes. Geneva,

Switzerland, ISO.

ISO/IEC 15504-2 (2003) - Software engineering —

Process assessment — Part 2: Performing an

assessment. 2003: Geneva, Switzerland.

ISO/IEC 15504-5:2012 (2012) Information technology -

Process Assessment - Part 5: An Exemplar Process

Assessment Model. Geneva, Switzerland, ISO.

Lee, I., Pappas, G., Cleaveland, R., Hatcliff, J., Krogh, B.,

Lee, P., Rubin, H. and Sha, L., High-Confidence

Medical Device Software And Systems. Computer,

2006. 39(4): p. 33 - 38.

McCaffery, F., Dorling, A. and Casey, V., (2010) Medi

SPICE: An Update. in International Conference on

Software Process Improvement and Capability

Determinations (SPICE). 2010. Pisa, Italy: Edizioni

ETS.

McCaffery, F. and Dorling, A., (2010) Medi SPICE

Development. Software Process Maintenance and

Evolution: Improvement and Practice Journal, 22, 255

– 268.

Mc Hugh, M., McCaffery, F. & Casey, V. 2011.

Standalone Software as an Active Medical Device In:

O'CONNOR ET AL (ed.) The 11th International

SPICE Conference Process Improvement and

Capability dEtermination. Dublin: Springer.

Rakitin, R., Coping with defective software in medical

devices. Computer, 2006. 39 (4): p. 40 - 45.

HEALTHINF2013-InternationalConferenceonHealthInformatics

138