Towards a Dynamic Tibial Component for Postoperative

Fine-tuning Adjustment of Knee Ligament Imbalance

Andrea Collo

1,2,3

, Shaban Almouahed

1,2

, Chafiaa Hamitouche

1,2

, Philippe Poignet

3

and Eric Stindel

2,4

1

Institut Mines-Télécom, Télécom Bretagne, Brest, France

2

Laboratoire de Traitement de l'Information Médicale, LaTIM INSERM UMR 1101, Brest, France

3

Laboratoire d'Informatique, de Robotique et de Microélectronique de Montpellier,

LIRMM UMR 5506 CNRS UM2, Montpellier, France

4

Centre Hospitalier Universitaire de Brest, CHU Brest - Service d'Orthopédie et de Traumatologie, Brest, France

Keywords: Instrumented Tibial Component, Adaptive Knee Prosthesis, Knee Ligament Imbalance.

Abstract: During TKA surgery, a correct tibiofemoral alignment of the installed prosthesis can be effectively achieved

by means of Computer-Assisted techniques. Unfortunately, the achievement of perfect ligament balance

conditions still remains as unsolved problem. Any inaccuracy during the operation may degenerate and lead

to prosthesis failure. Our aim is to develop an adaptive knee prosthesis, able to follow the physiological

evolution of the body and, potentially, to modify its shape to fit the patient's morphological changes. In this

paper, we focus on the actuation of the tibial component in order to compensate for collateral ligament

imbalances. We face with severe constraints concerning the available volume, the high-accuracy level and

system's solidity and biocompatibility. We discuss a model that we proposed in a previous work and we

highlight its drawbacks. We consider then three possible approaches to realise the actuation: the use of a

micromotor, the action of a magnetic field and the use of an external tool. After evaluating the pros and cons

of each case, the micromotor approach is selected. We conclude by introducing an original design of

adaptive tibial implant that we are currently developing.

1 INTRODUCTION

Total Knee Arthroplasty (TKA) consists in the

complete replacement of the knee joint by means of

a prosthesis. This operation is quite risky and

complicated, since the surgeon must be able to

restore the perfect mobility of the knee joint while

ensuring, at the same time, a long-lasting stability of

the installed implant. The outcome of TKA surgery

is thus greatly dependent on the surgeon's experience

and perception (Scuderi and Tria, 2006).

The two key achievements of TKA surgery are

the correct alignment of the prosthesis with respect

to the mechanical axis of the lower limb and the set

up of a proper tension for medial and lateral

ligaments (Vail and Lang, 2006). While a correct

tibiofemoral alignment can be effectively achieved

by means of Computer-Assisted Orthopaedic

Surgery (CAOS) techniques, the inaccuracy in

ligament balance still remains as unsolved problem

(Winemaker, 2002).

Concerning medial and lateral ligaments, the

tensioning conditions that are set up during the

surgery will not fit the predictable changes in

patient's weight, physiology and lifestyle. Thus,

throughout the first decade after the intervention,

knee balance conditions could become suboptimal,

leading to postoperative complications.

In this context, even the slightest inaccuracy in

the bone cutting process during the surgery may be

amplified and create serious complications, such as

component loosening and polyethylene early wear

(Almouahed, 2011). Undesired distances between

the prosthetic components can be generated and

collateral ligament tension values might change in

an uncontrolled way. As a consequence, the lifespan

of the installed implant risks being considerably

reduced and the patient may start suffering severe

pain already a few years after the surgery. In such a

case, the only solution is represented by revision

surgery. The patient undergoes a second operation

during which the prosthesis that has become

suboptimal is replaced by another one.

If primary TKA is a very complex operation,

revision surgery is even more delicate. The

95

Collo A., Almouahed S., Poignet P., Hamitouche C. and Stindel E..

Towards a Dynamic Tibial Component for Postoperative Fine-tuning Adjustment of Knee Ligament Imbalance.

DOI: 10.5220/0004189000950102

In Proceedings of the International Conference on Biomedical Electronics and Devices (BIODEVICES-2013), pages 95-102

ISBN: 978-989-8565-34-1

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

prosthetic knee articulation undergoing a

postoperative complication is less strong than before

and the second rehabilitation period is normally

more stressful than the first one. The development of

an autoadaptive knee prosthesis, able to follow the

physiological evolution of the body and, potentially,

to modify its shape to fit the patient's morphological

changes would represent a great innovation in the

field of orthopaedic surgery.

Our project falls within this framework. Our

objective is to develop an instrumented tibial

component to be employed in both the intraoperative

and postoperative periods. It is meant to be able to

check knee balance conditions immediately after the

rehabilitation stage and correct potential ligament

imbalances. In this sense, the active implant we are

developing necessarily embeds custom-designed

mechatronical components and a telemetry system,

in order to interact with the surgeon via a computer

interface.

The main constraints we face with are of

different nature. First, considering the small

dimensions of prosthetic parts, we need very

compact components. Secondly, the entire system

needs to be really robust, in order to face with the

whole set of efforts acting on the knee joint. Thirdly,

we must choose the optimal power supply and

control techniques in order to ensure a high accuracy

level. All these considerations have to be made by

keeping the biocompatibility issue as a basic

criterion for the selection of proper components.

1.1 State of the Art

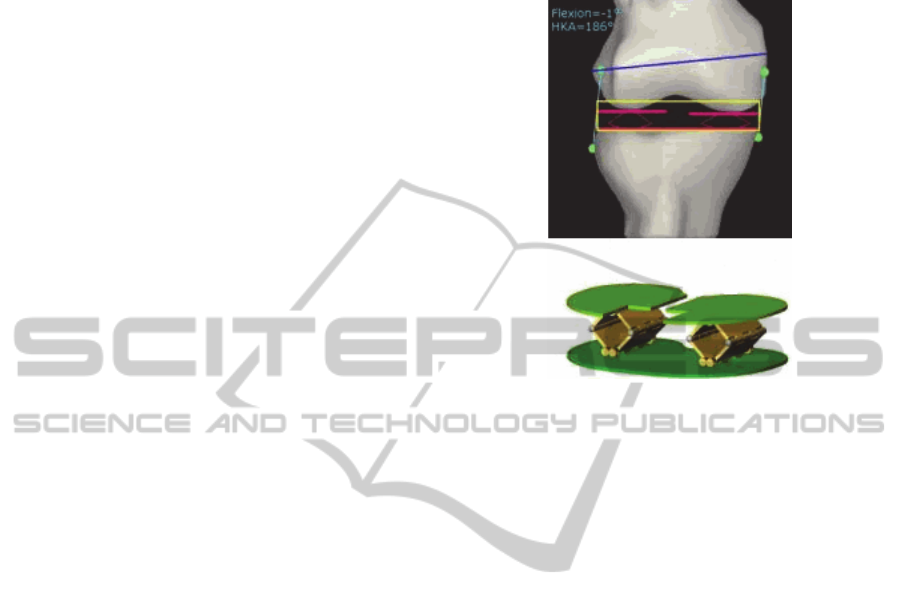

Marmignon et al., (2004) proposed two models of

instrumented knee distractor for intraoperative use.

The first one consisted of a tibial baseplate and two

separated femoral plates. Two scissor jack

mechanisms, each one controlling the position of a

single femoral plate, allowed to raise or lower the

two moving trays independently, by keeping them

parallel to the surface of the tibial baseplate (Figure

1). The upper surfaces of the two femoral

components, in contact with the femoral condyles,

were equipped with force-sensing resistances and

height sensors. By making use of a navigation

system, tibiofemoral gaps, ligament lengths and

distraction forces could be intraoperatively measured

and monitored with high accuracy.

The device's overall thickness measured 6.1 mm

and it could provide a remarkable distraction range

of 15 mm. A great weakness of this distractor was

the maximum overall distracting force that could be

produced, only 100 N. This value, too far from the

normal operating conditions of the knee joint (ISO

14243-3, 2004), led to the proposal of an alternative

design.

Figure 1: Example of use of the knee distractor

instrumented with two scissor jack mechanisms

(Marmignon et al., 2004).

The scissor jack mechanisms were thus replaced

with two rubber bladders (Marmignon et al., 2005),

to be inflated with a fluid (air or physiological

serum). The volume changes induced by the fluid

were manually controlled and led to the

displacement of the femoral plates with respect to

the tibial baseplate. This design offered better

performances, since each femoral plate could

develop a force of 100 N. Unfortunately, the

distraction range was reduced to 11 mm and the

parallelism of the system was no longer guaranteed,

leading to suboptimal working conditions.

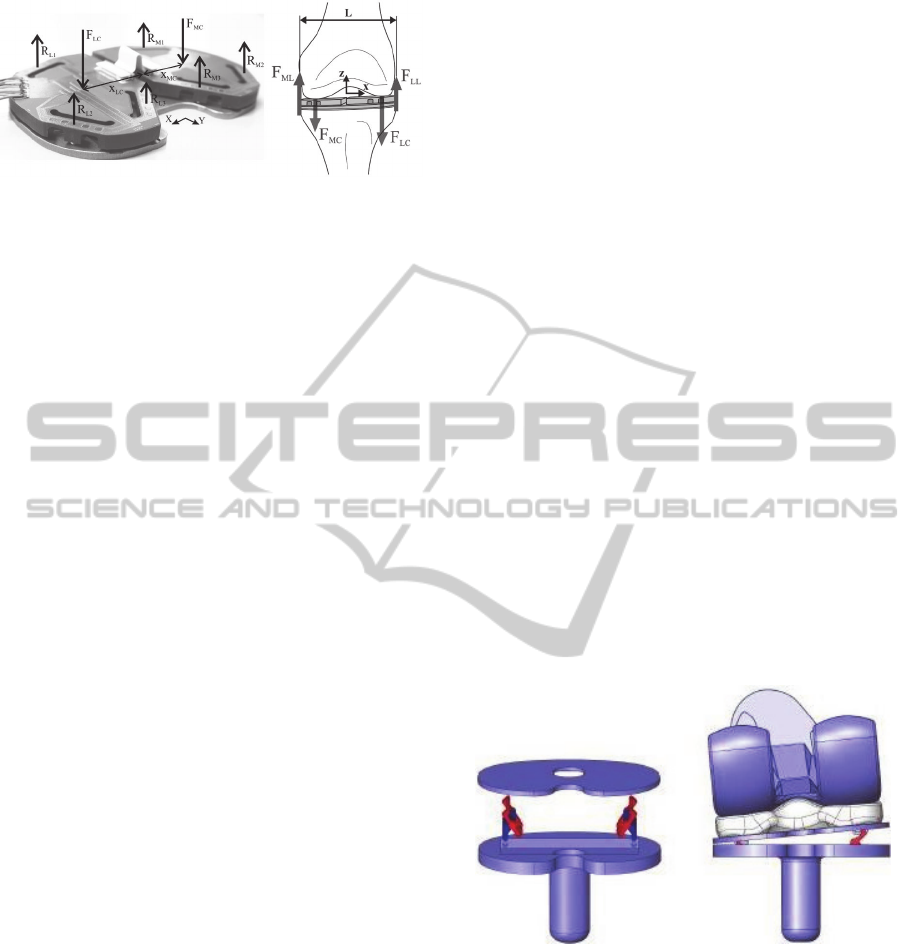

Crottet et al. (2005) proposed a small force-

sensing device to estimate knee ligament imbalance

intraoperatively. It consisted of a tibial baseplate of

6 mm thickness whose upper surface was equipped

with two sensitive plates, to be put in contact with

the two femoral condyles. Each plate had three

deformable bridges instrumented with strain gauges

(thick-film piezoresistive sensors). When a load was

applied to the articulation, it developed reaction

forces which caused proportional deformations of

the instrumented bridges (Figure 2).

The knowledge of sensors positions and their

measured data allowed to estimate the location of

the applied net tibiofemoral loads acting on the

medial and lateral compartments of the tibial

baseplate. With this information, ligament balance

conditions could intraoperatively be evaluated

throughout the whole knee kinematics.

BIODEVICES2013-InternationalConferenceonBiomedicalElectronicsandDevices

96

Figure 2: The forces measured by the tibial force-sensing

device (Crottet et al., 2005).

This flexibility of usage allowed a better bone

cuts planning, a more accurate components

positioning and gave the possibility to carry out fine-

tuning balance corrections with a high level of

precision. However, a major limitation stood in the

way ligaments were modelled for the computations:

they were reproduced by means of springs, a clearly

too strong approximation (Marmignon, 2004).

1.2 Description of the First proposed

Model

In the literature we can find many other

instrumented implants that actually own diagnostic

capabilities, but could only exploit them in the

intraoperative period. This means that they are used

as measurement tools before the pose of the actual

knee prosthesis, which will be installed once the

optimal conditions are set up. On the other hand,

what we want to develop is an adjustable prosthetic

component to be employed not only during TKA

surgery, but also postoperatively. Given that

tibiofemoral alignment conditions can be perfectly

obtained thanks to well-developed Computer-

Assisted Total Knee Arthroplasty (CATKA)

techniques, we focus on the problem of monitoring

and assessing collateral ligament tension values.

We refer to the smart knee implant proposed by

Almouahed et al. (2010). An instrumented tibial

component, part of a total knee prosthesis, was

equipped with four piezoelectric elements, intended

to be used as both force sensors and energy

harvesters. The total thickness of the tibial

component was 4.5 mm, in line with usual

dimensions. A first-version prototype of the entire

implant was developed and studied in laboratory by

direct wiring.

Collateral ligament balance conditions were

evaluated by adopting a Center of Pressure (CoP)-

based approach. Collected data were supposed to be

transmitted to the outside of the prosthesis thanks to

a wireless telemetry system (Lahuec et al., 2010). A

microprocessor and an antenna could be hosted in

the hollow stem of the tibial component. A very

strong point of this transmission system was its

characterisation as being totally self-powered. Its

power-supply was completely ensured by the

electric energy harvested by the four piezoelectric

elements during gait cycle motions.

System feasibility was confirmed by theoretical

studies (Almouahed et al., 2011) and a partner

laboratory is currently working on the power issue in

order to obtain definitive results.

This instrumented knee implant is the first one

able to postoperatively monitor and assess collateral

ligament balance, during an active range of motion

and without the need to be powered by an external

source of energy. Upon achievement of such

diagnostic capabilities, our next objective was to

actuate this knee implant, in order to have an active

prosthesis able to compensate for the detected

imbalance by autonomously correcting the position

of its components.

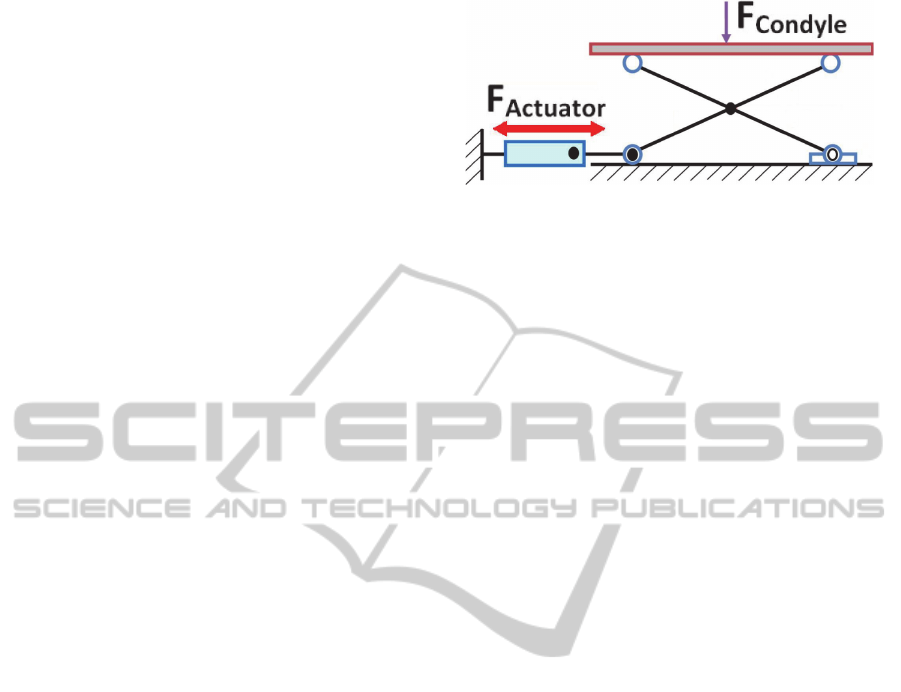

In a recent study (Almouahed et al., 2012) we

further developed this knee implant. We proposed to

instrument it with two embedded microactuators. In

this new design, the tibial component consisted of a

fixed baseplate and a mobile tray, the latter

connected to the former by means of two scissor lift

mechanisms (a Medial and a Lateral one). The goal

was to be able to move upwards and downwards the

upper mobile plate (Figure 3).

Figure 3: Location and example of use of the two scissor

lift mechanisms embedded in the fixed tibial baseplate

(Almouahed et al., 2012).

In this way, the relative position between the

polyethylene insert (properly fixed on the upper

surface of the mobile plate) and the fixed tibial part

could be adjusted in order to meet correct balance

conditions, both intraoperatively and

postoperatively. Each scissor mechanism was

supposed to be driven by a sliding pin, controlled by

a miniature linear actuator positioned in the fixed

tibial part.

TowardsaDynamicTibialComponentforPostoperativeFine-tuningAdjustmentofKneeLigamentImbalance

97

A detailed 3D CAD model of the whole implant

was realised and studied. Simulations led to the

estimation of its minimum lifespan and of the points

where peak Von Mises stresses occurred. More

practical issues, like the choice of a suitable

micromotor and its power supply, were not

considered. In this current work, we approach such

problems and propose a new design for the

adjustable autoadaptive knee implant.

2 POSSIBLE APPROACHES

After consultation with orthopedic surgeons, we

know that to restore a proper collateral ligament

tension we need to be able to lift up one side of the

mobile tibial plate, according to the detected loose

ligament (medial or lateral). We should be able to

compensate for up to 3 mm vertical distance, in

order not to affect the tibiofemoral alignment of the

prosthesis with respect to the lower limb mechanical

axis. The level of accuracy is clearly submillimetric.

The peak tibiofemoral force acting on the tibial

component during gait cycle is 2600 N (ISO 14243-

3, 2004). Consequently, the actuation system that we

are designing must be robust and resistant to strong

cyclic efforts.

The lift up of the tibial plate is carried out with

the patient in supine position. In such a condition,

the only tibiofemoral forces acting inside the knee

joint are due to collateral ligament tensions, which

result in a total compressive force of 150 N on each

side of the tibial plate (Marmignon, 2004). This is

the reference value that we need to consider while

looking for a good design.

A first consideration about the validity of the

proposed scissor lift mechanism can already be

made. Considering the entity of tibiofemoral efforts

and the small dimensions of the scissor structure, in

fact, a too high reaction force would be transmitted

to the micromotor shaft (Figure 4).

Simulations showed that, for a 3 mm lift up, the

peak tibiofemoral force of 2600 N acting on the

tibial baseplate would transmit to the actuator a

force higher than 4500 N. It does not exist any

micromotor tiny enough so as to fit the available

volume and, at the same time, able to oppose such

an important passive force.

A normal linear micromotor of dimensions

3x3x6 mm typically offers a stall force of 0.3 N.

These values are clearly too far from normal knee

cyclic efforts entity. The locking system is a key

issue for the implant durability and the scissor lift

mechanism is not a reliable solution.

Figure 4: The tibiofemoral efforts are transmitted to the

micromotor shaft via the scissor lift mechanism

(Almouahed et al., 2012).

The available volume to host the actuation

system is very small. We mainly have two

exploitable volume regions: the hollow cylindrical

tibial stem (17 mm diameter and 40 mm height) and

the fixed tibial baseplate (75x50 mm, 4.5 mm thick).

In addition to this, we can obtain further space by

removing a reasonably small bone quantity from the

resected tibia surface.

Everything must be carefully miniaturised. The

research of suitable components itself is really

complex and it gets strongly restricted by the

biocompatibility issue. We immediately discard any

invasive component, as well as any wireless power

transmission technique which may cause biological

damages.

We focused on three approaches to realise the

desired actuation: (1) to embed a micromotor within

the tibial baseplate, in order to move a miniaturised

mechanical structure, (2) to exploit the presence of

metallic/ferromagnetic components, properly

disposed inside the tibial implant, to be moved

without contact by exploiting the action of an

external magnetic field and (3) to use an external

tool to access to the prosthesis from outside, through

two small incisions, so as to adjust an internal

mechanism.

In the following, we will detail our research

activity. We will consider each approach and

highlight their advantages and drawbacks. After this

analysis, we will motivate the final choice of the

adopted approach.

2.1 Micromotor-based Approach

This is the most intuitive choice. Regardless of the

chosen design, a very strong point of microactuators

consists in the high accuracy level that they ensure

in mechatronic applications. The control of

electronic components can be very efficiently

achieved and provides reliable data.

The scissor lift mechanism was set aside, but a

priori we still have a wide variety of possible

BIODEVICES2013-InternationalConferenceonBiomedicalElectronicsandDevices

98

mechanical structures that can be embedded in the

prosthesis. In these terms, while component sizing is

not a big deal, a good trade-off must be found

between their dimension and their power. More

specifically, we need to find a micromotor which is

small enough and, at the same time, sufficiently

powerful. This is usually quite complicated, because

small dimensions inevitably give reduced

performances.

As previously explained, another problem is

represented by the locking issue. The micromotor

must be able to realise the actuation and keep the

new adjusted position with high durability. This

must be ensured by proper design solutions.

A further drawback of this approach is that the

micromotor needs to be powered and controlled

wirelessly. This is not easy to achieve, since even

miniaturised motors are not low-power consumption

devices (in general, 2-3 V power supply is needed).

However, all the necessary components for motor

control and data transmission (microprocessors,

integrated circuit and telemetry system) must be

positioned inside the prosthesis. As a consequence,

they all need to be miniaturised and assembled in the

optimal way so as to fit the very small available

volume.

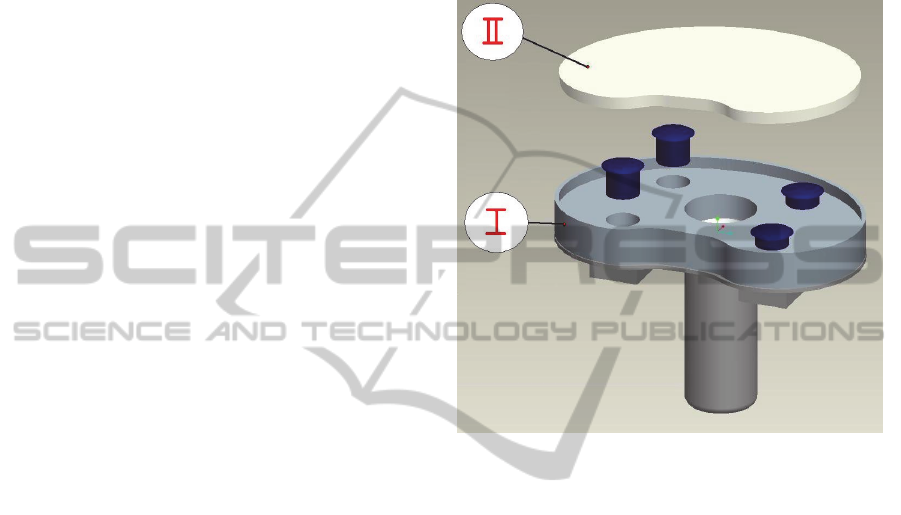

2.2 Magnetic Field Interaction-based

Approach

This approach is based on the action of an external

magnetic field properly generated around the knee.

The idea is to embed four magnetic screws within

the fixed tibial baseplate and control their screwing

without any contact, by exploiting magnetic

interaction. In their starting configuration, the

screws are completely embedded in the tibial tray

(Figure 5), located in their housings that are

perpendicular to the baseplate surface. Screw heads

are in contact with the upper mobile plate and, when

unscrewed, they push it up and realize its lateral lift

on the desired side. At least two screws for each

side, medial and lateral, are needed in order to

ensure good stability conditions.

The use of magnetic fields in biomedical

applications is very common. From the

biocompatibility point of view, then, a priori this

approach should not be problematic. Magnetic fields

can be generated with specific tools, often equipped

with coils that are generally fixed to their lower limb

only during the medical visit. Such devices are not

invasive and usually fit to the patient's morphology.

A strong point of magnetic screws is that they

actually are passive components that offer a very

long lifespan. They do not require any power supply,

not even during the actuation process. The tensile

strength and resistance that they offer depend on

their diameter (between 0.5 and 1.5 mm) and pitch,

two values to be both optimised (preferably

according to ISO standards) in order to optimise

wear resistance properties.

Figure 5: The screws embedded within the intermediate

fixed tibial tray (I), in order to push up or down the upper

mobile plate (II).

Nowadays the control of magnetic fields is

achieved with very high accuracy and magnetic

interaction is actually exploited in many high-

precision positioning devices. In our case, we could

find some difficulties in localizing the action of the

external field on one single screw, while avoiding

any interaction with the other three. Operating

conditions get severely complicated by the reduced

spaces we face with. In order to have a good control

of the screws through the biological tissues and the

prosthetic parts, the magnetic field we need has to be

very precise and strong. At the same time, the

biocompatibility constraint imposes not to damage

biological tissues. Then, the magnetic action should

not be too powerful. In these terms, a good

compromise has to be found.

Another biocompatibility aspect is represented

by the presence of ferromagnetic elements inside the

human body. The material chosen for composing the

magnetic screws must not be dangerous for the

patient and should not limit their daily life activities.

A more delicate issue is the mobility of magnetic

screws and the resistance they oppose to motion. In

TowardsaDynamicTibialComponentforPostoperativeFine-tuningAdjustmentofKneeLigamentImbalance

99

other words, we want to adjust their screwing

without making a too high effort; on the other hand,

once in the new position, we want them to be solid

and rigidly fixed, so as to provide a good resistance.

2.3 External Tool-based Approach

This is an alternative approach, based on an external

tool employed to access to the prosthesis and adjust

its shape. We start from the consideration that small

skin incisions under 5 mm length leave no scar after

recovery. The tibial baseplate of the installed TKA

prosthesis can be accessed through two small

incisions, a medial and a lateral one. The idea is to

use a custom-designed tool, that we can define as a

“double screwdriver”, in order to adjust the position

of the upper mobile tibial plate.

In this particular design, the fixed tibial tray

embeds a worm screw. Its thread is in contact with a

corresponding worm gear part located on the lower

surface of the mobile plate (Figure 6). The two

threads considered together form a worm drive gear

arrangement. Thanks to their relative position, the

rotation of the screw produces the one-side shift of

the mobile tibial plate. This movement modifies the

inclination of the polyethylene insert only along the

Medio-Lateral direction, without modifying the

prosthesis aligmnent with respect to the lower limb

mechanical axis. The overall tibial component

thickness is 7 mm and the mobile plate can be lifted

up to 3 mm maximum.

The most interesting aspect of this approach is its

extremely low invasiveness: general anaesthesia

procedure is not required and no scar will remain on

the patient's skin. Consequently, the hospitalisation

period can be greatly reduced and this represents a

very interesting advantage to the patient.

The worm drive structure that is embedded

within the tibial tray is actually a passive structure. It

does not need any power supply and it ensures a

very long lifespan. Only when the external tool is

employed, the positioning mechanism responds to its

solicitations and realizes the prosthesis actuation.

Another very strong point of the worm drive

structure is its natural mechanical irreversibility. The

worm screw rotation causes the worm gear motion

and not viceversa. Once the desired inclination is

set, tibiofemoral forces keep on pushing on the

upper plate surface through the polyethylene insert.

This action produces the rotation of the worm gear

part which is rigidly fixed onto the lower surface of

the mobile plate. Thanks to the system's

irreversibility, this rotation does not produce any

movement and the new position is solidly kept.

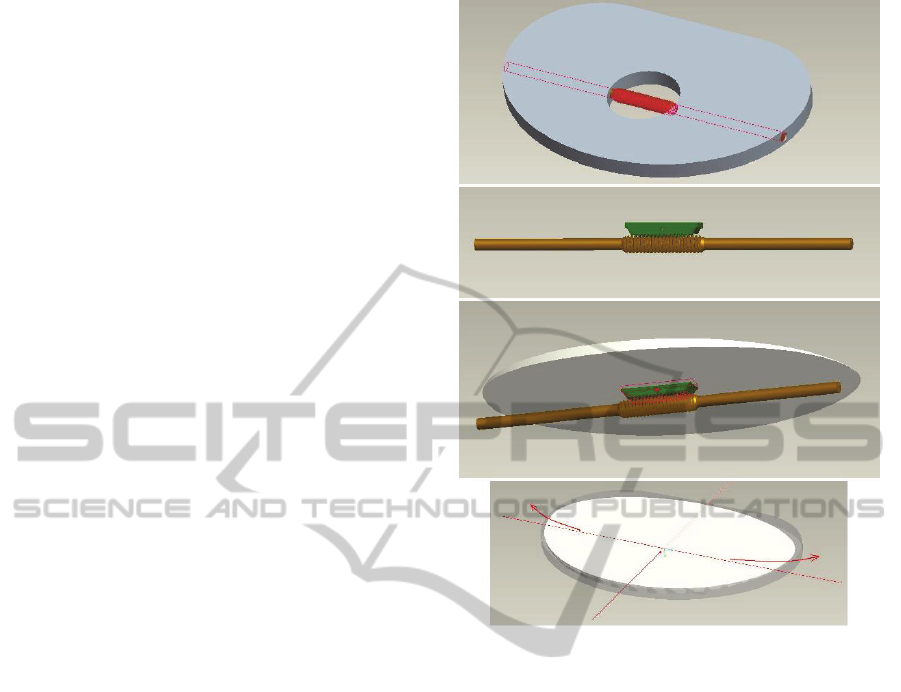

Figure 6: The worm drive gear arrangement is completely

embedded in the tibial component and controls the medio-

lateral translation of the upper mobile tibial plate.

A further advantage of this approach is the fact

that the external tool can be custom-designed. Thus,

both its performances and control can be very

accurately defined.

Unfortunately, the risk of infection is a really

serious drawback. Even if nowadays sterilisation

procedures are very reliable, especially in hospital

environments, the introduction of any external body

inside the knee articulation after TKA surgery is still

not recommended. Any single bacterium that, by

chance, enters in contact with the prosthesis-bone

interface might be able to initiate an infection

process. In the worst-case scenario, after just one

month even the prosthetic detachment might take

place.

Another problem of the proposed design is the

fact that the medio-lateral translation of the mobile

tibial plate modifies the tension of both the collateral

ligaments at the same time. The tray slides laterally

and gets lifted up on the side corresponding to the

loose ligament. At the same time, the lift down of

the plate on the other side inevitably releases the

other ligament. In this sense, it gets more difficult to

BIODEVICES2013-InternationalConferenceonBiomedicalElectronicsandDevices

100

define a proper correcting action since the tension

values of both the collateral ligaments must be

continuously monitored.

3 SELECTED APPROACH AND

PROPOSED MODEL

After the analysis of the advantages and drawbacks

of each possibility, the micromotor approach was

selected as the most reliable choice in terms of

accuracy and performances. For our application,

precision is a key issue and microactuators can be

very reliably controlled. The drawbacks we

considered about them (the dimensions/power

compromise, the locking system and wireless

alimentation and control) all represent technological

limitations that can be overcome by proper design

solutions.

The only micromotor technology that properly

satisfies all the constraints of our project is that of

piezoelectric motors. They can produce very strong

actuation forces even if their dimensions are

incredibly small. Moreover, besides a very long

lifespan, they offer a nanometer positioning

accuracy. A manufacturer we are currently in

contact with produces such kind of microactuators

with a very interesting feature: both the power

supply and the motor control are carried out by

radiofrequency. RFID transmission ensures low

power consumption (less than 0.5 V obtained by

electrical impulses at a given frequency) in

conditions of perfect biocompatibility and very fast

response times (less than 1 ms).

In this work we can introduce the original

actuation design we are developing. A more detailed

description will be object of a future publication, on

which we are already working. Basically, the most

relevant differences between this design and the

previous ones stand in: (1) the direction in which

actuation is realised and, consequently, (2) the type

of micromotor we want to employ.

Tibiofemoral efforts act perpendicularly with

respect to the mobile tibial plate that we want to lift

up. As shown for the scissor mechanism model, a

linear micromotor acting on the tibial baseplate

plane would be greatly involved in the locking

procedure, not being able to ensure system solidity.

In our new design, the mobile plate lift up is

realised thanks to the displacement of some specific

components inside the tibial baseplate. This

displacement is driven by a screw-nut mechanism

where the screw can only rotate and the nut

translates. The screw head is rigidly connected to the

shaft of a rotary piezoelectric micromotor, which

can be wirelessly controlled by the clinician. Thus,

the overall system positioning can be achieved with

high precision.

The most interesting aspect of such design is that

the micromotor is not involved in the locking

procedure. The screw-nut system is properly

dimensioned so as to be irreversible. This property is

exploited to solidly keep the mobile tibial plate in its

desired lifted up position.

Besides the realisation of a detailed 3D CAD

model of the proposed tibial component, a

theoretical mechanical study of the system has been

carried out to evaluate the force distribution among

the different components. Initial results showed that

a 0.6 Nm torque is able to realise the actuation and

laterally lift the mobile tibial plate up to 3.3 mm.

Moreover, solidity and resistance are ensured by the

screw-nut thread, which offers great tensile strength

performances. These results are quite encouraging

and we are currently working on their improvement

and optimisation.

4 CONCLUSIONS AND

PERSPECTIVES

In this paper we discussed an instrumented tibial

component to be used both intraoperatively and

postoperatively. The two objectives of our work

consisted in being able to check collateral ligament

tension conditions and correcting potential

imbalances.

The first point was achieved by employing the

instrumented tibial implant that had been previously

proposed by our team. In this model, four

piezoelectric elements were embedded into the tibial

tray and their use successfully provided diagnostic

data about ligament tension values.

In order to reach the second goal, the operation

to be performed in order to restore proper ligament

tension values consisted in adjusting the position of

the tibial tray. The implant was initially supposed to

be actuated by two scissor lift mechanisms. This

design was not able to ensure proper blocking

conditions and could not meet all the constraints of

the project. Thus, the scissor lift mechanism was

rejected in favour of another design which could be

able to better face with normal knee operating

conditions.

We considered three different approaches to

realize the prosthesis actuation: the first one with a

TowardsaDynamicTibialComponentforPostoperativeFine-tuningAdjustmentofKneeLigamentImbalance

101

micromotor, the second one with a magnetic field

and the last one with an external tool. Our research

work consisted in evaluating the advantages and

drawbacks of each case. This led us to select the

micromotor approach as the most reliable one.

Different design solutions have been analysed

and discussed. We are currently developing an

original design of the actuated tibial implant, based

on the use of two rotary piezoelectric motors. This

model has been theoretically studied and simulations

on a detailed 3D CAD model proved its feasibility.

The 3D model optimisation stage will be followed

by the realization of a prototype, which will be

tested with a knee simulator. Results will be

presented in a future work.

REFERENCES

Almouahed, S., 2011. Etude, mise en oeuvre et évaluation

de prothèse autonome et prédictive du genou. Ph.D.

Télécom Bretagne - LaTIM INSERM U1101, Brest.

Almouahed, S., Gouriou, M., Hamitouche, C., Stindel, E.,

Roux, C., 2010. Design and evaluation of

Instrumented Smart Knee Implant. In IEEE

Transactions on Biomedical Engineering, vol. 58, n°

4, pp. 971–982.

Almouahed, S., Gouriou, M., Hamitouche, C., Stindel, E.,

Roux, C., 2011. The use of piezoceramics as electrical

energy harvesters within instrumented knee implant

during walking. In IEEE/ASME Transactions on

Mechatronics, Focused Section on Sensing

Technologies for Biomechatronics, vol. 16, pp. 799-

807.

Almouahed, S., Hamitouche, C., Stindel, E., Roux, C.,

2012. Finite Element Lifetime Prediction of a

Miniature Adjustable Orthopedic Device. In 34th

Annual International Conference of the IEEE

Engineering in Medicine and Biology Society

"Engineering Innovation in Global Health" -

EMBC'12.

Crottet, D., Maeder, T., Fritschy, D., Bleuler, H., Nolte, L.

P., Pappas, I. P., 2005. Development of a force

amplitude- and location-sensing device designed to

improve the ligament balancing procedure in TKA. In

IEEE Transactions on Biomedical Engineering, vol.

52, pp. 1609-1611.

International Organisation for Standardization, 2004. ISO

14243-3 Implants for surgery – Wear of total knee-

joint prostheses – Part 3: Loading and displacement

parameters for wear-testing machines with load

control and corresponding environmental conditions

for test.

Lahuec, C., Almouahed, S., Arzel, M., Hamitouche, C.,

Jézéquel, M., Stindel, E., Roux, C., 2010. A self-

powered telemetry system to estimate the

postoperative instability of a knee implant. In IEEE

Transactions on Biomedical Engineering, vol. 58, n°3,

pp. 822–825.

Marmignon, C., 2004. Modèle et instruments robotisés

pour l'étude de la biomécanique per-opératoire de

l'équilibre ligamentaire du genou. Ph.D. Université

Joseph Fourier, Grenoble.

Marmignon, C., Leimnei, A., Cinquin, P., 2004. Robotized

distraction device for knee replacement surgery. In

Proc. CARS, pp. 638-643.

Marmignon, C., Leimnei, A., Lavallée, S., Cinquin, P.,

2005. Automated hydraulic tensor for Total Knee

Arthroplasty. In Int J Med Robot, vol. 1, n

o

4, pp. 51-

57.

Scuderi, G. R. and Tria, A. J., 2006. Knee Arthroplasty

Handbook: Techniques in Total Knee and Revision

Arthroplasty, Springer. New York.

Vail, T. P., Lang, E., 2006. Surgical techniques and

instrumentation in Total Knee Arthroplasty. In: W. N.

Scott, Surgery of the Knee, Churchill Livingstone, pp.

1493-1498. New York.

Winemaker, M. J., 2002. Perfect balance in total knee

arthroplasty: the elusive compromise. In Journal of

Arthroplasty, vol. 17, n

o

1, pp. 2-10.

BIODEVICES2013-InternationalConferenceonBiomedicalElectronicsandDevices

102