Fabrication of Straight Stainless-steel Micro-coils for the Use of

Biodevice Components

Toshiyuki Horiuchi, Hiroshi Sakabe, Takao Yuzawa and Daichi Yamamoto

Tokyo Denki University, 5 Senju-Asahi-cho, Adachi-ku, Tokyo, Japan

Keywords: Micro-coil, Laser-scan Lithography, Electrolytic Etching, Electrode Array, Bio-device.

Abstract: Fabrication method of straight micro-coils of stainless steel was investigated for applying the coils to bio-

measurements. As a non-magnetizable material, SUS304 stainless steel pipes with outer and inner diameters

of 100 and 60 μm were used. Specimen pipes coated with positive resist films were exposed to a violet laser

beam, and helical resist patterns were delineated. The pipes masked by the helical patterns were wetly

etched in electrolytic etchant composed of sodium chloride, ammonium chloride, and boric acid. As a result,

micro-coils with almost homogeneous widths were successfully fabricated. The calculated spring constant

was in favourable a range of 0.7-2.4 N/mm. The new micro-coil fabrication method is feasible for the use of

bio-device components.

1 INTRODUCTION

Various micro-fabrication methods have been

developed for realizing new bio-devices.

Combination of lithography and etching is one of the

representative methods. Because fine patterns with

complicated shapes are easily formed on flat

substrates, various micro-fluidic devices, cell arrays

to separate bio-materials, electrodes of bio-sensors

are fabricated using the technology.

On the other hand, any methods had hardly been

developed to form patterns onto fine cylindrical

wires or pipes with diameters of 50-500 μm.

Recently, however, laser-scan lithography to

delineate arbitrary patterns onto cylindrical surfaces

of fine wires or pipes with diameters of less than 100

μm was developed (Horiuchi and Sasaki, 2012). As

an application of the new method, precise micro-

coils were successfully fabricated by etching the

pipes using the helical resist patterns as masking

materials (Horiuchi et al., 2011). Micro-coils were

also fabricated by electroplating nickel into helical

space patterns formed on a fine core wire, and

pulling the wire off afterwards (Horiuchi et al.,

2011).

Because nickel micro-coils fabricated by these

methods had appropriate rigidity and flexibility as

micro-springs, they were practically applied to the

springs packed in fine electrical probe pins of

semiconductor integrated-circuit testers.

In addition to this application, finely patterned

cylindrical parts will be very useful for developing

new bio-devices. For this reason, accuracies of the

patterning and etching are evaluated here, and it is

tried to fabricate stainless steel micro-coils durable

for bio-environments. From view points of cost,

strength and durability, stainless steel is superior to

nickel. Relationship between the spring constant and

the coil parameters are also clarified.

2 NEEDS OF CYLINDRICAL

BIODEVICE COMPONENTS

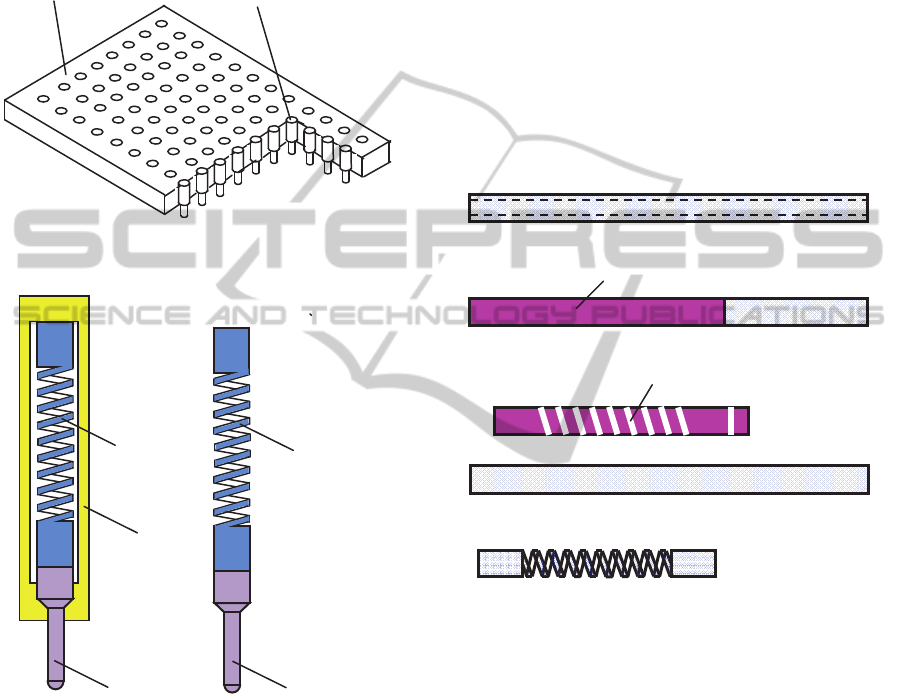

As important bio-devices, fine electrical probes

arrayed in two-dimensional matrixes are

conveniently used to pick up electrical signal flows

on the surfaces of living organs or dermis, as shown

in Fig. 1. For example, bipolar electrodes arranged

in a 10×12 matrix with an inter-electrode distance of

1 mm were used to detect the signal propagation on

the atrium surface of a rabbit (Honjo et al., 2003);

(Honjo et al., 2003). Besides, a 10×10 electrode

array was used for chemo-sensing of cancer cells

(Liu et al., 2009). Although rigid electrode pins were

also used, electrode pins with built-in coil springs or

electrode pins coupled with coil-springs are

preferable, as shown in Fig. 2, because the electrode

pins should be softly pressed to bio-tissues with

bumpy surfaces. In addition, to arrange electrode

114

Horiuchi T., Sakabe H., Yuzawa T. and Yamamoto D..

Fabrication of Straight Stainless-Steel Micro-Coils for the Use of Biodevice Components.

DOI: 10.5220/0004217201140119

In Proceedings of the International Conference on Biomedical Electronics and Devices (BIODEVICES-2013), pages 114-119

ISBN: 978-989-8565-34-1

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

pins densely in an array, straight coil springs with a

small diameter are favourable.

In addition, micro-coils are also useful for

detecting various bio-signals in local narrow areas.

For this use, various types of sensing coils were

proposed (

Ramadan et al., 2006).

Electrodepin

Substrate

(Insulator)

Figure 1: Schematic figure of an electrode array.

Diameters and array size are deformed in the figure.

Barrel

Coilspring

Electrodepin

Coilspring

Electrode

p

in

(a) Built-in type (b) Naked type

Figure 2: Schematic figures of electrode pins for the use of

bio-sensing.

In such electrical measurement use, the micro-

coils should not be magnetisable, because induced

magnetic fields cause measurement errors. From this

point of view, coil-springs of non-magnetisable

materials are preferred.

On the other hand, micro-coils are also applied to

realize special magnetic actuators for biomedical use.

For example, actuators of micro-manipulator and

tweezers were presented (Barbic, 2002).

For the biomedical use, materials not becoming

rusty are very favourable in general, and strength

and durability for the repeating use are required

frequently. Considering these conditions, non-

magnetisable stainless steels are one of the most

appropriate materials.

3 FABRICATION METHOD OF

STAINLESS MICRO-COILS

3.1 Fabrication Process

Micro-coils were fabricated by the process shown in

Fig. 3. SUS304 stainless steel pipes with outer and

inner diameters of 100 and 60 μm and length of 50

mm were prepared as specimens.

(a) Preparation of a specimen pipe

(b) Resist coating

(c) Helical patterning

(d) Wet-etching

Figure 3: Micro-coil fabrication process.

They were coated with films of positive resist

PMER P LA900PM (Tokyo Ohka Kogyo) by the

dipping method. Using laser scan lithography,

helical coil patterns were delineated on the specimen

pipes. The patterned pipes were wetly etched in an

electrolytic etchant applying appropriate voltage.

Because the specimens were masked by the helical

resist patterns, they were etched into coils.

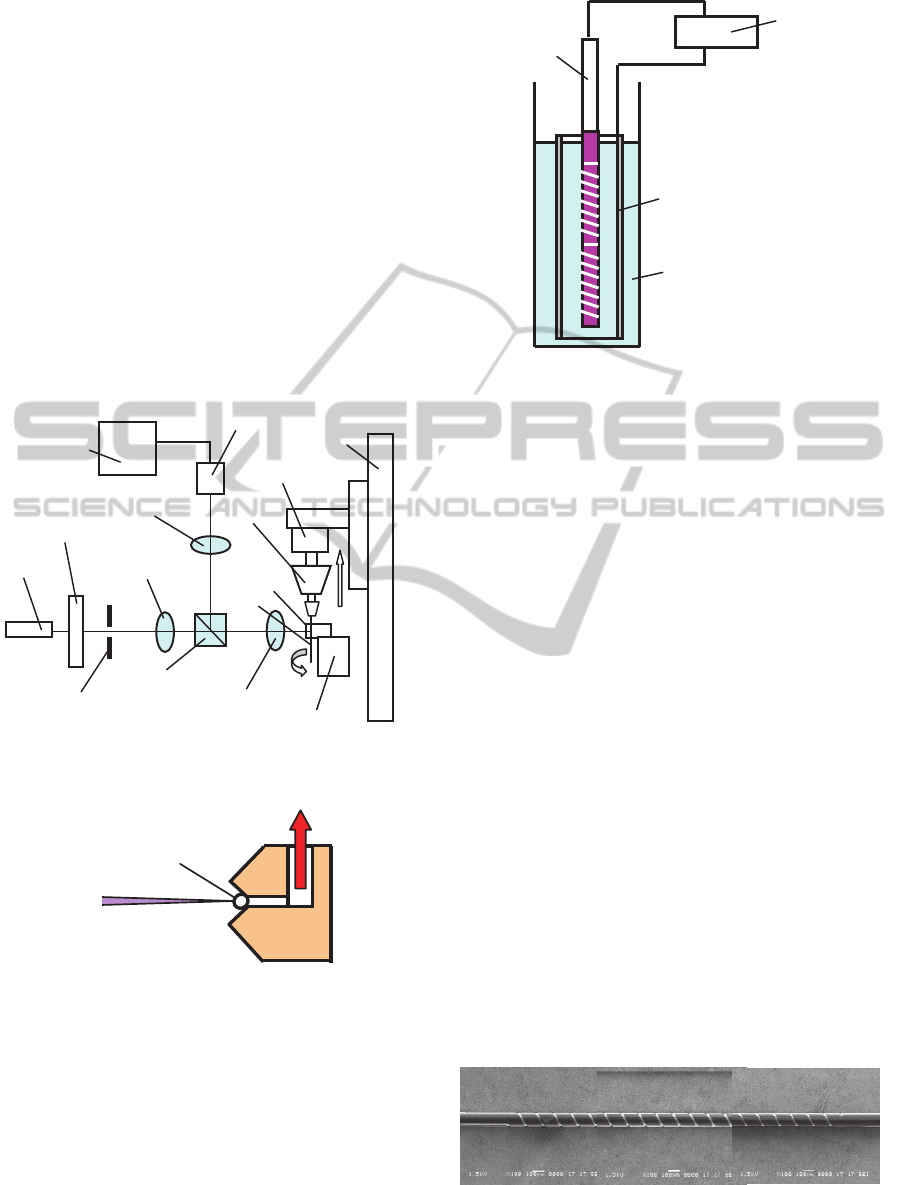

3.2 Laser Scan Lithography

Patterning principle of the laser-scan lithography

onto fine pipes is shown in Fig. 4. As a source,

semiconductor violet laser with a wavelength of 408

nm was used. Nominal output power of the laser was

15 mW. The ejected laser light beam was reshaped

using a pinhole with a diameter of 500 μm. The

Resist

Helical space patterns

FabricationofStraightStainless-SteelMicro-CoilsfortheUseofBiodeviceComponents

115

outlet of the pinhole was projected onto a specimen

pipe using the projection optics being composed of a

10X object lens and 2X imaging lens. Accordingly,

the laser spot size on the specimen was

approximately 25 μm. The specimen pipes and wires

were held and guided using a specially prepared half

vacuum chuck with a V-shape guide, as shown in

Fig. 5. The pipes were chucked at three separate

linear chucking vacuum ports. Because the

specimens were guided by the V-shape walls of the

chuck, the irradiated position of the laser beam was

maintained always constant, even if the specimens

were moved and rotated along the guide, or slightly

curved by nature before they were chucked.

Although the delineated pattern widths depended

on the laser beam spot size, they were considerably

adjusted by changing the scanning speed.

Vacuum

laser

Violet

Shutter

Imaginglens(1X)

Monitor

CCDcamera

Rotationstage

Chuck

guide

Imaginglens(2X)

Objectlens(10X)

Pinhole

Beamsplitter

Guideadjuststage

Linearstage

Display

Pipe

Figure 4: Principle of laser-scan exposure system.

Specimenpipe

Halfvacuum

Laserbeam

Figure 5: Principle of half-vacuum support guide.

3.3 Electrolytic Etching

Etching was performed holding the pipe specimen

vertically in an etchant bottle, and placing an

aluminium cylindrical cathode surrounding the

specimen. The specimen pipe was used as an anode,

as shown in Fig. 6. As an etchant, mixture of water,

sodium chloride (NaCl), ammonium chloride, and

boric acid was used. The etchant was heated on a

hotplate, and the temperature was kept at 40-60ºC.

Specimenpipe

(Anode)

−

Aluminumpipe

(Cathode)

Electrolyticetchant

(NaCl+NH

4

Cl+H

3

BO

3

+H

2

O

)

+

Power

supply

Figure 6: Schematic figure of dissociation etching.

4 FABRICATION OF

MICRO-COILS AND

EVALUATION

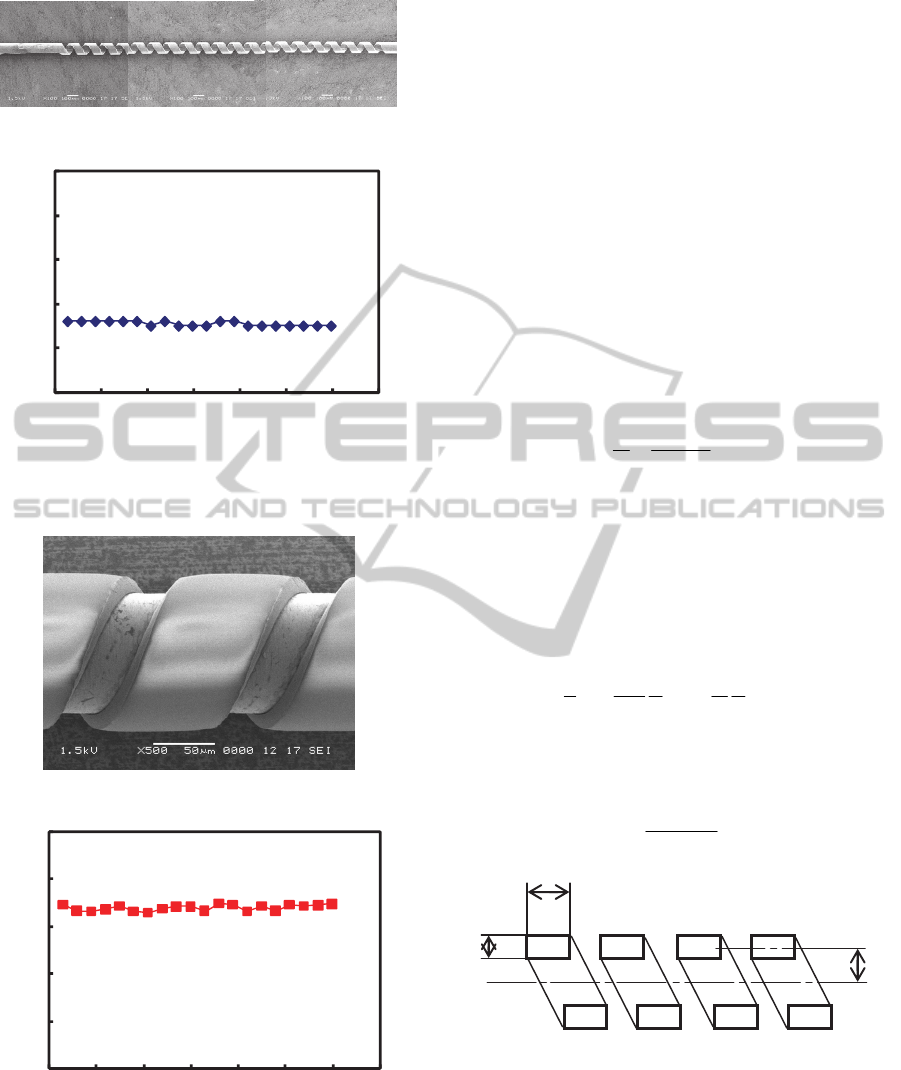

Micro-coils with a pitch of 150 μm, turn number of

20, and the length of 3 mm were fabricated, and the

accuracy was evaluated. In the lithography process,

the resist was coated in 4 μm thick, and the

delineation speed was set at 50 μm/s. The etching

time was determined by monitoring the electrolytic

etching voltage, and was approximately 40 s. The

resist patterns were removed after etching the

specimens by dipping them in the resist remover.

Figs. 7 and 8 show a patterned pipe and a

fabricated micro-coil. Space pattern widths along the

coil were almost constant, as shown in Fig. 9, and

the width variation was within ±1 μm for the mean

width of 15.5 μm. The error was almost equal to the

measurement error.

Resist patterns should have perpendicular

sidewalls to obtain the aimed widths stably with

good repeatability. From this point of view, the

resist patterns had favourite cross sections, as shown

in Fig. 10. This superiority probably comes from the

use of half-vacuum chuck and a fact that the

exposure beam spot size is kept always constant.

Figure 7: Helical pattern delineated on a specimen pipe.

BIODEVICES2013-InternationalConferenceonBiomedicalElectronicsandDevices

116

Figure 8: Micro-coil fabricated by electrolytic etching.

0

10

20

30

40

50

0 500 1000 1500 2000 2500 3000 3500

Position(μm)

Spacepatternwidth(μm)

Figure 9: Width variation of space patterns along the

specimen axis.

Figure 10: Sidewall profiles of a helical resist pattern.

0

20

40

60

80

100

0 500 1000 1500 2000 2500 3000 3500

Position(μm)

Spacepatternwidth(

μ

m)

Figure 11: Space width variation of a fabricated coil.

Because the pipes were undercut during the

etching, space widths of the fabricated coils were

wider than the space pattern widths, as shown in Fig.

11. The width differences between the resist pattern

and the coil were approximately equal to twice of

the pipe thickness. However, the coil space widths

were also almost homogeneous, and the deviation

was ±2 μm for the mean width of 68 μm. Because

the coil pitch was 150 μm, coil widths were

approximately 82 μm. It was also verified that

natural pipe parts were remained at both ends in

arbitrary lengths, if necessary.

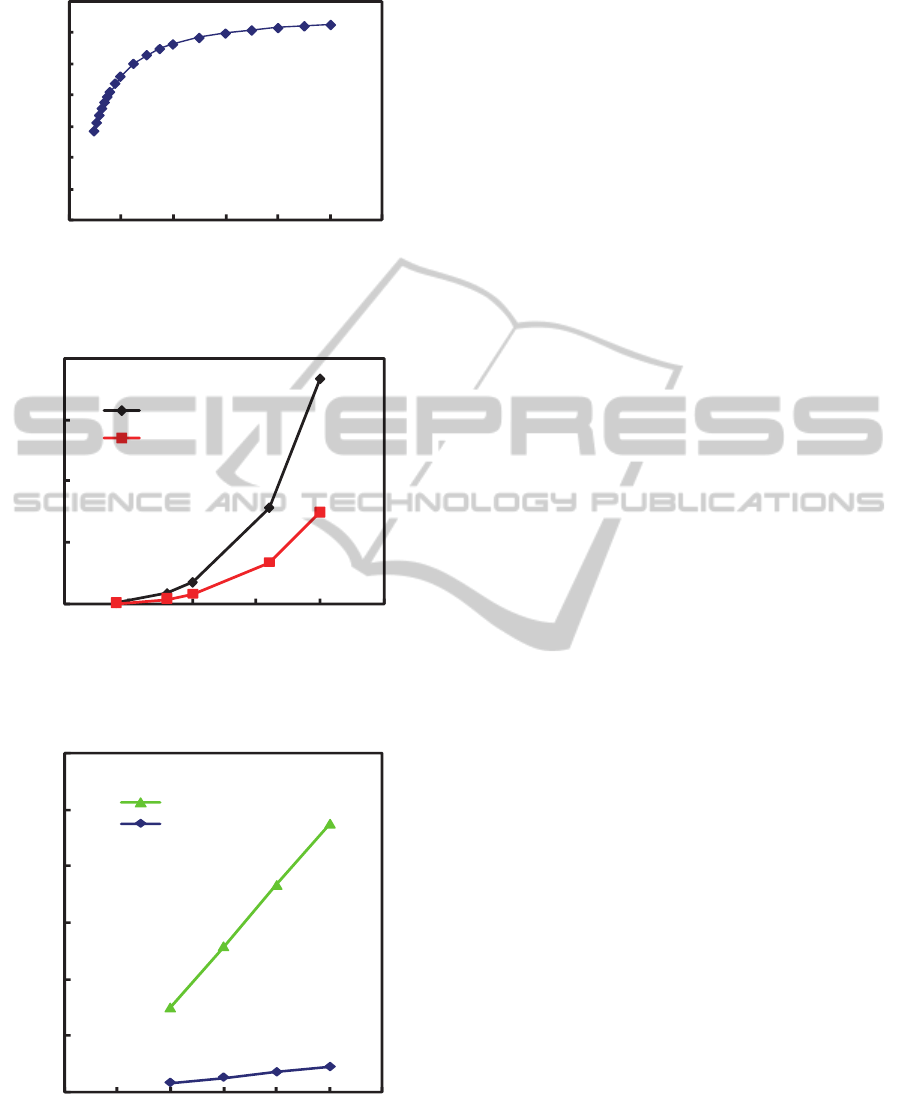

5 SPRING CHARACTERISTICS

DEPENDENCE ON SIZES

Spring constant was calculated if micro-coils had

appropriate rigidity or flexibility. Spring constant k

was calculated by eq. (1) (Utoguchi et al., 1957).

3

3

2 nR

hbG

P

k

(1)

Here, P is the axial load [N],

δ

is the distortion [μm],

G is the shearing modulus [N/mm

2

], b is the

thickness of the coil [μm], h is the width of the coil

element [μm], n is the number, and R is the mean

radius, as shown in Fig. 12. β is the constant

dependent on the ratio of h/b, and calculated by eq.

(2) (Shibahara, 1977).

b

h

h

b

2

tanh

192

1

3

1

5

(2)

Since function tanh x is expressed by eq. (3), β is

calculated, as shown in Fig.13.

xx

xx

ee

ee

x

tanh

(3)

h

b

R

1

2...

n

Coil

number

Figure 12: Size parameters of a micro-coil.

When material pipes with an outer diameter of

100 μm, k was calculated, as shown in Figs. 14 and

15. Because k is proportional to 3rd power of b, the

rigidity largely changes depending on the pipe wall

thickness.

FabricationofStraightStainless-SteelMicro-CoilsfortheUseofBiodeviceComponents

117

0

0.05

0.1

0.15

0.2

0.25

0.3

0.35

024681012

Sidelengthratioh/bofcoilcrosssection

Constantβ

Figure 13: Constant β used for the calculation of spring

constant.

Coilwidth

0

0.5

1

1.5

2

0 5 10 15 20 25

系列1

系列2

80μm

40μm

Wallthicknessofmaterialpipe(μm)

Springconstant(N/mm)

Figure 14: Spring constant dependence on wall thickness

of material pipe.

0

0.5

1

1.5

2

2.5

3

0 20406080100120

系列1

系列2

Coilwidth(μm)

20μm

10μm

Wallthicknessofmaterialpipe

Springconstant(N/m

m

)

Figure 15: Spring constant dependence on coil width.

Calculated spring constant values were in a

favourite range. However, perhaps it is felt

apprehensive that the coils are slightly too stiff. This

time, specimen pipes with a wall thickness of 20 μm

were used. However, pipes with a wall thickness of

10 μm are also commercially available. Therefore,

far flexible springs can also be fabricated, if

necessary.

Because the wall thickness is strictly cared by the

pipe maker, spring constant variation caused by the

wall thickness dispersion is very small. This is a

noteworthy advantage of this fabrication method.

On the other hand, k is simply proportional to the

width h of the coil element. Because h is

controllable by the scan exposure speed or the

etching time, the spring constant can be finely

adjustable by controlling h.

Required stiffness of the micro-coil spring

depends on the application. Therefore, it is

preferable that the spring constant can be easily

changed in a wide range.

6 CONCLUSIONS

Micro-coil springs of SUS304 stainless steel were

successfully fabricated by etching pipes masked by

helical patterns. Despite of the scan exposure, resist

patterns had good cross section profiles with

perpendicular sidewalls, and pattern width

fluctuation was small enough. This superiority

probably depends on the use of half-vacuum

specimen guide in the exposure system.

After the lithography, patterned pipes were finely

etched in the electrolytic etchant. Pattern width

variation in the longitudinal direction of the coil was

less than ±2 μm. Because the spring constant is

decided by the mean width of the coil, above width

fluctuation is permissible.

It was clarified that the spring constant was in an

expected range, and could be changed in

considerably wide ranges by selecting appropriate

shape parameters. The new stainless steel micro-

coils will be applicable to various bio-devices.

ACKNOWLEDGEMENTS

This work was partially supported by Research

Institute for Science and Technology of Tokyo

Denki University, Grant Number Q11T-01.

BIODEVICES2013-InternationalConferenceonBiomedicalElectronicsandDevices

118

REFERENCES

Barbic, M., 2002. Magnetic wires in MEMS and bio-

medical applications, Journal of Magnetism and

Magnetic Materials, 249, 357-367.

Horiuchi, T. and Sasaki, R., 2012. New Laser-Scan

Exposure System for Delineating Precise Helical

Patterns onto Sub-50-μm Wires, Japanese Journal of

Applied Physics, 51, 06FL01.

Horiuchi, T., Ishii, H., Shinozaki, and Y., Ogawa, T., 2011.

Laser Scan Lithography onto Fine Pipes and Wires

with Sub-100-nm Diameters, Journal of Photopolymer

Science and Technology, 24, 373-378.

Horiuchi, T., Ishii, H., Shinozaki, Y., Ogawa, T., and

Kojima, K., 2011. Novel Fabrication Method of

Microcoil Springs Using Laser-Scan Helical

Patterning and Nickel Electroplating, Japanese

Journal of Applied Physics, 50, 06GM10.

Honjo, H., Inada, S., Lancaster, M. K., Yamamoto, M.,

Niwa, R., Jones, S. A., Shibata, N, Mitsui, K.,

Horiuchi, T., Kamiya, K., Kodama, I., and Boyett, M.

R., 2003. Sarcoplasmic Reticulum Ca2+ Release Is

Not a Dominating Factor in Sinoatrial Node

Pacemaker Activity, Circulation Research, 1-4.

Honjo, H., Boyett, M. R., Niwa, R., Inada, S., Yamamoto,

M., Mitsui, K., Horiuchi, T., Shibata, N, Kamiya, K.,

and Kodama, I., 2003. Pacing Induced Spontaneous

Activity in Myocardial Sleeves of Pulmonary Veins

After Treatment With Ryanodine, Circulation, 1937-

1943.

Liu, Q., Yu, J., Xiao, L., Tang, J. C. O., Zhang, Y., Wang,

P., and Yang, M., 2009. Impedance studies of bio-

behavior and chemosensitivity of cancer cells by

micro-electrode arrays, Biosensors and Bioelectronics,

24, 1305-1310.

Ramadan, Q., Samper, V., Poenar, D. P., and Yu, C., 2006.

An integrated microfluidic platform for magnetic

microbeads separation and confinement, Biosensors

and Bioelectronics, 21, 1693-1702.

Shibahara, M., 1977. Zairyo Rikigaku (Strength of

Materials) Rikogaku-sha, 95-96.

Utoguchi, T., Kawada, Y., and Kuranishi, M.,1957. Zairyo

Rikigaku (Strength of Materials) Shokabo, 110-111.

FabricationofStraightStainless-SteelMicro-CoilsfortheUseofBiodeviceComponents

119