Polymeric Micro Check Valve for Glaucoma Treatment

Considering Rate of Aqueous Humor Formation

Chang-Ju Park

1

, Jaekwon Lee

2

, Byungphil Mun

3

, Jae-Yong An

4

, Seunghwan Moon

2

,

and Jong-Hyun Lee

1,2

1

Department of Medical System Engineering, Gwangju Institute of Science and Technology, Gwangju,

Republic of Korea

2

School of Mechatronics, Gwangju Institute of Science and Technology, Gwangju, Republic of Korea

3

Production Engineering Research Institute, LG Electronics, Seoul, Republic of Korea

4

Future Device R&D Department New Device Team, LG Electronics, Seoul, Republic of Korea

Keywords: Glaucoma Drainage Device, Intraocular Pressure, Micro Check Valve, Polymeric, Cracking Pressure,

Aqueous Humor Formation.

Abstract: This paper describes a novel glaucoma drainage device (GDD) to regulate intraocular pressure (IOP)

considering the rate of aqueous humor formation. The device functionally consists of a polymeric cannula

(silicone tube) and a micro check valve (PDMS: polydimethylsiloxane). The check valve has three layers: a

top layer (cover), which has rounded edges to reduce fibrosis, an intermediate layer (thin movable valve

membrane), and a bottom layer (base plate). A feedforward channel is employed in the top layer to prevent

reverse flow by compensating the pressure of the outlet channel. The thickness of thin the PDMS membrane

was determined considering the cracking pressure and the rate of aqueous humor formation. The cracking

pressure in-vitro test was conducted at 15 mmHg, which lies within the normal intraocular pressure range (10

~ 20 mmHg). The experimental mean value and standard deviation of the flow rate at the cracking pressure

was 2.18 ± 0.69 µL/min, which is confirmed to cover the rate of aqueous humor formation in the normal

human eye (1.5 ~ 3.4 µL/min). Flow in a reverse direction was not observed.

1 INTRODUCTION

Glaucoma is an eye disorder associated with

abnormally increased intraocular pressure (IOP) due

to occlusion of Schlemm’s canal. It permanently

induces resultant visual field loss and progressive

blindness by damaging the optic nerve system. Three

types of glaucoma treatment methods are mainly

used to lower the IOP, including medication, laser

surgery, and glaucoma surgery depending on the

severity. One of the methods of refractory glaucoma

treatment is a drainage device to surgically lower the

IOP (Shuchi and Louis, 2010). Many researchers

have worked to develop such a drainage device for

glaucoma patients. Typically, Molteno, Krupin,

Baerveldt, and Ahmed valves are commercially

available devices, which usually consist of two

components, namely, a cannula and a base plate. The

plate is fixed onto the cornea with sutures, and the

cannula shunts aqueous humour from the anterior

chamber into the reservoir (Brian A Francis et al.,

1998).

Recently, many efforts to develop a drainage

device using microfabrication technologies, called

microelectromechanical systems (MEMS), have

taken advantage of size reduction and batch

processes. In particular, micro check valves are

effective drainage valves for glaucoma patients,

because they easily control the cracking pressure for

regulation of the intraocular pressure and effectively

prevent unexpected reverse flow and/or dust from

outside the eyeball. However, unsuitable device

shapes, such as sharp edges of the plate and cannula,

and non-biocompatible materials can cause failures,

such as inflammatory reactions. Also, the

complicated fabrication of the valve membrane (for

instance, using gray-scale photomask or through-

hole process) might induce a severe variance in

cracking pressure and/or flow rate (Jeffrey Chun-Hui

Lin et al., 2010), (Seunghwan Moon et al., 2012).

This paper presents a novel glaucoma drainage

device (GDD) with a micro check valve, whose flow

64

Park C., Lee J., Mun B., An J., Moon S. and Lee J..

Polymeric Micro Check Valve for Glaucoma Treatment - Considering Rate of Aqueous Humor Formation.

DOI: 10.5220/0004244200640067

In Proceedings of the International Conference on Biomedical Electronics and Devices (BIODEVICES-2013), pages 64-67

ISBN: 978-989-8565-34-1

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

rate is determined considering the rate of aqueous

humor formation. The device was realized by a

simple fabrication process using all-polymeric

biocompatible materials. The fabricated device was

experimentally evaluated in terms of flow rate,

cracking pressure, and reverse flow.

2 DESIGN

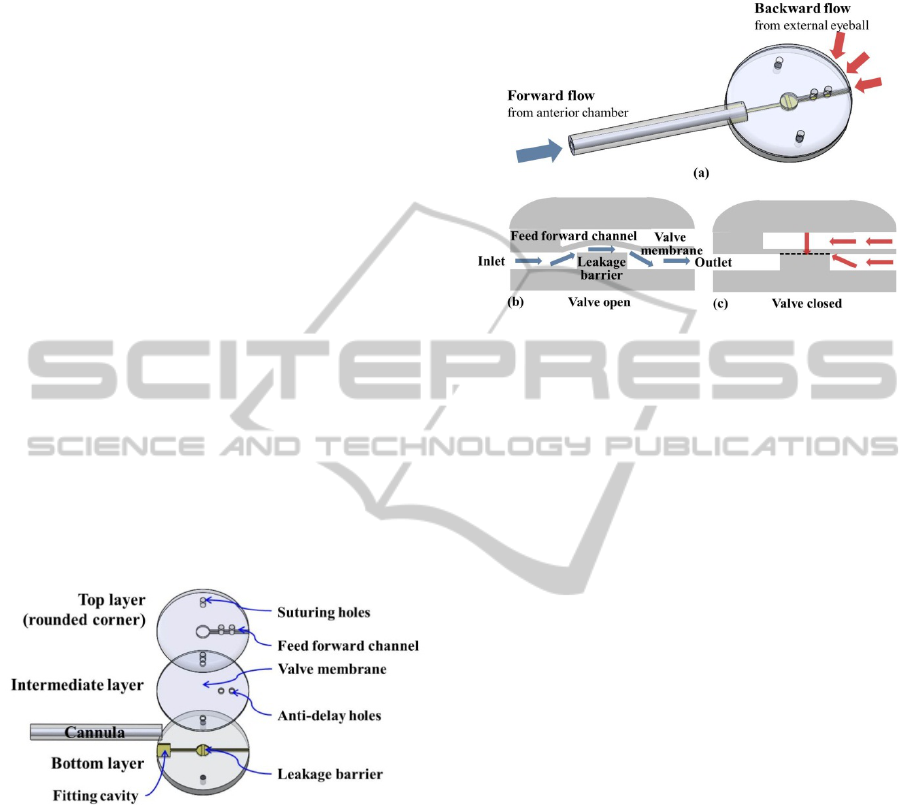

Figure 1 shows the configuration of the proposed

GDD with a leakage barrier and a valve membrane.

The GDD functionally comprises a silicone cannula

and a PDMS micro check valve. The PDMS valve

consists of s three layers. The top layer contains a

feedforward channel including a valve membrane to

prevent reverse flow from outside the eyeball. The

top and intermediate layers have several anti-delay

holes to reduce the pressure delay between the

feedforward channel and the fluidic channel. The

bottom layer comprises a fluidic channel and a

leakage barrier to maintain the appropriate cracking

pressure.

The base plate has a fitting cavity into which the

tip of the cannula is inserted. Suturing holes are

commonly formed onto all three layers to mount the

device on the eyeball for implantation.

Figure 1: Schematic of the glaucoma drainage device

(GDD) fabricated by the MEMS process.

3 OPERATION PRINCIPLE

Figure 2 shows the operation principle of the GDD

with a micro check valve that is normally closed.

When the intraocular pressure (P

i

) is higher than the

external pressure (P

e

) plus the cracking pressure (P

c

),

the valve membrane is deflected upward; therefore,

the aqueous humor generated from the anterior

chamber can flow out of the eyeball. When P

e

is

greater than or equal to the intraocular pressure (P

i

),

the membrane returns to its initial shape because the

feedforward channel is employed, preventing reverse

flow by compensating for the applied pressure of the

outlet channel.

Figure 2: Operation principle of the micro check valve for

regulating intraocular pressure: (a) bird's eye view, (b) the

check valve in open state, and (c) the check valve in closed

state. Dashed line represents the interface that makes

physical contact with no stiction.

4 FABRICATION

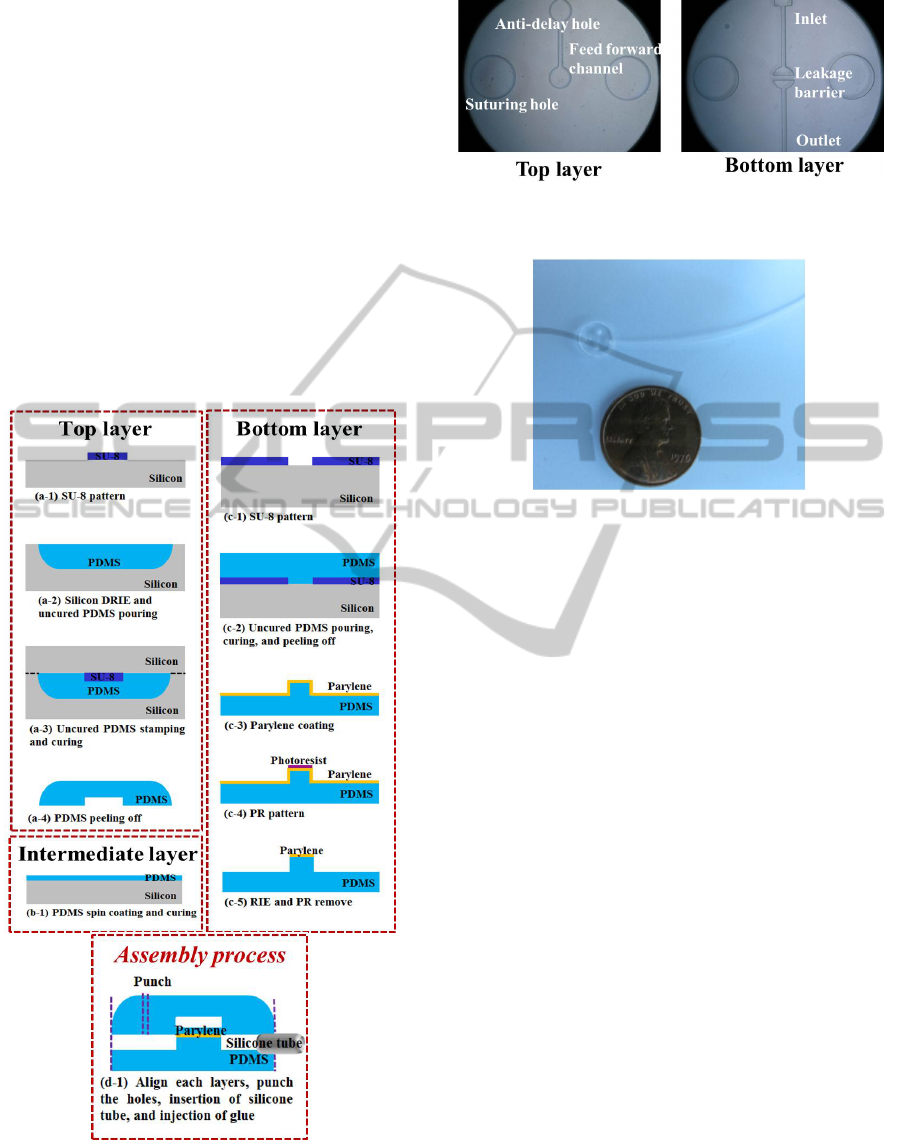

Figure 3 shows the fabrication sequence of the

proposed GDD. First, a mold for the top layer was

fabricated using a negative photoresist (PR; SU-8).

The 100 μm-high SU-8 was patterned on a silicon

substrate. Second, another mold for rounding the

corners of the top layer was fabricated using an

isotropic process of deep reactive-ion etching

(DRIE). Third, the molds were aligned after pouring

uncured PDMS (Sylgard® 184, Dow Corning) on

the round mold. Fourth, the PDMS replica was

separated from the molds after curing at 60°C for 2

hours in a convection oven.

The intermediate layer, which is used to actuate

the valve, was fabricated by spin coating of uncured

PDMS on the glass, and it was cured under the same

conditions.

For the bottom layer, a PDMS replica was peeled

off of the patterned SU-8 mold. Next, parylene of 1

μm thickness was deposited onto the PDMS replica

of the bottom layer using LPCVD (PDS2010,

Specialty Coating Systems). Then, the PR was

selectively patterned on the parylene layer. After

selective etching of the parylene layer using reactive

ion etching (RIE), the PR was removed. Finally, the

PDMS bottom layer was dipped into acetone and

buffered hydrofluoric acid (BHF) to remove the

residual PR and silica-like layers, respectively

(Yinhua Lei et al., 2011).

The top and intermediate layers were bonded

PolymericMicroCheckValveforGlaucomaTreatment-ConsideringRateofAqueousHumorFormation

65

after treatment with O

2

plasma, and they were

punched for fabrication of the anti-delay hole using a

micro punch (Harris Uni-core). Then, the bottom

layer was assembled with the top and intermediate

layer after O

2

plasma treatment, and it was punched

to shape the main body and suturing holes. The

cannula (TYGON® S-54-HL Microbore tubing) was

inserted into the fluidic channel and fixed with

biocompatible bond (Henkel Loctite Corp.).

Microscopic images of the fabricated PDMS

replica of the top and bottom layers are shown in

figure 4.

Figure 5 shows a photo image of the fabricated

GDD whose diameter and thickness are 7.7 mm and

1 mm, respectively. The length of the cannula can be

individually adjusted considering the status of the

patient in surgery.

Figure 3: Fabrication sequences of glaucoma drainage

devices (GDD); (a) the top layer (cover), (b) the

intermediate layer (valve membrane), (c) the bottom layer

(base plate), and (d) the assembly process of the three

layers and cannula.

Figure 4: Microscopic images of the fabricated PDMS

replica of the top and bottom layers.

Figure 5: Image of the fabricated glaucoma drainage

device

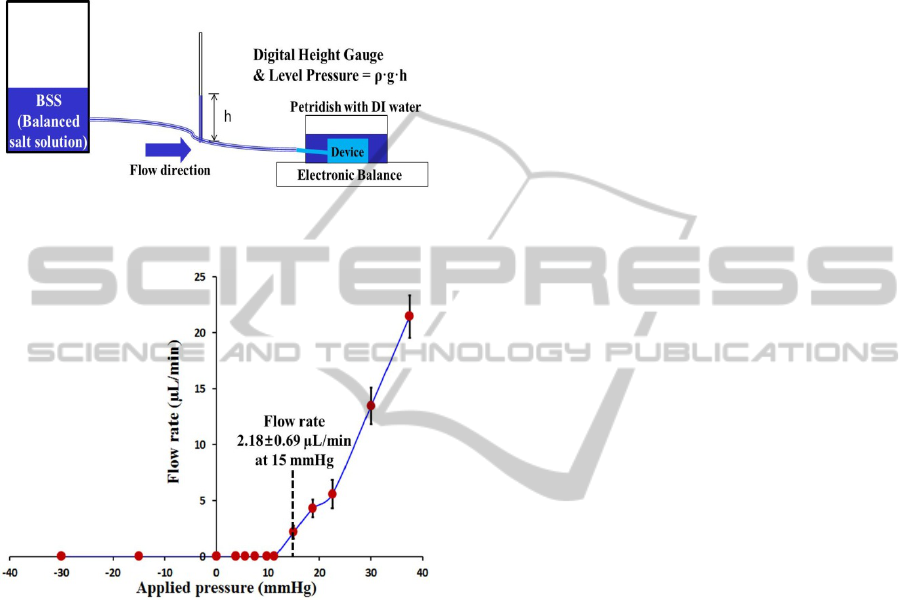

5 IN VITRO TEST

The flow characteristics of the micro check valve are

shown in figure 6. A balanced salt solution (BSS),

which has properties similar to those of the aqueous

humor, was used to measure the flow rate using an

electronic balance (AdventurerTM AR2140). Prior

to the application of hydrostatic pressure to the inlet

(cannula), the device was dipped into BSS to

maintain experimental conditions similar to those of

an in vivo experiment.

The membrane thickness of the device was 58

μm, and the diameter of valve membrane was 500

μm. Every data point of the fabricated GDD was

obtained three times at 3 min intervals for the

applied pressure.

Figure 7 shows the experimental flow rates of the

proposed GDD with respect to the applied pressure.

The results show that the flow rate is proportional to

the applied pressure when the applied pressure is

larger than the cracking pressure. The cracking

pressure was 15 mmHg, which lies within the

intraocular pressure range of normal patients (10 ~

20 mmHg). The mean value and standard deviation

of the flow rate were 2.18 ± 0.69 µL/min at cracking

pressure, which is large enough to cover the rate of

aqueous humor formation in a normal human eye

(1.5 ~ 3.4 µL/min). Meanwhile, reverse flow was not

BIODEVICES2013-InternationalConferenceonBiomedicalElectronicsandDevices

66

observed when hydrostatic pressure (up to 30 mmHg)

was applied to the outlet and the feedforward

channel. The in-vitro test results demonstrate that the

proposed GDD has high potential for the treatment

of glaucoma in view of cracking pressure, flow rate,

and the prevention of the unwanted reverse flow.

Figure 6: Illustration of experimental setup to measure the

flow rate of the fabricated GDD.

Figure 7: Flow rate of the proposed GDD (glaucoma

drainage device) with respect to applied pressure.

(thickness of valve membrane: 58 um, diameter of valve

membrane: 500 um; cracking pressure: 15 mmHg).

6 FURTHER WORKS

The fabricated glaucoma drainage device will be

mounted on a rabbit’s eye for further study.

Reliability testing (cracking pressure, flow rate, and

reverse flow) will be carried out, and inflammatory

reaction will be investigated through the in-vivo

animal test.

ACKNOWLEDGEMENTS

This research was supported by a grant from the

Institute of Medical System Engineering (iMSE) of

the Gwangju Institute of Science and Technology

(GIST), Republic of Korea.

REFERENCES

Brian A. Francis, Andres Cortes, Janet Chen, and Jorge A.

Alvarado, 1998. Opthalmology, 105(9); 1708-1714

Jeffrey Chun-Hui Lin, Feiqiao Yu, and Yu-Chong Tai,

2010. IEEE 23rd International Conference on Micro

Electro Mechanical Systems (MEMS), 1107 - 1110

Seunghwan Moon, Seongmin Im, Jaeyong An, Chang Ju

Park, Hwang Gyun Kim, Sang Woo Park, Hyoung Ihl

Kim, and Jong-Hyun Lee, 2012. Biomed Microdevices,

14; 325–335

P. Shuchi, R. P. Louis, 2010. Seminars in Ophthalmology,

25(5-6); 265–270

Yinhua Lei, Yaoping Liu, Wei Wang, Wengang Wu, and

Zhihong Li, 2011. Lab Chip, 11; 1385

PolymericMicroCheckValveforGlaucomaTreatment-ConsideringRateofAqueousHumorFormation

67