An Agent-based Model of Autonomous Automated-Guided Vehicles

for Internal Transportation in Automated Laboratories

Lluís Ribas-Xirgo and Ismael F. Chaile

Department of Microelectronics and Electronic Systems, School of Engineering

Universitat Autònoma de Barcelona, Bellaterra, Catalunya, Spain

Keywords: Agent-Based Modelling, Mixed-Reality Environments, Multi-Agent Systems, Physical Agents.

Abstract: Agent-based modelling enables simulating complex systems and controlling them, as well. In the industrial

domain there are plenty of these systems not only because of the size but also because of the need for fault-

tolerance and adaptability. Typically, these cases are solved by dividing systems into different dimensions,

including the transportation one. In this paper, we take this approach to build a framework to develop and

control transportation in applications within the industrial domain, which will be tested on an automated

laboratory. The framework is based on a multi-agent simulator that contains the model of the plant with

transportation agents having a multi-layered architecture. The lower-level layers correspond to those that

would be embedded into physical transportation agents. Therefore, while agents communicate to each other

within the simulator environment, communication between upper-level layers and lower-lever layers of each

agent is done internally for the simulated parts and externally for the real counterparts. The simulator can be

used stand-alone to functionally validate a system or in combination with real agents as a

monitoring/controlling tool. Preliminary results prove the viability of the framework as a design tool and

show the difficulties to work with physical agents.

1 INTRODUCTION

The industrial domain is populated with highly

complex and demanding applications that also are

required to be flexible and robust. Therefore, it has

become commonplace to use divide-and-conquer

strategies to develop the systems for these appli-

cations. For instance, splitting system designs with

respect to different aspects of the application, which

include the one for internal transportation of material

(Schreiber and Fay, 2011).

In this paper, we focus on this aspect to develop

a framework in which transport systems for

applications in the industrial domain can be designed

and further deployed.

These systems are also required to be as efficient

as possible. Taking into account that efficiency must

include cost of failures and planning changes, it

turns out that a robust and flexible system has more

chances to be more globally efficient that others that

lack these characteristics, possibly because of being

centrally controlled. Following this and other similar

reasonings, industry has turned to use agents and

agent technology to obtain fault-tolerant and

adaptable systems.

Our approach resembles that of (Fernández-

Caballero and Gascueña, 2009) on complete

development environments for agent-based systems

and uses an agent-based model (ABM) of the

transport system that accepts inputs from the rest of

the system and outputs control data for the physical

transportation units as well as other data to the

system. Differently from their proposal and other

works alike, our approach uses a single ABM tool to

simplify the development framework and minimize

the development costs.

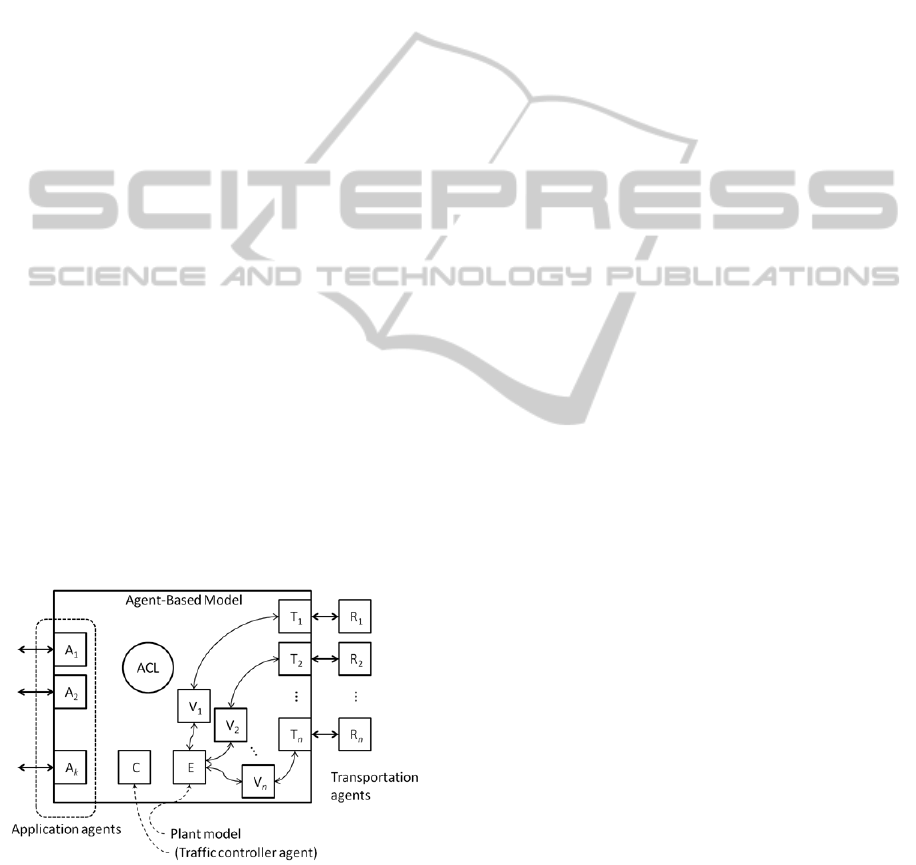

The proposed ABM has a relatively simple

architecture (see Fig. 1), that organizes agents into

two classes: the one for the external elements

(application-related agents, A

j

) to the transportation

system and the one for the vehicles or taxis (agents

T

i

with links to physical, R

i

, and virtual, V

i

, lower-

level layers).

The model is run under inputs that come from

external agents and physical elements and generates

outputs for the latter ones. This control loop might

be too slow for many applications unless physical

262

Ribas-Xirgo L. and Chaile I..

An Agent-based Model of Autonomous Automated-Guided Vehicles for Internal Transportation in Automated Laboratories.

DOI: 10.5220/0004257702620268

In Proceedings of the 5th International Conference on Agents and Artificial Intelligence (ICAART-2013), pages 262-268

ISBN: 978-989-8565-38-9

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

elements have embedded some controllers and

relation with the ABM is done at a higher level of

abstraction. However, even with this solution, ABM

has to be executed fast enough to interact at real

time with the physical elements. This requires agents

to be efficient in taking decisions, which usually

goes against relexive, ellaborated behaviours and to

have simple communication protocols that enable

negotiations to occur within a few messages.

In the proposed framework, the model has three

use cases: 1) for functional validation; 2) for plant

characterization, which includes testing whether real

time requirements are met, parameter identification,

and controller setup, and 3) as a model for the

controller of the transportation system, including a

mixed-reality environment for monitoring and

supervising in human-assisted operation.

As the framework could not be tested on a real

application, it has been tested with a realistic one

that could be operated with automated-guided

vehicles (AGVs) built on small robots.

For this, we have focused the work on automated

laboratories of clinical analyses, as they use

relatively simple transport infrastructures in which

small AGVs can successfully replace conveyors.

The paper is organized as follows. The next

section is devoted to outline the used of agent-based

models in the transportation arena and our approach.

Section 3 highlights the application in automated

laboratories, while the following sections detail the

mechanisms for plant characterization and

synchronization between the simulator and the real

world. The last section concludes this paper by

summarizing the contribution of our work and

devising short and long term continuation lines.

Figure 1: Multi-agent architecture of the transportation

system.

2 AGENT-BASED MODELLING

Typically, ABM is used to analyze, via simulation,

social behaviour of individuals and how it is affected

by changes on individual behaviour, as presented,

for instance, by Kashif et al. (2011). Additionally,

ABMs can be taken as systems models and used to

control them by generating the commands to the

individuals so that they behave as required by the

related applications.

2.1 ABMs as System Simulators

In the review of ABM for transport logistics done by

Davidsson et al. (2005) it is noted that agents are

used mainly to support decision taking but not to

automate processes, i.e. not as distributed system

controllers.

In fact, as shown in a more recent review by

Santa-Eulalia, Halladjian, D’Amours, and Frayret

(2011), agents are used to distribute the problem into

its participants, which collaborate to solve their local

problems. Although this review applies to supply

chain management, conclusions can be extended to

the study case on automated laboratories, as they

have to be supplied with samples and sample

ordering and distribution has to be solved.

In Armendáriz et al. (2011), a business model on

a carpooling application is created upon an ABM. In

this model, passengers can share cars that move

autonomously in a network with independent traffic

lights and local conflict solving at intersections. This

model can only be successful if users are matched to

the right cars in real-time. Similarly, in automated

laboratories, samples should be grouped so that each

group may follow the same minimal route.

2.2 ABMs as System Controllers

Most applications require be implemented with

systems able to work with dynamically changing

demands, and transportation systems are not an

exception. The paper by De Wolf and Holvoet

(2003) follows the same reasoning and, as other

authors, state that systems should be transformed

into autonomic ones to cope with complexity.

In autonomic systems, components tell others

what they want and not how to attain the

corresponding goals. Following this principle, the

automated laboratory for the study case is divided

into two parts: the one of the transportation and the

one for the application, which tells the first one what

is needed but no how it must be fulfilled.

AnAgent-basedModelofAutonomousAutomated-GuidedVehiclesforInternalTransportationinAutomatedLaboratories

263

De Wolf and Holvoet (2003) propose using

ABM to build a model of the system and include one

module to analyze de dynamics of the system (in our

case, this module is in charge of measuring

differences between expected behaviour and sensed

one) and another to control the rest of the system (in

our case, the physical agents which are controlled by

their virtual counterparts). Additionally, cost

functions have to be measured with respect to model

parameters so they can be adjusted to keep

efficiency at the desired reference level. This is a

top-level controller built on top of local, agent

controllers. (We have not planned to include such a

top-level controller because of the relative simplicity

of the case study.)

The main problem to use ABM as a controller is

that ABM can run in real time with the physical

requirements of the system and its application.

2.3 ABM to Control Traffic in

Transportation Systems

Systems of agents have already been used to control

traffic. The idea is to have a traffic system that can

be self-regulated from individual choices and that

requires as little assistance as possible from agents at

a higher level of hierarchy. In other words, the idea

is that transport orders from the applications are

handled by transportation agents in an autonomous

manner, with minimal information from other

agents, including those who may act as planners and

routers.

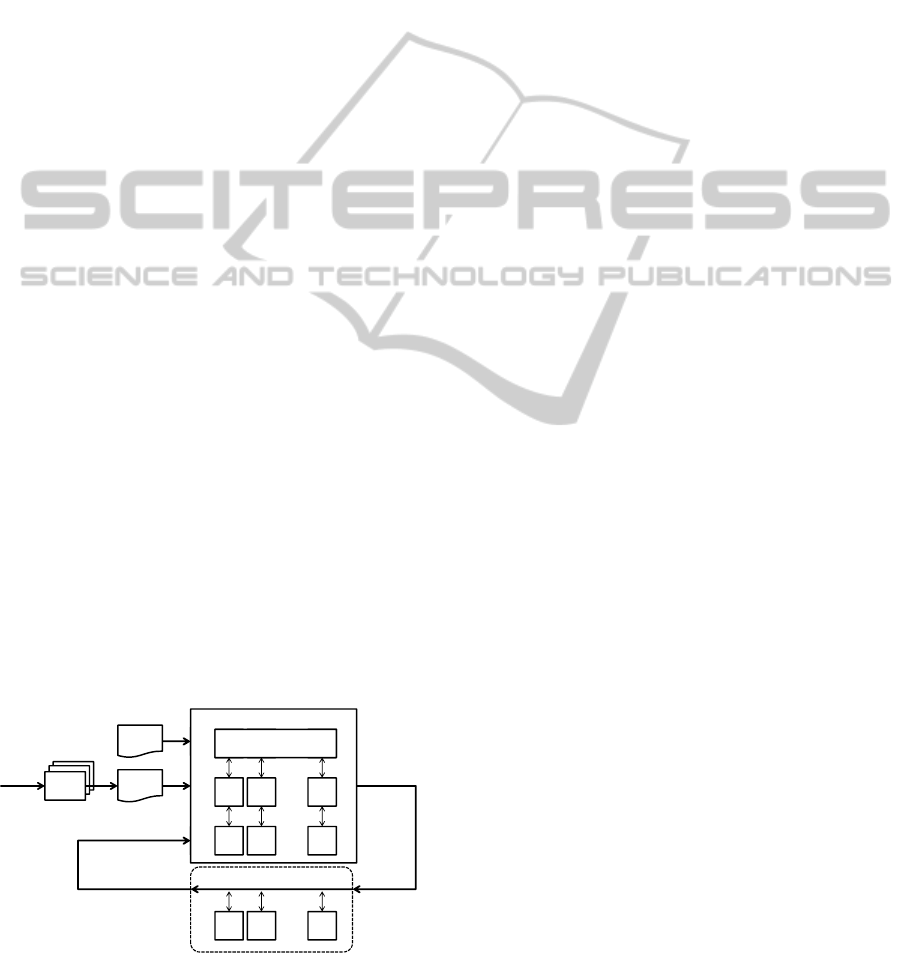

Fig. 2 illustrates how this control scheme is

organized. Topology of the plant and the number of

transportation agents (here and after referred to as

taxis) are among the variables that configure the

model that is used for controlling the real plant.

The higher level modules of the taxis ({T

i

}) get

orders from agents that represent other modules of

the application ({A

j

}) and try to fulfil them.

Figure 2: Architecture of an ABM controller.

To do so, taxis must negotiate with application

agents {A

j

} and other workmates which jobs they

take and, when in transit, how can they be done in

the more efficient way. In taking the decisions, taxis

have knowledge of their own state and the state of

their lower-level counterparts ({V

i

}). Results of

deliberations are transformed into requests to the

{V

i

} and also to the real robots {R

i

}. The last set of

requests is, in fact, the output of the ABM controller.

And the inputs include the replies to these requests

from robots, hence closing the loop between the

controller and the controlled system.

Note that the variability of incoming orders

increases the complexity of a central planner and/or

a traffic coordinator thus making it difficult to attain

any gain in cost or throughput. Consequently, the

taxis operate autonomously, with less guarantee of

optimality but with the benefits of this mode of

operation with respect to flexibility and robustness.

3 AUTOMATED LABORATORIES

Laboratories of clinical analyses have progressively

been transformed into complex “manufacturing”

facilities, able to produce thousands of analyses per

hour from blood and other body fluids’ samples.

In these facilities, samples are dropped into tubes

that are placed in racks which are delivered to

different analyzing machines by using a conveyor

system (Ribas-Xirgo, Miró-Vicente, Chaile and

Velasco-González, 2012).

Unfortunately, some tests done by analyzers

have to be repeated, not all racks have to stop at the

same analyzers and there can be several analyzers

which can do the same job, though with different

workload capacities.

As a result, the complexity of managing this kind

of laboratories is quite high, even though the use of

conveyors sets some layout constraints to the

transport systems thus limiting it. Things can go

worse when conveyors are replaced with agent-

based AGVs (automated-guided vehicles), as they

have more degrees of freedom.

However, the choice for autonomous AGVs

relieves the plant planner from operating with lots of

data and makes it possible to obtain optimal

transport orders, which will be taken by AGVs.

Additionally, the MAS-based transport gains

flexibility and robustness.

In the following, we shall explain the details

about the layout of the plant and the behavior of the

AGVs for the study case selected to validate our

development and deployment framework.

E(plantmodel)

T

1

ABM

application

{topology,#taxis,...}

T

1

T

2

T

n

Realplant

V

1

V

2

V

n

orders

A

1..k

A

1..k

A

1..k

...

...

V

1

V

2

V

n

E(plantmodel)

config

R

1

R

2

R

n

...

{answers }

{requests }

ICAART2013-InternationalConferenceonAgentsandArtificialIntelligence

264

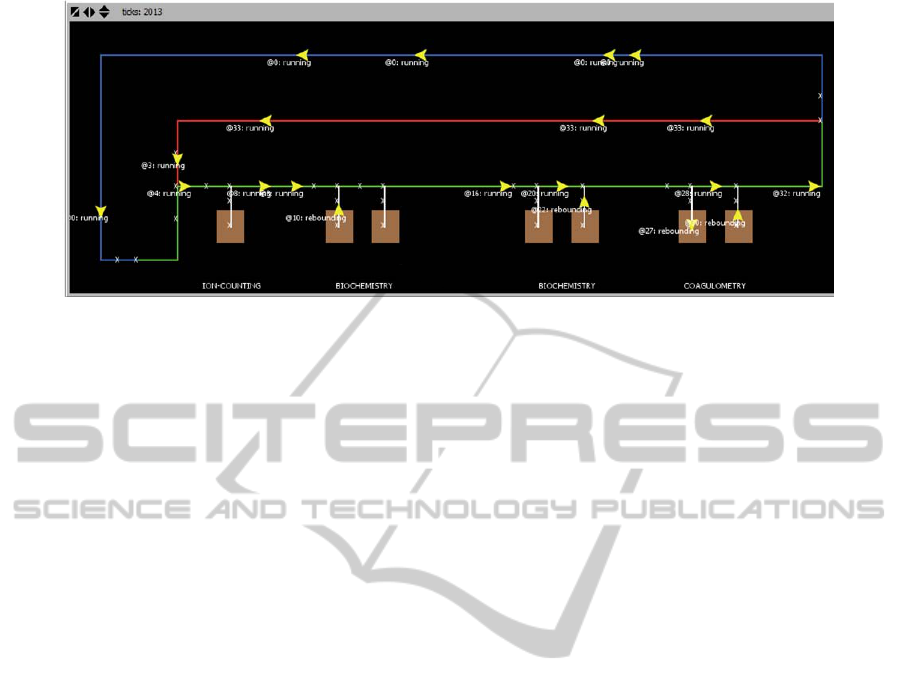

3.1 Plant

To include most of the characteristics of actual

plants of automated laboratories, the case study

includes four different analyzers: one ion-counting

unit, one coagulometry analyzer and two

biochemical units, as most of the samples require

measuring biochemical factors.

The layout of the plant (Fig. 3) is quite similar to

that of a conveyor system where conveyors are

replaced by autonomous AGVs, thus not requiring

much infrastructure. In this case, to simplify vehicle

operations, robots move around by following a line

with marks, which are used by AGVs to self-locate

within the plant map. In fact, they are used to

indicate a programming spot, a bifurcation or a

junction. The type of the mark is determined by

AGVs in accordance with their location in the plant.

The programming spots at the loading dock

(bottom left) and at the beginning of the return lane

(second to topmost and rightmost cross) are places

where the LIMS tell AGVs which kind of tests

should be done on the samples they carry and which

tests have been done successfully, respectively.

There is a re-circulating lane (middle line) that

can be used by AGVs that carry samples that wait

for acknowledgement of their tests or to repeat them,

in case the tests go wrong.

At the beginning of the returning lane (topmost

rightmost mark), AGVs have their tube racks

unloaded, and, at the waiting queue, they have their

batteries re-charged (if needed), and follow their

pace to the programming spot.

3.2 Transportation Agents

In the proposed system, samples are transported

from one point to another by robots, which are

intended to give the whole flexibility and fault-

tolerance, and to relieve the global controller from

most of the systems’ complexity in planning

(Himoff, Rzevski, Hinton and Skobelev, 2006).

As already indicated, the overall planning is done

by the LIMSs, which link samples and tests and,

subsequently, samples to sets of analyzers. These

data are used by taxis to determine their goals, i.e.

their destinations.

In Wojtusiak, Warden, and Herzog (2011) it is

shown that an evolutionary learning process to

optimize individual order selection and routing gives

best results that a greedy approach. However,

because of the simplicity of the case-study network

and that there are only one collection and one ending

spots, we have opted by implementing a greedy

approach with some learning from experience when

solving conflicts.

Each taxi features an AGV that is aware of its

own position, recognizes the environment and

communicates with others to coordinate their

movements. AGVs use information about the plant

to determine to which analyzer they should go to

satisfy the requirements of their loads the fastest

they can. Currently, in our model, AGVs randomly

choose from compatible goals, i.e. they can go to

either biochemical analyzer on a random basis, as

the focus of this work is about validating the

proposed ABM-based controller.

When an AGV arrives at its destination, it docks

at the port of the corresponding analyzer so that it

can begin with its work. In case it is busy, the taxi

puts itself on hold in a parking area (short wait) or

goes on to a compatible destination or to the re-

circulation lane (long wait).

In the model, the high-level of taxis {T

i

} is

responsible for telling the lower-levels, simulated

{V

i

} and real {R

i

}, what actions to do, and the low

levels to reply with data about the results of these

actions. Note that {T

i

} and {V

i

} are executed on an

ABM simulator while {R

i

} on the embedded

controllers of the robots of the system, i.e. on actual

AGVs. At present, the ABM is run on Netlogo and

the robots are Boebots from Parallax.

4 PLANT CHARACTERIZATION

Model accuracy depends on good characterization of

the actual plant. Static data such as traffic network

and nominal characteristics of vehicles such as

average speed and energy consumption can be used

for functional validation of the system and as a set of

initial values for the model. However, in order to

control a real plant, parameters should be as accurate

as possible so they have to be estimated from a

series of test runs.

Our model includes a mechanism for parameter

identification and updating that can be used for both

plant characterization and continuous model

adaptation.

To activate the mechanism, the model has to be

set to real-time mode instead of discrete mode. In

fact, this mode of operation is the only one possible

when working with actual taxis.

Plant characteristics are of two types: the ones

that define its traffic network and the ones that

define the functional and non-functional behaviour

of the taxis. We assume the traffic network be

constant and defined by a topological graph that is

known to all taxis of the system.

AnAgent-basedModelofAutonomousAutomated-GuidedVehiclesforInternalTransportationinAutomatedLaboratories

265

Figure 3: Plant layout from its simulator within Netlogo.

Each taxi tags the topological graph with data

related to the cost it takes to itself to get to a node or

to perform some action at a node.

In a simple version, the cost data consists of the

time to go from a node to another and the time

devoted at each node to decide which outgoing arc

to take.

For instance, the characterization of an arc for a

given taxi consists of measuring how long it takes to

travel from the origin to the destination. And the

characterization of the time required to perform an

action is done by measuring the time to complete it

after being requested to. Such measures are done

indirectly from messages between the ABM and the

physical part of the taxi.

For every order request from a T

i

to a R

i

, it is

recorded the delay time that takes to T

i

to get a reply

from R

i

. This delay is compared to the previous one

in the same node or arc of the map graph and

updated accordingly so that further decisions of T

i

and the reactive behaviour of V

i

are more accurate to

the reality. Note that the characterization is made at

every communication so taxis may end up by having

very different “views” of the traffic network and

behaving in a very different manner.

Other characteristics can be measured by the

robots and transmitted with the acknowledgement

messages but, in the first version of the proposed

model, these are not taken into account.

5 MIXED-REALITY

SIMULATION AND CONTROL

ENVIRONMENT

To accurately monitor any timing problem between

controller and real robots, and also when operating

with real robots in a mixed-reality environment,

messages from {R

i

} and {V

i

} have to be

synchronized.

In this section we shall explain the problems

of controlling real AGVs with an ABM and of

synchronizing the reality and the simulation.

5.1 Real-Time Monitoring

In real-time mode, all delays are compared to the

worst-case execution time (WCET) of the body of

the main control loop so to guarantee that no inputs

from the plant will be lost or taken into account out

of time. Therefore the control loop has a cycle

period only compatible with robots whose embedded

controllers can understand quite complex

instructions, with execution times larger than the

WCET of the model.

This is the usual case in transport systems with

lower-level parts of taxis executing actions such as

“go to the next landmark”, “take the next turning to

the right” or “dock at the machine pier”.

To prevent ABM from missing input data or

sending outdated orders, our model controls that all

measured delays go above 2 times the model WCET.

There are some alternatives to operate with

delays closer to the WCET such as including time-

stamps into the messages or minimizing it by

appropriately modifying the scheduling of agent

execution, as presented by Mathieu and Secq (2012).

However, they are not implemented because

experiments show that the previous rule is normally

satisfied.

For instance, a simulation of an ABM of the case

study with 20 AGVs gives a WCET of 16mS. When

operated with real robots, communication is

estimated (we have real data only for up to 4 robots)

to take an extra time of 20mS per control cycle. As a

consequence, the ABM controller can handle real

time at frequencies of 14 cycles per second.

ICAART2013-InternationalConferenceonAgentsandArtificialIntelligence

266

This frequency implies that simulated ABM can

control 20 real robots {R

i

} with an spatial resolution

under the cm, which is acceptable for the laboratory

previously presented, even if working at 25% more

than the maximum throughput of the top current

analyzers (8000 tests/hour). Note that marks and

objects are more than one cm away from each other.

5.2 Synchronization with Reality

The view of the model enables creating a mixed-

reality environment in which it is possible to design,

supervise and control transport systems of

applications.

As already explained, the model records the

actual delays between requests from T

i

and

corresponding acknowledgements from R

i

, but also

compares them to the delays from V

i

.

For every request-ack. pair between T

i

and {R

i

,

V

i

}, if the actual delay is longer, the view of the

corresponding agent remains stand still until the time

gap is covered. On the other side, if the real delay is

shorter than the expected one, the view is updated

for the missed, un-simulated time. This fact implies

that the WCET must be twice as short as the shortest

delay so that these extra periods required by the

simulator to synchronize virtual robots to their

physical counterparts do not cause any loss in inputs

from the actual plant. Therefore this synchronizing

mechanism works fine only if the control loop

period is shorter than half the delays to be measured.

6 CONCLUSIONS

In this work we have focused on the internal

transportation aspect of systems that run applications

on the industrial domain and proposed a framework

to design and deploy the corresponding subsystems.

The framework uses an ABM simulator as a key

tool that is used in the following cases: 1) for

functional validation; 2) for plant characterization,

which includes testing whether real time

requirements are met, parameter identification, and

controller setup, and 3) as a model for the controller

of the transportation system, including a mixed-

reality environment for monitoring and supervising

in human-assisted operation.

We have shown that the higher levels can be

simulated and, thus, verified in a straithforward

manner and that it is possible to synchronize the

model execution with the real plant to use it as an

actual controller.

Preliminar results show that the proposed

strategy minimizes the time-to-prototype as the

development platform is the same that the

deployment one.

In the near future we expect to have complete

experimental results on real-time control with this

framework and to develop strategies to solve

synchronization conflicts when simulation and

reality differ.

REFERENCES

Armendáriz, M., Burguillo, J.C., Peleteiro, A., Arnould,

G., Khadraoui, D. (2011). Carpooling: A multiagent

simulation in Netlogo. In Proc. of the 25th European

Conf. on Modelling and Simulation (ECMS), Krakow

(Poland).

Davidsson, P., Henesey, L., Ramstedt, L., Törnquist, J.,

Wernstedt, F. (2005). An analysis of agent-based

approaches to transport logistics. In Transportation

Research Part C 1. 255–271.

De Wolf, T., Holvoet, T. (2003). Towards Autonomic

Computing: Agent-Based Modelling, Dynamical

Systems Analysis, and Decentralised Control. In Proc.

of the First Int’l. Workshop on Autonomic Computing

Principles and Architectures.

Fernández-Caballero, A., Gascueña, J.M. (2009). Develo-

ping Multi-Agent Systems through Integrating Prome-

theus, INGENIAS and ICARO-T. In Proc. of Int’l.

Conf. on Agents and Artificial Intelligence (ICAART).

Himoff, J., Rzevski, G., Hinton, M., Skobelev, P. (2006).

MAGENTA Technology: Multi-Agent Logistics i-

Scheduler for Road Transportation. In Proc. of

AAMAS, Hokkaido (Japan).

Kashif, A., Binh Le., X.H., Dugdale, J., Ploix, S. (2011).

Agent-based framework to simulate inhabitants’

behaviour in domestic settings for energy

management. In Proc. of Int’l. Conf. on Agents and

Artificial Intelligence (ICAART).

Mathieu, P., Secq, Y. (2012). Environment Updating and

Agent Scheduling Policies in Agent-based Simulators.

In Proc. of Int’l. Conf. on Agents and Artificial

Intelligence (ICAART), 170-175.

Ribas-Xirgo, Ll., Miró-Vicente, A., Chaile, I. F., Velasco-

González, A. J. (2012). Multi-Agent Model of a

Sample Transport System for Modular In-Vitro

Diagnostics Laboratories. In Proc. of Emerging

Technologies and Factory Automation (ETFA),

Krakow (Poland).

Santa-Eulalia, L.A., Halladjian, G., D’Amours, S., Frayret,

J.-M. (2011). Integrated methodological frameworks

for modeling agent-based advanced supply chain

planning systems: A systematic literature review. In J.

Ind. Eng. & Management, JIEM, 2011 – 4(4):624-668.

Schreiber, S., Fay, A. (2011). Requirements for the

benchmarking of decentralized manufacturing control

AnAgent-basedModelofAutonomousAutomated-GuidedVehiclesforInternalTransportationinAutomatedLaboratories

267

systems. In Proc. of Emerging Technologies and

Factory Automation (ETFA).

Wojtusiak, J., Warden, T., Herzog, O. (2011). Agent-

based Pickup and Delivery Planning: The Learnable

Evolution Model Approach. In Proc. of Int’l. Conf. on

Complex, Intelligent and Software Intensive Systems

(CISIS), 1-8.

ICAART2013-InternationalConferenceonAgentsandArtificialIntelligence

268