Constrained Minimum-Variance PID Control using Hybrid

Nelder-Mead Simplex and Swarm Intelligence

N. Pillay and P. Govender

Optimization Studies Unit, Dept. of Electronic Engineering, Durban Univeristy of Technology, Kwa-Zulu Natal,

Republic of South Africa

Keywords: Achievable Performance, Minimum Output Variance, Hybrid Optimization, PID Controller, SISO System.

Abstract: The paper proposes the use of an efficient hybrid optimization routine by combining Nelder-Mead simplex

with Particle Swarm algorithm (NMPSO) to synthesize a proportional-integral-derivative (PID) type

controller. The conceived controller is capable of providing the best possible performance for regulating

stochastic disturbances under closed loop conditions. A global optimal solution is found by exploiting the

process output variance expression in terms of its closed loop impulse response coefficients. The results of

which are used to define an achievable lower bound of the PID performance in terms of the output variance

of the closed loop system. Several simulation examples drawn from literature are used to demonstrate the

efficacy of the proposed methodology.

1 INTRODUCTION

Controller performance assessment (CPA) has

gained interest from researchers and academics

during the last two decades (Harris, 1989; Huang

and Shah, 1999; Hugo, 2006; Veronesi and Visioli,

2011). Seminal work conducted by Harris (1989)

sparked considerable interest in the field. This is

indicated by numerous CPA methods that have

emerged. Excellent reviews on the subject can found

in Jelali (2006) and Qin (1998). CPA is mainly used

to verify the health of a current control system by

clarifying whether it is operating optimally within

certain constraints such as delay time, disturbance

and process characteristics. In today's competitive

economic climate it has become crucial for

controllers to operate optimally in order to reduce

product wastage and provide minimal output

variance. In this paper, the structural constraint

imposed by PID type controllers is the focus as it

directly impacts on output variance and is widely

used for industrial control.

When stochastic disturbances affect the control

system, it is usually desired to achieve minimum

output variance (Harris, 1989). For time invariant

linear discrete time systems with time delay, which

have no finite zeros on or outside the unit circle,

minimum variance control (MVC) represents the

best possible control to alleviate the negative effects

of stochastic disturbances (

Åström, 1979). It is worth

noting that a practical implementation of the MVC

algorithm for process control would lead to

excessive wear on the final control element. This is

due to its wide bandwidth and noise amplification

which leads to the aggressive control action (Hugo,

2006). However these problems are not a deterrent

when using the algorithm for CPA. A controller

performance index (CPI) can thus be defined as one

that compares the current process output to the

output that would have occurred if some "optimal"

controller had been applied to the process such as

the technique proposed by Harris (1989) using

MVC. The methodology does present a serious

drawback however since it does not take controller

structure into consideration. Owing to this

limitation, the MVC performance benchmark is

unobtainable and highly optimistic for low order

controllers such as the PID type (Jelali, 2006). Since

PID type controllers are commonly used for

industrial control due to their transparent control

algorithm and cost versus benefit ratio they provide

its "achievable" performance is an important task

(Ko and Edgar, 2004; Sendjaja and Kariwala, 2009;

Agrawal and Lakshminarayanan, 2003).

Furthermore, a controller specific performance

bound provides valuable insight as to whether a

more advanced control algorithm is required to

330

Pillay N. and Govender P..

Constrained Minimum-Variance PID Control using Hybrid Nelder-Mead Simplex and Swarm Intelligence.

DOI: 10.5220/0004263403300337

In Proceedings of the 5th International Conference on Agents and Artificial Intelligence (ICAART-2013), pages 330-337

ISBN: 978-989-8565-39-6

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

achieve the desired control objective. A key

difficulty in characterizing achievable performance

for a restricted structure controller is the non-

convexity for the resulting optimization problem for

which no direct and simple global solution is

possible (Sendjaja and Kariwala, 2009).

In the literature, researchers have proposed using

gradient-based methods (Agrawal and

Lakshminarayanan, 2003; Ko and Edgar, 2004) and

solving a series of non-convex programs using sums

of squares (SOS) programming (Sendjaja and

Kariwala, 2009) for determining the optimal

solution. Recently, the use of DividingRECTangles

(DIRECT) algorithm was proposed by Veronesi and

Visioli, 2011. Also, Shahni and Malwatkar, 2011

suggested using a ring of iterations based on the

M

ATHWORKS

®

Optimization Toolbox. In this paper

we propose using a hybrid optimization strategy for

determining achievable PID performance.

The paper is arranged as follows: Section II gives a

review of the derivation of the objective function as

given by (Shahni and Malwatkar, 2011). The global

minimization of which would provide the best

possible PID control. It is important to note that

their derivation is given in terms of the controller

gains which is later exploited in the subsequent

sections by the proposed algorithm; Section III

describes the hybrid optimization algorithm; Section

IV shows the use of the proposed algorithm to

determine the global optimal solution; Section IV

also discusses the simulation experiments that were

conducted and compares the results to the methods

of Huang and Shah (1999) and Sendjaja and

Kariwala (2009). An analysis of the results is also

given in this section; Section V concludes the study.

2 PROBLEM FORMULATION

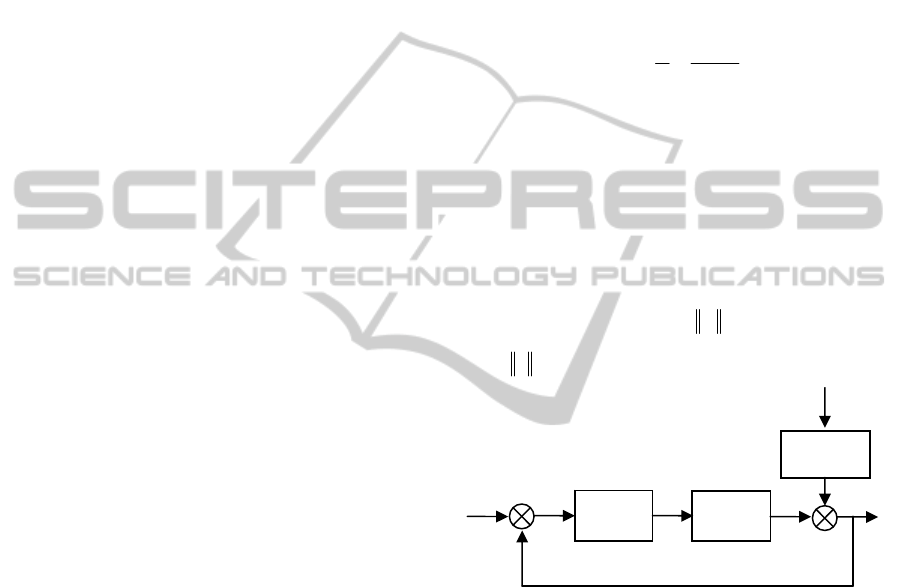

We consider the typical closed loop single-input

single-output (SISO) feedback control system shown

in Figure 1. The process output variable is given

as

()yt

, with the controller signal denoted by

()ut

and the disturbance driving white noise being

represented by

()at

.

t

is the sample interval. The

process output is given as

11

() ( ) () ( ) ()yt gq ut hq at

(1)

where

1

()

g

q

and

1

()hq

represent the process and

disturbance transfer functions respectively. The

symbol

1

q

represents the backshift operator. For

the sake of brevity and convenience, the backshift

operator

1

q

and sample time

t

will be omitted in

the subsequent sections unless circumstances

necessitate its presence. It is worth noting that the

control system set-point

()rt

does not vary in this

study since the focus is for regulating stochastic

disturbances. Hence for regulatory control of the

SISO system shown in Figure 1 the transfer between

y

and

a

is:

(2)

We make the following assumptions for the closed-

loop system

G

(Sendjaja and Kariwala, 2009).

1.

Process (g) and disturbance (h) transfer

functions are stable, causal and contain no

zeros on or outside the unit circle except at

infinity due the time delay.

2.

a

is a random white noise sequence.

The output variance is defined as:

(3)

where is the H

2

norm.

Figure 1: Discretized single loop feedback control scheme.

The minimum variance (MV) benchmark can be

obtained by (Huang and Shah, 1999):

(4)

where

d represents the process delay time and d

m

is

the

th

m

discrete impulse response of the disturbance

model

d . Since we are determining an achievable

lower performance benchmark for PID type

controllers, Eq. (4) may not be attainable for this

controller structure. In order to reduce output

variance in terms of the PID structure limitation the

following expression requires solving:

2

()at

1

()kq

1

()

g

q

1

()hq

()yt

()rt

()ut

1

yh

G

agk

1

2

0

d

M

Vm

m

yh

2

2

()Var y G

ConstrainedMinimum-VariancePIDControlusingHybridNelder-MeadSimplexandSwarmIntelligence

331

(5)

Now the structure of a digital version of the PID

controller which can be found published in many

textbooks on process control is (Ko and Edgar,

2004).

(6)

where

, and represent the proportional, integral

and derivative gains of the PID controller

respectively. Eq. (3) can be written as

(7)

where

i

G

represents the closed loop impulse

response system. Now the

th

m

element of may

be defined by which gives the

closed loop impulse response coefficients for the

system . . In this paper the

number of the closed loop impulse response

coefficients is limited to

4md . This ensures that

the closed loop impulse response converges and

computational power is not exhausted unnecessarily.

It is assumed that since the system converges and

approximately equals to zero at the

th

m

element;

. Eq.(7) can now be written as

(8)

Once the controller parameters are known the

coefficients of can easily be determined using

the "impulse" function in the M

ATHWORKS

®

MATLAB

®

software package. However determining

the controller gains that provide a global optimal

solution is a non-trivial task. Details of the

optimization algorithm used in this regard are

discussed in the next section.

3 HYBRID OPTIMIZATION

ALGORITHM

The basis of integrating the Nelder-Mead (NM)

simplex routine and Particle Swarm Optimization

(PSO) is merely to combine their distinct

advantages. It will be shown later that this proves to

yield an efficient search routine capable of

determining high quality solutions for the problem

discussed in the previous section. This section

introduces the individual search procedures of NM

and PSO, followed by a description of the hybrid

NMPSO.

3.1 Nelder-Mead Simplex Search Method

The Nelder-Mead simplex algorithm (Nelder and

Mead, 1965) is a widely used numerical method for

solving nonlinear unconstrained optimization

problems. This computationally compact

optimization routine can be invoked in MATLAB

®

Optimization Toolbox 5.0 using the function

"fminsearch". The optimization function attempts to

minimize a real-valued function

()

f

x

using only

function values without any derivative information

(explicit or implicit) (Lagarias et al., 1998). Four

key scalar operations form the basis of rescaling the

simplex based on the local behavior of the objective

function. These are: reflection (

), expansion (

),

contraction (

) and shrinkage (

). Through these

procedures the simplex can successively improve

itself and approach on the optimum. Universal

choices used in the standard NM algorithm are

(Lagarias et al., 1998):

1, 2, 0.5, 0.5

A review of the steps to the search routine as

described by Lagarias et al. is given below:

1.

Initialization. The minimization of function

()

f

x for

n

x

begins with a generation of

vertices located at points in

n

. The simplex

points are generated around the initial guess

0

x

of

1n

points for

n

-dimensional vectors

x

.

For

2n

, three points construct a triangle and

3n

, four points generate a tetrahedron and so

forth. Iteration

k

begins by ordering and

labeling these vertices as

() () ()

12 1

...

kk k

n

f

ff

,

where

()k

i

f

denotes

()

()

k

i

f

x

.

()

1

k

f

is referred to

P

K

012

...

i

GGGGG

I

K

D

K

() ( )

T

ii

Var y G G

(0,1,...,)

m

Gm

i

G

imi

GG

min ( ) min( )

PID

PID

T

mi mi

k

k

Var y G G

mi

G

12

12 3

1

1

PID

kkq kq

k

q

1

P

ID

kKKK

2

(2)

P

D

kKK

3

D

kK

2

2

min ( ) min

PID PID

kk

Var y G

ICAART2013-InternationalConferenceonAgentsandArtificialIntelligence

332

as the best function value and

()

1

k

n

f

as the worst

function value. Similarly

()

1

k

x

is referred to as

the best point and

()

1

k

n

x

as the worst point in

n

.

At each step in the iteration, the algorithm

discards the current worst point

()

1

k

n

x

, and

replaces it with another point into the simplex.

For the sake of convenience, superscript

k

is

omitted.

2.

Reflection. A reflection point

r

x

is computed

from

(9)

where

1

n

i

i

x

X

n

is the centroid of the

n

best

vertex points except

1n

x

. Evaluate

()

rr

f

fx

.

If

1 rn

f

ff

, accept the reflected point

r

x

and

terminate the iteration.

3.

Expansion. If

1r

f

f , compute the expansion

point,

(10)

Evaluate

()

ee

f

fx

. If

er

f

f

, accept

e

x

and

terminate the iteration, otherwise if

er

f

f

accept

r

x

and terminate the iteration.

4.

Contraction. If

rn

f

f

generate contraction

between

X and the better of

1n

x

and

r

x

.

a.

An outside contraction is performed if

1nrn

f

ff

and computed by

(11)

Evaluate

()

cc

f

fx

. If

cr

f

f

, accept

c

x

and

terminate the iteration, otherwise go to shrink

operation in step 5.

b.

An inside contraction is done if

1rn

f

f

and

calculated by

11

()(1)

cc n n

x

XXx Xx

(12)

Evaluate

()

cc cc

f

fx

. If

1cc n

f

f

, accept

cc

x

and terminate the iteration, otherwise go to

shrink operation in step 5.

5.

Shrink. Evaluate

f

at the

n

points

11

()

ii

vx xx

,

2,..., 1in

. The vertices

of the simplex at the next iteration is

12 1

, ,...,

n

x

vv

.

The algorithm is terminated until a stopping criterion

is satisfied. An example of a possible terminating

criterion can be maximum number of iterations. In

the case of equal function values being evaluated,

the points need to be ordered according to tie-

breaking rules. Further details of these rules can be

found in (Lagarias et al., 1998). The main

shortcoming of this search methodology is that it can

only find local minimums which depend entirely

upon the initial simplex starting point

0

x

.To find

different local minimums, the algorithm must start

with different and appropriate initial simplex

guesses.

3.2 Particle Swarm Optimization

Algorithm

The PSO technique, developed by Kennedy and

Eberhart (1995), is a computational based

optimization technique for dealing with problems in

which a best solution can be represented as a point

or surface within an n-dimensional search space.

The PSO concept is based on an analogy of the

social interaction that exists in flocking birds and

swarming bees. The technique, much like a genetic

algorithm (GA), is stochastic in nature and is

population based. However a major difference

between the PSO and GA is that the latter employs

genetic operators which filter out poor performing

individuals through natural selection. A key

distinguishing feature of the PSO is that all

individual particles are retained where members of a

group tend to follow the lead of the best in the

group. Each particle or agent also has a memory to

remember the best position that it has visited and the

knowledge of how the other agents around it have

performed. The procedure of PSO is reviewed

below.

1.

Initialization. Randomly generate agents within

the search space in which each particle

represents a potential solution. Each particle is

assigned an initial random velocity.

11

()(1)

rn n

x

XXx Xx

() ( )(1)

11

xX xXX Xx X x

er

nn

11

() ( )(1)

cr n n

x

XxXX Xx X x

ConstrainedMinimum-VariancePIDControlusingHybridNelder-MeadSimplexandSwarmIntelligence

333

2.

Velocity Update. Each agent flies through the

search space dynamically adjusting its velocity

and positional trajectories. These adjustments

are based on the personal experiences of the

agent in question, plus its knowledge of how its

companions have performed. The agents

position and velocity for the

th

i

particle within

an

n

-dimensional space are updated by the

following equations:

(13)

(1) () (1)

,,,

kkk

in in in

s

sv

(14)

pi ,...,2,1

qn ,...,2,1

With regards to (13) and (14):

()

,

k

in

v

= velocity of

agent i at iteration k,

= constriction factor,

1

c

=

cognitive acceleration,

2

c

= social acceleration,

()rand

= random number between 0 and 1,

p

best

=p-best of agent i,

gbest

= g-best of the

group,

()

,

k

in

s

= current position of agent i at iteration k,

p = number of agents, q=number of dimensions to

the optimization problem. Some popular variants of

the PSO algorithm include the inertia weight and the

constriction actor approach. In this study we have

used Clerc’s Type 1 constriction factor algorithm to

limit each agent’s velocity (Clerc, 1999). This

ensures a robust global convergence as each agent’s

velocity trajectory decreases when approaching the

best solution (Clerc, 1999). The constriction factor is

computed by

(15)

where,

12

(, )cc

.

It is worth noting that

must be greater than 4 to

ensure a proper value for

. A commonly used

value for

is 4.1 which gives a constriction factor

constant of

0.7298

. This constant multiplier

value was used in all the experiments.

3.3 Hybrid Nmpso

The task of the hybrid search is to find the absolute

best set of controller parameters that satisfy the

objective function under certain constraints. In order

to ensure positive values of the controller parameters

the following inequalities are considered:

1

0k

,

2

0k

,

3

0k

. Values that violate these constraints

are penalized with a very large number resulting in a

poor cost function. It is worth noting that for a PI

controller the search space is given by two

dimensions (

2n

) whereas for a PID controller

three dimensions (

3n

) are created. Hence for a PI

controller each agent has a starting point of

0

[0;0]x

and for a PID controller the agent’s

initial position is given by

0

[0;0;0]x

. During the

PSO routine of the hybrid search the fitness function

defined by Eq. 8 is minimized and the best controller

parameters are saved. If after several unsuccessful

consecutive attempts the PSO algorithm fails to

improve on the current

gbest

position then the

search automatically switches over to the NM

optimization. The

gbest

position found by the PSO

algorithm is used as the starting point for the NM

search. The same fitness function (Eq. 8) is used for

the NM search. If a better

gbest

is found then this

new point is used in the PSO search and the

procedure is repeated until convergence is reached.

If the NM search is unsuccessful in determining a

better position then the algorithm terminates when a

terminating condition such as maximum number of

iterations is satisfied. The procedure for the hybrid

NMPSO search is presented in Figure 2.

It should be noted however that the proposed

algorithm is applied to known system transfer

functions. Thus the assumption is made that the

algorithm is applied on accurate models of process

and disturbance dynamics. Several examples

showing the effectiveness of the hybrid NMPSO

routine is given the next section.

4 ILLUSTRATIVE EXAMPLES

4.1 Preliminaries for the Experiments

Several simulation examples taken from literature

are used to verify the usefulness of the proposed

algorithm. These examples were taken from

(Sendjaja and Kariwala, 2009; Ko and Edgar, 2004

and Agrawal and Lakshminarayanan, 2003). All

simulations were conducted using the PC based test

platform with specifications given in Table 1.

Process (

g

) and disturbance ( h ) transfer functions

used in the simulation models are shown in Table 2.

(1) () () ()

,,1 ,,2 ,

[ ()( ) ()( )]

kk k k

in in in in n in

v v c rand pbest s c rand gbest s

2

2

24

ICAART2013-InternationalConferenceonAgentsandArtificialIntelligence

334

1. Initialization. Generate a

population of size

p

with each

agent having a starting point

0

[0;0]x

for PI or

0

[0;0;0]x

for

PID.

Repeat

2. PSO method. Apply PSO to randomly

generate

p

number of particles in

the

n

-dimensional search space.

2.1 Fitness Function. Using the

agent’s current position

compute its fitness

according to Eq. (8).

Agents that violate the

constraints:

1

0k

,

2

0k ,

3

0k are penalized

with a large fitness

factor.

2.2 Selection. Select the global

best;

gbest

from the

population.

2.3 Velocity Update. Apply

velocity and position

updates to each agent

using Eqs. (13) and (14).

2.4 Stall. If after several

successive attempts the

algorithm does not improve

on

gbest

, go to Step 3

otherwise go to Step 2.

3. NM method. Simplex generated

around initial point given

by

gbest

.

3.1 Fitness Function. Evaluate

each simplex point

function using Eq.

(8).Order simplex points

from lowest function value

()

1

k

f

to highest

()

1

k

n

f

.

3.2 NM operators. Compute

reflection (

), expansion

(

), contraction (

) or

shrinkage (

) according

to Eqs. (9)–(12).

3.3 Global update. If a lower

global minimum is found

update position for

gbest

and go to Step 2.

Otherwise continue until some

termination condition is satisfied.

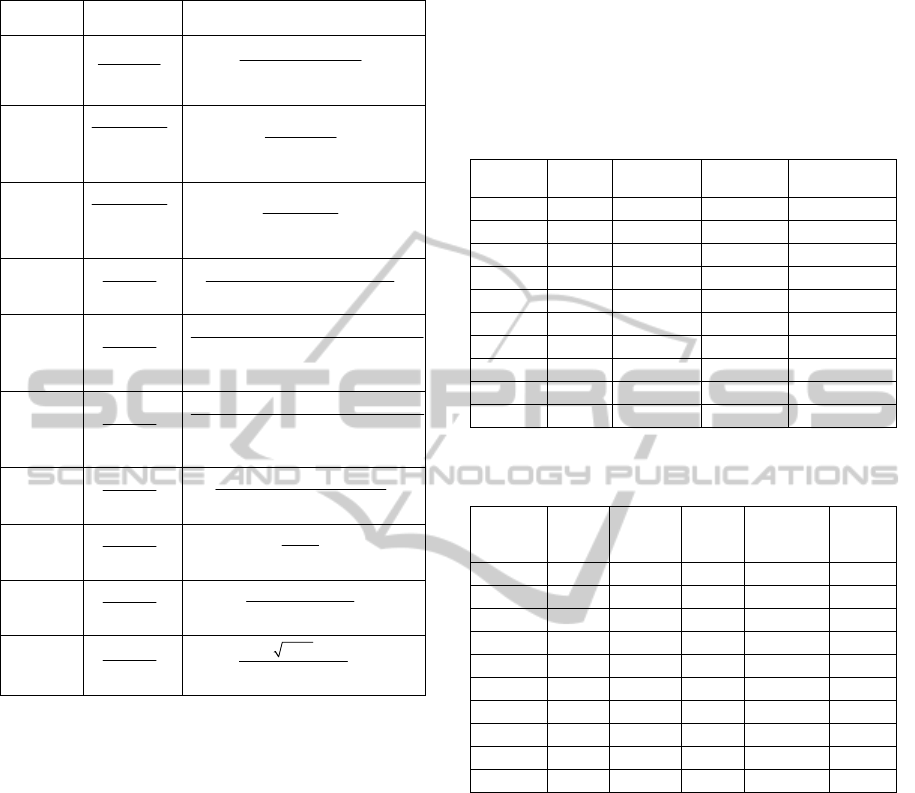

Figure 2: Hybrid NM-PSO algorithm.

When NMPSO algorithm fails to improve on the

current solution after ten consecutive attempts it

automatically terminates and the best solution is

saved. The maximum number of iterations is set to

100 as an additional exit condition. The swarm

parameters used are:

12

2.05cc

with population

size of

20p

. Table 3 and Table 4 give the results

of the minimum variance PI and PID respectively

for the proposed method. The overall performance

of the NMPSO search is compared to that of the

SOS programming method of Sendjaja and Kariwala

(2009) and MV lower bound (Huang and Shah

1999). It is worth noting that the proposed NMPSO

optimisation algorithm provides accurate repeatable

solutions. Each example shown in Table 2 was

tested for ten trial runs and the results indicate the

stability and consistency of the proposed search

algorithm. The stochastic nature of the PSO is useful

in determining globally optimal regions within the

search space whilst the NM provides a finer search

in locally optimal regions. The proposed algorithm

is efficient and has the ability to find high quality

solutions in relatively short times even though the

algorithm written in MATLAB

®

has room for

considerable improvement.

Table1: Test PC platform specifications.

Processor

Intel ® Core™ i5 CPU 650 @

3.20GHz

Motherboard XCPI x64

RAM 4.00 GB

Software

MATHWORKS

®

MATLAB

®

7.10.0

(R 2010a)

4.2 Discussion of Results

The proposed method is applied to find the lower

bound of the minimum variance PI/D for several

examples taken from literature. Some significant

observations for the examples are given below.

1.

With regards to the results provided in Table 3

it is surprising to note that example 3 took the

shortest time (29.9 seconds) to solve even

though the process transfer function has the

largest dead time from the set of experiments.

Overall results for the time taken indicate that

PID controller's takes longer time to solve.

This is expected since the PID controller adds

another dimension to the problem as an

additional variable (

3

k

) is involved.

ConstrainedMinimum-VariancePIDControlusingHybridNelder-MeadSimplexandSwarmIntelligence

335

Table 2: Simulation models used in the experiments.

Example

g

h

1

5

0.2

1

10.8

q

q

1

11

(1 )(1 0.4 )qq

2

12

1

0.08919

1 0.8669

q

q

1

0.08919

1 08669q

3

28

1

0.5108

1 0.9604

q

q

1

0.5108

1 0.9604q

4

6

1

10.8

q

q

1

111

10.6

(1 0 .5 )(1 0 .6 )(1 0.7 )

q

qqq

5

6

1

10.8

q

q

1

1111

10.2

(1 )(1 0.3 )(1 0.4 )(1 0.5 )

q

qqqq

6

6

1

10.8

q

q

1

1111

10.6

(1 )(1 0.5 )(1 0.7 )(1 0.6 )

q

qqqq

7

5

1

0.1

10.8

q

q

111

0.1

(1 )(1 0.3 )(1 0.6 )qqq

8

3

1

0.1

10.8

q

q

1

1

1 q

9

6

1

0.1

10.8

q

q

11

0.1

(1 )(1 0.7 )qq

10

3

1

0.1

10.8

q

q

12

0.001

(1 )(1 0.2 )qq

2. The proposed algorithm gives solutions that are

in agreement with the SOS programming

method of Sendjaja and Kariwala (2009) for

all the cases shown in Table 5. The

dimensionless values provided in Table 5

represent the closed loop variance. As noted

by Sendjaja and Kariwala (2009) the

controller structure imposes severe

limitations on controller performance as

shown in examples 6, 7 and 9 for PI control.

This indicates for these cases that the MV

lower bound presents a highly optimistic

benchmark for a low order PI control

structure. There are no controller structure

limitations for examples 2, 4 and 10

operating under PID control as there is little

difference between MV lower bound and

PID-MV for these examples.

3.

Improved achievable lower bounds are given by

the proposed NMPSO algorithm when

compared to the SOS programming method

for examples 3 and 6 for PI control and

examples 1, 7, 8 and 9 for PID control.

Table 3: NMPSO simulation results for minimum variance

PI controller.

Example

1

k

2

k

Iterations

Time taken

(s)

1 1.1175 -0.9891 23 49.49

2 0.3246 -0.3257 19 34.05

3 0.0333 -0.0334 19 29.90

4 0.0248 -0.0250 19 45.96

5 0.2101 -0.1880 31 78.03

6 0.2499 -0.2274 19 65.70

7 2.8056 -2.5376 27 64.77

8 3.4225 -2.9821 35 59.52

9 2.2861 -2.0495 35 67.91

10 3.3609 -2.9233 24 51.97

Table 4: NMPSO simulation results for minimum variance

PID controller.

Example

1

k

2

k

3

k

Iterations

Time

taken

(s)

1 2.8724 -4.4735 1.7873 47 114.56

2 1.8485 -3.4099 1.5627 47 110.00

3 0.0367 -0.0369 0.000 101 135.01

4 0.1383 -0.2598 0.1220 61 168.31

5 0.7382 -1.2336 0.5322 47 162.55

6 0.8743 -1.4796 0.6487 68 236.25

7 8.4515 -13.869 5.9375 62 161.29

8 6.6043 -9.4092 3.4838 54 100.23

9 8.5550 -14.389 6.295 83 187.76

10 6.2277 -8.7216 3.1414 59 124.83

5 CONCLUSIONS

A hybrid optimization routine which combines the

efficient global and local search capabilities of PSO

and NM respectively has been proposed. The

methodology was used to determine achievable

lower performance bounds for restricted structure

PI/D controllers. It is obvious that the achievable

PI/D performance bounds can be employed in a

performance monitoring context to evaluate the

performance of PI/D controllers operating in real-

world control loops. Future work will include

streamlining the hybrid NMPSO algorithm for use

on real-world process control loops. This would

include the use of a suitable online system

identification procedure to work in conjunction with

ICAART2013-InternationalConferenceonAgentsandArtificialIntelligence

336

Table 5: Performance comparison of proposed methodology for minimum variance PI and PID controllers.

Example

MV

(Huang and

Shah, 1999)

PI controller

SOS programming method

(Sendjaja and

Kariwala,2009)

(lower bound, upper bound)

PID controller

SOS programming method

(Sendjaja and

Kariwala,2009)

(lower bound, upper bound)

Proposed

NM-PSO method

(PI-MV)

Proposed

NM-PSO method

(PID-MV)

1 2.9427 (3.5154, 3.5186) (3.0730, 3.0730) 3.5179 3.0679

2 0.0310 (0.0313, 0.0314) (0.0310, 0.0310) 0.0314 0.0310

3 3.0112 (3.1703, 3.1706) (3.0492, 3.0495) 3.1502 3.0493

4 3.4004 (3.4408, 3.4408) (3.4065, 3.4065) 3.4399 3.4059

5 11.9528 (17.7044, 17.7477) (13.6341, 13.8243) 17.7414 13.7207

6 58.3406 (122.4089, 123.6037) (83.5605, 89.6983) 117.4932 85.9108

7 0.2978 (0.5856, 0.5884) (0.4278, 0.4278) 0.5608 0.4166

8 3.0000 (3.7002, 3.7050) (3.2093, 3.2093) 3.7030 3.1923

9 0.3144 (0.5949, 0.5968) (0.4288, 0.4288) 0.5964 0.4199

10 0.0023 (0.0027, 0.0027) (0.0024, 0.0025) 0.0027 0.0024

the proposed algorithm to determine minimum

variance PI/D controllers.

REFERENCES

Agrawal, P., Lakshminarayanan, S., 2003. Tuning

Proportional-Integral-Derivative Controllers using

Achievable Performance Indices, Ind. Eng. Chem.

Res., Vol. 42, pp. 5576-5582.

Åström K.J., 1979. Introduction to Stochastic Control

Theory, Academic Press, London.

Clerc, M., 1999. The swarm and the queen: towards a

deterministic and adaptive particle swarm

optimisation, In proceedings of the congress on

evolutionary computation, Washington DC, United

States of America, pp. 1951-1957.

Eberhart, R.C., Kennedy, J., 1995. A new optimiser using

particle swarm theory. In proceedings of the sixth

international symposium on micro machine and

human science, Nagoya, Japan, pp.39-43.

Harris, T.J., 1989. Assessment of Control Loop

Performance, The Canadian Journal of Chemical

Engineering, Vol. 67, pp. 856-861.

Huang, B., Shah, S.L., 1999. Performance Assessment of

Control Loops: Theory and Applications, Springer-

Verlag, London, UK.

Hugo, A.J., 2006. Performance assessment of single-loop

industrial controllers, Journal of Process Control,

Vol.16, pp.785-794.

Jelali, M., 2006. An overview of control performance

assessment technology and industrial applications,

Control Engineering Practice, vol. 14, pp. 441-466.

Ko, B.S., Edgar, T.F., 2004. PID Control Performance

Assessment: The Single-Loop Case, AIChE Journal,

Vol. 50, No.6, pp.1211-1218.

Lagarias, J.C., Reeds, J.A., Wright, M.H., Wright, P.E.,

1998. Convergence properties of the Nelder-Mead

Simplex method in low dimensions, Society for

Industrial and Applied Mathematics, Vol.9 No.1, pp.

112-147.

Nelder, J. A., Mead, R., 1965. A simplex method for

function minimization, Computer Journal, Vol.7,

pp.308-131.

Qin, S. Joe., 1998. Control performance monitoring – A

review and assessment, Computers in Chemical

Engineering, vol. 23(2), pp. 173-186, 1998.

Sendjaja, A.Y., Kariwala, V., 2009. Achievable PID

performance using sums of squares programming,

Journal of Process Control, Vol.19, pp.1061-1065.

Shahni, F., Malwatkar, G.M., 2011. Assessment

minimum output variance with PID controllers,

Journal of Process Control, Vol. 21, pp. 678-681.

Veronesi, M., Visioli, A., 2011. Global Minimum-

variance PID Control ,18

th

International Federation of

Automatic Control (IFAC), pp. 7891-7896.

ConstrainedMinimum-VariancePIDControlusingHybridNelder-MeadSimplexandSwarmIntelligence

337